Water-soluble porphyrin sulfonate-hyperbranched polymer two-phase composite catalyst and preparation and application thereof

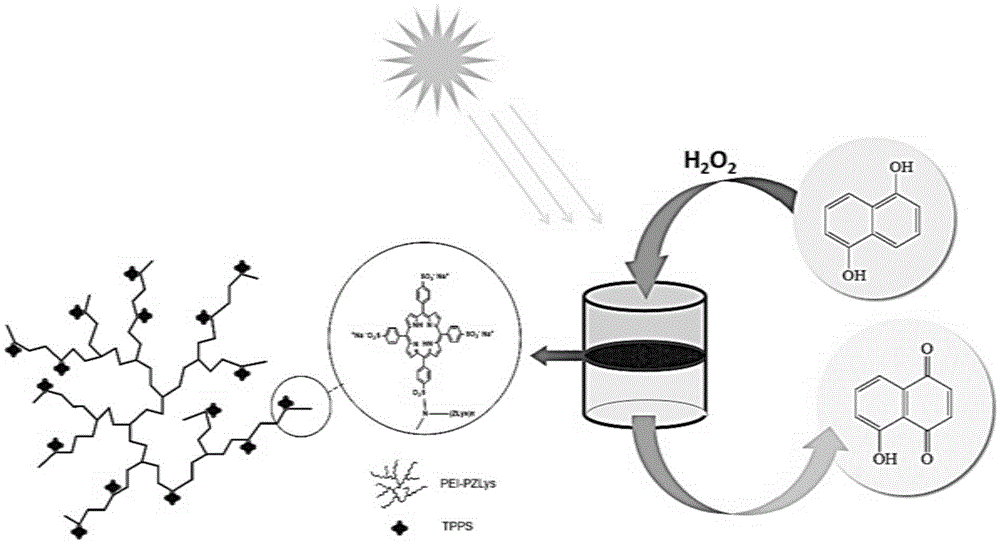

A technology of hyperbranched polymer and composite catalyst, applied in the chemical industry, can solve problems such as being unfavorable for catalyst reuse and reducing catalytic effect, and achieve the effects of good catalytic activity and stability, strong catalytic stability and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

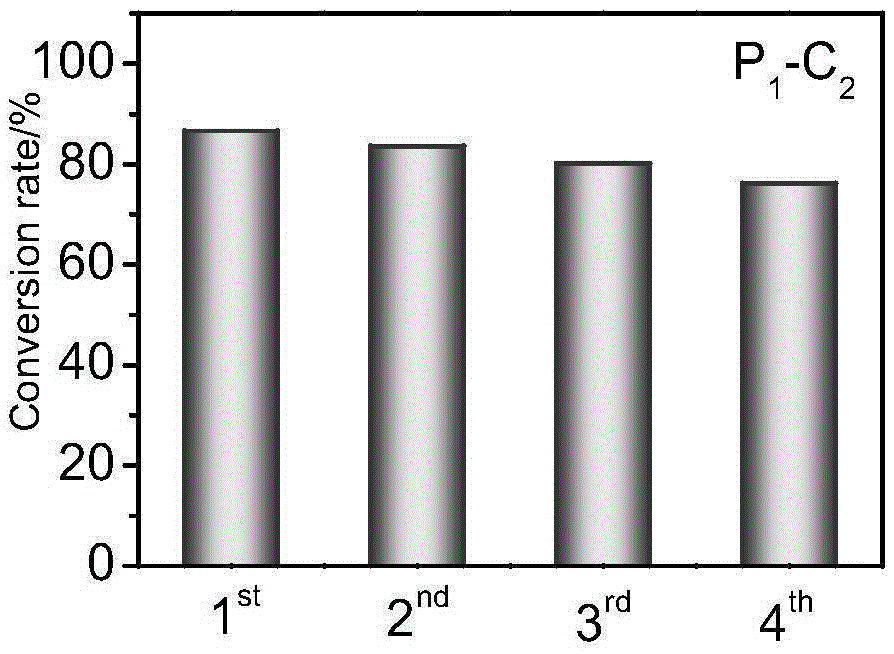

[0035] water-soluble porphyrin sulfonate P 1 and hyperbranched polymer C 2 (n=323) as raw material, synthetic water-soluble sulfonic acid porphyrin-hyperbranched polymer P1 -C 2 :

[0036] as well as

[0037] This embodiment includes the following steps:

[0038] Step 1) Synthesis of tetraphenylporphyrin: In a 1000mL three-necked flask, add 30.9mL benzaldehyde and 500mL propionic acid, stir electrically and heat to reflux, control the temperature at 130°C, and use a dropping funnel to drop 20.9mL into Freshly distilled pyrrole in 100mL propionic acid (completely added dropwise within 30min), keep stirring at high speed, the solution gradually turns brownish black, continue to reflux for 40min, cool to 80°C, add 200mL ethanol while stirring, cool, and filter with suction. The product was obtained in 8.5 g, yield 18.4%.

