Novel BCZT-based energy storage ceramic material and preparation method and application thereof

A ceramic material, energy storage technology, applied in fixed capacitor parts, fixed capacitors, laminated capacitors, etc., can solve the problems of large dielectric loss, energy storage efficiency lower than 75%, less research, etc., and achieve low dielectric loss. , Improve the energy storage density and energy storage efficiency, the effect of low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention relates to a BCZT-based energy storage ceramic with the characteristics of high energy storage density, moderate dielectric constant, high breakdown strength, small dielectric loss, good temperature and frequency stability and a preparation method thereof. In the present invention, utilize solid phase synthesis (Ba 0.85 Ca 0.15 )(Zr 0.10 Ti 0.90 ) 1-x (Ni y Nb z ) x o 3 Powder, wherein, 0.1≤x≤0.8, 00.85 Ca 0.15 )(Zr 0.10 Ti 0.90 ) 1-x (Ni y Nb z ) x o 3 Energy storage ceramic materials. The energy storage ceramics of the present invention can be used in the manufacture of energy storage capacitors, such as energy storage multilayer ceramic capacitors, and expand the application field of barium calcium zirconate titanate (BCZT) ceramic materials in energy storage, which is conducive to promoting high energy storage The application and development of energy density ceramic technology has a good application prospect. In addition, the method o...

Embodiment 1

[0050] The energy storage ceramic material consists of:

[0051] (Ba 0.85 Ca 0.15 )(Zr 0.10 Ti 0.90 ) 0.9 (Ni 1 / 3 Nb 2 / 3 ) 0.1 o 3 (x=0.1, y=1 / 3, z=2 / 3)

[0052] (1) Calculate the required BaCaO according to the composition of the above chemical formula 3 , CaCO 3 , ZrO 2 、TiO 2 、Ni 2 o 3 and Nb 2 o 5 Quality, mixed by wet ball milling method, mixed for 24 hours according to the mass ratio of raw materials: balls: deionized water = 1:1.2:1.5, so that all components were mixed evenly. After drying, pass through a 40-mesh sieve, briquette in an air atmosphere, raise the temperature to 1250°C at a rate of 2°C / min, and keep it warm for 2 hours. The synthetic composition is (Ba 0.85 Ca 0.15 )(Zr 0.10 Ti 0.90 ) 0.9 (Ni 1 / 3 Nb 2 / 3 ) 0.1 o 3 (x=0.1, y=1 / 3, z=2 / 3) powder;

[0053] (2) Into the powder synthesized in step (1). According to the material: ball: deionized water = 1:2:0.8 ratio of wet fine grinding for 48 hours, discharge and dry, pass through a 40-m...

Embodiment 2

[0063] The energy storage ceramic material consists of:

[0064] (Ba 0.85 Ca 0.15 )(Zr 0.10 Ti 0.90 ) 0.8 (Ni 1 / 3 Nb 2 / 3 ) 0.2 o 3 (x=0.2, y=1 / 3, z=2 / 3)

[0065] (1) repeat the preparation method of embodiment 1 by above-mentioned formula and obtain present embodiment;

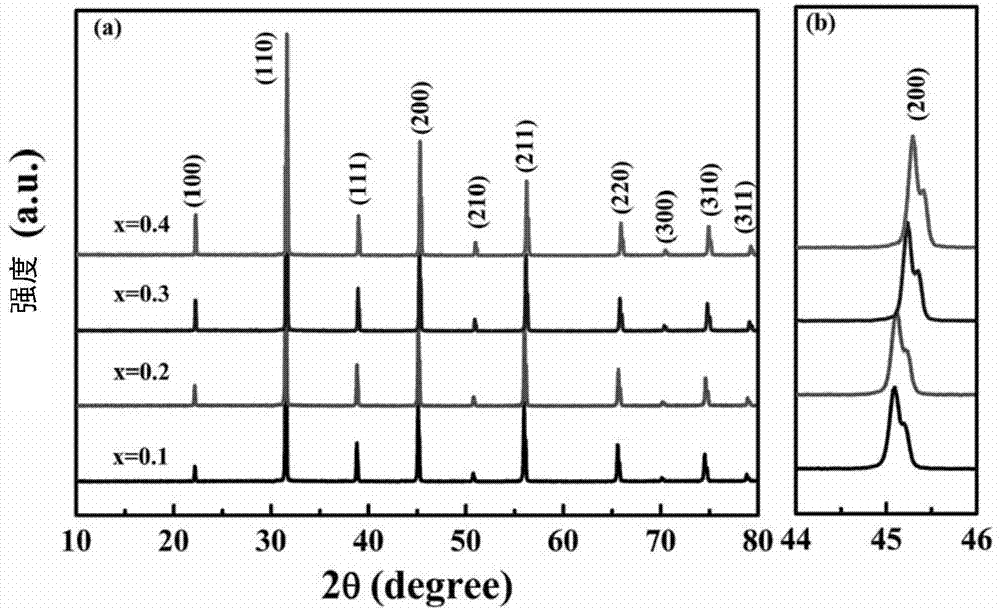

[0066] (2) Carry out XRD test to present embodiment, test result sees figure 1 ;

[0067] (3) carry out surface SEM observation to present embodiment, Fig. 2 (b) has provided the surface topography structure Fig. 2 of present embodiment ceramic sample;

[0068] (4) Observations of the dielectric thermogram and the dielectric spectrum were carried out to the ceramic sample, and the test results are shown in Fig. 3 and Fig. 4;

