Method for preparing high-performance barium strontium titanate pyroelectric ceramics by post-annealing process

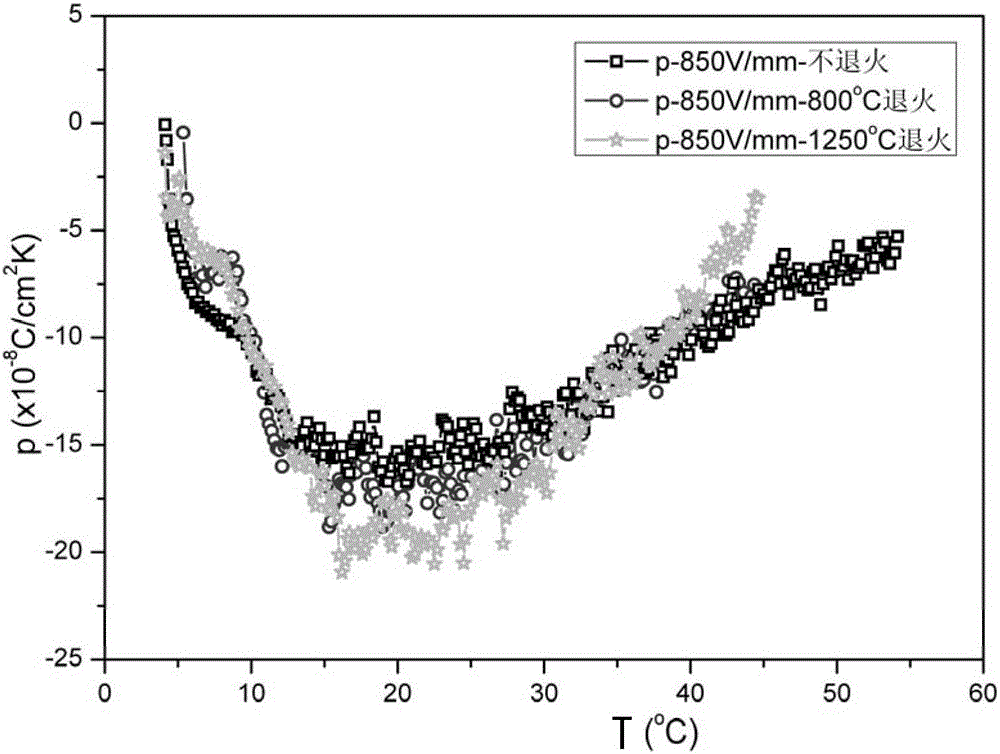

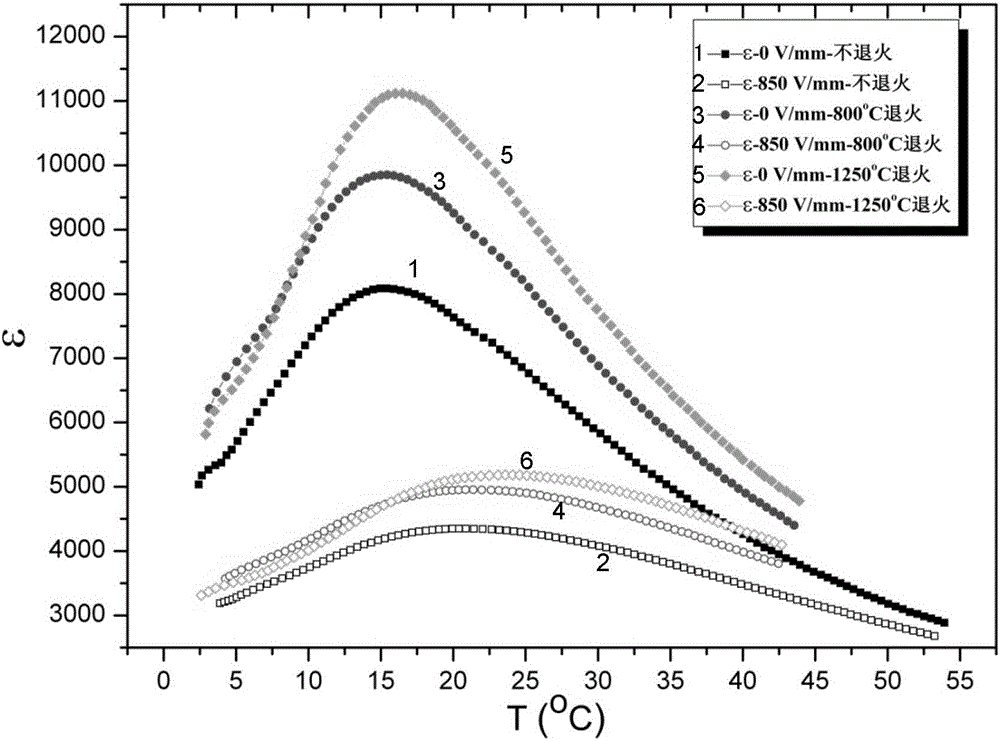

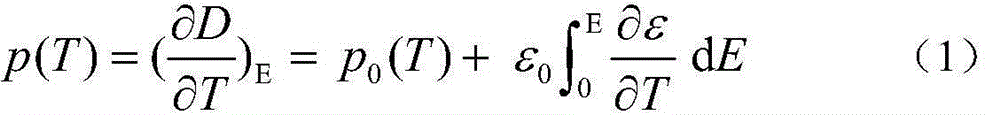

A technology of pyroelectric ceramics and barium strontium titanate, which is applied to thermoelectric devices with thermal changes in dielectric constant, etc., can solve the problem of difficulty in preparing high-performance BST pyroelectric ceramics, and achieves low cost, high sample purity, and high thermal stability. The effect of high discharge coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the sintered barium strontium titanate ceramics is not limited, for example, the following method can be used:

[0039] a) first according to the general formula Ba x Sr 1-x TiO 3 Weigh out the stoichiometric BaCO 3 , SrCO 3 and TiO 2 Powder, use wet ball milling process to mix all powders evenly, doping elements can be added in the general formula, such as Ca, Y, Mn, Sm, Fe, etc., doping elements can be oxides and / or carbonates, for example form to join;

[0040] b) drying and briquetting, and synthesizing in air at a synthesis temperature of 1000-1200°C and a holding time of 1-3 hours to obtain BST blocks;

[0041] c) pulverizing and sieving the BST block obtained in step b), and refining the powder with a wet ball milling process;

