Method for preparing wide-temperature zone phase change type pyroelectric ceramic material

A technology of pyroelectric ceramics and phase change, applied in the field of preparation of pyroelectric ceramic materials, can solve problems such as difficult to meet the requirements of pyroelectric devices, narrow pyroelectric peak temperature range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

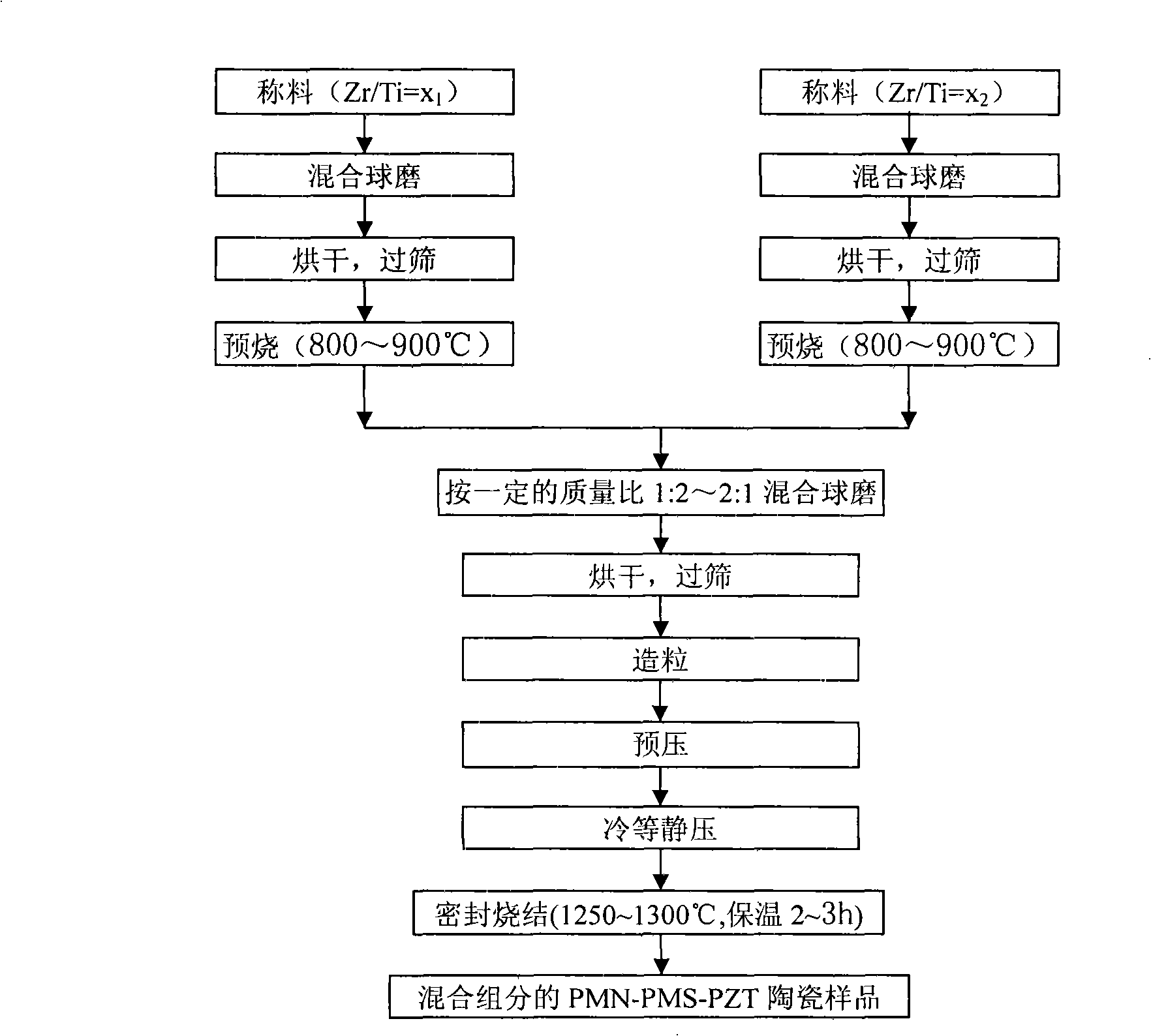

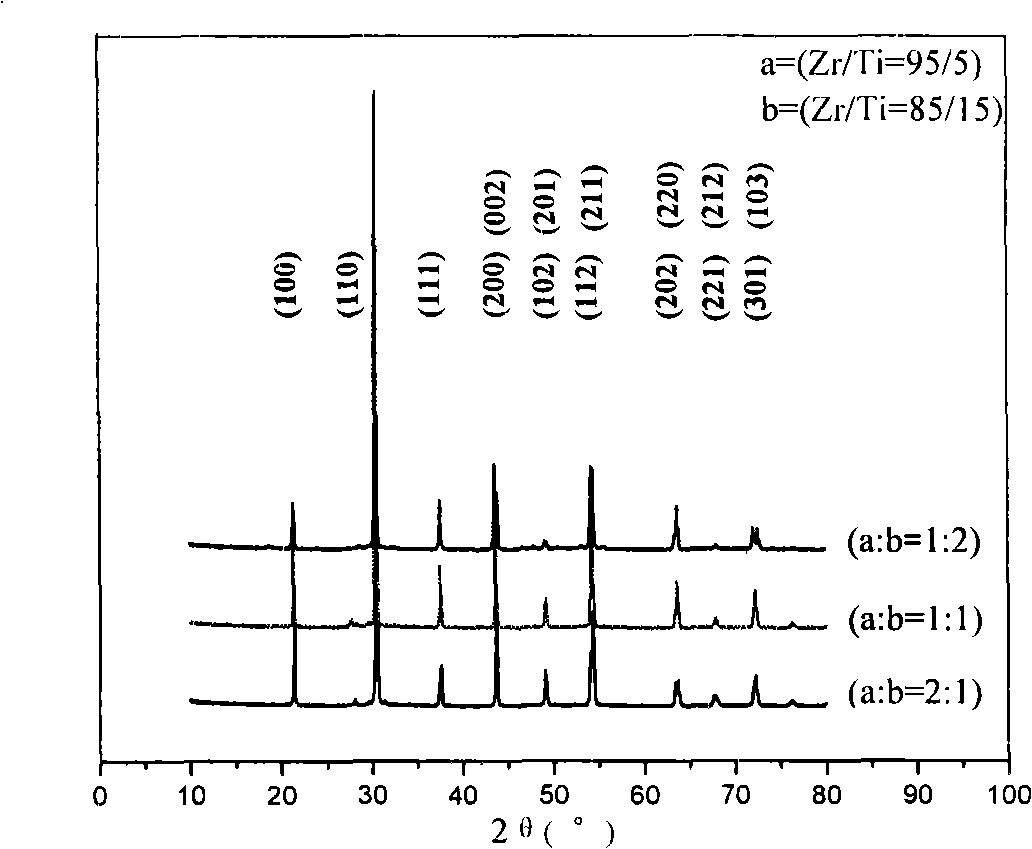

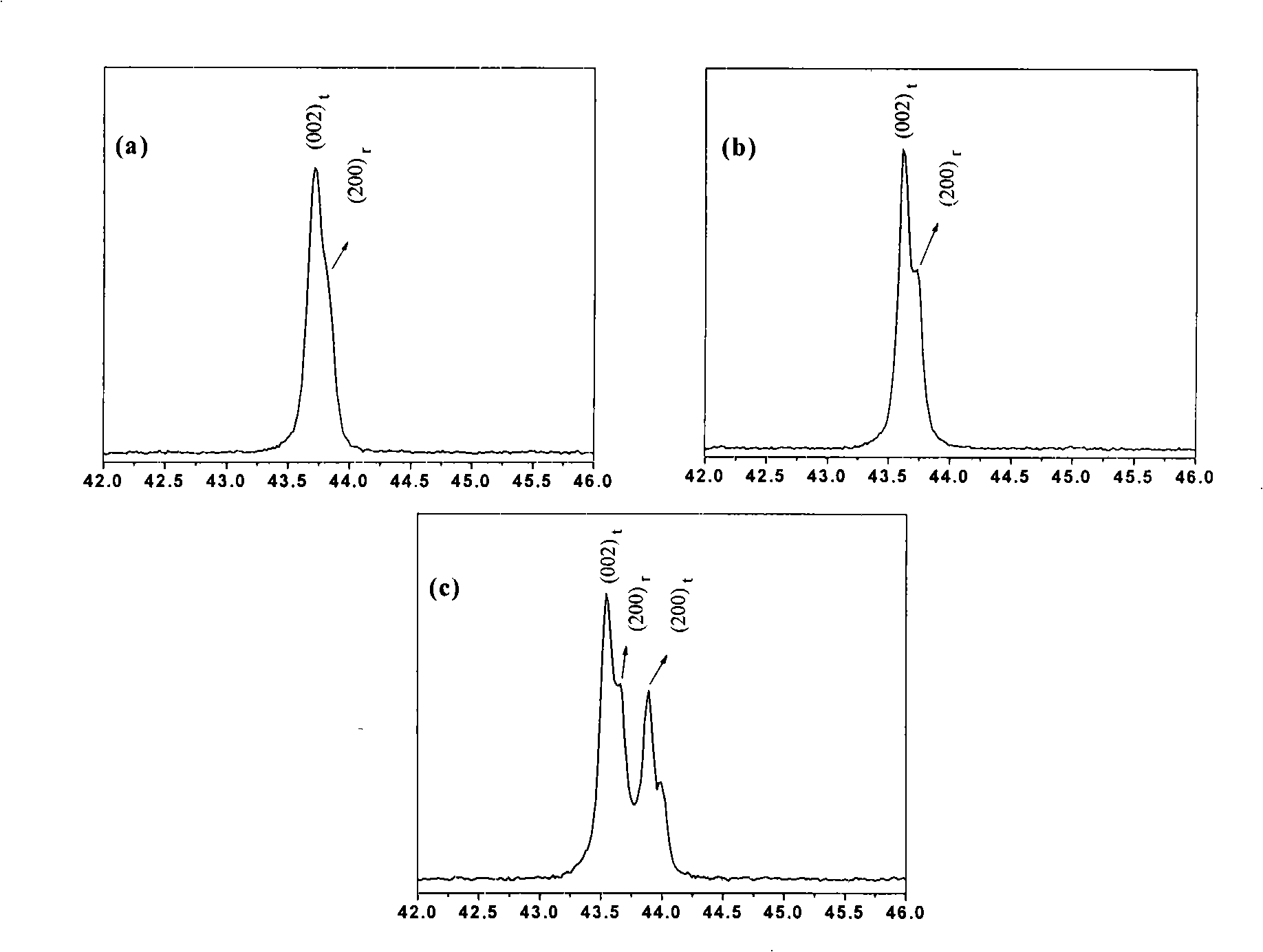

[0022] According to the chemical formula Pb[(Mn 0.33 Nb 0.67 ) 0.5 (Mn .33 Sb 0.67 ) 0.5 ] 0.08 (Zr x Ti 1-x ) 0.92 o 3 [referred to as PMN-PMS-PZT(x)], will analyze pure PbO, ZrO 2 、TiO 2 , Nb 2 o 5 , Sb 2 o 3 powder and Mn(NO 3 ) 2 Two kinds of PMN-PMS-PZT