TiO2/Co-supported carbonaceous fiber electromagnetic wave absorbing material and preparation method and application thereof

A technology of absorbing materials and carbon fibers, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc., can solve the problems of inability to provide dielectric polarization loss and magnetic loss, difficulty in obtaining electromagnetic wave absorption performance, unfavorable practical applications and Industrial production and other problems, to achieve the effect of excellent electromagnetic wave absorption performance, excellent impedance matching performance, and unique microscopic shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A kind of TiO 2 The preparation method of the carbonaceous fiber electromagnetic wave absorbing material of Co load, comprises the steps:

[0055] (1) Dissolve 2.5mmol cobalt acetylacetonate in 10ml DMF, add 0.25ml anhydrous acetic acid after fully dissolving, then add 2.5mmol isopropyl titanate drop by drop, stir again after fully dissolving, then add 1.5g PVP, stir vigorously Obtain a homogeneous viscous solution;

[0056] (2) Under 12kV high-voltage electrostatic conditions, the viscous solution in step (1) is spun by a high-voltage electrospinning process to obtain organic fibers, which are dried at 50° C. for 12 hours, and then dried at 200° C. Insulated for 2h to carry out pre-oxidation treatment;

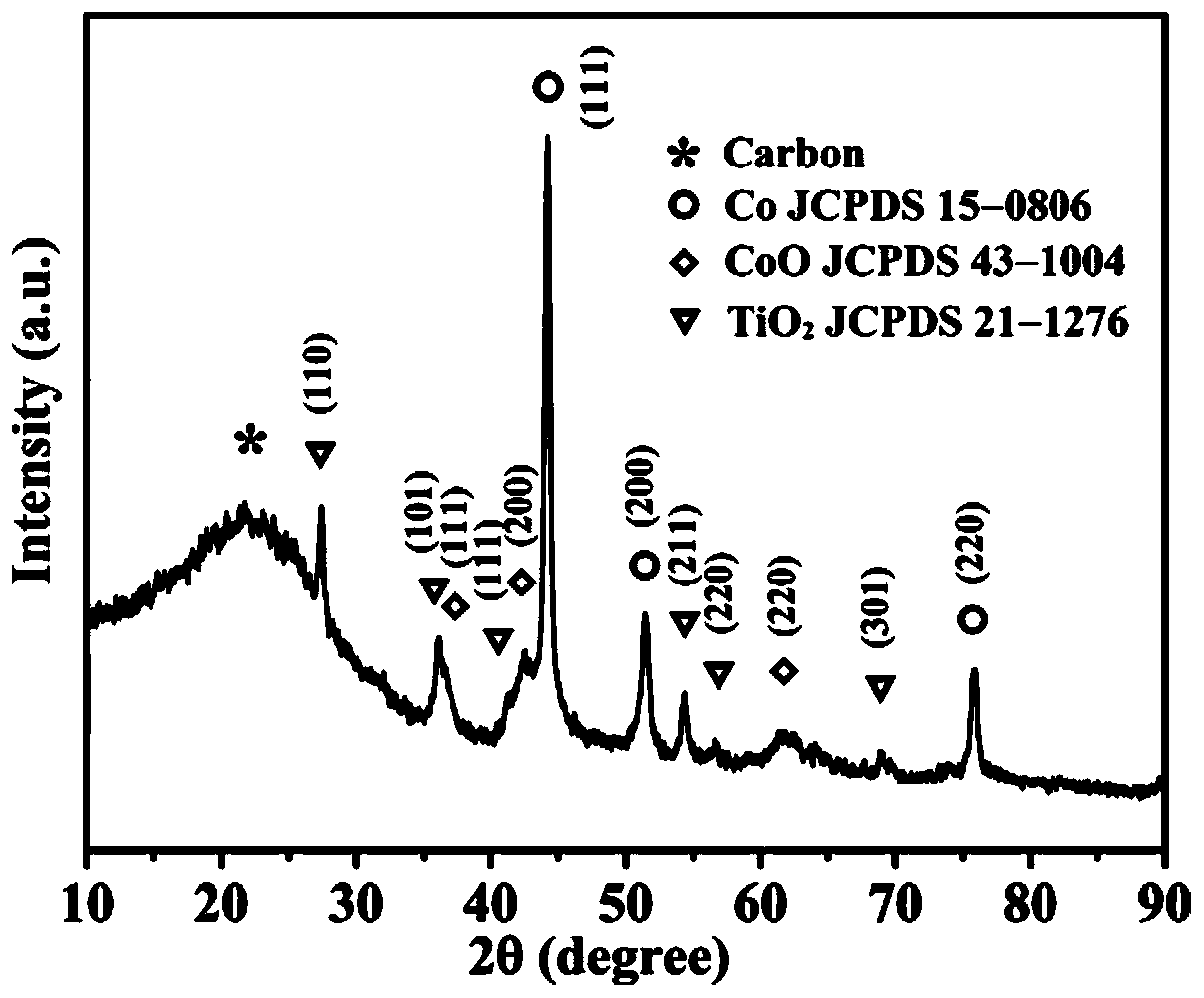

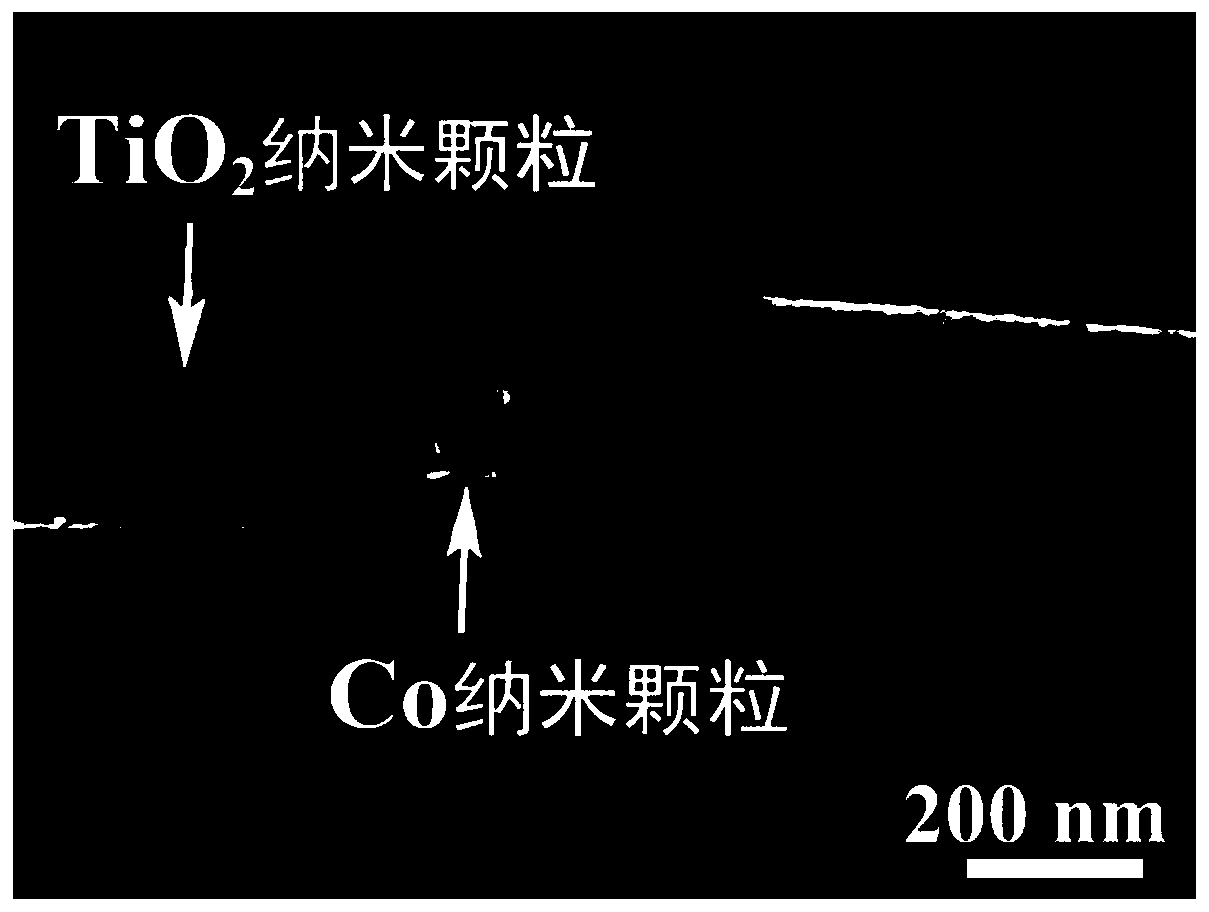

[0057] (3) Put the product after the pre-oxidation treatment in step (2) in a closed tube furnace, and in a nitrogen atmosphere, keep it at 700 ° C for 2 hours for high-temperature calcination treatment to obtain TiO 2 / Co loaded carbon fiber electromagnetic wave a...

Embodiment 2

[0059] A kind of TiO 2 The preparation method of the carbonaceous fiber electromagnetic wave absorbing material of Co load, comprises the steps:

