Two-phase composite microwave dielectric ceramic material for filter and preparation method thereof

A technology of microwave dielectric ceramics and filters, which is applied in the field of two-phase composite microwave dielectric ceramic materials for filters, can solve the problems of high temperature coefficient of resonance frequency, easy grain growth, high sintering temperature, etc., and achieve good dielectric properties and quality The effect of high factor and optimized material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11

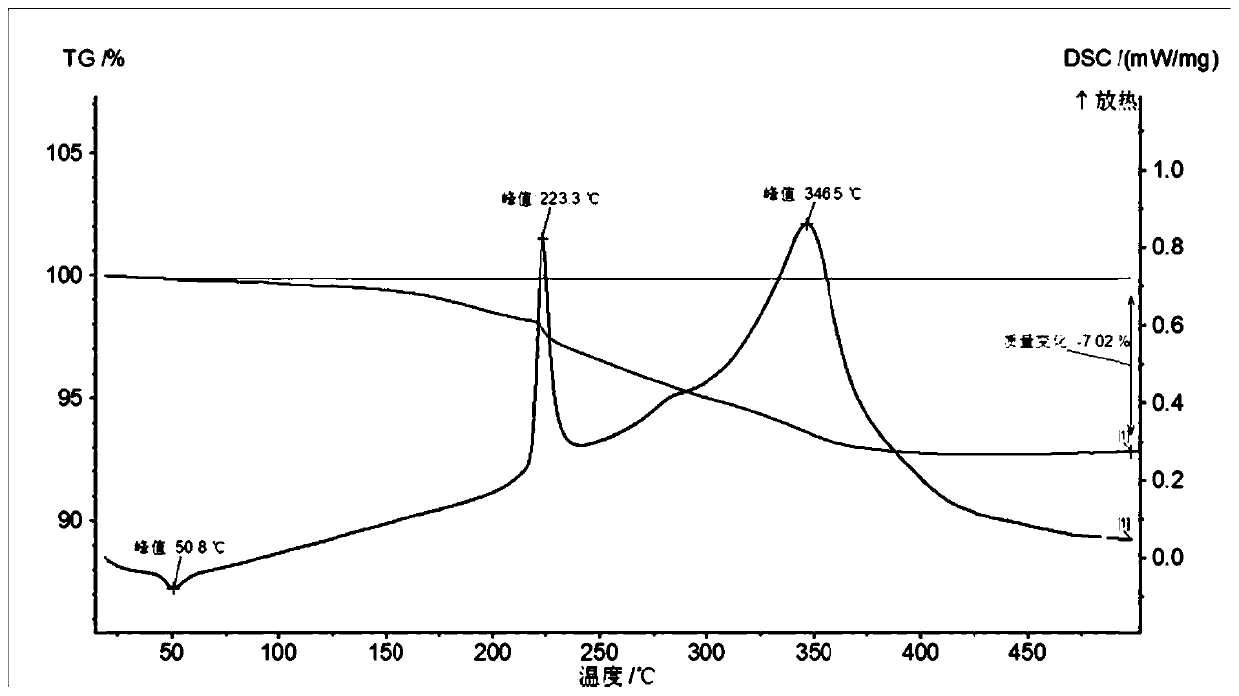

[0035] Respectively according to the following table 1 (Mg 1-x-y Ca x co y ) 2 TiO 4 The structure and stoichiometric ratio of the material are MgO, CaO, CoO, TiO 2 Mix to obtain a mixture, and add water to mix according to the ratio of mixture: water mass ratio of 1:1.2, and add ammonium salt dispersant accounting for 0.8wt% of the total amount of the mixture, and use columnar zirconium balls for ball milling, The ball milling time is 3-5 hours to carry out preliminary mixing and dispersing of the materials, then place them in a sand mill, use zirconium balls with a diameter of 0.65mm as the grinding medium for further dispersion, and use a microwave dryer to dry until the moisture content is less than 1% after grinding. After the material is sieved with a pulverizer, it is calcined using a pusher furnace. The calcining temperature is 1155° C., and the holding time is 3 hours. The burned material is placed for subsequent use, and the (Mg 1-x-y Ca x co y ) 2 TiO 4 mat...

experiment example

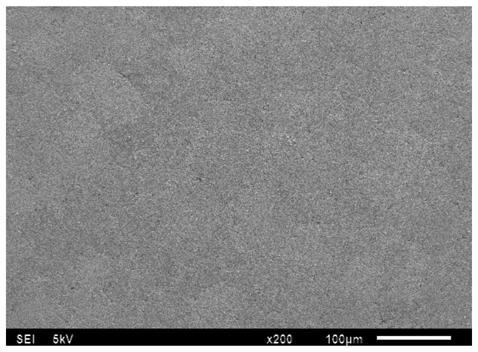

[0045] The above-mentioned granulated materials were respectively subjected to dry pressing molding, wherein, the electron microscope picture of the green body after the pressing of the material in Example 1 is shown in the attached figure 2 , it can be seen that the compactness of the green body after dry pressing is very good.

[0046] The above-mentioned granulated materials were respectively molded and sintered, and the sintering temperature of each green body was recorded, and the holding time was 4h, and the properties of the microwave dielectric ceramic materials prepared in the above-mentioned Examples 1-11 and Comparative Examples 1-3 were respectively analyzed. test. Test performance specifically includes:

[0047] 1) Using the dielectric resonant cavity method proposed by Hakki and Coleman to test the dielectric constant of the material, the f*Q value at 25°C, and the frequency temperature coefficient τf;

[0048] The frequency temperature coefficient τf means th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com