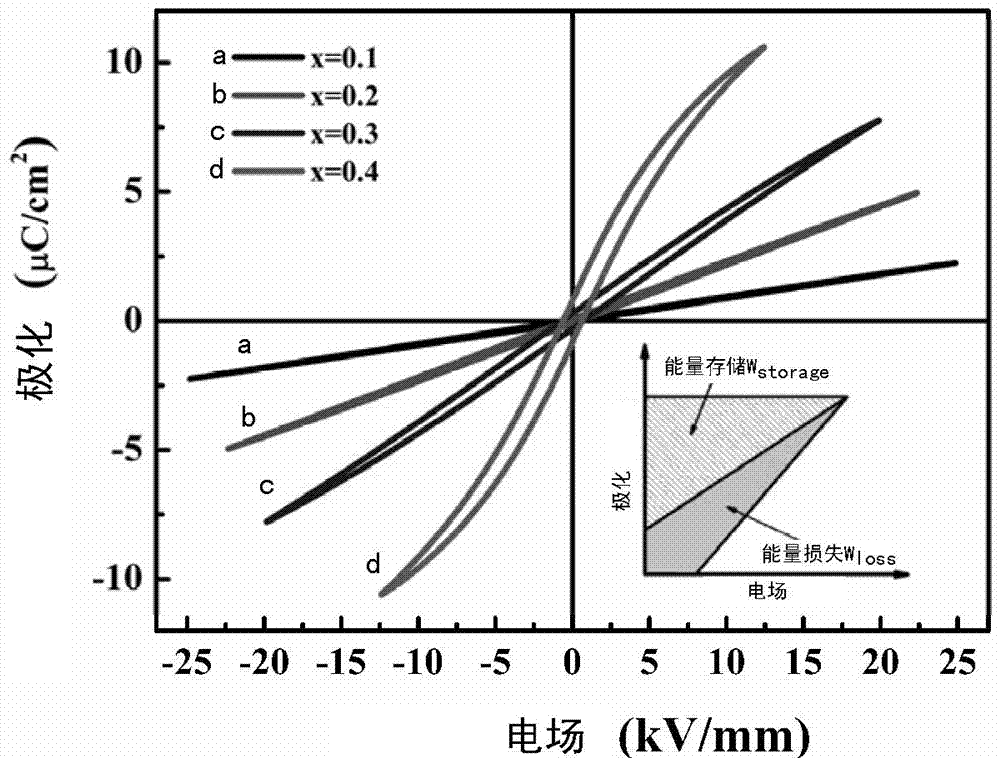

[0069] (5) The hysteresis loop was measured at room temperature for the ceramic sample of this embodiment, and the test results are shown in Figure 5 ;

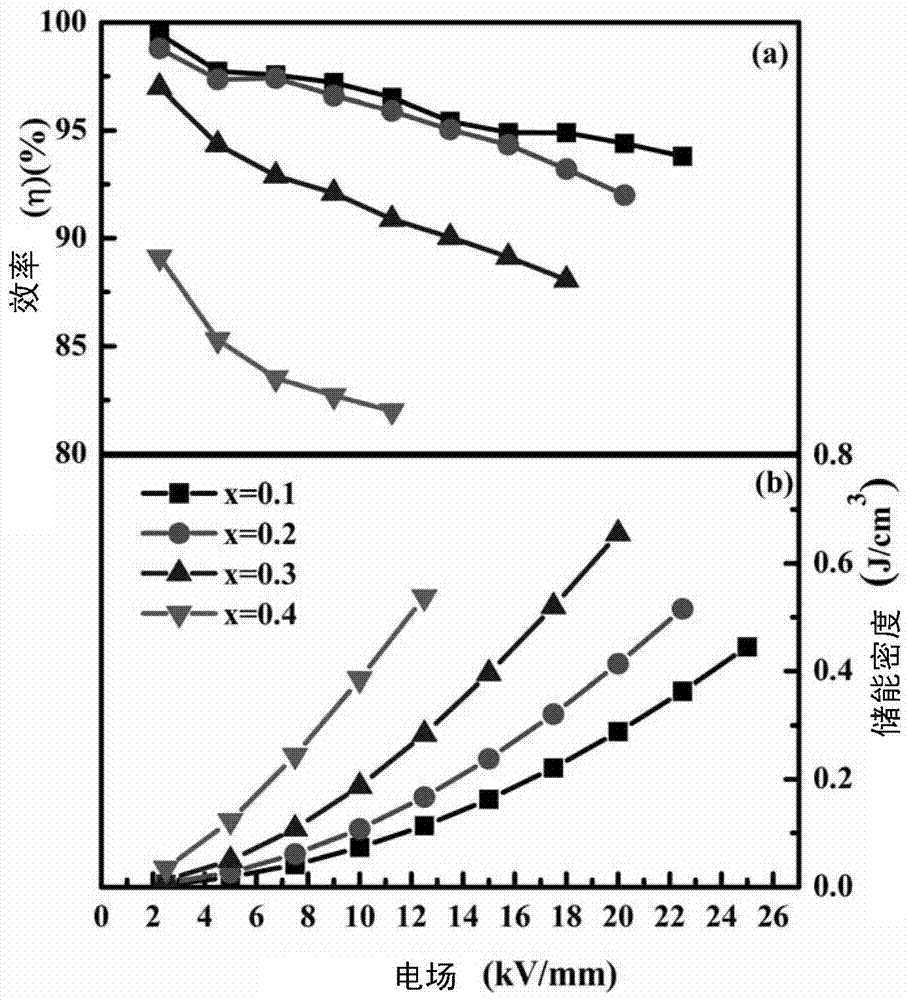

[0070] (6) Test the energy storage density and energy storage efficiency under different electric fields for the cerami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com