Ba(1-x)SrxTiO3-BaX6Ti6O19(X=Mg, Zn) diphasic composite micro-wave ceramic material and preparation method thereof

A srxtio3-bax6ti6o19, bax6ti6o19 technology is applied in the field of two-phase composite microwave ceramic materials to achieve the effects of moderate dielectric constant, no toxic side effects, and high dielectric tunable characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the two-phase composite microwave ceramic material provided by the present invention specifically comprises the following steps:

[0032] (1) Using the traditional electronic ceramic powder preparation process, through the solid-state reaction method, select BaTiO 3 and SrTiO 3 (99.9%, 100nm, provided by Shandong Guoteng Functional Ceramic Material Co., Ltd.) as the main raw material, according to a certain Ba / Sr molar ratio ingredients, the prepared raw materials are placed in a nylon ball mill jar, and zirconia balls and absolute ethanol or Ball mill with deionized water for 20 to 24 hours, pre-calcine at 1100°C for 4 hours after the discharge is dried, and Ba (1-x) Sr x TiO 3 (x=0.3~0.6) powder.

[0033] (2) adopt solid phase reaction method, synthesize Ba according to following reaction equation (1-x) Sr x TiO 3 -BaX 6 Ti 6 o 19 (X=Mg, Zn) powder:

[0034] BaTiO 3 +5TiO 2 +6MgO=BaMg 6 Ti 6 o 19

[0035] BaTiO 3 +5TiO 2 +6...

Embodiment 1~5

[0043] Preparation of Ba (1-x) Sr x TiO 3 -BaX 6 Ti 6 o 19 (x=0.50, 0.45, 0.40; X=Mg, Zn) two-phase composite microwave ceramic material:

[0044] According to Ba 0.5 Sr 0.5 TiO 3 、Ba 0.55 Sr 0.45 TiO 3 and Ba 0.6 Sr 0.4 TiO 3 The stoichiometric ratio, respectively weighed 46.6454gBaTiO 3 and 36.7034 g SrTiO 3 , 51.3099g BaTiO 3 and 33.0331 g SrTiO 3 , 55.9744g BaTiO 3 and 29.3627gSrTiO 3 Put the powder in a nylon ball mill jar, add zirconia balls and absolute ethanol, mill for 24 hours, and pre-calcine at 1100°C for 4 hours after the discharge is dried, and Ba 0.5 Sr 0.5 TiO 3 、Ba 0.55 Sr 0.45 TiO 3 and Ba 0.6 Sr 0.4 TiO 3 The powder is ready for use. In addition, weigh 16.3422g BaTiO 3 , 27.9930g TiO 2 , 16.9429g MgO and 16.3422g BaTiO 3 , 27.9930gTiO 2 , 34.2222g ZnO powder was placed in a nylon ball mill tank, zirconia balls and deionized water were added, ball milled for 24 hours, after the discharge was dried, it was pre-calcined at 1250°C...

