Polyaniline/carbon nano tube/nanometer silver particle conductive composite material and preparation method thereof

A conductive composite material and nano-silver particle technology, applied in the field of composite materials, can solve problems such as control signal interference and signal transmission obstacles, and achieve the effects of solving the problem of reunion, low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

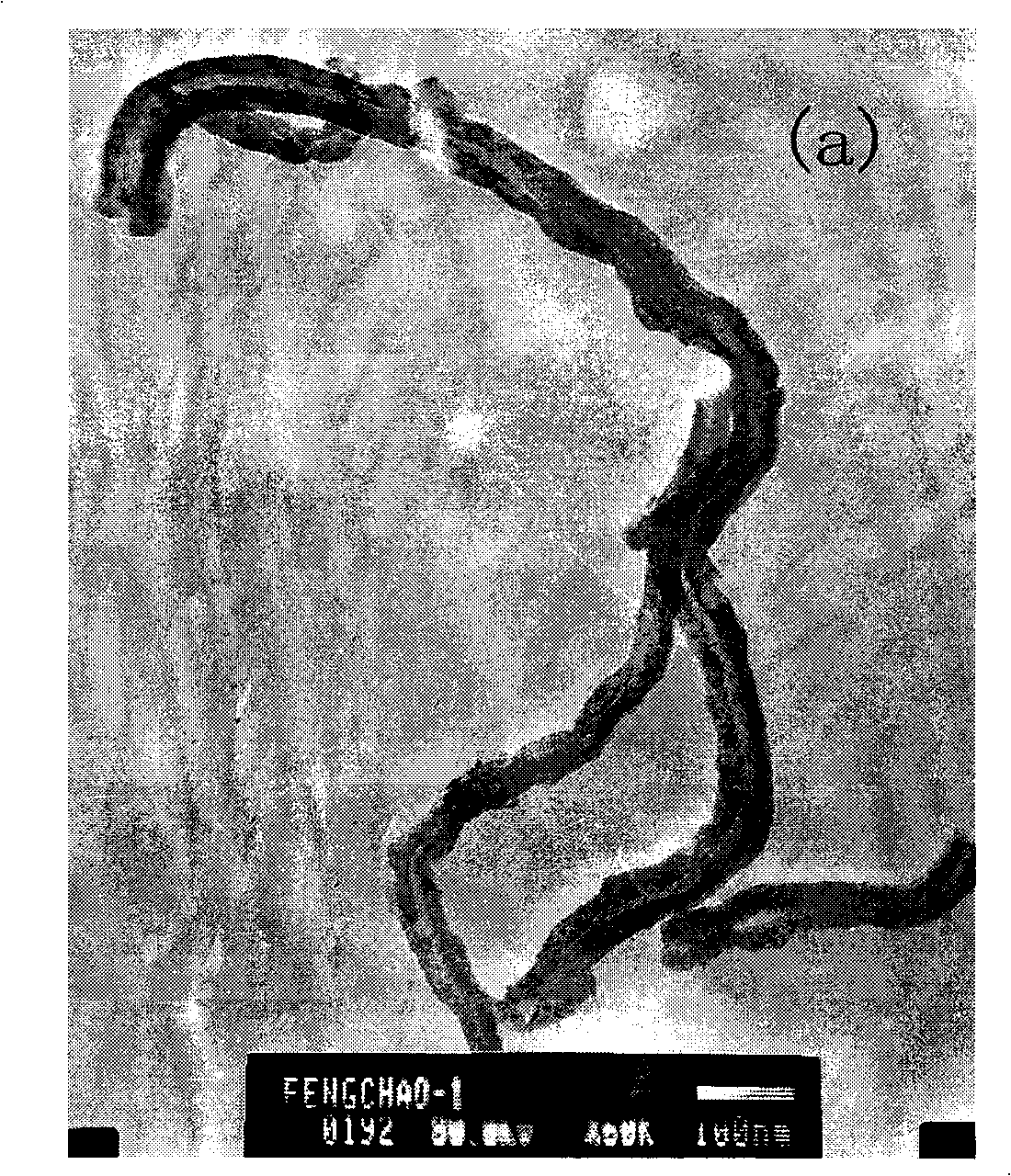

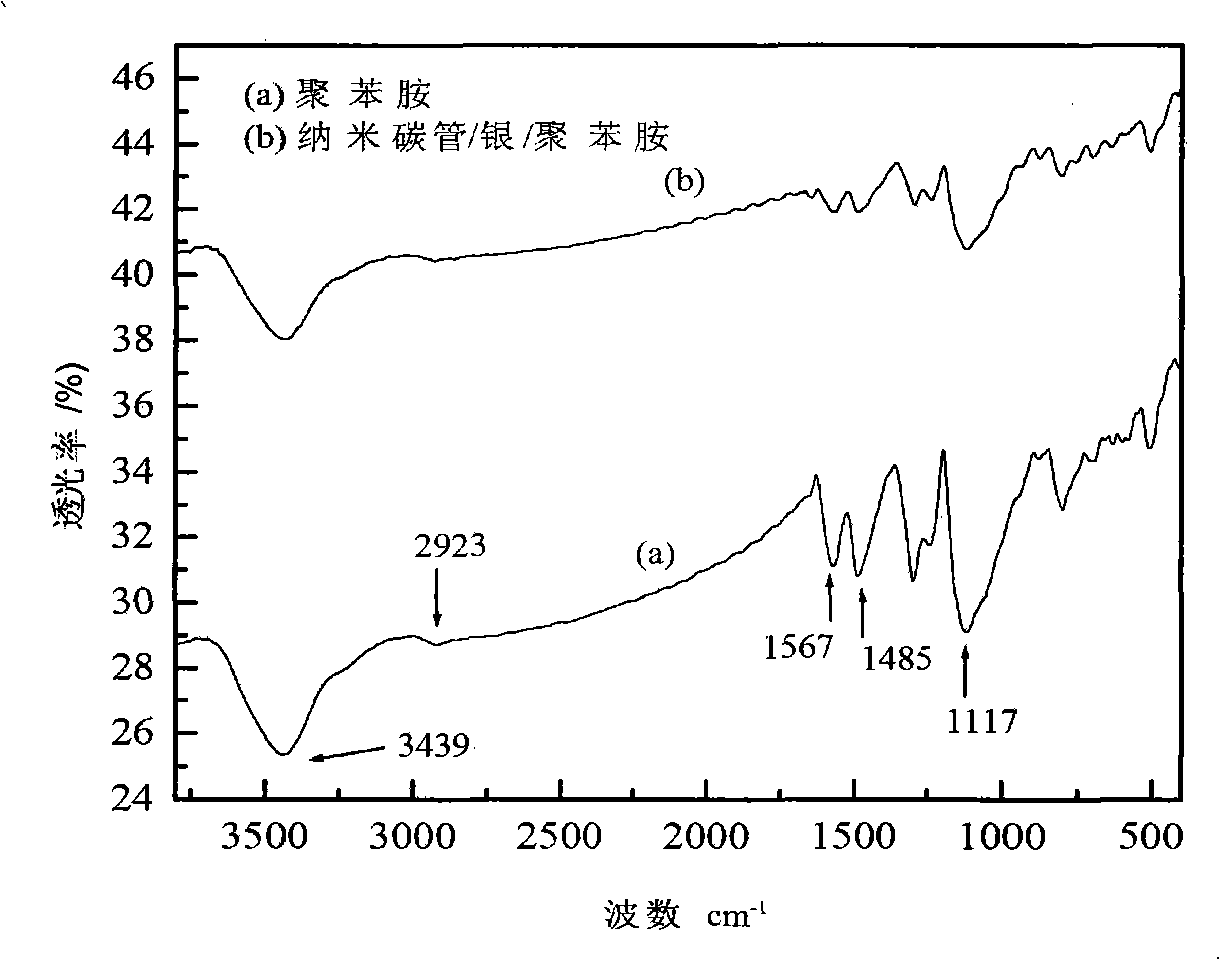

[0041] Embodiment 1, measure 50ml of 0.001M silver nitrate solution prepared in advance in a 250ml round-bottomed flask, add 50ml absolute ethanol and 10ml polyethylene glycol-400, place in an ultrasonic instrument, ultrasonic 15min at 40KHZ, 200W, make Mix it evenly. Add 0.04 g of purified carbon nanotubes, and continue to sonicate for 10 min. 60ml of 0.001M ascorbic acid solution was added dropwise under vigorous stirring, and the reaction was stirred at room temperature for 6h. The reaction product was filtered with a microporous membrane, washed, vacuum-dried at 60° C. for 24 hours, and ground to obtain a composite filler of carbon nanotubes and nano-silver particles, which was set aside.

