Low-temperature sintered microwave ceramic material and preparation method thereof

A microwave ceramic and low-temperature sintering technology, applied in the field of materials, can solve the problems of poor loss characteristics, difficult to zero-adjust the frequency temperature coefficient, and reduce the sintering temperature, and achieve the effects of high Q value, low price and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

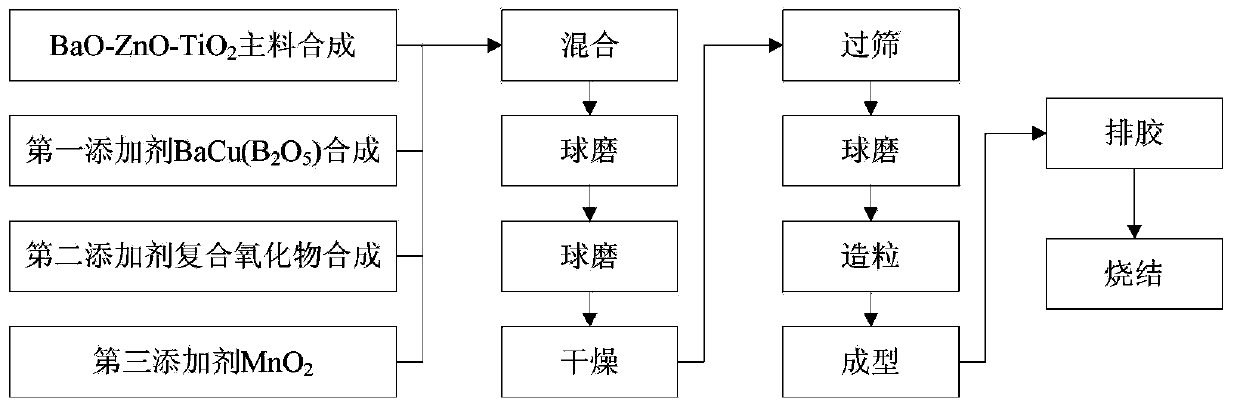

[0039] A preparation method of low-temperature sintered microwave ceramic material, such as figure 1 shown, including the following steps:

[0040] Step 1: BaO-ZnO-TiO 2 Synthesis of main ingredients. Include the following steps:

[0041] Step 1-1: Take BaCO 3 , ZnO and TiO 2 As raw material, according to BaO:ZnO:TiO 2 =1:(0.1~0.7):4 The molar ratio is used to prepare the material, and the prepared material is ball-milled with deionized water as the ball-milling medium, after ball-milling, it is dried at 100°C and passed through a 40-mesh sieve;

[0042] Step 1-2: pre-calcine the mixture treated in step 1-1 at a temperature of 1000°C to 1100°C for 3 to 5 hours to obtain the main crystal phase as BaTi 4 o 9 and BaZn 2 Ti 4 o 11 BaO-ZnO-TiO 2 Ingredients.

[0043] Step 2: First additive synthesis. Include the following steps:

[0044] Step 2-:1: Take BaCO 3 , CuO and B 2 o 3 As a raw material, the material is prepared according to the molar ratio of Ba:Cu:B=1:1:...

Embodiment 1

[0053] Example 1: BaO-ZnO-TiO 2 Comparison of changes in the ratio of main ingredients.

[0054] According to BaO-ZnO-TiO 2 Main ingredient is fixed as 100g, the first additive BaCu (B 2 o 5 ) is fixed at 13g, the second additive composite oxide is fixed at 0.1g, the third additive MnO 2 It is fixed at 0.3g proportioning and weighing. In this process, mainly in BaO-ZnO-TiO 2 Changing BaO-ZnO-TiO in the synthesis of main materials 2 Ratio of main ingredients. Wet milling, adding polyvinyl alcohol aqueous solution to the dried material for granulation, pressing under 25Mpa pressure to obtain a cylindrical green body with a diameter of 15mm and a thickness of 8mm, and then sintering in the air, depending on the ratio of main materials The sintering conditions are slightly changed, the heating rate is 3°C / min, and the low-temperature sintered microwave dielectric ceramics can be prepared with the furnace cooling. The main formula changes, sintering process and dielectric pe...

Embodiment 2

[0055] Embodiment 2: the first additive BaCu (B 2 o 5 ) comparison of doping amount changes.

[0056] According to BaO:ZnO:TiO 2 =1:0.2:4 Synthesis of BaO-ZnO-TiO 2 The main material, the porcelain material formula according to BaO-ZnO-TiO 2 Main ingredient is fixed as 100g, the first additive BaCu (B 2 o 5 ) are 3g, 5g, 7g, 9g, 11g, 13g respectively, the second additive composite oxide is fixed at 0.3g, the third additive MnO 2 It is fixed at 0.3g proportioning and weighing. Wet milling, adding polyvinyl alcohol aqueous solution to the dried material for granulation, pressing under 25Mpa pressure to obtain a cylindrical green body with a diameter of 15mm and a thickness of 8mm, and then sintering in the air, depending on the ratio of main materials The sintering conditions are slightly changed, the heating rate is 3°C / min, and the low-temperature sintered microwave dielectric ceramics can be prepared with the furnace cooling. The main formula changes, sintering process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com