Embodiment 1

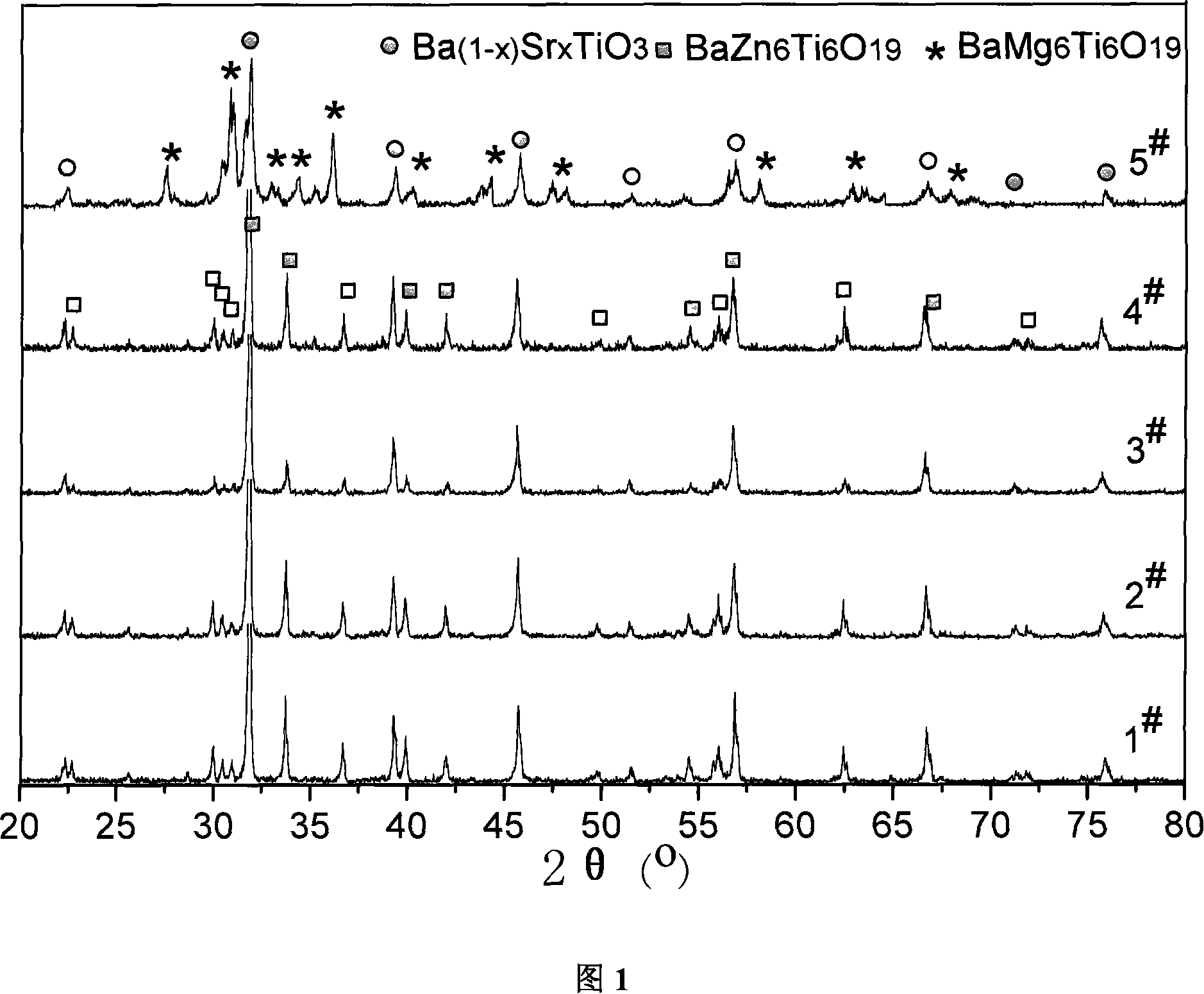

[0050] Example 1 # -5 # Ba obtained from the formula (1-x) Sr x TiO 3 -BaX 6 Ti6 o 19 (x=0.50,0.45,0.40; X=Mg, Zn) the X-ray diffraction analysis collection of materials of composite microwave ceramic material is as shown in accompanying drawing 1;

