Silver electrode composite material of lithium secondary battery and low temp. preparation method thereof

A lithium secondary battery and composite electrode technology, applied in the field of electrochemical power supply, can solve the problems of wide particle size distribution, uneven distribution, inevitable melting and agglomeration of silver particles, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Will NH 4 OH solution and AgNO 3 0.01mol of [Ag(NH 3 ) 2 ]OH solution, then LiMn 2 o 4 matrix and [Ag(NH 3 ) 2 ]OH according to the molar ratio of 1:0.067 to make a solution and put it on a magnetic stirrer to stir evenly. 3 CHO solution until the reaction is complete, i.e. Ag + All reduced to metal. Filter and wash with distilled water and then dry to obtain 96wt% LiMn 2 o 4 / 4wt%Ag composite powder.

[0020] Grind the powder obtained by the above synthesis method into a slurry with acetylene black and polyvinylidene fluoride (PVDF) in a weight ratio of 85:7:8 in N-methylpyrrolidone (NMP) medium, and coat on the aluminum foil and dried, the film thus made is the positive electrode, the metal lithium foil is the negative electrode, the polypropylene film of Celgard Company of the United States is the diaphragm, and the LiPF 6 -PC+DMC (1:1) is the electrolyte, and the charge and discharge test is carried out. The first discharge capacity between 4.4-3V under ...

