Layered/acicular two-phase composite enhanced rare earth magnesium alloy and preparation technology thereof

A composite reinforcement, rare earth magnesium technology, applied in the field of magnesium alloys, can solve the problems of low mechanical properties, uneven distribution, less research and development of alloys, etc., to achieve good results, improve hardness, and achieve the effect of alloy structure and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

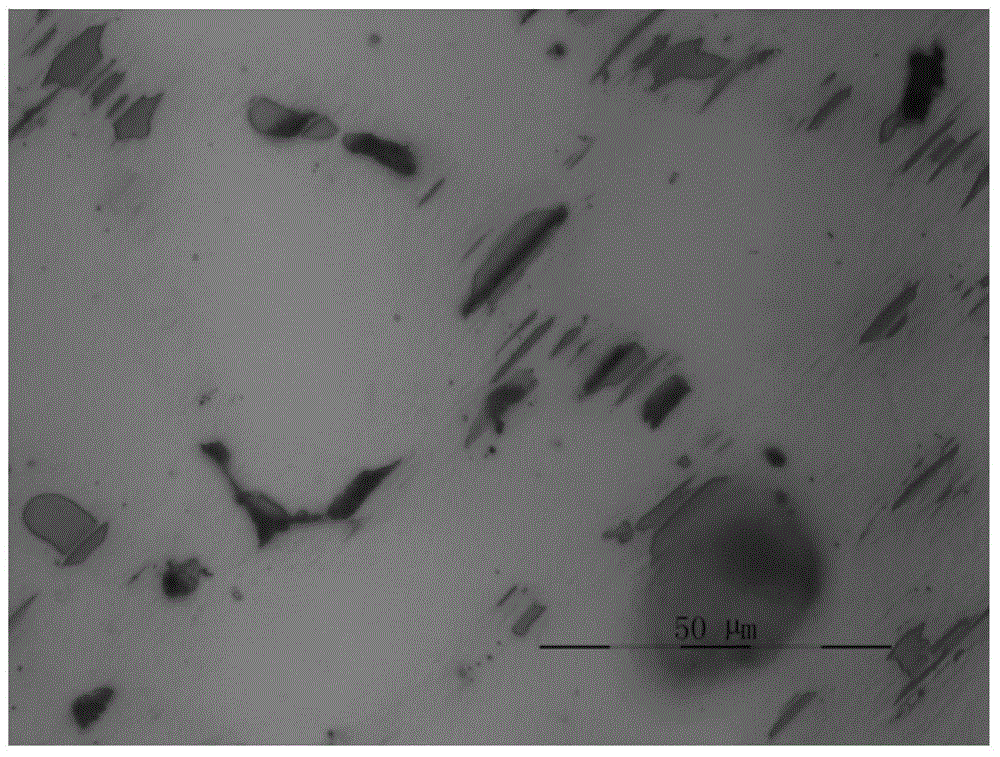

[0027] Now the Mg-Er master alloy, pure Zn and pure magnesium are removed from the scale layer, and the design alloy composition is Mg-6Er-4Zn (wt.%). First place the master alloy in a dry pot and melt it under a protective atmosphere. When the temperature rises to 760°C, stir, keep warm for 20 minutes, remove slag, and adjust the current. When the furnace temperature drops to 740°C, add pure magnesium and stir , keep warm for 10 minutes, remove slag, adjust the current, and when the furnace temperature drops to 700°C, add pure Zn, stir, keep warm for 10 minutes, remove slag, then raise the temperature to 760°C, keep warm, and stand still for 30 minutes. When the temperature of the alloy liquid drops to 720°C, pour it into an iron mold. The volume fraction of layered structure in the prepared alloy is about 10%, such as figure 1 As shown, its average hardness value is about 56HV.

[0028] The obtained layered structure alloy was subjected to solution treatment at 480°C, and th...

Embodiment 2

[0030] Now remove the scale layer of Mg-Er master alloy, pure Zn and pure magnesium, and design the alloy composition as Mg-14Er-7Zn. First place the master alloy in a dry pot and melt it under a protective atmosphere. When the temperature rises to 780°C, stir, keep warm for 20 minutes, remove slag, and adjust the current. When the furnace temperature drops to 740°C, add pure magnesium and stir , keep warm for 20 minutes, remove slag, and adjust the current flow. Finally, when the furnace temperature is lowered to 700°C, add pure Zn, stir, hold heat for 15 minutes, remove slag, and adjust the current flow. Raise the temperature of the furnace to 760°C, keep it warm and let it stand for 30 minutes. When the temperature of the alloy liquid drops to 740°C, pour it into an iron mold. The volume fraction of layered structure in the prepared alloy is about 25%, and its average hardness value is about 60HV.