[0042] Add the above-prepared composite filler of carbon nanotubes and nano-silver particles into 1ml of aniline, place it in an ultrasonic instrument, and sonicate at 40KHZ and 200W for 15min, then add 40ml of 1M HCl to it, and continue to sonicate for 10min. In an ice-salt bath (0-5...

Embodiment 2

[0044] Example 2, take 50ml of 0.001M silver nitrate solution prepared in advance in a 250ml round bottom flask, add 55ml of absolute ethanol and 10ml of polyethylene glycol-400, place it in an ultrasonic instrument, and ultrasonicate for 15min at 40KHZ and 200W. Make it well mixed. Add 0.06 g of purified carbon nanotubes, and continue to sonicate for 10 min. Under the condition of vigorous stirring, 70 ml of 0.001M ascorbic acid solution was added dropwise, and the reaction was stirred at room temperature for 6 h. The reaction product was filtered with a microporous membrane, washed, vacuum-dried at 60° C. for 24 hours, and ground to obtain a composite filler of carbon nanotubes and nano-silver particles, which was set aside.

[0045] Add the above-prepared composite filler of carbon nanotubes and nano-silver particles into 1ml of aniline, place it in an ultrasonic instrument, and sonicate at 40KHZ and 200W for 15min, then add 50ml of 1M HCl to it, and continue to sonicate f...