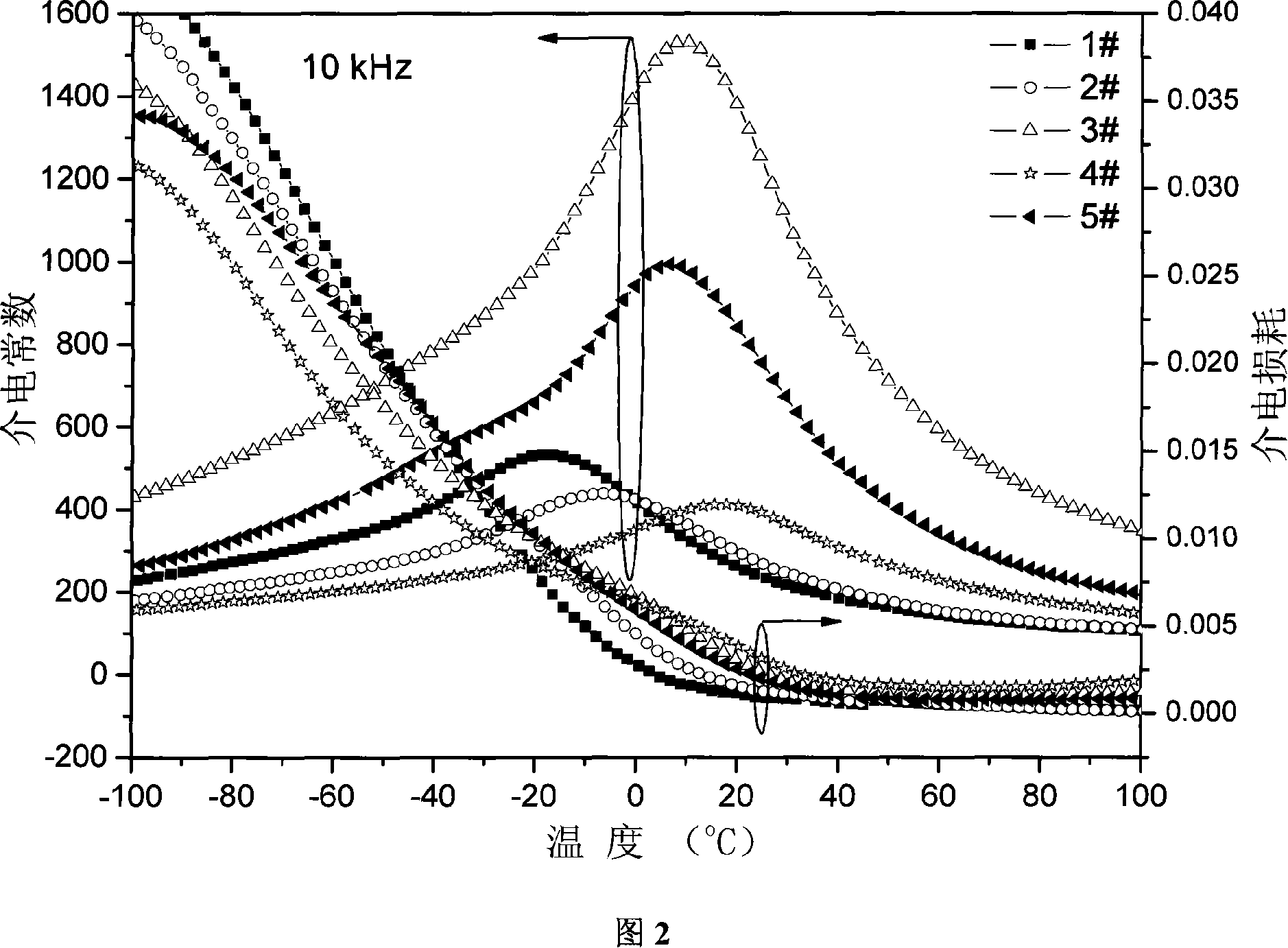

[0051] Example 1 # -5 # Ba obtained from the formula (1-x) Sr x TiO 3 -BaX 6 Ti 6 o 19 (x=0.50,0.45,0.40; X=Mg, Zn) the relational curve of dielectric constant and loss and temperature of composite microwave ceramic material is as shown in accompanying drawing 2;

