Composite microwave ceramic materials with dielectric adjustable and method for preparing same

A microwave ceramic and dielectric technology, which is applied in the field of microwave ceramic materials and their preparation, can solve the problem that the dielectric tunability of low-fire microwave materials and barium titanate composite materials cannot be found, and the high sintering temperature and dielectric tunability cannot be overcome. Deterioration and other problems, to achieve the effects of high dielectric tunable characteristics, high Q value, and low sintering temperature

Inactive Publication Date: 2010-12-01

TONGJI UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the sintering temperature of materials modified by these methods is generally around 1400°C, which cannot overcome the defect of high sintering temperature, and the dielectric tunability will deteriorate rapidly due to the introduction of the second phase.

These limit its application in ferroelectric phase shifters

According to literature search, the current improvement of barium titanate materials is mainly to improve the comprehensive dielectric properties of barium titanate materials by ion substitution, doping modification or composite low-loss microwave dielectric materials in barium titanate materials. Its adaptability in device applications, did not find any report on the dielectric tunability of low-fever microwave materials and barium titanate composites

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2~9

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

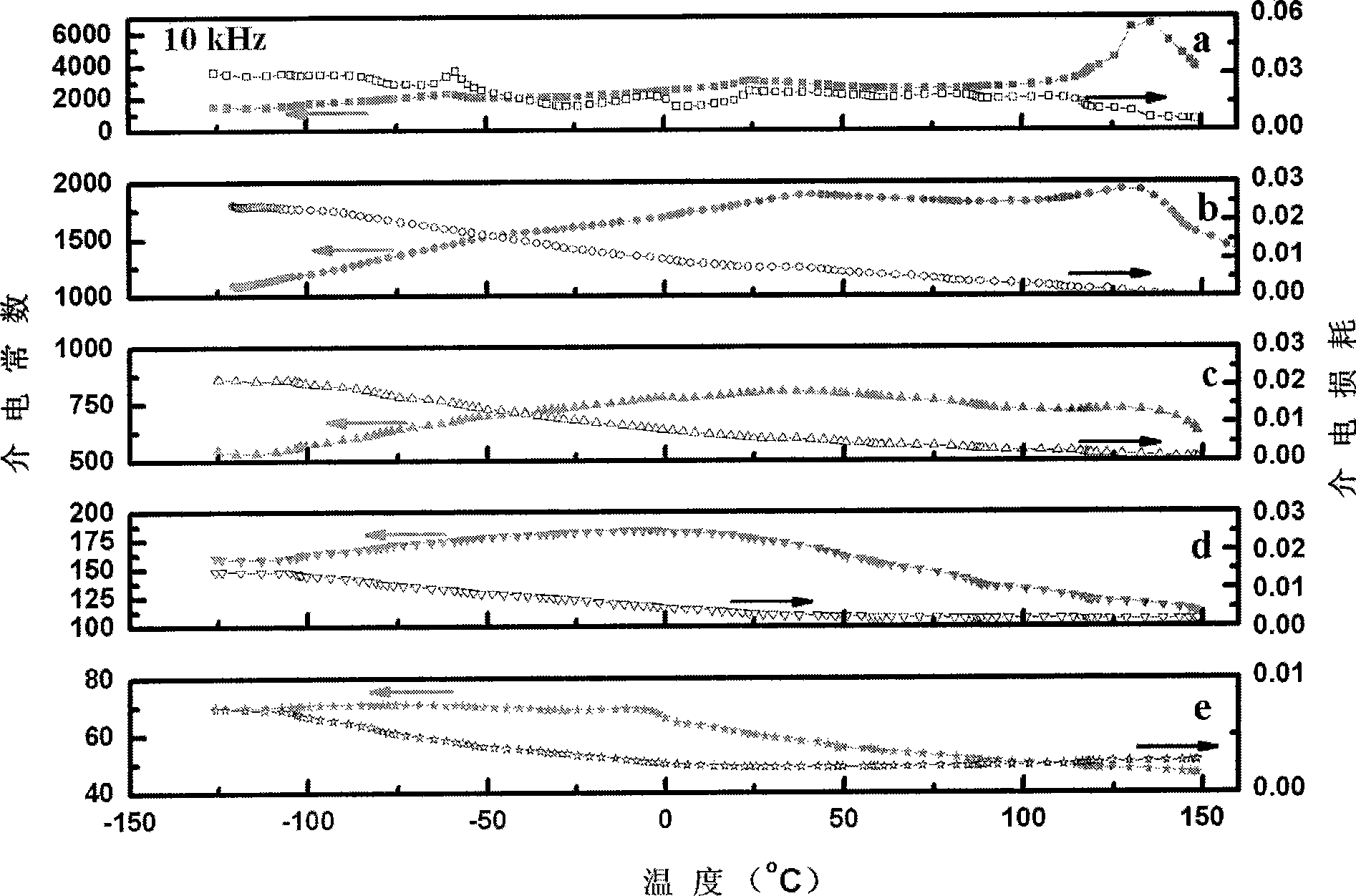

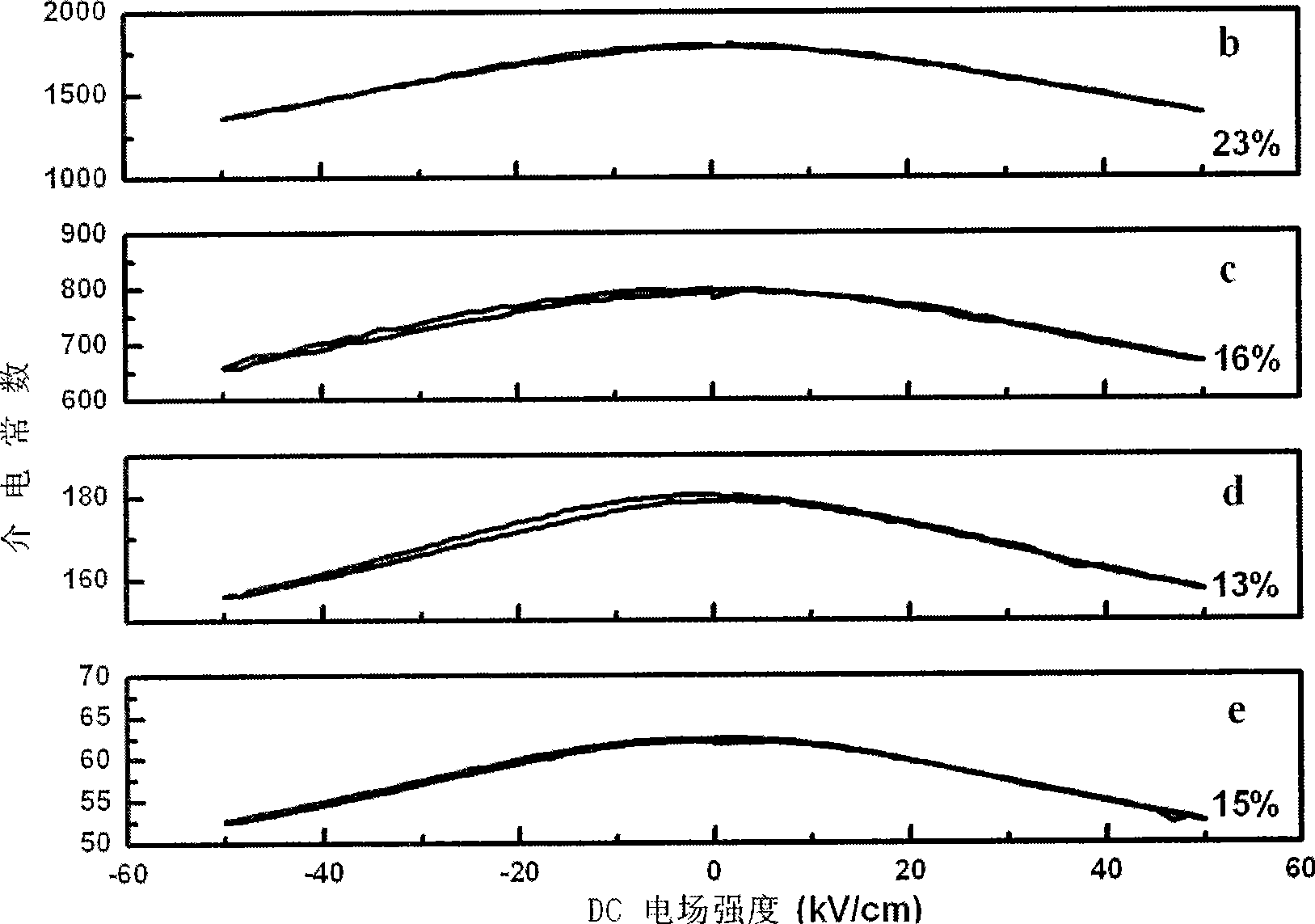

