Rare earth doped spherical nano titanium dioxide preparation method

A nano-titanium dioxide, titanium dioxide technology, applied in titanium dioxide, titanium oxide/hydroxide, nanotechnology for materials and surface science, etc., can solve problems such as low efficiency and long preparation cycle of nano-titanium dioxide, to improve efficiency and improve The effect of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

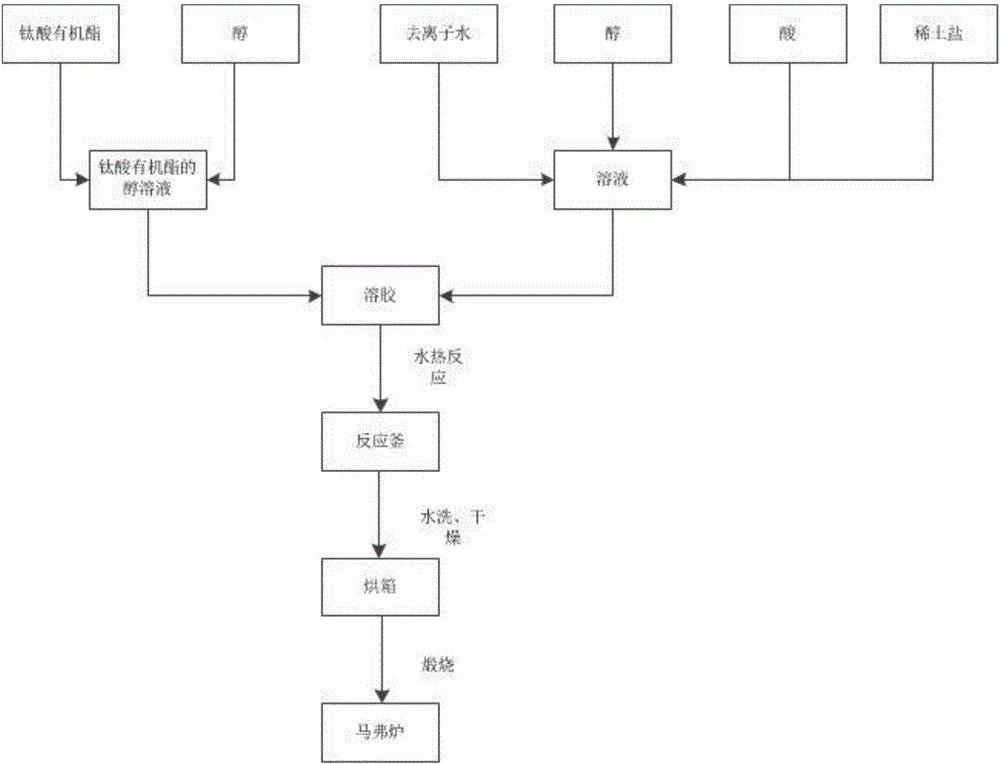

Method used

Image

Examples

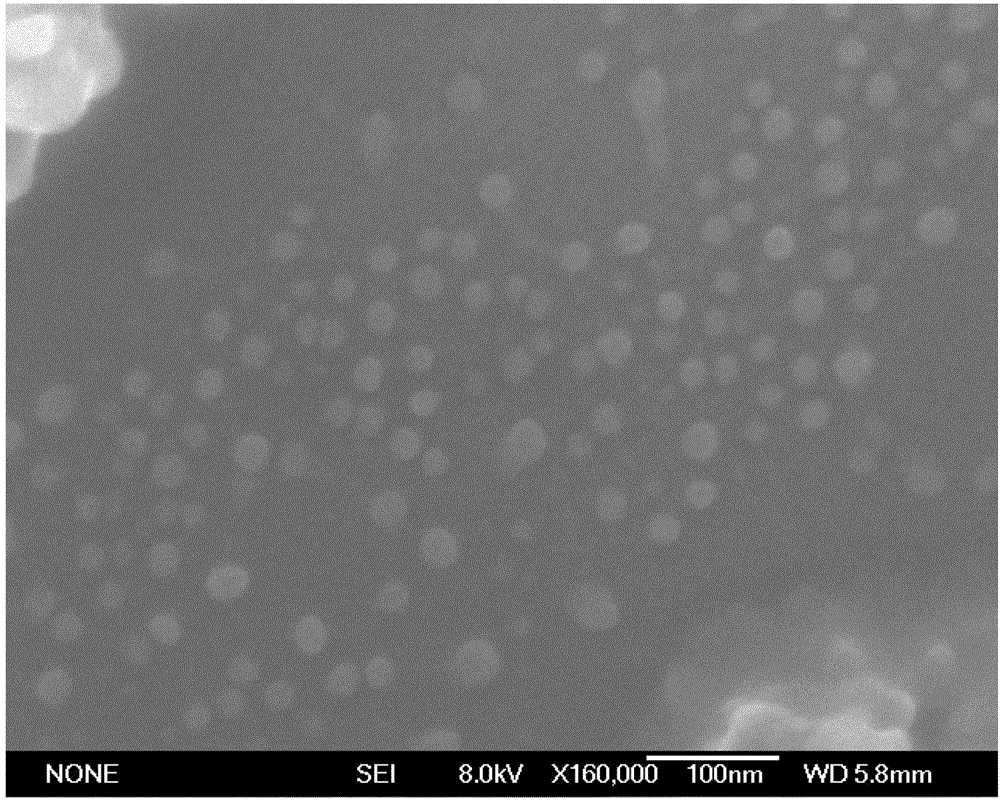

Embodiment 1

[0047] A preparation method of titanium dioxide doped with rare earth, the specific steps are as follows:

