High-Curie-temperature strontium-barium niobate pyroelectric ceramic material and preparation method thereof

A technology of pyroelectric ceramics and strontium barium niobate, applied in the field of preparation of strontium barium niobate pyroelectric ceramic materials, greatly improving the pyroelectric performance of materials, can solve problems such as poor pyroelectric performance, and achieve improved Effect of pyroelectric performance, high Curie temperature, and improved pyroelectric coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

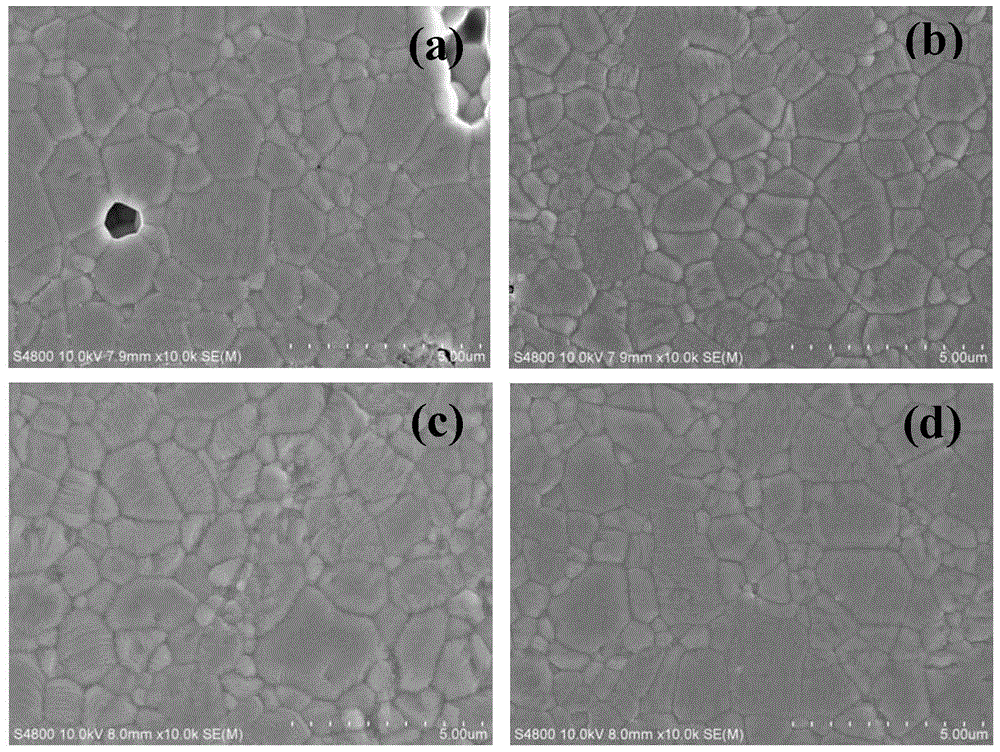

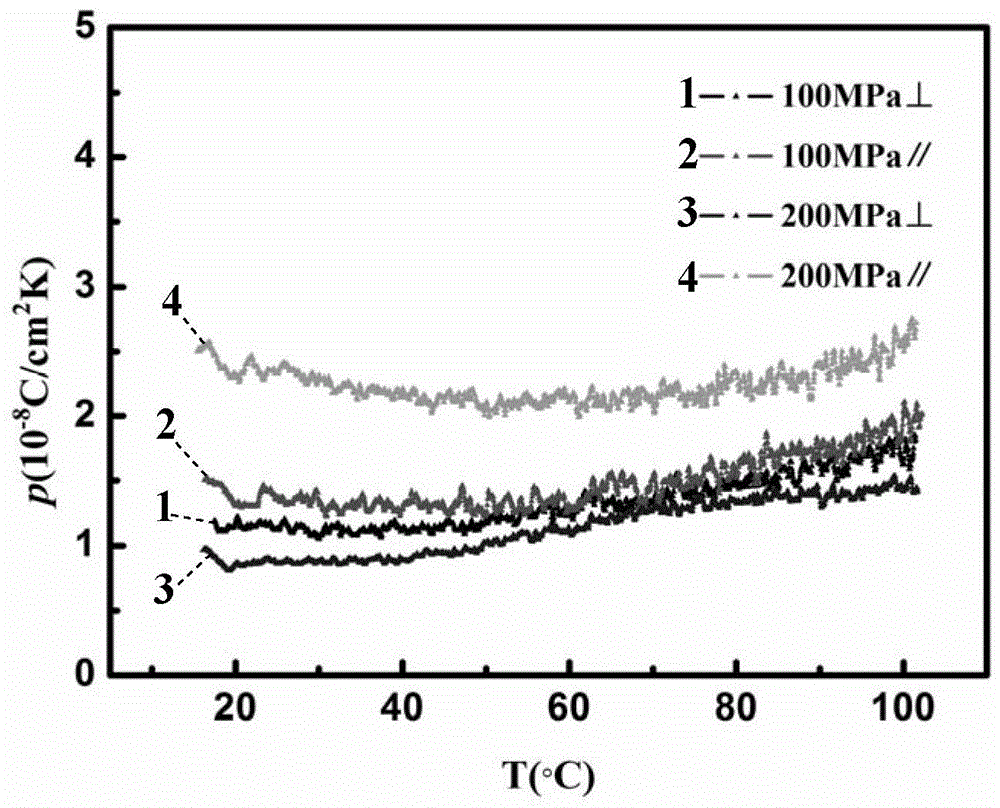

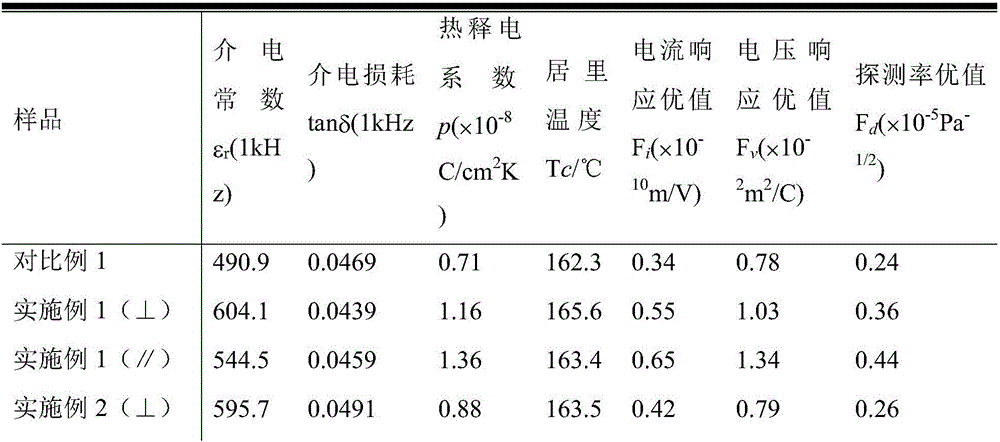

Embodiment 1

[0036] The difference between this embodiment and Comparative Example 1 is three points: 1. Sr 0.3 Ba 0.7 Nb 2 o 6 The green body is formed by cold isostatic pressing. ②The prepared Sr 0.3 Ba 0.7 Nb 2 o 6 The green body is placed in a graphite mold, with ZrO 2 Fill the green body with powder and completely cover the green body, raise the temperature to 1150°C at a rate of 1.5°C / min, start uniaxial linear pressure, continue to heat up to 1260°C at the same rate, and at the same time the pressure reaches 100MPa, heat preservation and pressure After 4 hours, finally release the pressure linearly at 10MPa / min and cool down to room temperature with the furnace cooling, and the whole sintering process is carried out under air atmosphere. ③The sintered samples were cut parallel to the hot pressing axis and perpendicular to the hot pressing axis, cleaned, dried, screen printed with silver paste, then dried, silver burned, polarized and tested for electrical properties. The re...

Embodiment 2

[0039] The only difference between this embodiment and embodiment 1 is that the maximum pressure is increased to 200MPa. The rest of the content of this embodiment is the same as that described in Embodiment 1.

[0040] Thin the thickness of the prepared pyroelectric ceramic sample to 0.5 mm, use gasoline, detergent, absolute ethanol, and deionized water to ultrasonically clean it for 15 minutes, and then print silver paste with screen after drying. After sintering for 30 minutes, ceramic samples were made to measure their electrical properties. The polarization treatment conditions of ceramic samples are as follows: put the obtained ceramic samples in silicone oil, apply a DC electric field of 7kV / mm to the ceramic samples when heating the silicone oil to 210°C, keep the electric field at 7kV / mm for 60min, and then keep the electric field strength unchanged Cool down to 40°C naturally, remove the electric field and take out the ceramic samples. Finally, the intrinsic pyroel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com