The invention belongs to the technical field of electronic materials and devices, and discloses a dielectric adjustable compound microwave ceramic material and a preparation method thereof. The compound microwave ceramic material is prepared by compounding AMP2O7 with BTO. The components of the compound microwave ceramic material and the percentage compositions of the components by weight are as follows based on the total weight of the compound microwave ceramic material: 50.0 to 97.5 percent of BaTiO3; and 2.5 to 50.0 percent of AMP2O7, in which A is Ca or Sr, and M is Zn or Cu. The traditional electronic ceramic preparation process adopted is simple; the cost is low; the material system is environment-friendly without toxicity or side effect; the compound microwave ceramic material has remarkable performance, and is applicable for development and design of adjustable microwave devices.

Description

Composite microwave ceramic material with adjustable dielectric and preparation method thereof technical field The invention belongs to the technical field of electronic materials and devices, and in particular relates to microwave ceramic materials and their preparation. Background technique Barium titanate (BaTiO3, denoted as BTO) is a ferroelectric material with a typical perovskite structure (ABO3), which has excellent dielectric nonlinearity, that is, the nonlinear characteristic that the dielectric constant changes with the applied electric field. The tuning characteristic can be applied in the microwave phase shifter. The equivalent dielectric constant of the circuit is changed by an external electric field, and then the wave velocity and wavelength of the electromagnetic wave are controlled to achieve the change of the phase shift. And because of its high dielectric constant, the size of components can be greatly reduced, which conforms to the trend of miniaturizat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B35/468

Inventor 翟继卫姜海涛

Owner TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com