Ba(1-x)Sr(x)TiO3-Zn2TiO4 diphasic composite ceramic material preparation method thereof

A technology of ceramics and composite powders, which is applied in the direction of ceramics and inorganic insulators to achieve the effects of moderate dielectric constant, broadened application range, and high dielectric adjustable characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0033] Preparation of Ba (1-x) Sr x TiO 3 -Zn 2 TiO 4 (x=0.50, 0.45, 0.40) two-phase composite microwave ceramic material:

[0034] According to Ba 0.5 Sr 0.5 TiO 3 、Ba 0.55 Sr 0.45 TiO 3 and Ba 0.6 Sr 0.4 TiO 3 The stoichiometric ratio, respectively weighed 46.6454gBaTiO 3 and 36.7034 g SrTiO 3 , 51.3099g BaTiO 3 and 33.0331 g SrTiO 3 , 55.9744g BaTiO 3 and 29.3627gSrTiO 3 Put the powder in a nylon ball mill jar, add zirconia balls and absolute ethanol, mill for 24 hours, and pre-calcine at 1100°C for 4 hours after the discharge is dried, and Ba 0.5 Sr 0.5 TiO 3 、Ba 0.55 Sr 0.45 TiO 3 and Ba 0.6 Sr 0.4 TiO 3 The powder is ready for use. In addition, weigh 32.560g ZnO and 15.980gTiO 2 Put the powder in a nylon ball mill jar, add zirconia balls and deionized water, mill for 24 hours, and pre-calcine at 1100°C for 4 hours after the discharge is dried. After grinding, Zn 2 TiO 4 The powder is ready for use.

[0035] Take by weighing the above-mentio...

