Magnetically reinforced photocatalysis wind wheel and air purification method

A photocatalysis and wind wheel technology, applied in the field of air purification, can solve the problems of secondary pollution, less photocatalyst, unfavorable long-term use, etc., and achieve the effects of strengthening purification capacity, improving oxygen enrichment and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

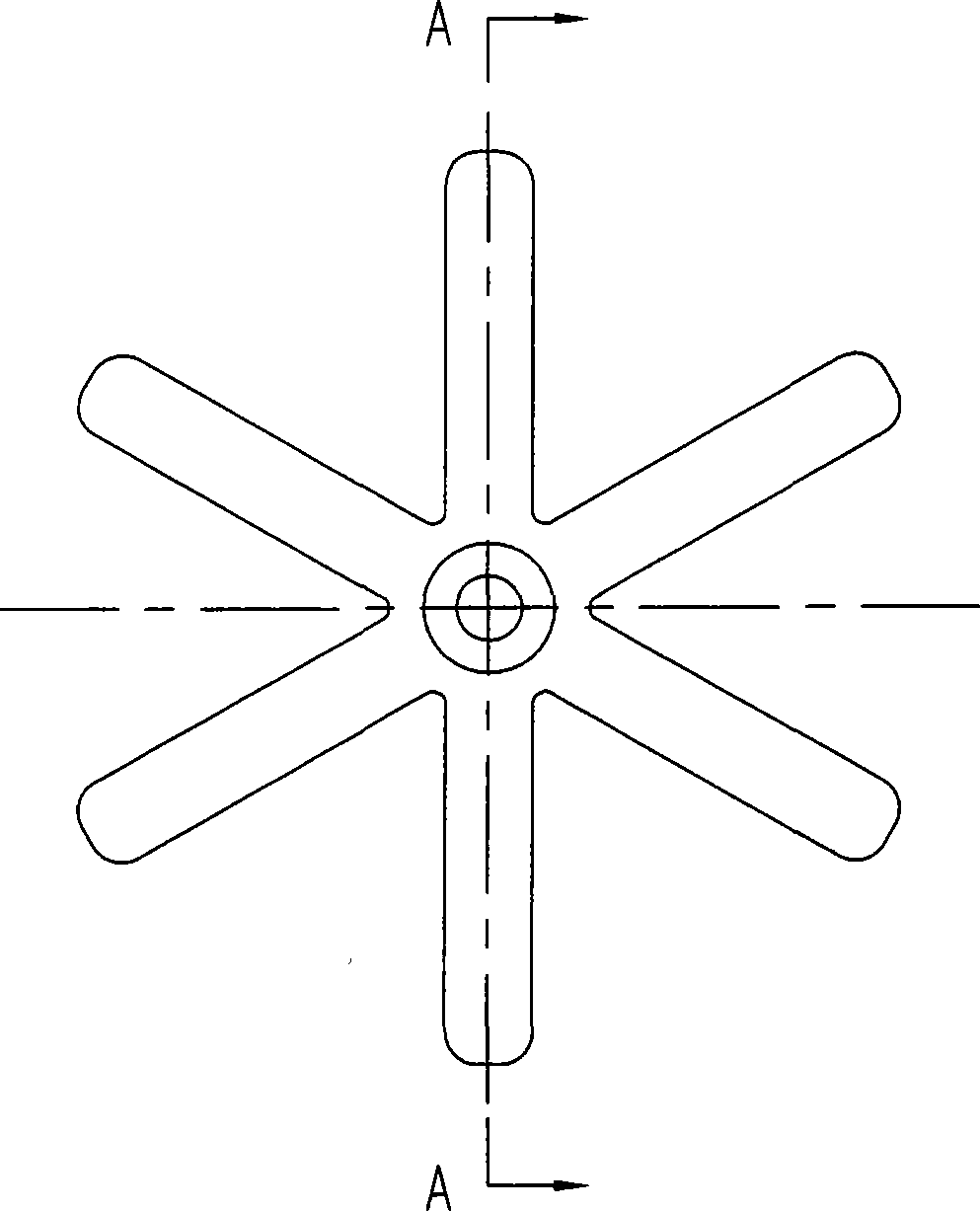

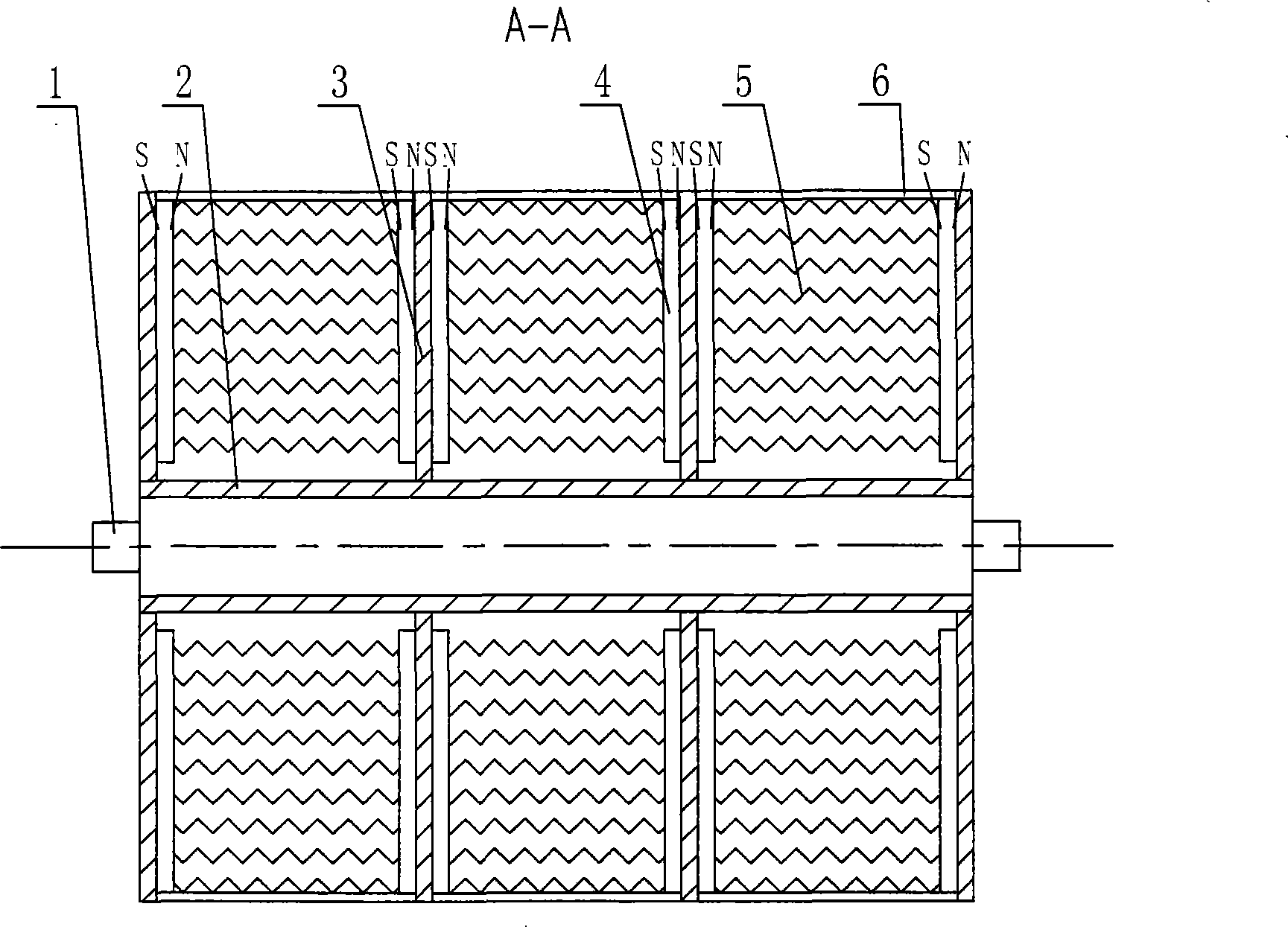

[0033] exist figure 1 , 2Among them, the magnetically strengthened photocatalytic wind wheel of this embodiment is composed of a wheel shaft 1, a shaft sleeve 2, a skeleton 3, a permanent magnet 4, a magnetically conductive photocatalytic foam metal 5, and a nonmagnetically conductive fixed net 6.

[0034] In this embodiment, 6 radially evenly distributed skeletons 3 are connected to form a skeleton disk. The skeleton disk is a magnetically conductive stainless steel skeleton disk, or it can be a nonmagnetic material skeleton disk. On the shaft sleeve 2, 4 A skeleton disc, the wheel shaft 1 is sleeved in the shaft sleeve 2, and the wheel shaft 1 is connected with the driving mechanism with a coupling piece during use to drive the wheel shaft 1 to rotate. A permanent magnet 4 is attached to the inner surface of the left end frame 3, the shape of the permanent magnet 4 is a cuboid, the outer end surface of the permanent magnet 4 is an S pole, and the inner end surface is an N p...

Embodiment 2

[0044] Two skeleton disks are installed on the shaft sleeve 2 of this embodiment, and each skeleton disk is composed of four skeletons 3 uniformly distributed in the radial direction, and four magnetically strengthened catalytic units are installed on the two skeleton disks. The structure of the enhanced catalytic unit is the same as that of the magnetically enhanced catalytic unit in Example 1. Other components and the coupling relationship of the components are the same as in Embodiment 1.

[0045] The steps of using the above-mentioned magnetically strengthened photocatalytic wind wheel to purify air are the same as in Example 1.

Embodiment 3

[0047] In this embodiment, 5 skeleton disks are evenly distributed on the shaft sleeve 2, and each skeleton disk is composed of 8 skeleton disks 3 evenly distributed in the radial direction, and a total of 32 magnetically enhanced catalytic units are installed on the 5 skeleton disks. , The structure of the magnetically strengthened catalytic unit is the same as that of the magnetically strengthened catalytic unit in Example 1. Other components and the coupling relationship of the components are the same as in Embodiment 1.

[0048] The steps of using the above-mentioned magnetically strengthened photocatalytic wind wheel to purify air are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com