[0060] (1) Dissolve 3mmol of cobalt nitrate in 10ml of DMF, add 0.3ml of anhydrous acetic acid after fully dissolving, then add 2mmol of isopropyl titanate drop by drop, fully dissolve again and then add 2g of PVP, stir vigorously to obtain a uniform viscous solution ;

[0061] (2) Under 10kV high-voltage electrostatic conditions, the viscous solution in step (1) is spun by a high-voltage electrospinning process to obtain organic fibers, which are dried at 45° C. for 24 hours, and then dried at 180° C. Insulated for 2h to carry out pre-oxidation treatment;

[0062] (3) Put the product after the pre-oxidation treatment in step (2) in a closed tube furnace, and in a nitrogen atmosphere, keep it at 650 ° C for 3 hours for high-temperature calcination treatment to obtain TiO 2 / Co loaded carbon fiber electromagnetic wave absorbing m...

Embodiment 3

[0064] A kind of TiO 2 The preparation method of the carbonaceous fiber electromagnetic wave absorbing material of Co load, comprises the steps:

[0065] (1) Dissolve 2mmol of cobalt nitrate in 10ml of DMF, add 0.2ml of anhydrous acetic acid after fully dissolving, then add 3mmol of tetrabutyl titanate drop by drop, fully dissolve again and then add 2.5g of PVP, stir vigorously to obtain uniform viscosity solution;

[0066] (2) Under 14kV high-voltage electrostatic conditions, the viscous solution in step (1) is spun by a high-voltage electrospinning process to obtain organic fibers, which are dried at 60° C. for 15 hours, and then dried at 150° C. Insulated for 3h to carry out pre-oxidation treatment;

[0067] (3) Put the product after the pre-oxidation treatment in step (2) in a closed tube furnace, and in a nitrogen atmosphere, heat it at 600°C for 5h for high-temperature calcination treatment to obtain TiO 2 / Co loaded carbon fiber electromagnetic wave absorbing materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com