Embodiment 1

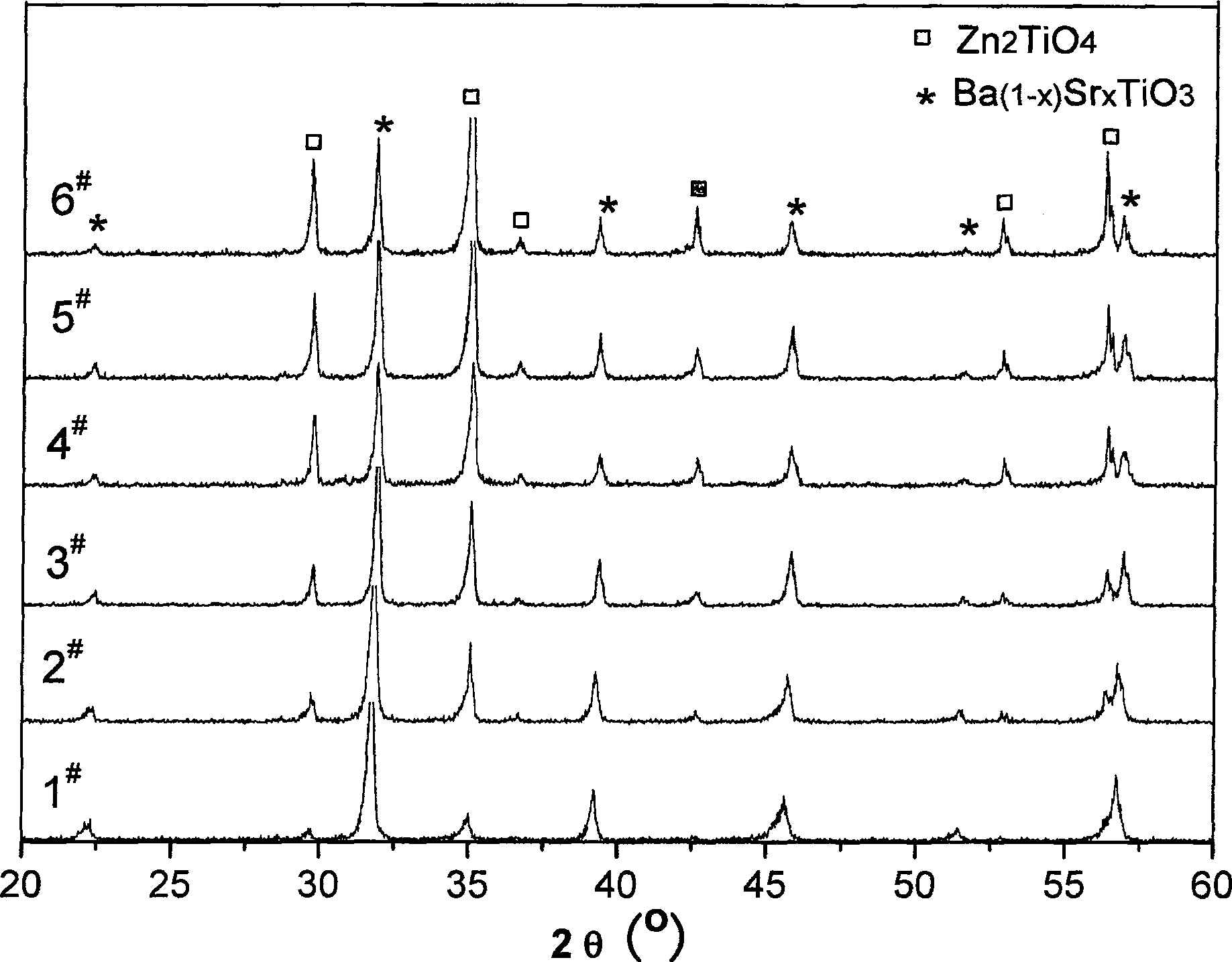

[0042] Example 1 # -6 # Ba obtained from the formula (1-x) Sr x TiO 3 -Zn 2 TiO 4 (x=0.50,0.45,0.40) The X-ray diffraction analysis collection of composite microwave ceramic material is as attached figure 1 shown.

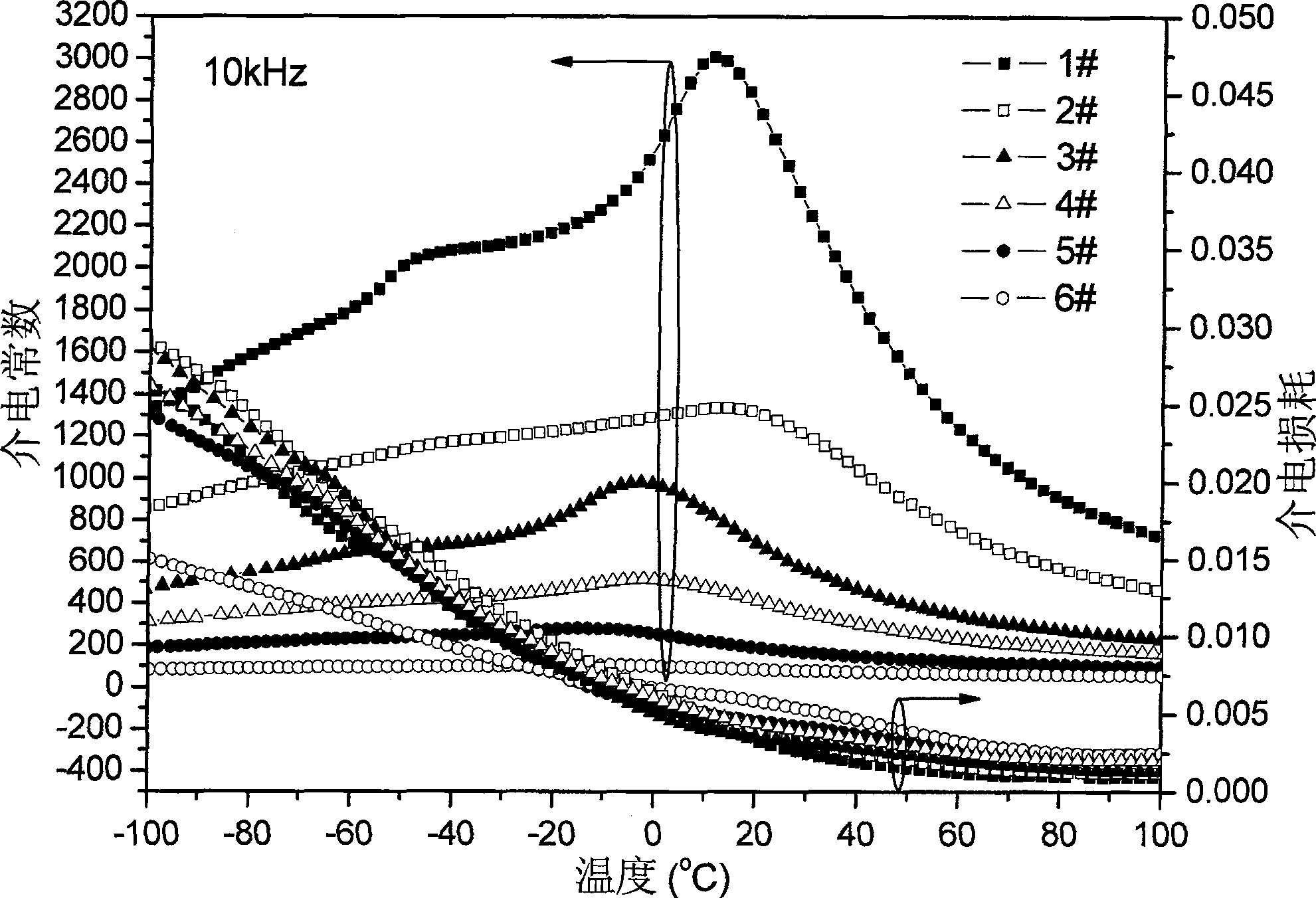

[0043] Example 1 # -6 # Ba obtained from the formula (1-x) Sr x TiO 3 -Zn 2 TiO 4 (x=0.50, 0.45, 0.40) The relationship curves of the dielectric constant and loss of the composite microwave ceramic material with temperature are as attached figure 2 shown.

