Reduced graphene oxide-based hollow Co-MOF composite flexible electrode material and preparation method thereof

A graphene-based, flexible electrode technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of large volume expansion limit applications, serious stacking of graphene sheets, Co-MOF retention, etc., to achieve easy regulation, Ease of large-scale preparation and the effect of improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

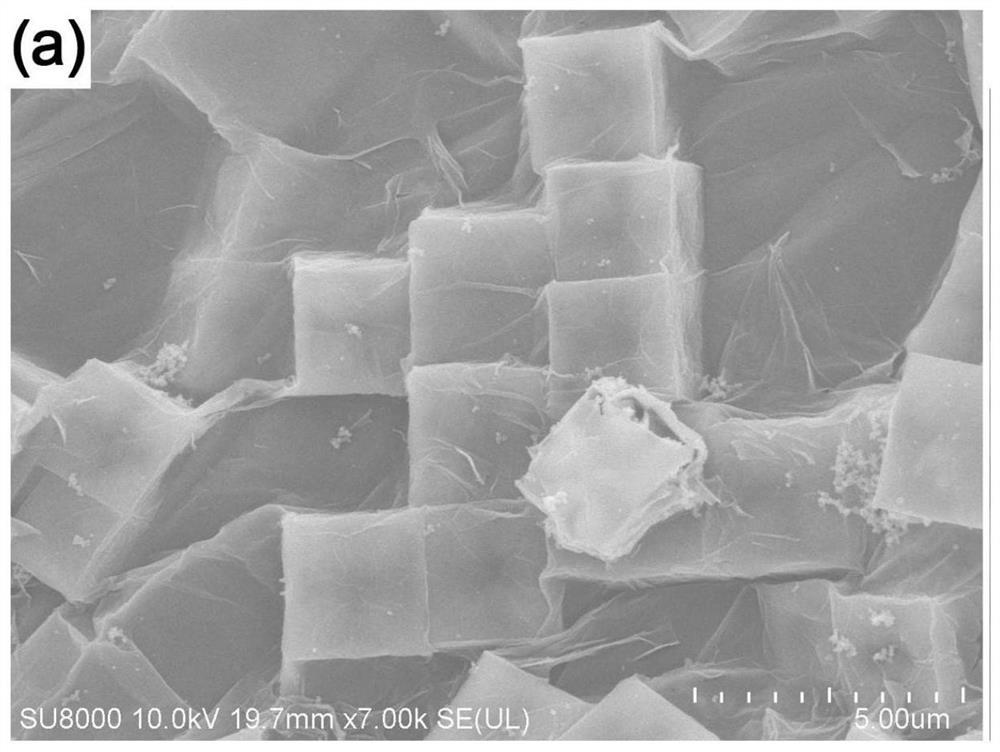

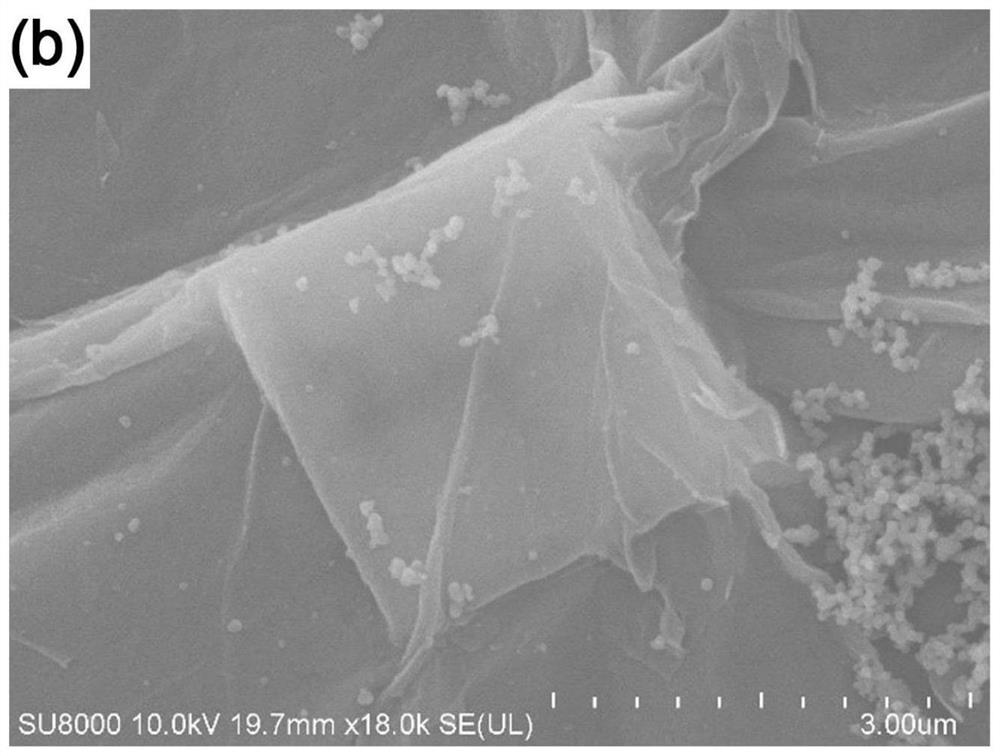

Image

Examples

Embodiment 1

[0027] A method for preparing a reduced graphene oxide-based hollow Co-MOF composite flexible material, comprising the following steps:

[0028] S1: Add a certain amount of pre-prepared Co-MOF to a certain amount of GO dispersion, mix at a ratio of 3:1 or other, and then stir for 5-10min with a defoaming mixer to obtain a mixture of Co-MOF and GO liquid.

[0029] S2: Transfer the uniformly stirred mixture to a petri dish of a certain size, and freeze-dry to obtain a graphene oxide-based Co-MOF composite material.

[0030] S3: Pour the pre-heated ammonium sulfide solution (wt 20%, 50-90°C) into the graphene oxide-based Co-MOF composite film obtained after freeze-drying for rapid reductive cross-linking treatment, and the Co-MOF is etched simultaneously After 1-5 minutes, the residual ammonium sulfide was washed away with DIW, and then freeze-dried again to obtain a flexible self-supporting membrane composite electrode material of reduced graphene oxide and hollow Co-MOF.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com