Method for preparing ZnO/ZnGaNO two-phase composite structure photocatalytic powder

A composite structure and photocatalytic technology, applied in the field of photocatalytic materials, can solve the problems of hindering the redox reaction of photogenerated carriers, affecting the migration of photogenerated carriers, affecting the absorption of visible light, etc., and achieves short preparation time, low cost, and decolorization powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

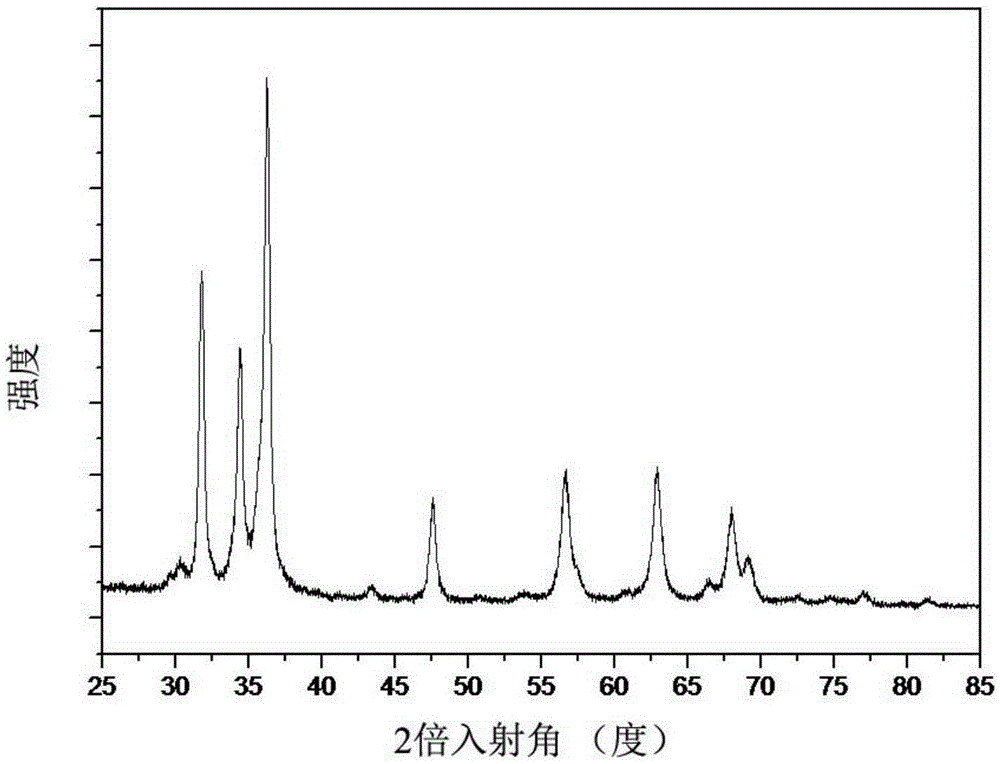

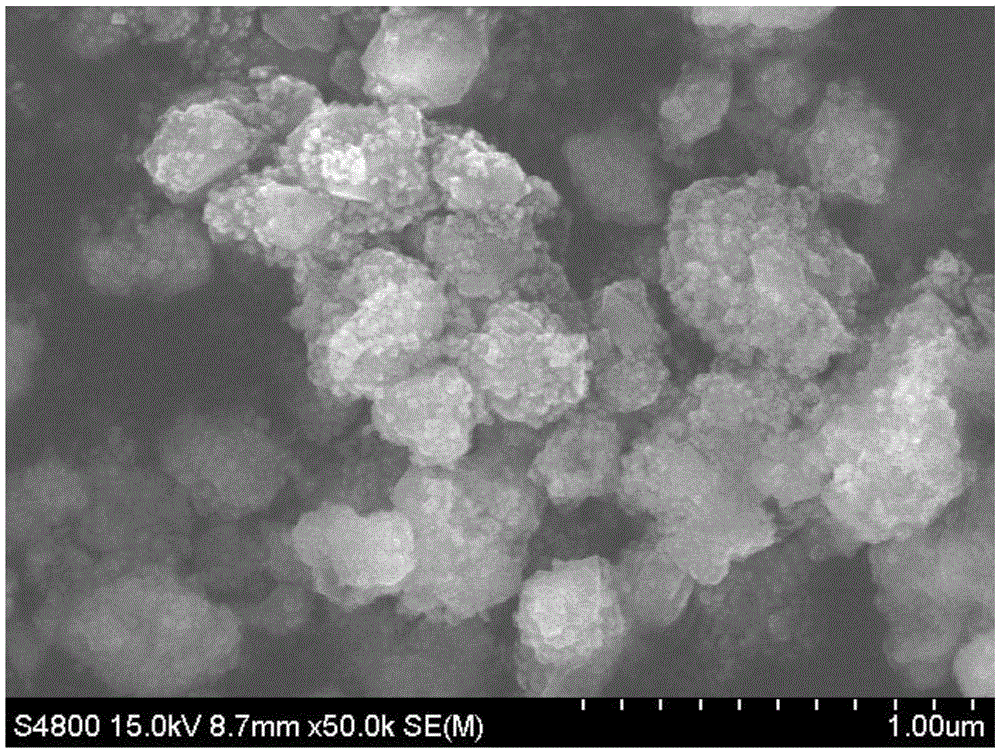

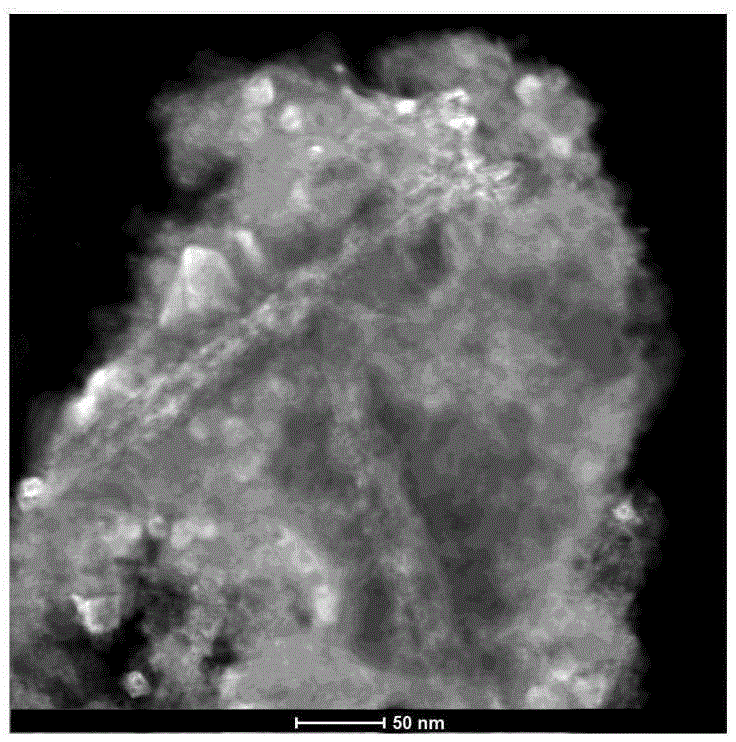

[0046] Embodiment 1: Preparation of ZnO / ZnGaNO two-phase composite structure powder

[0047] (1) 12 grams of Ga(NO 3 ) 3 9H 2 O and 12 g of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 100 mL of aqueous solution, and then the mixed metal solution of gallium and zinc was quickly poured into 70 mL of 1mol / L Na 2 CO 3 In the solution, stir constantly at the same time, the mixing speed is 30mL / s, and the stirring speed is 1500rpm, and a white precipitate is obtained; when all the metal solution is poured, the pH of the mixed solution is adjusted to 8 with 2mol / L NaOH solution;

[0048] (2) Put the obtained mixed solution in a water bath at 80° C. for 12 hours while keeping constant stirring.

[0049] (3) centrifuging the precipitate and washing it with deionized water, repeated three times; drying the centrifuged precipitate at 80° C. for 12 hours to obtain a white solid;

[0050] (4) The precursor was obtained by grinding the white solid into powder with an agate mortar. Put the...

Embodiment 2

[0059] Embodiment 2: Preparation of ZnO / ZnGaNO two-phase composite structure powder