[0042]d) drying after discharge, adding a certain amount of binder, pre-pressing after granulation, aging, sieving, isostatic pressing, and plastic discharge to obtain the BST embryo body;

[0043] e) Sin...

Embodiment 1

[0056] First weigh BaCO 3 , SrCO 3 and TiO 2 powder, and add a small amount of CaCO 3 , Y 2 o 3 , MnCO 3 For powder, use wet ball milling process to mix all the powders evenly; the mass ratio of material, ball milling medium and deionized water is 1:1.5:1.2, the ball milling time is 24 hours, and the ball milling medium is agate balls.

[0057] Dry the abrasive, add deionized water with 4% of the total powder mass, briquette, and synthesize in the air at a synthesis temperature of 1150°C and a holding time of 2 hours to obtain BST blocks; pulverize, pass through a 40-mesh sieve, and then add For 2.7wt% ZnO powder, mix the powder evenly by wet ball milling process; the mass ratio of material, ball milling medium and deionized water is 1:2.0:0.8, the ball milling time is 48 hours, and the ball milling medium is agate balls.

[0058] Drying, adding PVA solution as a binder, granulating, aging for 24 hours, sieving, pre-pressing and isostatic pressing, the blank is discharge...

Embodiment 2

[0062] The annealing temperature of the BST ceramics is 1250° C., and the annealing time is 2 hours, and the remaining contents are the same as those described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com