Heterojunction nano material diaphragm used for lithium-sulfur battery as well as preparation method thereof

A nanomaterial, lithium-sulfur battery technology, applied in the direction of lithium batteries, battery components, non-aqueous electrolyte batteries, etc., can solve the problems of low utilization rate of active materials, difficulty in commercialization, shuttle effect dynamics, etc., to achieve easy Effects of generalization, good kinetics and electrochemical performance, cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

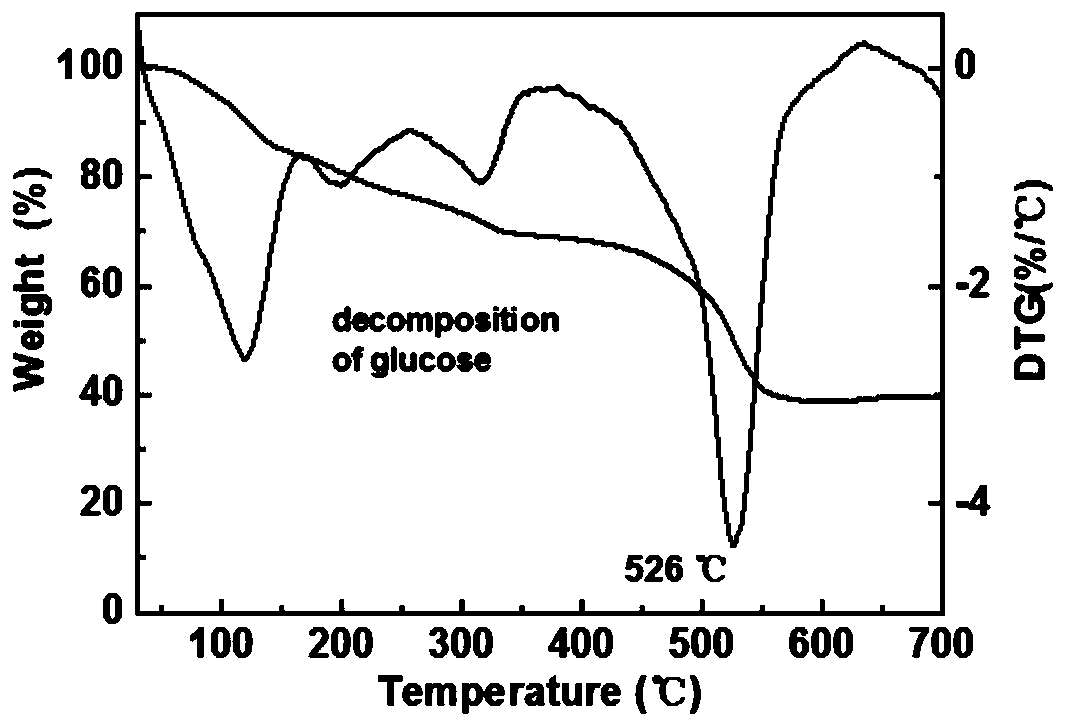

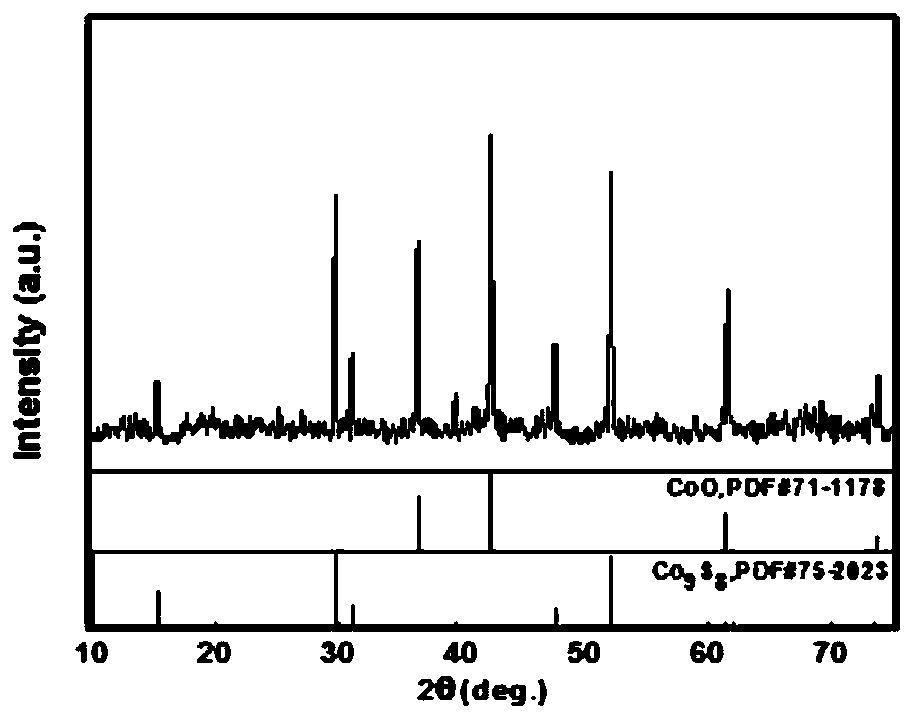

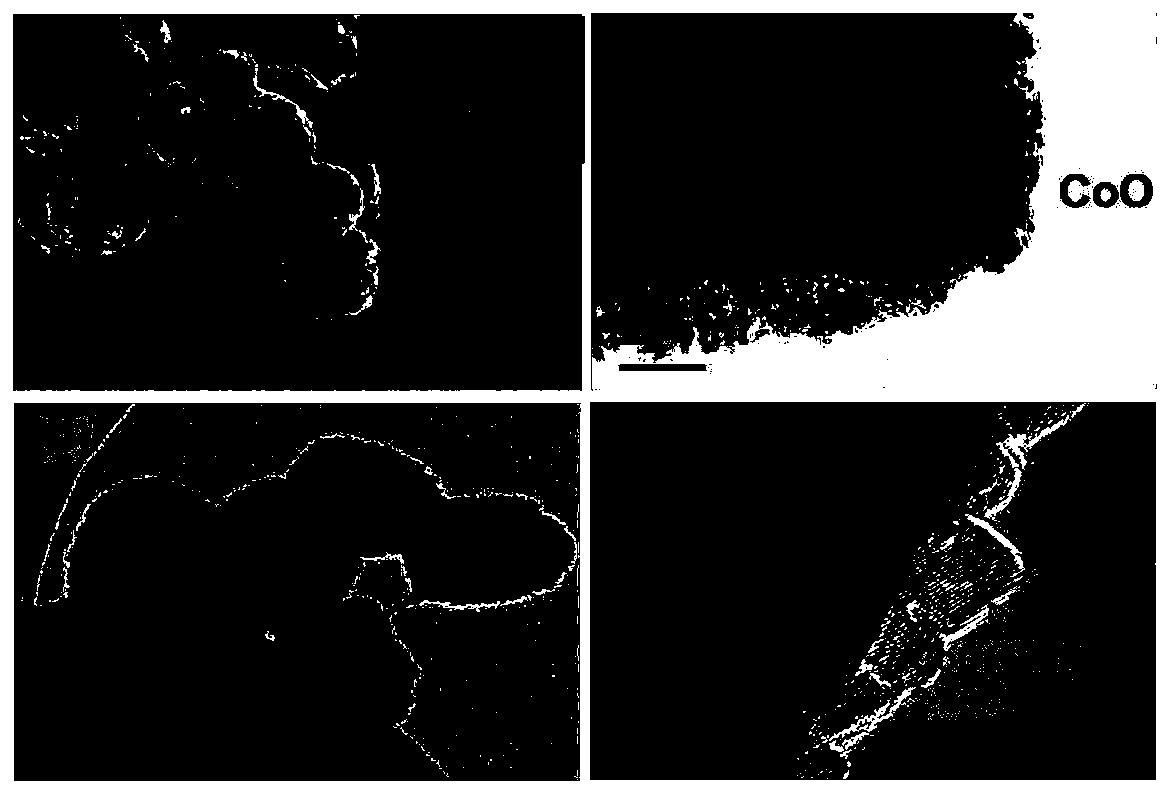

[0021] Glucose and cobalt sulfate were formulated into an aqueous solution at a mass ratio of 0.25:1, and then sprayed into a dry powder at 150°C by spray drying. Place the obtained powder in the constant temperature zone of the tube furnace, raise the temperature to 600°C at 10°C / min under 200ml / min argon atmosphere, keep it warm for 2h, cool down to 350°C at a rate of 10°C / min, and then cool with the furnace to room temperature, the cobalt sulfide / cobalt oxide heterojunction is obtained. The prepared heterojunction nanomaterials and graphene were uniformly dispersed in ethanol, covered on the surface of the diaphragm by suction filtration, and dried at 60°C to obtain a multifunctional diaphragm with a modified layer. The thickness of the modification layer is 1-20 μm.

[0022] attached figure 1 It is the thermogravimetric curve of the precursor obtained by spraying. It can be found that the range of 50-400 °C is the decomposition range of glucose, and the process of carbot...

