Medium-temperature sintered composite niobate high-frequency medium ceramic and preparation method thereof

A high-frequency dielectric, niobate technology, applied in ceramics, inorganic insulators, etc., can solve the problems of unadjustable temperature coefficient and dielectric constant to be further improved, and achieve low dielectric loss, no pollution in the process, and broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

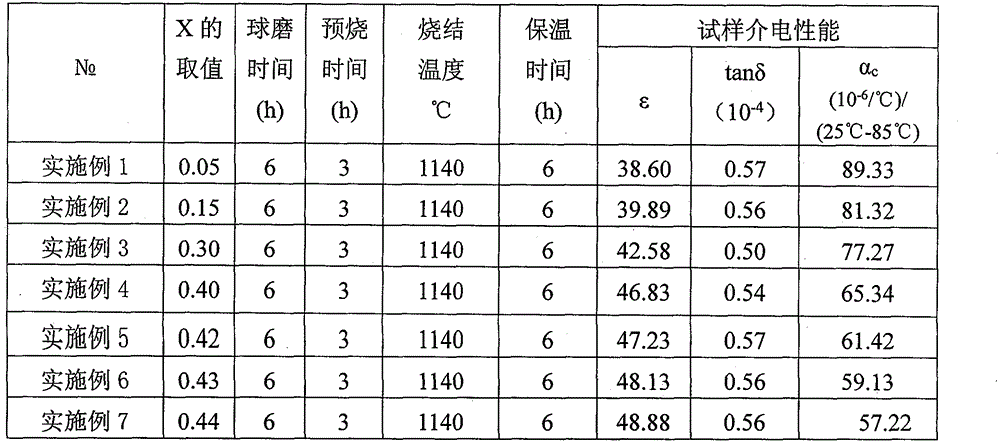

[0019] The present invention will be further described below in conjunction with embodiment.

[0020] The present invention adopts chemical raw materials ZnO and Nb with a purity greater than 99.9% 2 o 5 and TiO 2 , carry out batching and mixing according to the formula, add in the nylon ball mill jar according to the ratio of mixed raw materials: deionized water: zirconium ball mass ratio of 1: 1.6: 1.6, and ball mill on a planetary ball mill at a speed of 400r / min for 2 to 6 hours ;Dried in a 1500W infrared drying oven at 80-120°C, pre-fired at 900°C for 3 hours to obtain a frit (precursor); add paraffin wax as a binder to the frit for granulation, and sieve , and then use a powder tablet press to press a green body at a pressure of 260MPa, and sinter the green body at 1020-1170°C for 1.5-6 hours to obtain a high-frequency dielectric ceramic.

[0021] See Table 1 for details of the raw material composition relationship of specific embodiments of the present invention.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric properties | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com