Embodiment 3

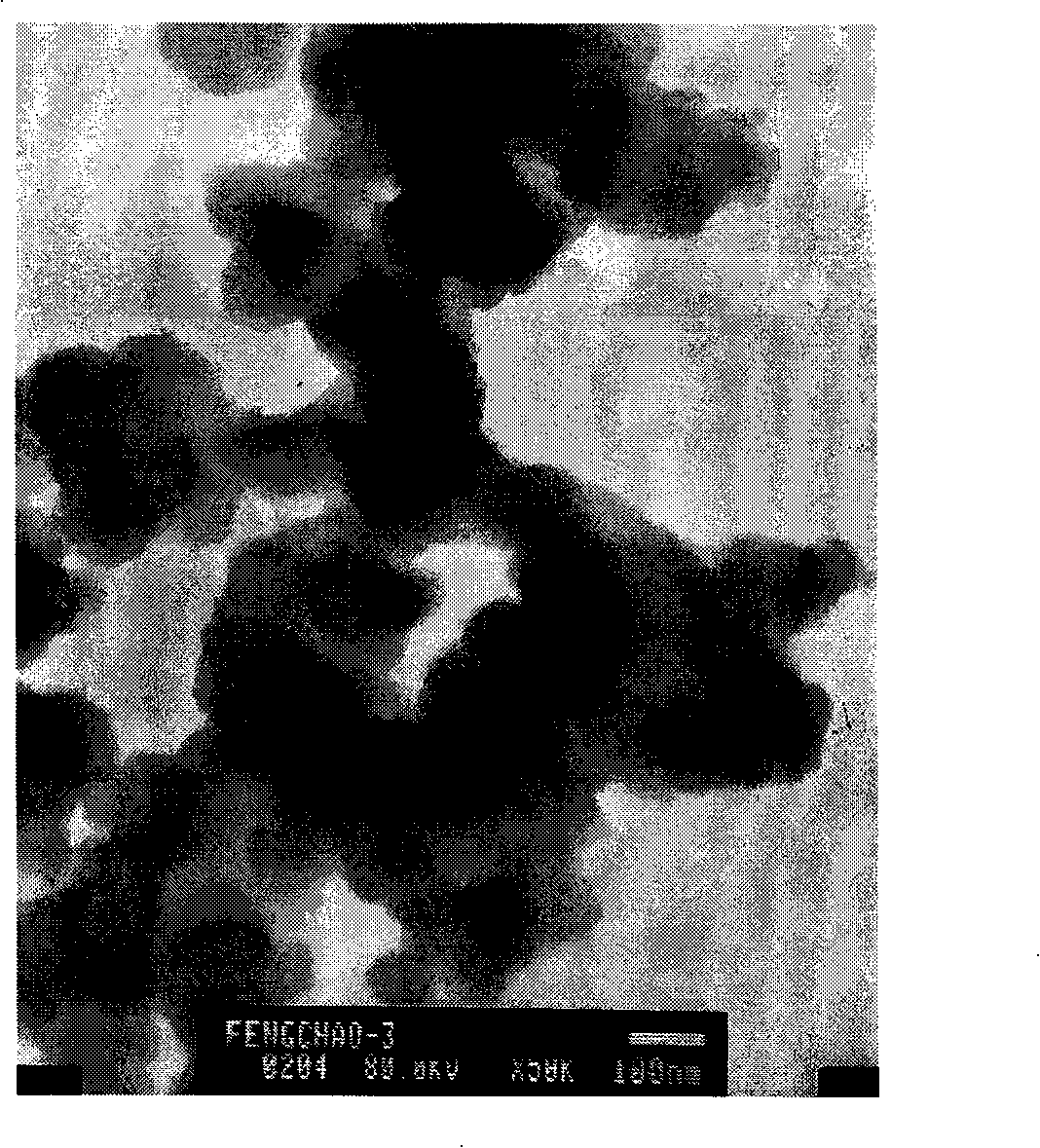

[0047] Example 3, take 50ml of 0.001M silver nitrate solution prepared in advance in a 250ml round bottom flask, add 60ml of absolute ethanol and 10ml of polyethylene glycol-400, place it in an ultrasonic machine, and ultrasonicate for 15min at 40KHZ and 200W. Make it well mixed. Add 0.08 g of purified carbon nanotubes, and continue to sonicate for 10 min. 80ml of 0.001M ascorbic acid solution was added dropwise under vigorous stirring, and the reaction was stirred at room temperature for 6h. The reaction product was filtered with a microporous membrane, washed, vacuum-dried at 60° C. for 24 hours, and ground to obtain a composite filler of carbon nanotubes and nano-silver particles, which was set aside.

[0048] Add the composite filler of carbon nanotubes and nano-silver particles prepared above into 1ml of aniline, place it in an ultrasonic instrument, and sonicate at 40KHZ and 200W for 15min, then add 60ml of 1M HCl to it, and continue to sonicate for 10min. In an ice-sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com