[0048] (1) Tetrabutyl titanate and absolute ethanol are mixed according to a volume ratio of 1:4 to obtain an absolute ethanol solution of tetrabutyl titanate, wherein the volume of tetrabutyl titanate is 5ml;

[0049] (2) Mix deionized water, absolute ethanol, and concentrated nitric acid by volume ratio 0.6:1:0.2 to obtain a mixed solution, and the volume of absolute ethanol used in this step is 5ml;

[0050] (3) adding cerium nitrate to the mixed solution obtained in step (2) and fully mixing;

[0051] (4) Under vigorous stirring, add the product obtained in step (3) dropwise to the absolute ethanol solution of tetrabutyl titanate obtained in step (1) to obtain a sol; In terms of the titanium element in the ester and the cerium element in the cerium nitrate, the mol ratio of the cerium nitrate added in the step (3) to tetrabutyl titanate is 0.01%;

[0052] (5) Put the...

Embodiment 2

[0056] A preparation method of titanium dioxide doped with rare earth, the specific steps are as follows:

[0057] (1) Tetrabutyl titanate and absolute ethanol are mixed according to a volume ratio of 1:5 to obtain an absolute ethanol solution of tetrabutyl titanate, wherein the volume of tetrabutyl titanate is 5ml;

[0058] (2) Mix deionized water, absolute ethanol, and concentrated nitric acid in a volume ratio of 1:1:0.4 to obtain a mixed solution, and the volume of absolute ethanol used in this step is 5ml;

[0059] (3) adding cerium nitrate to the mixed solution obtained in step (2) and fully mixing;

[0060] (4) Under vigorous stirring, add the product obtained in step (3) dropwise to the absolute ethanol solution of tetrabutyl titanate obtained in step (1) to obtain a sol; In terms of the titanium element in the ester and the cerium element in the cerium nitrate, the mol ratio of the cerium nitrate added in the step (3) to tetrabutyl titanate is 0.1%;

[0061] (5) Put...

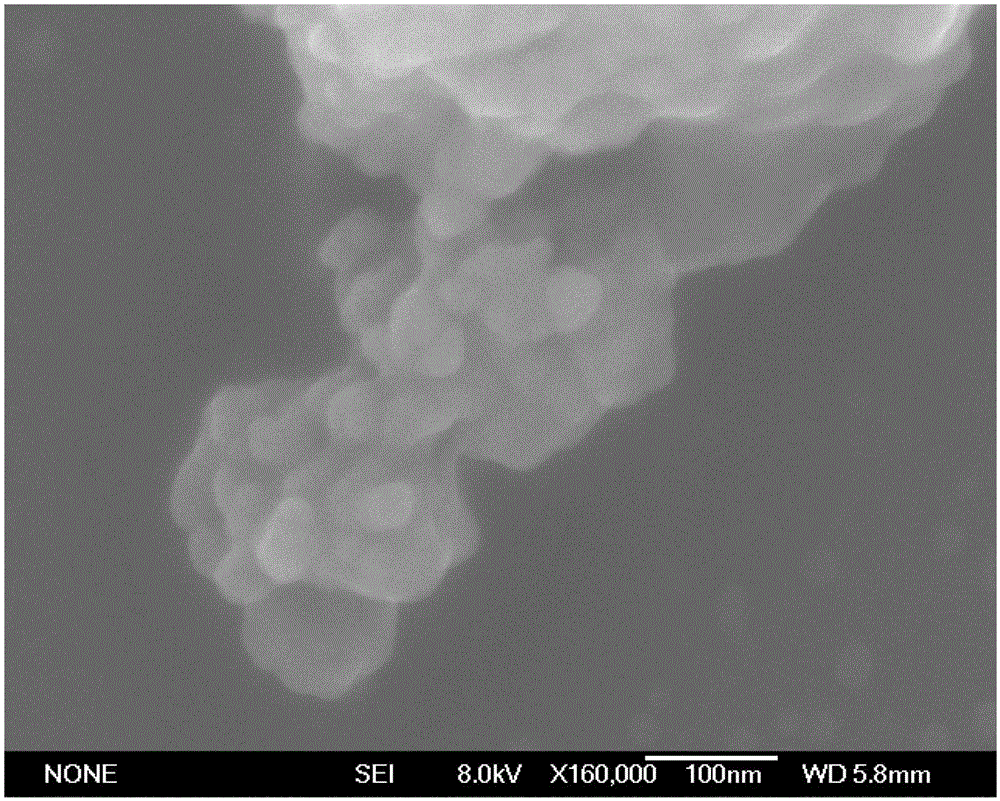

Embodiment 3

[0065] A preparation method of titanium dioxide doped with rare earth, the specific steps are as follows:

[0066] (1) Tetrabutyl titanate and absolute ethanol are mixed according to a volume ratio of 1:5 to obtain an absolute ethanol solution of tetrabutyl titanate, wherein the volume of tetrabutyl titanate is 5ml;

[0067] (2) Mix deionized water, absolute ethanol, and concentrated nitric acid by volume ratio 1.4:1:0.6 to obtain a mixed solution, and the volume of absolute ethanol used in this step is 5ml;

[0068] (3) adding cerium nitrate to the mixed solution obtained in step (2) and fully mixing;

[0069] (4) Under vigorous stirring, add the product obtained in step (3) dropwise to the absolute ethanol solution of tetrabutyl titanate obtained in step (1) to obtain a sol; In terms of the titanium element in the ester and the cerium element in the cerium nitrate, the mol ratio of the cerium nitrate added in the step (3) to tetrabutyl titanate is 0.7%;

[0070] (5) Put th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com