Embodiment 2

[0024] Glucose and cobalt sulfate were formulated into an aqueous solution at a mass ratio of 0.3:1, and then sprayed into a dry powder at 150°C by spray drying. Place the obtained powder in the constant temperature zone of the tube furnace, raise the temperature to 600°C at 10°C / min under 200ml / hydrogen atmosphere, keep it warm for 2h, cool down to 350°C at a rate of 10°C / min, and then cool to room temperature with the furnace , that is, cobalt sulfide / cobalt oxide heterojunction nanomaterials are obtained. The prepared heterojunction nanomaterials and graphene were uniformly dispersed in ethanol, covered on the surface of the diaphragm by suction filtration, and dried at 60°C to obtain a multifunctional diaphragm with a modified layer. The thickness of the modification layer is 1-20 μm.

Embodiment 3

[0026] Glucose and nickel sulfate were formulated into an aqueous solution at a mass ratio of 0.25:1, and then sprayed into a dry powder at 150°C by spray drying. Place the obtained powder in the constant temperature zone of the tube furnace, raise the temperature to 600°C at 10°C / min under 200ml / argon atmosphere, keep it warm for 2h, cool down to 350°C at a rate of 10°C / min, and then cool with the furnace to At room temperature, nickel sulfide / nickel oxide heterojunction nanomaterials are obtained. The prepared heterojunction nanomaterials and graphene were uniformly dispersed in ethanol, covered on the surface of the diaphragm by suction filtration, and dried at 60°C to obtain a multifunctional diaphragm with a modified layer. The thickness of the modification layer is 1-20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com