Negative composite material for lithium-ion battery and preparation method of negative composite material

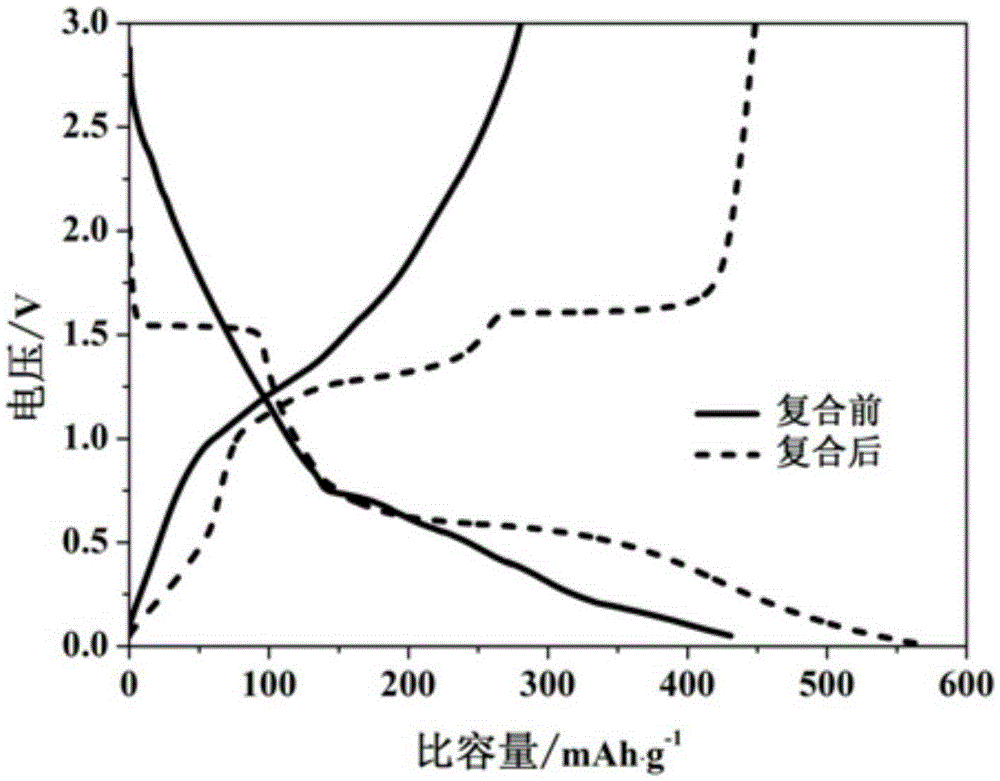

A lithium-ion battery and composite material technology, which is applied in the field of lithium-ion battery negative electrode materials and its preparation, can solve problems such as impact and poor battery safety performance, and achieve high Coulombic efficiency, high specific capacity, and good rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