Embodiment 2

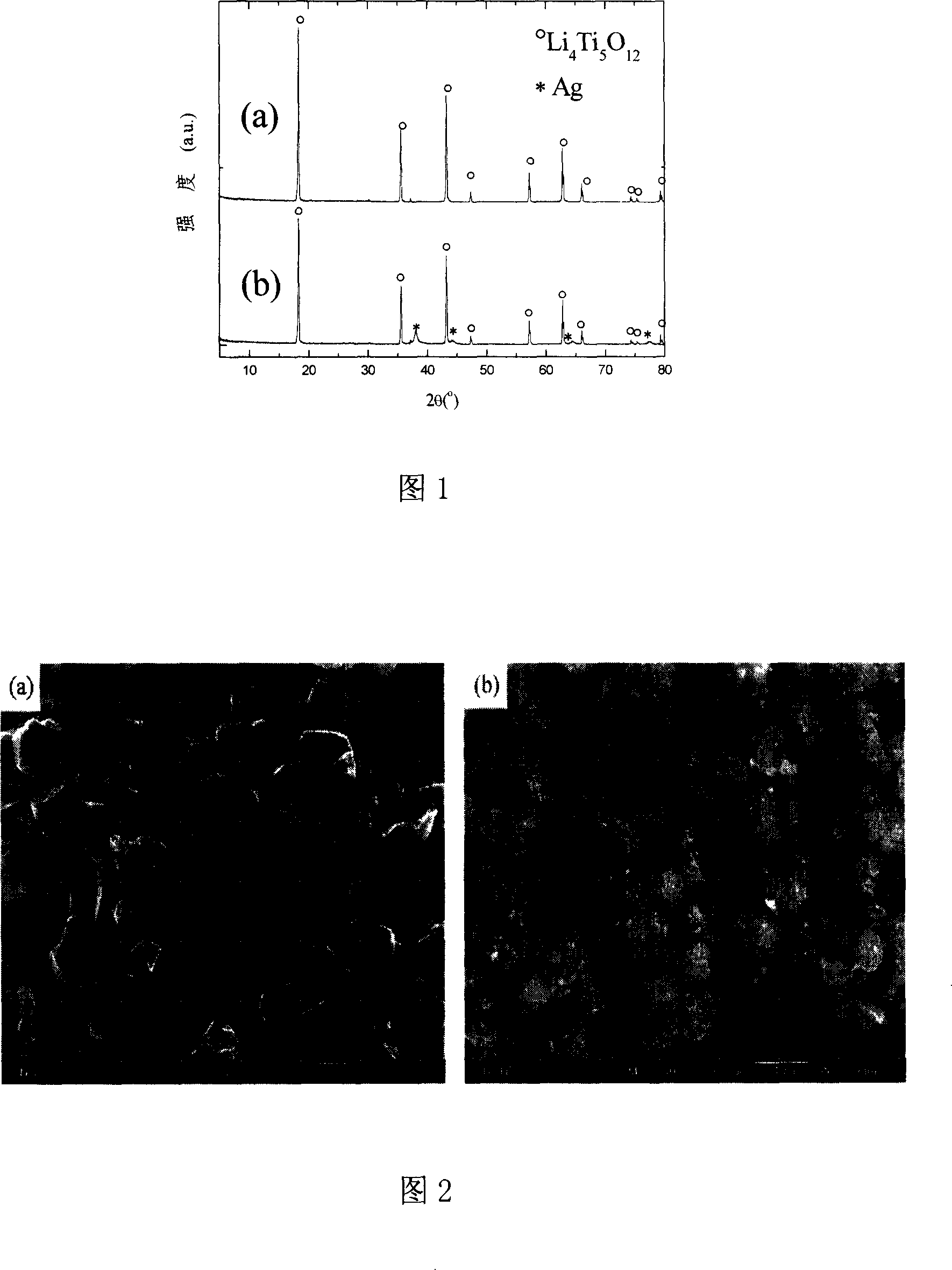

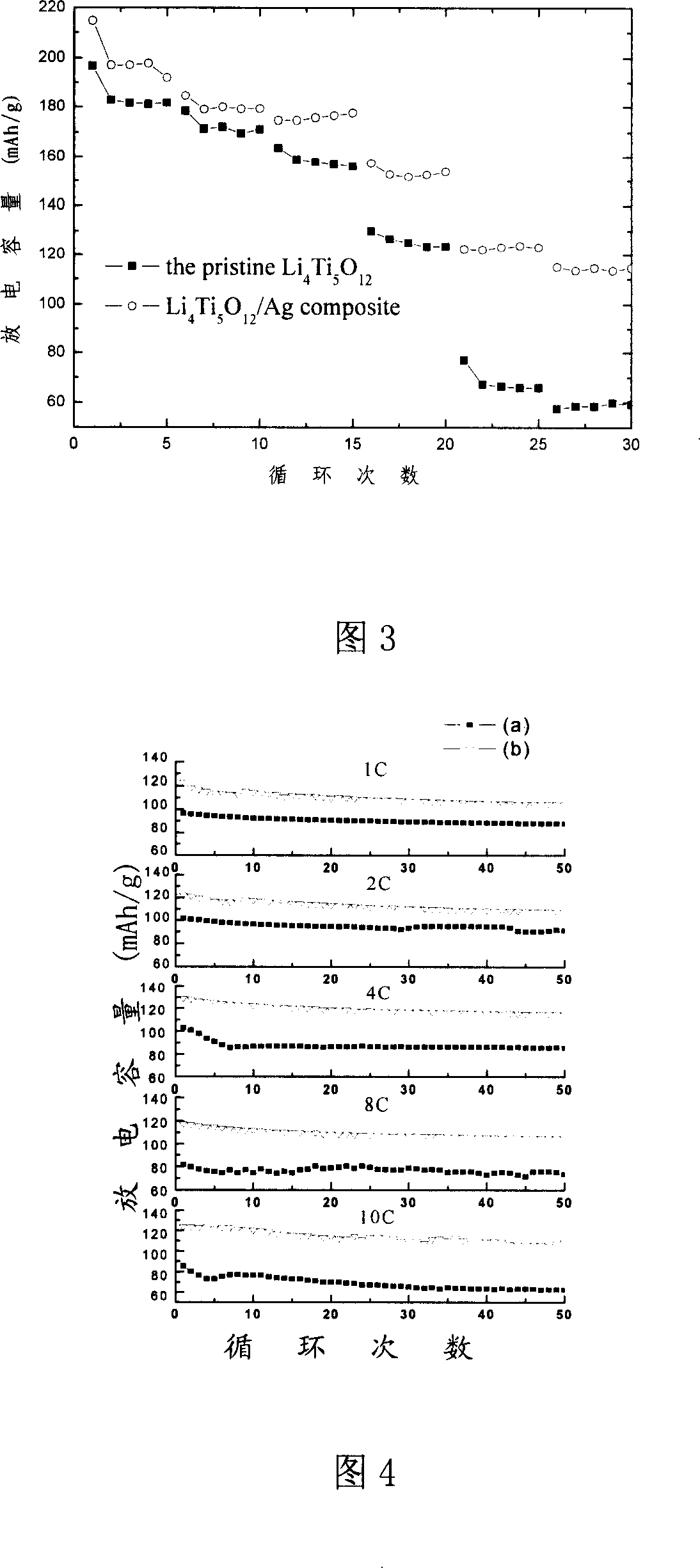

[0022] Will NH 4 OH solution and AgNO 3 0.01mol of [Ag(NH 3 ) 2 ]OH solution, then Li 4 Ti 5 o 12 Put the matrix into distilled water with a magnetic stirrer and stir evenly, and at a constant temperature of 80°C, slowly and constantly drop [Ag(NH 3 ) 2 ]OH and CH 3 CHO solution until the reaction is complete, that is, the prepared amount of Ag + All reduced to metal. After filtering and washing with distilled water, dry to obtain 96wt% Li 4 Ti 5 o 12 / 4wt%Ag composite powder. The electrode preparation method, battery assembly, and test conditions are the same as in Example 1. The charge and discharge test was carried out between 2.3-0.5V at 2C and 4C rates, and its first discharge capacity was 203.5 and 173.7mAh / g. The matrix compound Li prepared under the same conditions 4 Ti 5 o 12 The initial discharge capacity of the first discharge capacity of 162.2 and 150.7mAh / g, the first discharge capacity of the composite material containing the second phase silver w...

Embodiment 3

[0024] Will NH 4 OH solution and AgNO 3 0.01mol of [Ag(NH 3 ) 2 ]OH solution, and then LiCoO 2 matrix and [Ag(NH 3 ) 2 ]OH according to the molar ratio of 1:0.036 to prepare a solution and put it on a magnetic stirrer to stir evenly. Under the condition of a constant temperature of 80°C, drop CH 3 CHO solution until the reaction is complete, i.e. Ag + All reduced to metal. Filter and wash with distilled water and then dry to obtain 95wt% LiCoO 2 / 5wt% Ag composite powder. The electrode preparation method, battery assembly, and test conditions are the same as in Comparative Example 1. The first discharge capacity between 4.4-3V at 1C and 10C rates is 175.8 and 136.5mAh / g, and the matrix compound LiCoO prepared under the same conditions 2 The initial discharge capacities of the composites were 137.6 and 113.1mAh / g, respectively, and the initial discharge capacities of the composites containing the second phase silver were 21.73% and 17.14% higher, respectively. For th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com