Preparation method of high strength graphene based composite paper

A graphene-based, composite paper technology, applied in the direction of graphene, chemical instruments and methods, carbon compounds, etc., can solve the problems of large wetting angle and less functional groups on the surface of carbon fibers, and achieve easy uniformity, less introduction of impurities, and reduction The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] The experimental conditions and parameters of a preparation method of high-strength graphene-based composite paper are as follows:

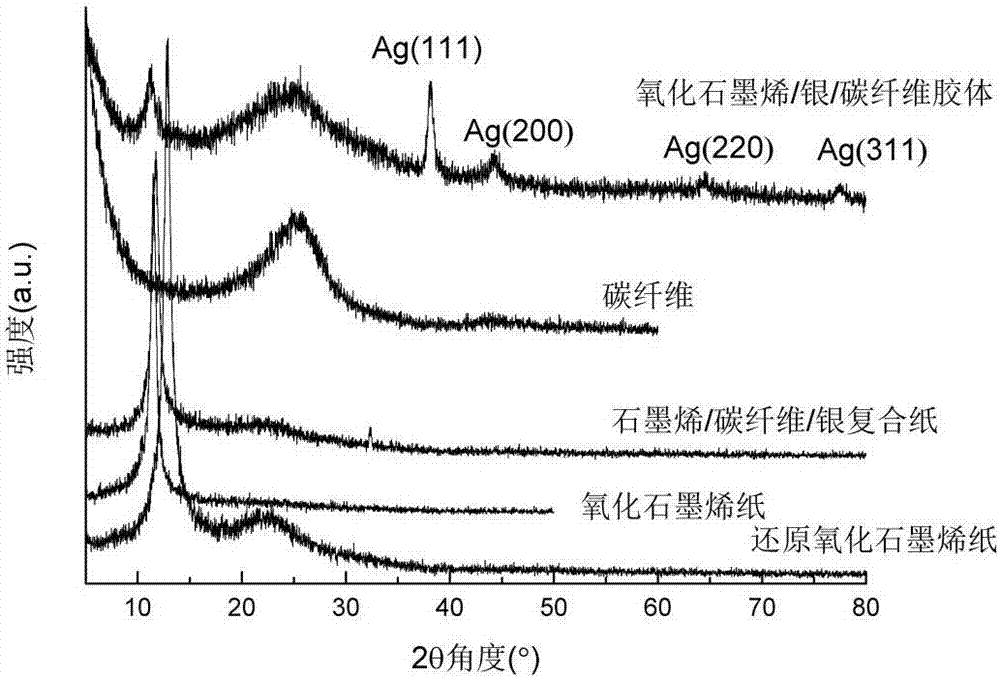

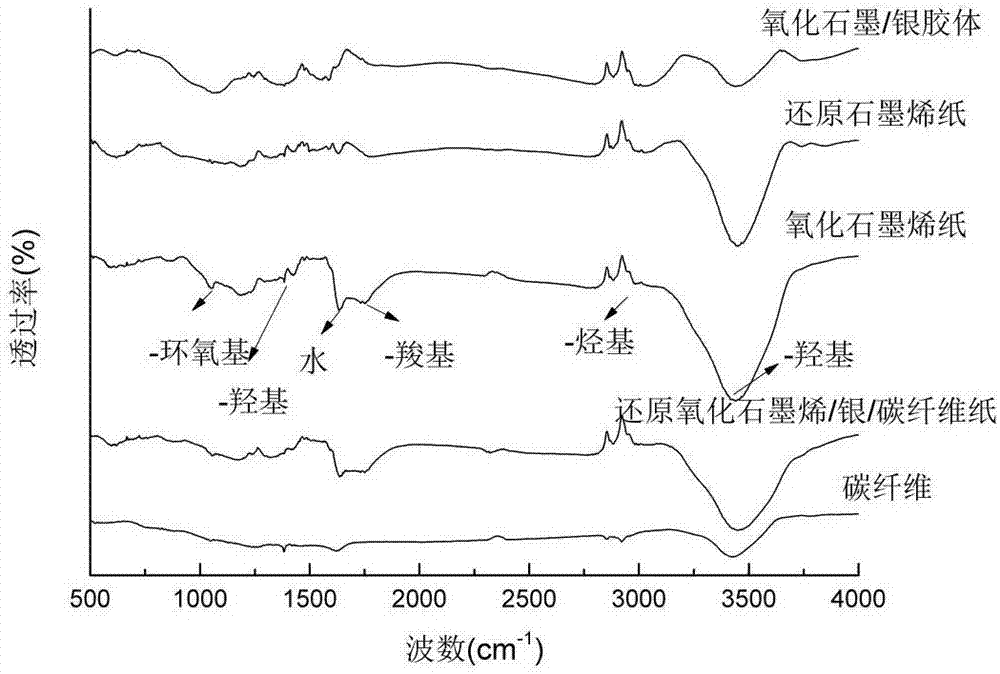

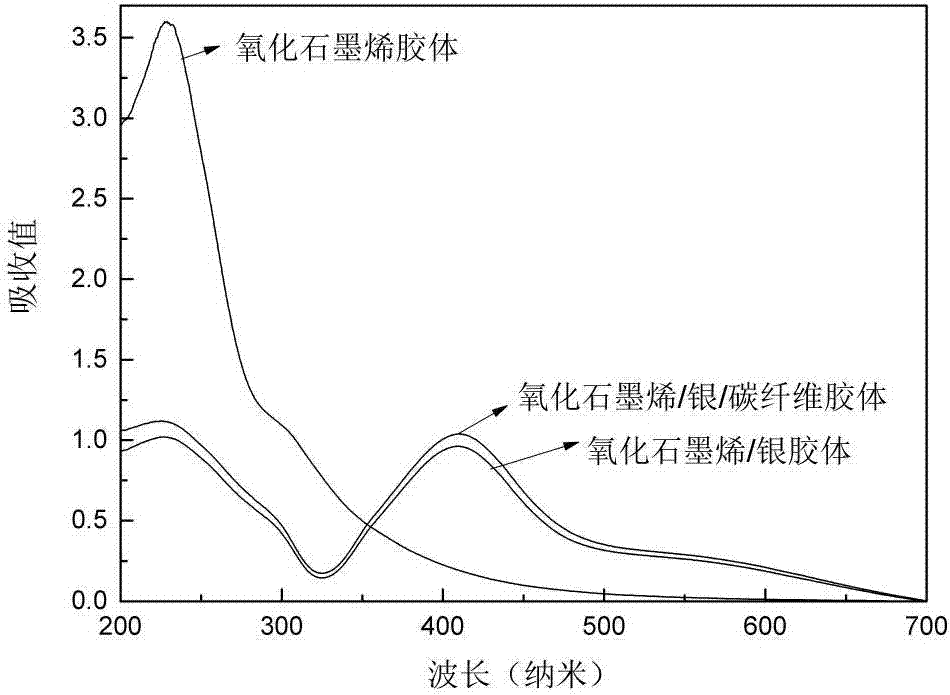

[0041] 1) Weigh 3g flake graphite, pour 360mL concentrated sulfuric acid (98%wt) and 40mL concentrated phosphoric acid (85%wt) in turn, add 3g, after fully stirring, slowly add 18g potassium permanganate; ℃, stir vigorously for 12 hours; cool to room temperature, pour the solution in the Erlenmeyer flask on 400g of ice, slowly add hydrogen peroxide (30%wt) until no bubbles are generated; after centrifugation in a high-speed centrifuge, remove the lower layer of sediment, and wash with 10% dilute hydrochloric acid three times, and then centrifuged with deionized water until the pH value was neutral. Obtain graphene oxide colloid.

[0042] 2) Take several glass slides, place them on the bottom of the petri dish, add the piranha lotion prepared according to concentrated sulfuric acid:concentrated phosphoric acid = 4:1, heat in a water bath a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com