Preparation method of CIGS solar cell film buffer layer material

A solar cell, copper indium gallium selenide technology, applied in circuits, photovoltaic power generation, electrical components and other directions, can solve the problems of poor film quality, poor photoelectric conversion performance, etc., achieve high quality factor, improve bonding strength, and improve dielectric. Performance and Effect of Photoelectric Conversion Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

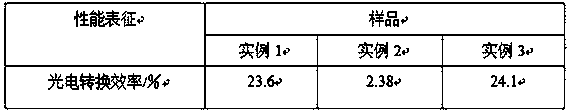

Examples

example 1

[0019] Take the glass plate and scrub it three times with acetone and absolute ethanol respectively, dry it naturally and immerse it vertically in the modified mixed solution. During the immersion control, add 5% acetic acid solution dropwise to the modified mixed solution, Control the dropping rate at 25mL / min, wait for 25 minutes to drop, stop the dropping and let it sit for 6 hours, take out the glass plate and rinse it with deionized water for 3 times, dry it with nitrogen and let it stand to get a coated glass plate; press In terms of parts by weight, weigh 45 parts of deionized water, 10 parts of tantalum dioxide, 3 parts of magnesium carbonate and 10 parts of barium carbonate and place them in a mortar, grind and disperse and collect the dispersion slurry, and spin coat the dispersion slurry onto the coating substrate On the surface of the glass plate, control the rotation speed of 4000r / min, after 25s, bake at 350°C for 3h, then raise the temperature to 600°C at 5°C / min...

example 2

[0021] Take the glass plate and scrub it with acetone and absolute ethanol for 4 times respectively, dry it naturally and immerse it vertically in the modified mixed solution. During the immersion, add 5% acetic acid solution dropwise to the modified mixed solution. Control the dropping rate at 27mL / min, wait for 27 minutes to drop, stop the dropping and let it stand for 7 hours to deposit, take out the glass plate and rinse it with deionized water 4 times, dry it with nitrogen and let it stand to get the coated base glass plate; then press In terms of parts by weight, weigh 47 parts of deionized water, 12 parts of tantalum dioxide, 4 parts of magnesium carbonate and 12 parts of barium carbonate and place them in a mortar, grind and disperse and collect the dispersion slurry, and spin coat the dispersion slurry to coat On the surface of the base glass plate, control the rotation speed of 4500r / min, after 27s, bake at 375°C for 4h, then raise the temperature to 625°C at 5°C / min,...

example 3

[0023] Take the glass plate and scrub it with acetone and absolute ethanol for 5 times respectively, dry it naturally and immerse it vertically in the modified mixed solution. During the immersion, add 5% acetic acid solution dropwise to the modified mixed solution. Control the dropping rate at 30mL / min, wait for 30 minutes to drop, stop dropping and let it stand for deposition for 8 hours, take out the glass plate and rinse it with deionized water for 5 times, dry it with nitrogen and let it stand to obtain a coated base glass plate; then press In terms of parts by weight, weigh 50 parts of deionized water, 15 parts of tantalum dioxide, 5 parts of magnesium carbonate and 15 parts of barium carbonate in a mortar, grind and disperse and collect the dispersion slurry, and spin coat the dispersion slurry until coating On the surface of the base glass plate, control the rotation speed of 5000r / min, after 30s, bake at 400°C for 5h, then raise the temperature to 650°C at 5°C / min, hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com