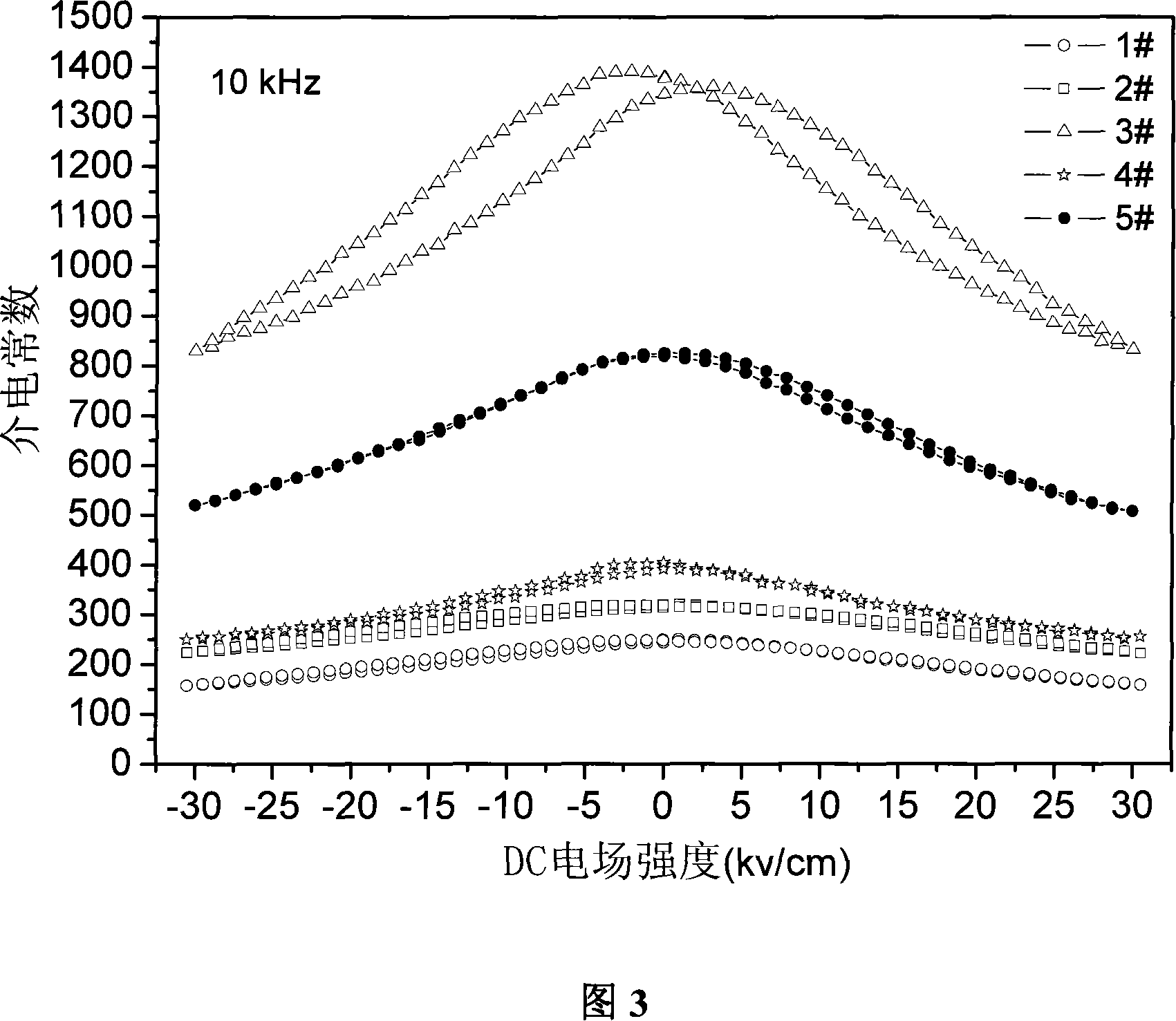

[0052] Example 1 # -5 # Ba obtained from the formula (1-x) Sr x TiO 3 -BaX 6 Ti 6 o 19 (x-0.50, 0.45, 0.40; X=Mg, Zn) the dielectric constant of the composite microwave ceramic material and the relationship curve of the applied DC field strength are as shown in accompanying drawing 3, wherein, 1 # 40wt% Ba 0.5 Sr 0.5 TiO 3 with 60wt% BaMg 6 Ti 6 o 19 Composite; 2 # 40wt% Ba 0.55 Sr 0.45 TiO 3 with 60wt% BaMg 6 Ti 6 o 19 Composite; 3 #...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter φ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com