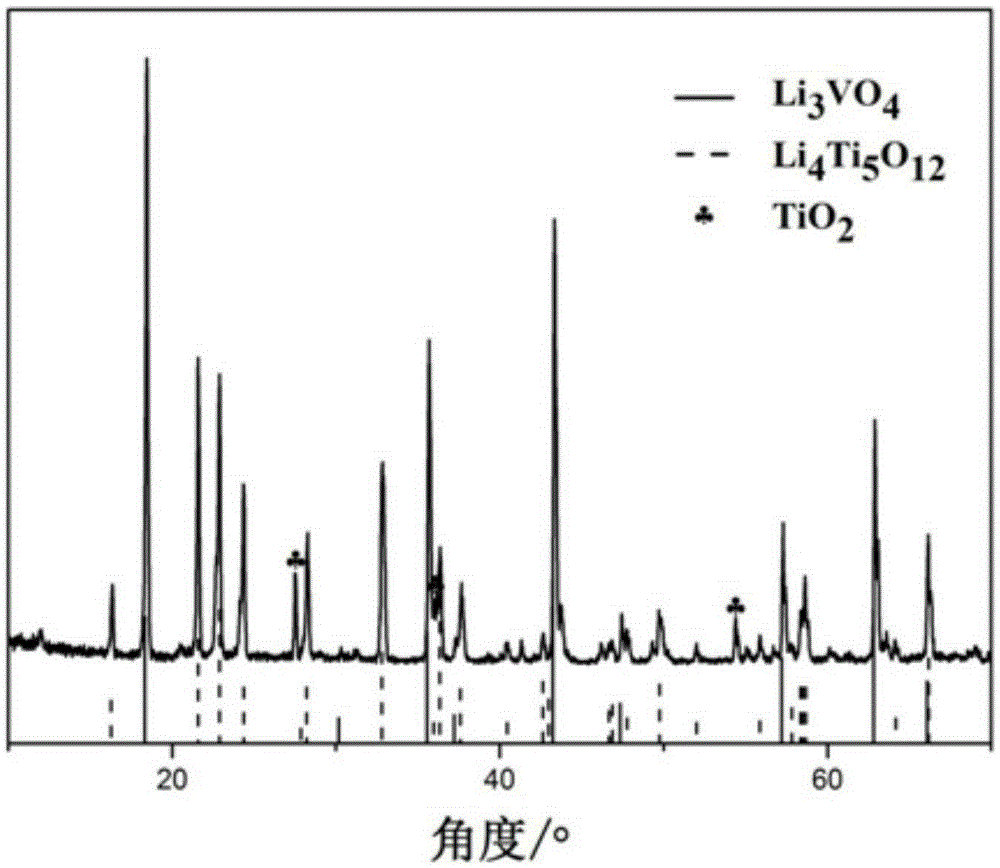

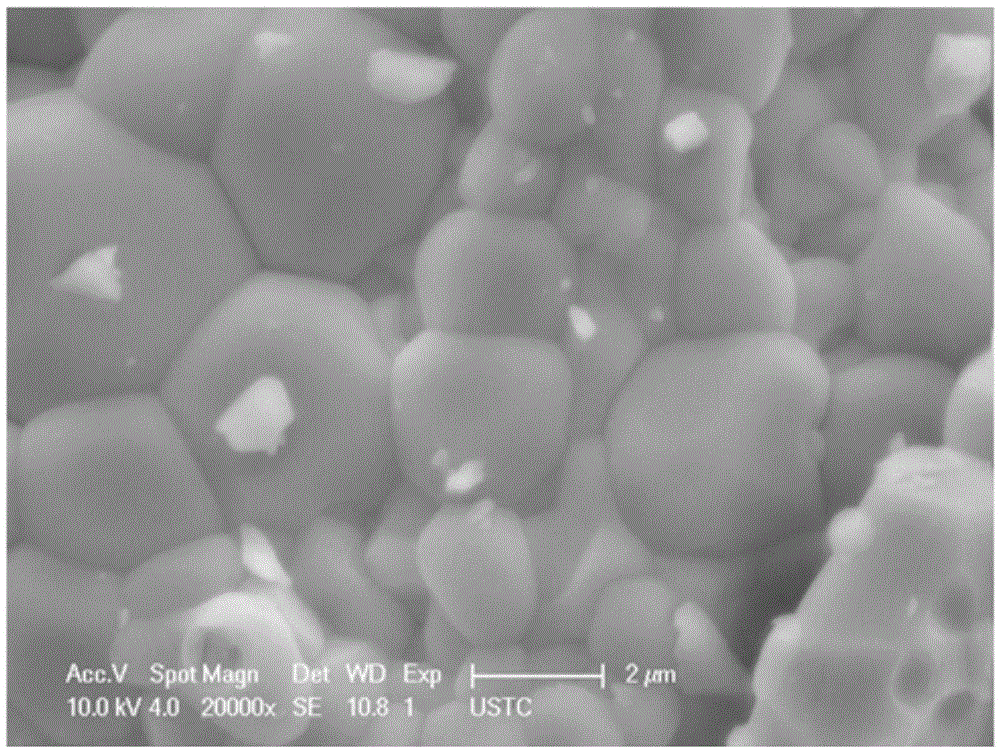

[0026] (1) According to the chemical formula xLi 3 VO 4 ·(1-x)Li 4 Ti 5 o 12 , when x=0.75, take 12.61g of citric acid and dissolve it in 300mL of deionized water to form a colorless and transparent citric acid solution, and take 3.51g of ammonium metavanadate according to the molar ratio Li:V=3.0~3.2:1 and slowly add A wine-red transparent solution was formed in the citric acid solution, and after magnetic stirring at room temperature for 1 hour to fully complex, add 9.365 g of lithium acetate dihydrate as a lithium source, and continue stirring for 0.5 hours to form a transparent solution A;

[0027] (2) When x=0.75, according to the molar ratio Li:Ti=4.0~4.1:5, weigh 17.36g of tetrabutyl titanate and dissolve it in 100mL of absolute ethanol, stir at room temperature for 2h to form uniform tetrabutyl titanate Ethanol solution, then weighed 13.45g lithium acetate dihydrate and added thereto, and continued to stir for 1h to form light yellow transparent solution B;

[002...

Embodiment 2

[0031] (1) According to the chemical formula xLi 3 VO 4 ·(1-x)Li 4 Ti 5 o 12, when x=0.75, take 12.61g of citric acid and dissolve it in 300mL of deionized water to form a colorless and transparent citric acid solution, and take 3.51g of ammonium metavanadate according to the molar ratio Li:V=3.0~3.2:1 and slowly add A wine-red transparent solution was formed in the citric acid solution, and after magnetic stirring at room temperature for 1 hour to fully complex, add 9.365 g of lithium acetate dihydrate as a lithium source, and continue stirring for 0.5 hours to form a transparent solution A;

[0032] (2) When x=0.75, according to the molar ratio Li:Ti=4.0~4.1:5, weigh 17.36g of tetrabutyl titanate and dissolve it in 100mL of absolute ethanol, stir at room temperature for 2h to form uniform tetrabutyl titanate Ethanol solution, then weighed 13.45g lithium acetate dihydrate and added thereto, and continued to stir for 1h to form light yellow transparent solution B;

[0033...

Embodiment 3

[0036] (1) According to the chemical formula xLi 3 VO 4 ·(1-x)Li 4 Ti 5 o 12 , when x=0.75, take 12.61g of citric acid and dissolve it in 300mL of deionized water to form a colorless and transparent citric acid solution, and take 3.51g of ammonium metavanadate according to the molar ratio Li:V=3.0~3.2:1 and slowly add A wine-red transparent solution was formed in the citric acid solution, and after magnetic stirring at room temperature for 1 hour to fully complex, add 9.365 g of lithium acetate dihydrate as a lithium source, and continue stirring for 0.5 hours to form a transparent solution A;

[0037] (2) When x=0.75, according to the molar ratio Li:Ti=4.0~4.1:5, weigh 17.36g of tetrabutyl titanate and dissolve it in 100mL of absolute ethanol, stir at room temperature for 2h to form uniform tetrabutyl titanate Ethanol solution, then weighed 13.45g lithium acetate dihydrate and added thereto, and continued to stir for 1h to form light yellow transparent solution B;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com