Preparation method of porous field pyroelectric ceramic material

A pyroelectric ceramic and field-induced technology, which is used in ceramic products, electrical radiation detectors, household appliances, etc. The effect of electric coefficient, good comprehensive pyroelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

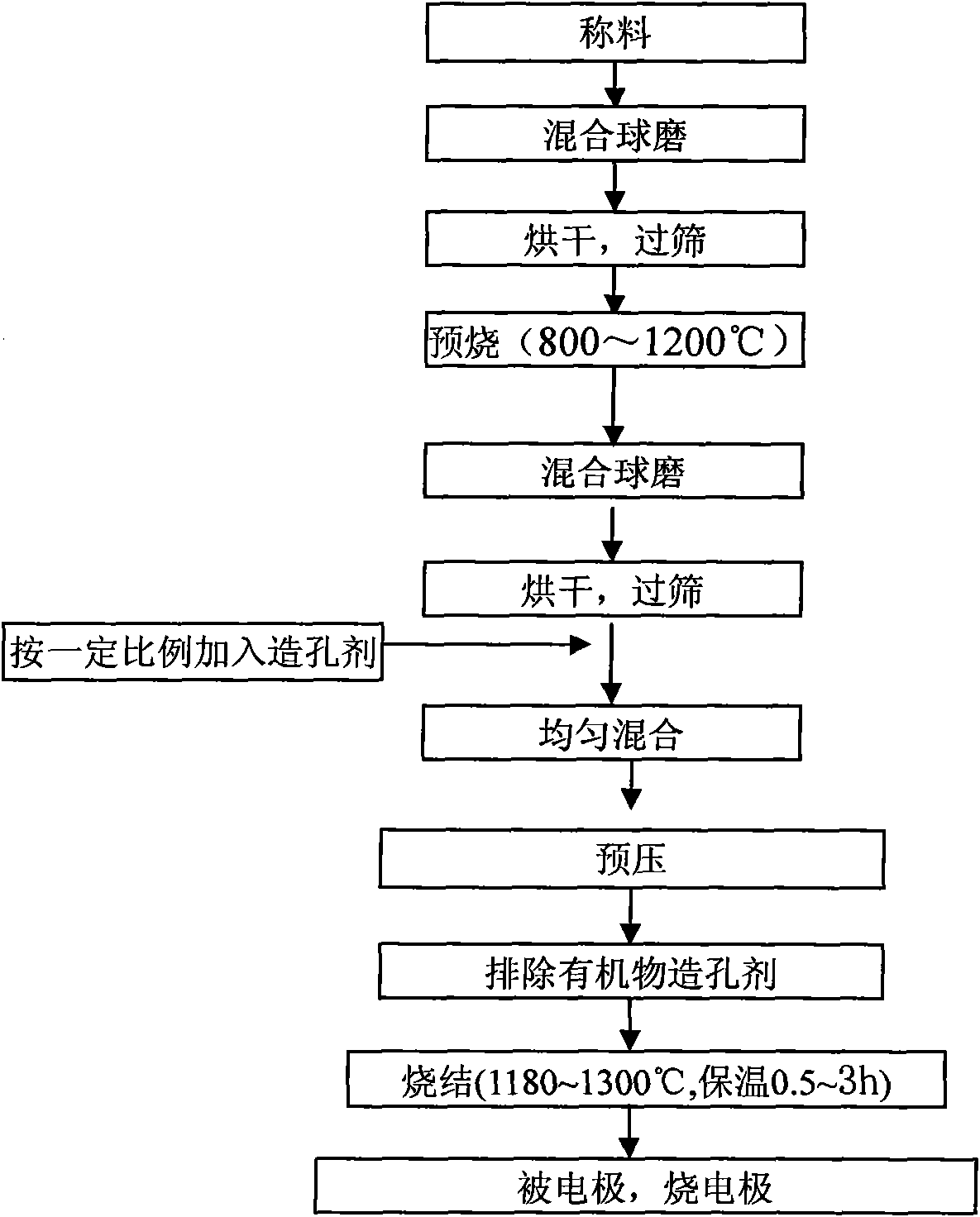

Method used

Image

Examples

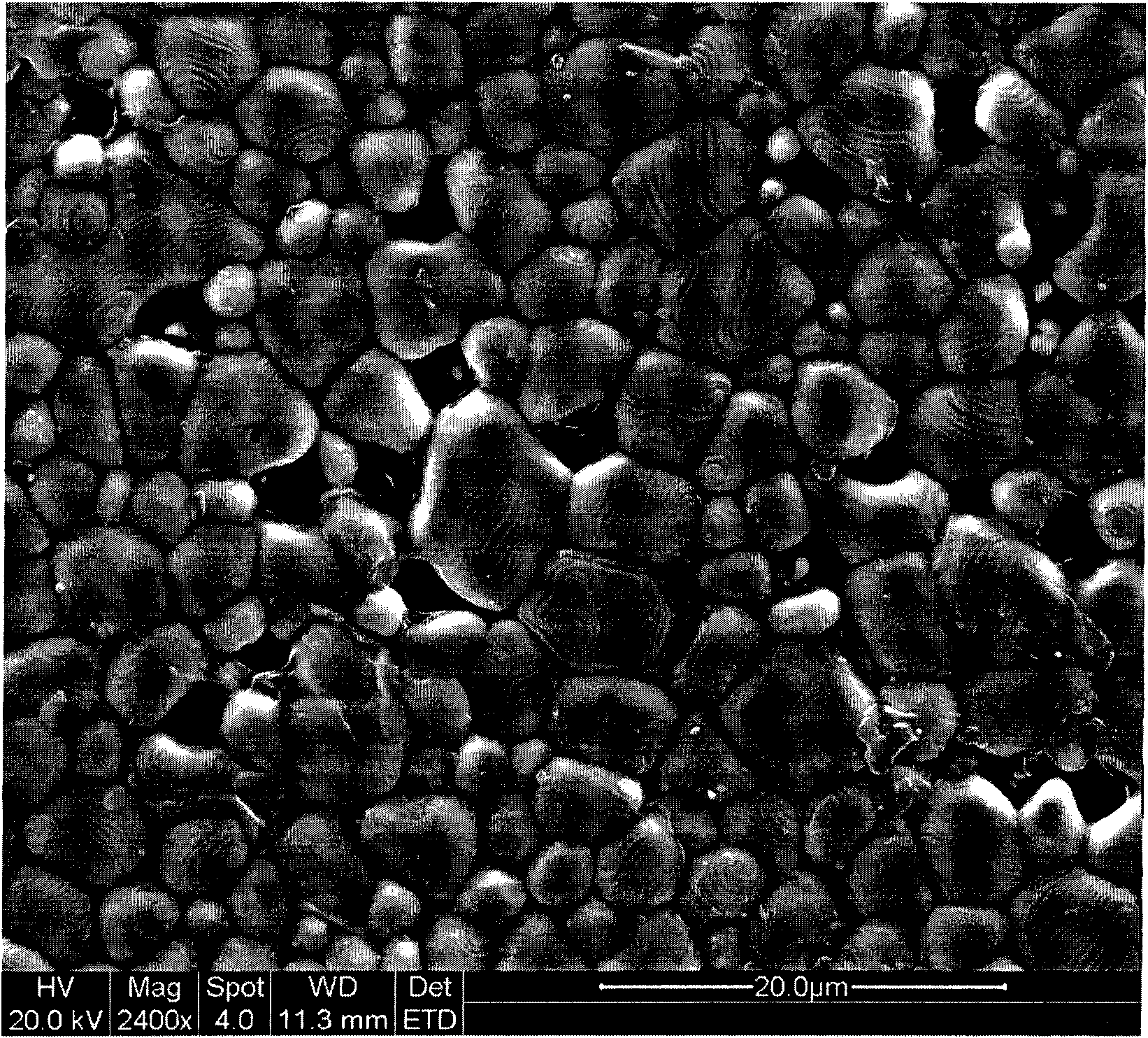

example 1

[0021] According to the chemical formula Ba 0.67 Sr 0.33 TiO 3 +0.6mol%Mn+1.2mol%Y, the analytically pure BaTiO 3 , SrTiO 3 powder and Mn(NO 3 ) 2 , Y(NO 3 ) 3 The solution is configured with BST ceramic powder according to the stoichiometric ratio in the respective chemical formulas. After ball milling, crushing, drying, and sieving, they are pre-fired at 1000°C for 2 hours, and ball milling, drying, and sieving are performed again. The pre-fired powder is uniformly mixed with polymethyl methacrylate (PMMA) powder and then pre-pressed (the molding process includes two steps of pre-forming and cold isostatic pressing), PMMA powder and pre-sintered The mass ratio of the powder is 1:100. Then keep it at 600°C for 2 hours to discharge organic matter such as PMMA, and keep it at 1200°C for 0.5 hour for sintering. The sintered samples were covered with silver and fired electrodes for testing.

[0022] Among them, the doping of manganese and yttrium is Mn(NO 3 ) 2 and Y(...

example 2-3

[0025] According to the chemical formula Ba 0.67 Sr 0.33 TiO 3 +0.6mol%Mn+1.2mol%Y, the analytically pure BaCO 3 , SrCO 3 、TiO 2 powder and Mn(NO 3 ) 2 , Y(NO 3 ) 3 Mixing is carried out according to the stoichiometric ratio in the respective chemical formulae.

[0026] The pre-burned BST powder was mixed with 3% and 5% starch, and kept at 500°C for 2 hours to remove the pore-forming agent. All the other are the same as Example 1, and the process parameters are shown in Table 2. Its performance is shown in Table 3.

example 4-5

[0028] The material was kept at 1230° C. and 1260° C. for 2 hours, and the rest were the same as in Example 1. The process parameters are shown in Table 2. Its performance is shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com