[0039] Its characteristic parameters are: MSm / z614.74; IR (KBr): 3317, 1596, 1473, 1441, 969, 700cm -1 ; 1 HNMR200MHz (CDCl 3 ): δ-2.65(s, 2H, α-H)...

Embodiment 2

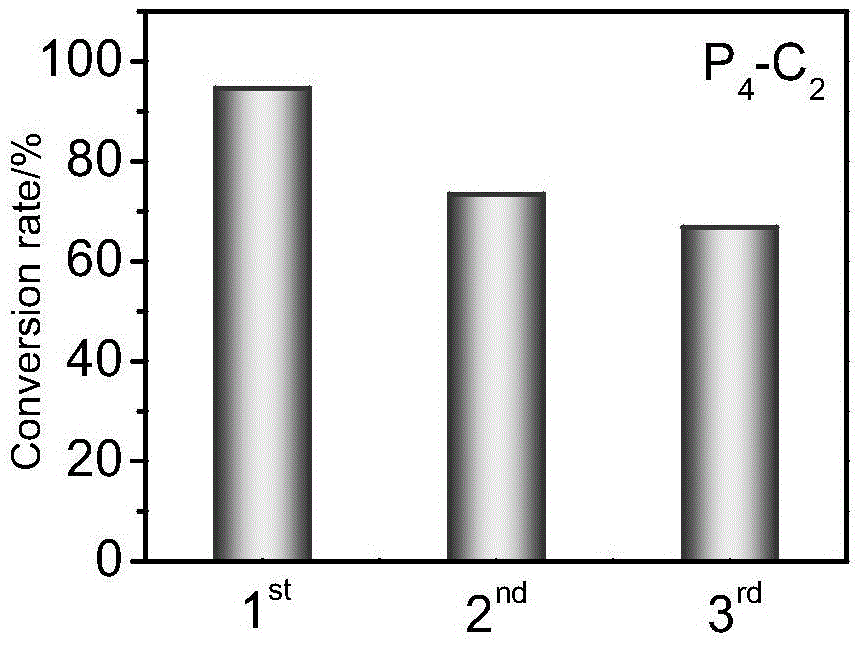

[0052] This embodiment is compared with embodiment 1, except that C 2 change to C 1 (n=257) or C 3 (n=383), that is, the two-phase interface catalyst by P 1 -C 2 Change to P 1 -C 1 or P 1 -C 3 Except, other is the same as embodiment 1, and the catalytic result of this embodiment is shown in table 2.

[0053] Table 2P 1 -C 2 ,P 1 -C 1 and P 1 -C 3 Catalytic Comparison of 1,5-Naphthalenediol

[0054]

[0055] For the comparison of the catalytic effects of two-phase interface catalysts prepared by hyperbranched polymers with different molecular weights on 1,5-naphthalenediol, it can be seen that when the molecular weight of hyperbranched polymers is moderate, it is C 2 When , its catalytic effect is the best, probably because when the molecular weight of the hyperbranched polymer is small, it is C 1 , its terminal group is less, which makes its solubility poor, which affects the combination with water-soluble sulfonic acid porphyrin, and then affects the full co...

Embodiment 3

[0057] This embodiment is compared with embodiment 1, except P 1 The concentration increased to 50μM, denoted as P 1 ’, others are the same as embodiment 1

[0058] The catalytic results of this embodiment are shown in Table 3. It can be seen that increasing water-soluble porphyrin sulfonate P 1 When the concentration is higher, the conversion rate will not change significantly, which may be because the porphyrin concentration increases, its arrangement is changed, and it is easy to agglomerate.

[0059] Table 3P 1 -C 2 with P 1 ’-C 2 Catalytic Comparison of 1,5-Naphthalenediol

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com