Two-phase composite compact ceramic oxygen permeable membrane and method of preparing the same

An oxygen-permeable membrane and composite oxide technology, which is applied in oxygen preparation, separation methods, semi-permeable membrane separation, etc., can solve the problems of low oxygen permeability and poor stability of oxygen-permeable membrane, and achieve high oxygen permeability and thermal expansion coefficient. Good, resource-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

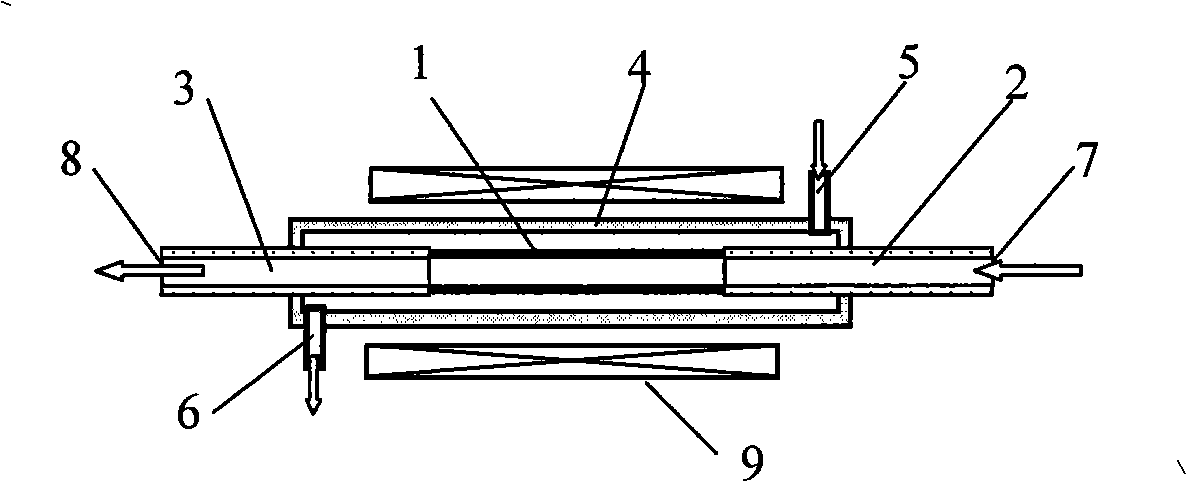

Method used

Image

Examples

Embodiment 1

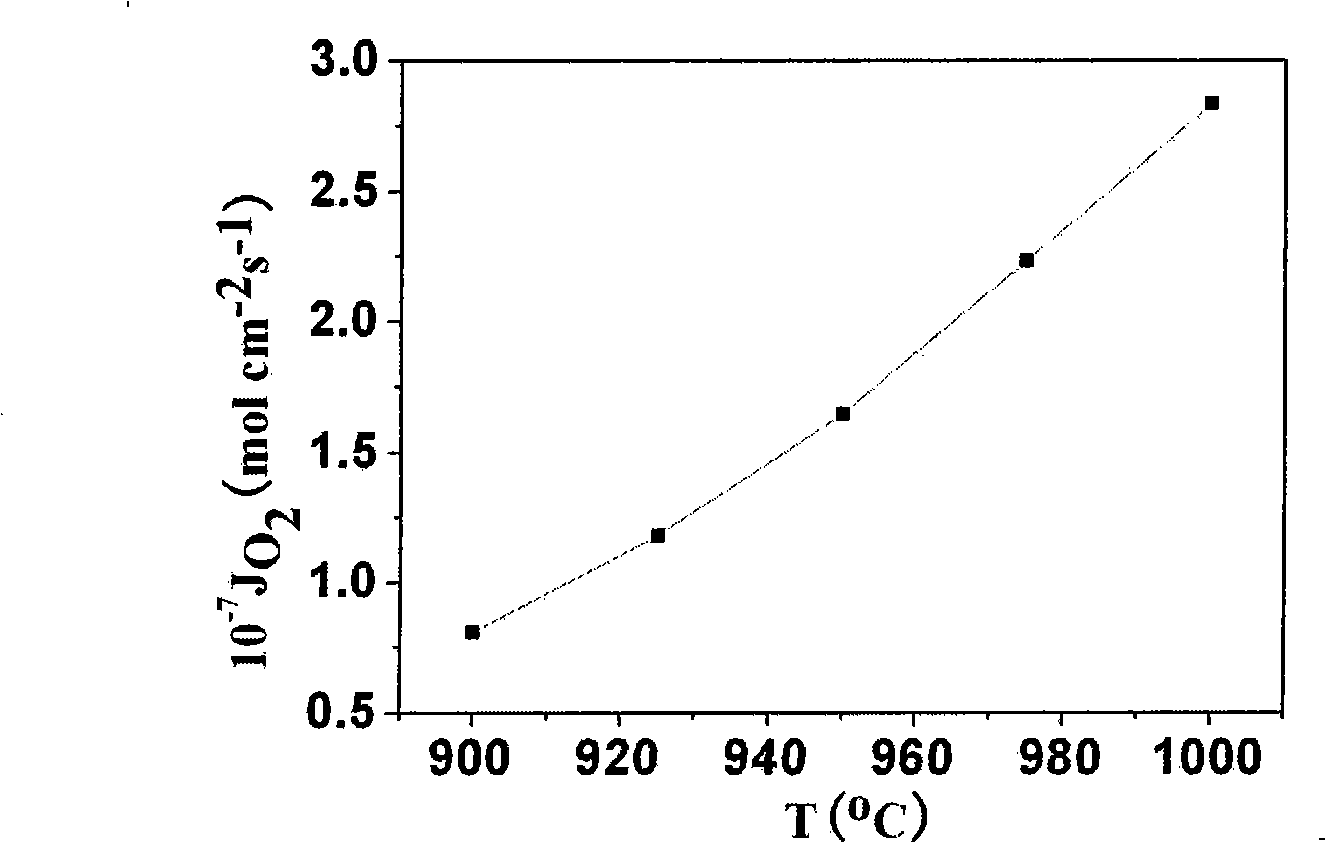

[0012] Example 1: Self-supporting hollow fiber tubular La 0.8 Sr 0.2 MnO 3 / Zr 0.84 Y 0.16 o 1.92 Preparation and Application of (LSM / YSZ) Dual-Phase Composite Dense Ceramic Oxygen Permeable Membrane

[0013] In the dual-phase composite dense ceramic oxygen-permeable membrane in this example, the electronically conductive phase is the LSM powder synthesized by the solid-state reaction method: accurately weigh the SrCO2 according to the LSM stoichiometric ratio 3 , La 2 o 3 and Mn 2 o 3 , using ethanol as the medium to ball mill and mix the raw material powder for 24 hours; after drying, react and roast at 1100°C for 10 hours, and pulverize to obtain LSM powder, which is detected by X-ray diffraction (XRD), which is a pure perovskite phase.

[0014] The ionic conductive phase adopts the fluorite type YSZ powder purchased from the market.

[0015] Mix the above LSM and YSZ powders according to the volume ratio of 0.67:1, mix them uniformly by ball milling in ethanol fo...