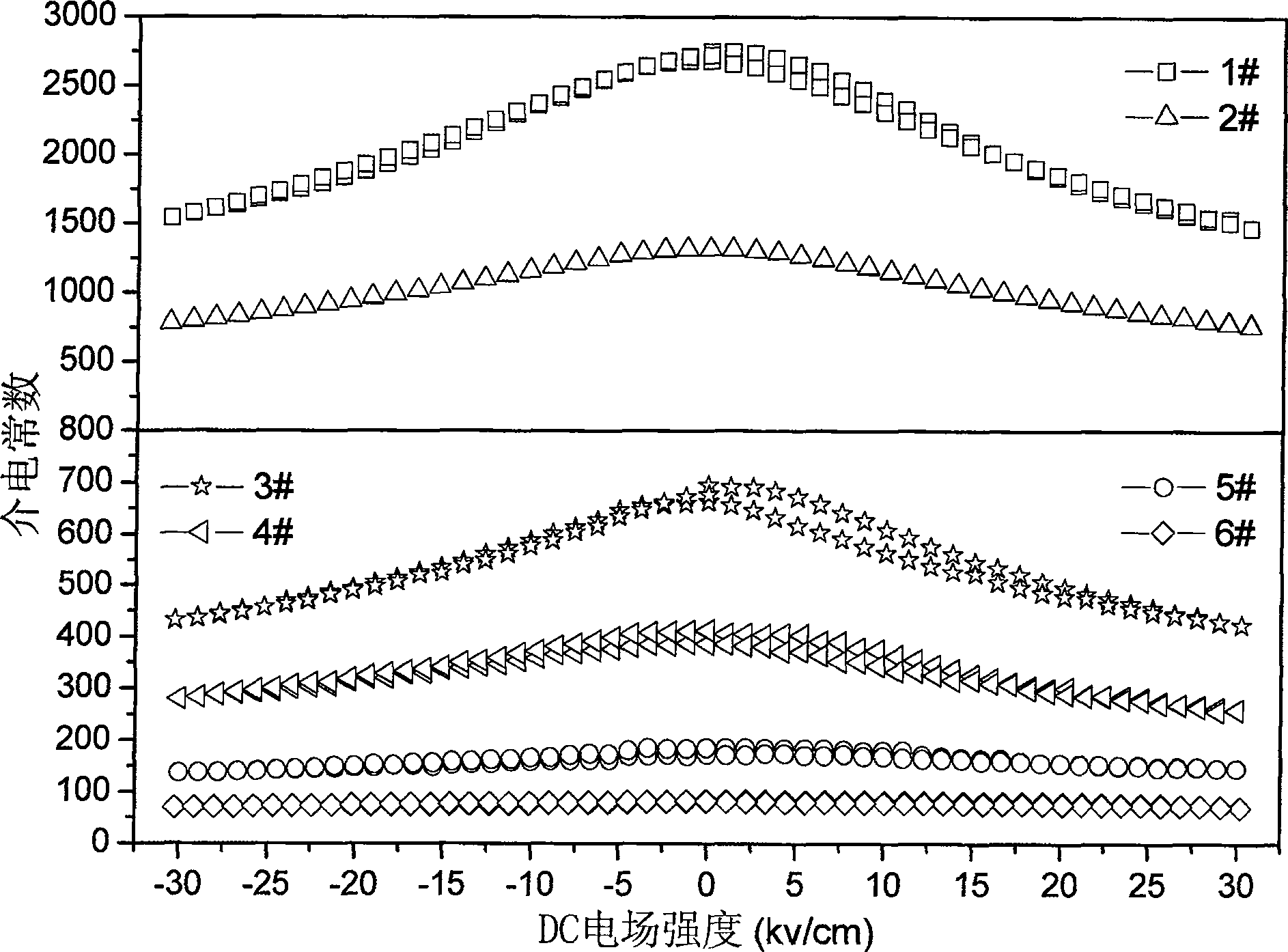

[0044] Example 1 # -6 # Ba obtained from the formula (1-x) Sr x TiO 3 -Zn 2 TiO 4 (x=0.50, 0.45, 0.40) The relationship curve between the dielectric constant of the composite microwave ceramic material and the applied DC field strength is as attached image 3 As shown, among them, 1 # 20wt% Ba 0.5 Sr 0.5 TiO 3 with 80wt% Zn 2 TiO 4 Composite; 2 # 30wt% Ba 0.5 Sr 0.5 TiO 3 with 70wt% Zn 2 TiO 4 Composite; 3 # 40wt% Ba 0.55 Sr 0.45 TiO 3 Composite with 60wt%; 4 # 50wt% Ba 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com