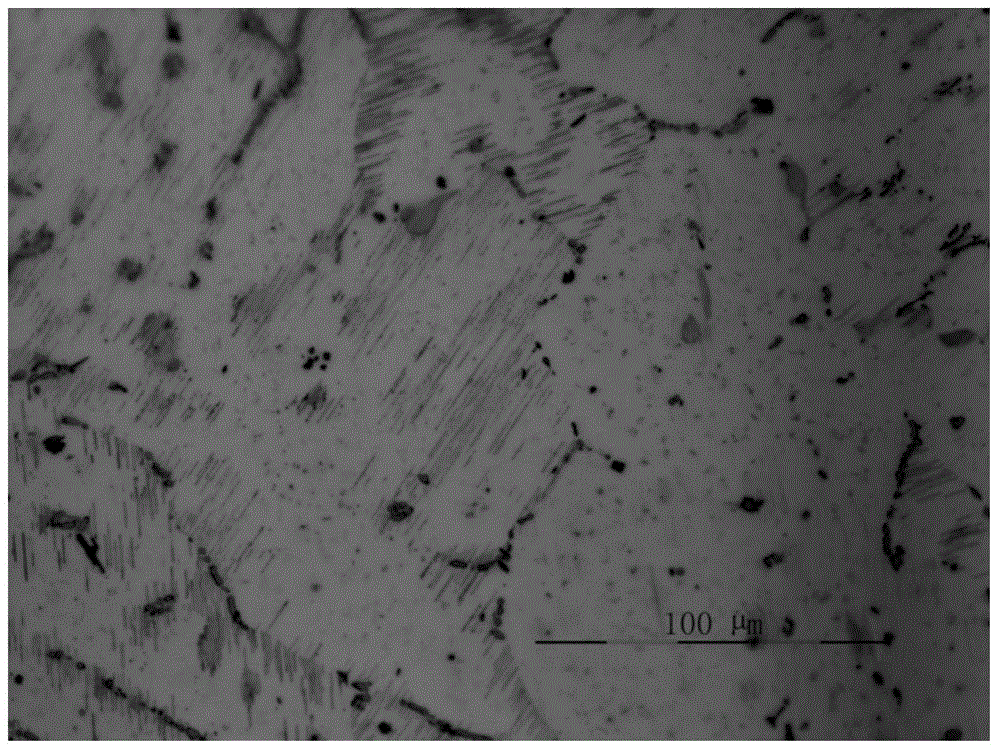

[0031] The alloy was subjected to solid solution treatment at 450°C for 1...

Embodiment 3

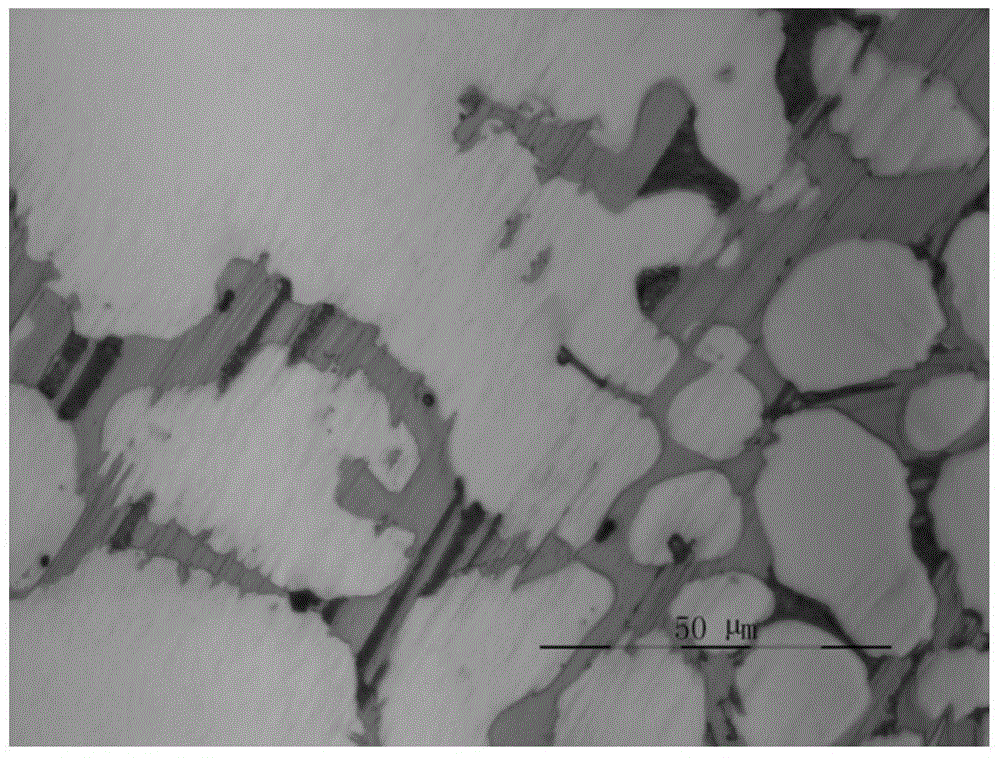

[0033] Now remove the scale layer of Mg-Er master alloy, pure Zn and pure magnesium, and design the alloy composition as Mg-15Er-5Zn. First place the master alloy in a dry pot and melt it under a protective atmosphere. When the temperature rises to 780°C, stir, keep warm for 20 minutes, remove slag, and adjust the current. When the furnace temperature drops to 740°C, add pure magnesium and stir , keep warm for 10 minutes, remove slag, and finally, when the furnace temperature is lowered to 700°C, add pure Zn, stir, keep warm for 15 minutes, and remove slag. Raise the temperature of the furnace to 760°C, keep it warm and stand still for 30 minutes. When the temperature of the alloy liquid drops to 740°C, pour it into an iron mold. The volume fraction of the layered structure in the obtained alloy is about 35%, such as image 3 As shown, its average hardness value is about 75HV.

[0034] The obtained layered structure alloy was subjected to solution treatment at 500°C, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hardness value | aaaaa | aaaaa |

| Average hardness value | aaaaa | aaaaa |

| Average hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com