Embodiment 2

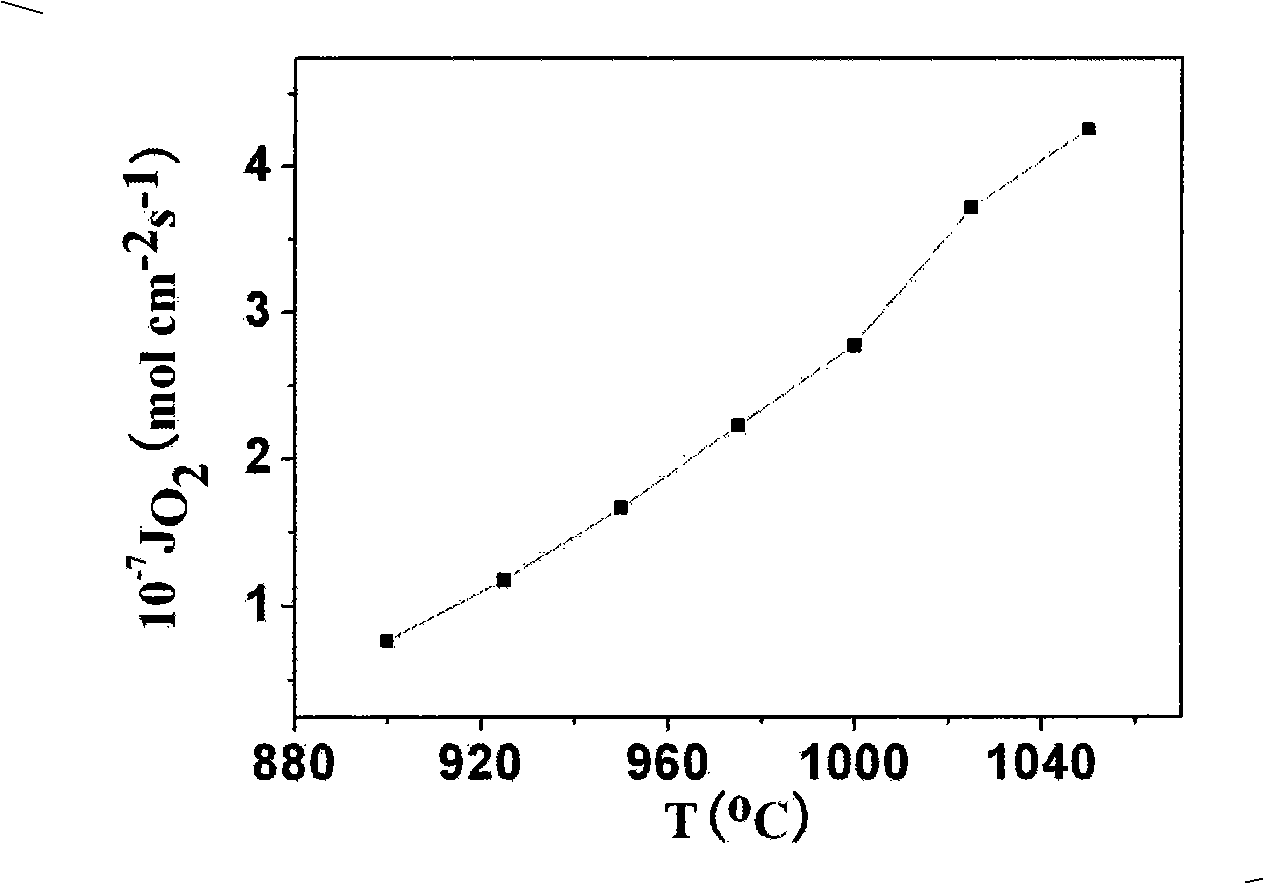

[0025] Example 2: Preparation and use of hollow fiber tubular LSM and YSZ dual-phase composite dense ceramic oxygen permeable membrane supported by porous YSZ support

[0026] First prepare the porous YSZ support body and the LSM / YSZ raw material powder by the same method as in Example 1. Then, ethanol was used as a dispersant to prepare a uniform slurry, and the LSM / YSZ green film was prepared on the outer surface of the porous YSZ support by the dipping method, and dried at room temperature for 48 hours in still air. In order to prevent the slurry from entering the support tube during immersion, both ends of the support tube can be sealed before immersion.

[0027] The hollow fiber tubular LSM / YSZ green membrane supported by the porous YSZ support prepared above is co-fired at high temperature. The sintering process is as follows: firstly, the temperature is raised from room temperature to 800 °C at a rate of 0.5 °C / min, and the temperature is kept for 4 hours. ; then raise...

Embodiment 3

[0032] Example 3: Preparation of self-supporting flat LSM / YSZ dual-phase composite dense ceramic oxygen-permeable membrane

[0033] Adopt the same method as in Example 1 to prepare LSM / YSZ raw material powder, adopt the molding die of corresponding size and shape, make self-supporting flat plate type LSM / YSZ dual-phase composite ceramic green body under isostatic pressing, other conditions remain unchanged, A self-supporting flat LSM / YSZ dual-phase composite dense ceramic oxygen permeable membrane with a film thickness of 10 mm can be obtained.

[0034] By adjusting the volume ratios of the above-mentioned ion-conducting phase and electron-conducting phase to 0.6:1 and 1.8:1 respectively, the sintering temperatures were 1200°C and 1500°C, and other conditions remained unchanged, a two-phase composite dense ceramic transparent Oxygen film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com