powders, x=95 and x=85, are prepared in the solution according to the stoichiometric ratio in the respective chemical formulas. After ball milling, crushing and sieving respectively, they are pre-calcined at 800°C for 6 hours, and the pre-calcined synthetic The two powders are mixed uniformly, pulverized, sieved, and formed according to PMN-PMS-PZT (95): PMN-PMS-PZT (85) = 1: 2 (wherein the forming process includes preforming and cold isostatic pressing two steps), and then sintered at 1265°C for 2 hours in a double-crucible sealed atmosphere. Grind the sintered sample, clean it, coat it with silver, and burn the electrode. Then place the sample in silicone oil at 120°C and add a 3KV / mm electric field to...

example 2--3

[0024] The PMN-PMS-PZT (95) and PMN-PMS-PZT (85) powder after pre-burning are pressed according to PMN-PMS-PZT (95): PMN-PMS-PZT (85)=1: 1 and 2: 1 to mix. All the other are the same as Example 1, and the process parameters are shown in Table 2. Its performance is shown in Table 3.

example 4-5

[0026] Mix the pre-fired PMN-PMS-PZT (95) and PMN-PMS-PZT (85) powders according to PMN-PMS-PZT (95): PMN-PMS-PZT (85) = 1:2, and sinter The temperatures were 1200°C and 1300°C, respectively. The material after firing the electrode is polarized in silicone oil at 100-120°C with a voltage of 3-5KV / mm for 15-20 minutes, and then cooled to room temperature under pressure. All the other are the same as Example 1, and the process parameters are shown in Table 2. Its performance is shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com