[0060] (1) 12 grams of Ga(NO 3 ) 3 9H 2 O and 17.82 g of Zn(NO 3 ) 2 ·6H 2 O was dissolved in 100 mL of aqueous solution, then the mixed metal solution of gallium and zinc was poured into 70 mL of 1M Na 2 CO 3 In the solution, the mixing speed is 10mL / s, and the stirring speed is 1000rpm; when all the metal solution is poured, adjust the pH of the mixed solution to 7 with 2M NaOH solution;

[0061] (2) Put the obtained mixed solution in a water bath at 80° C. for 12 hours while keeping constant stirring.

[0062] (3) centrifuging the precipitate and washing it with deionized water, repeated three times; drying the centrifuged precipitate at 80° C. for 12 hours to obtain a white solid;

[0063] (4) The precursor was obtained by grinding the white solid into powder with an agate mortar. Put the precursor into a high-temperature energy-saving tube furnace for sintering at 800°C and react ...

Embodiment 3

[0064] Embodiment 3: Preparation of ZnO / ZnGaNO two-phase composite structure powder

[0065] (1) 2 grams of Ga(NO 3 ) 3 9H 2 O and 7.4 g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 100 mL of aqueous solution, then the mixed metal solution of gallium and zinc was poured into 75 mL of 0.1M Na 2 CO 3 In the solution, the mixing speed is 1mL / s, and the stirring speed is 500rpm; when all the metal solution is poured, adjust the pH of the mixed solution to 9 with 2M NaOH solution;

[0066] (2) Put the obtained mixed solution in a water bath at 80° C. for 12 hours while keeping constant stirring.

[0067] (3) centrifuging the precipitate and washing it with deionized water, repeated three times; drying the centrifuged precipitate at 80° C. for 12 hours to obtain a white solid;

[0068] (4) The precursor was obtained by grinding the white solid into powder with an agate mortar. Put the precursor into a high-temperature energy-saving tube furnace for sintering at 800°C and react with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com