Preparation method of glass phase free two-phase composite microwave dielectric ceramic material Li2TiO3-Li2WO4

A technology of microwave dielectric ceramics and glass phases, applied in the field of preparation of low-temperature microwave dielectric ceramic materials, can solve the problems of reducing the Q value of materials, cracking of terminal electrodes, etc., and achieve the effect of high quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

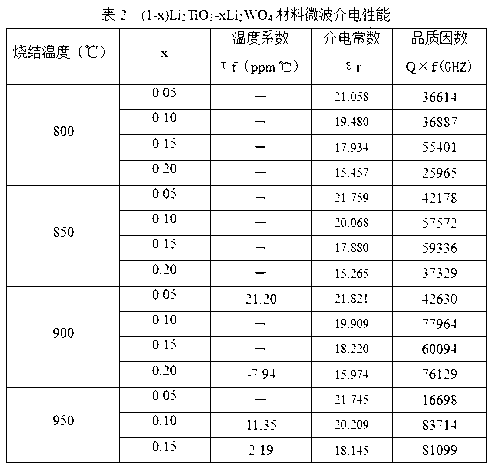

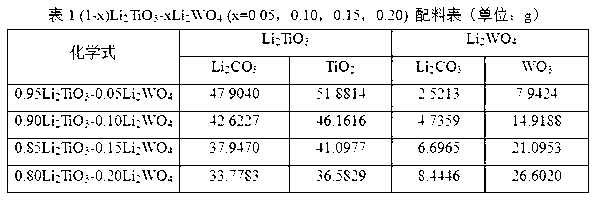

[0018] Now the concrete example of microwave dielectric ceramic material of the present invention is described as follows: According to (1-x) Li 2 TiO 3 -xLi 2 WO 4 (x=0.05, 0.10, 0.15, 0.20) chemical formula, convert the mass of each raw material required, and then accurately weigh each analytical pure raw material: Li 2 CO 3 (99.9%), TiO 2 (99.7%), WO 3 (99.0%). The weighing quality is shown in Table 1.

[0019]

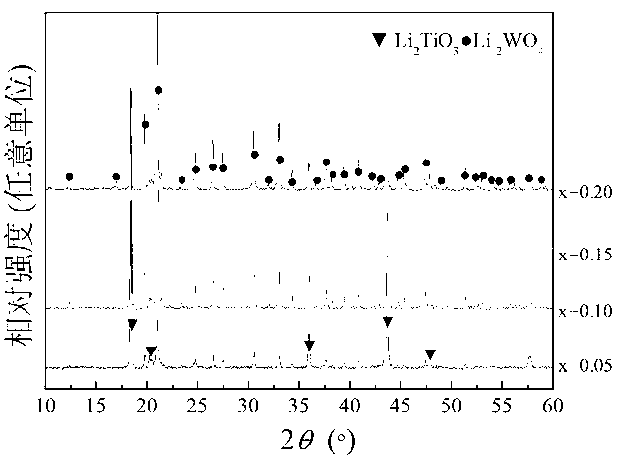

[0020] Put the accurately weighed raw materials into the resin ball mill tank, add alcohol and ZrO 2 Grinding balls; the weight ratio of the three is: material: balls: alcohol = 1:4:0.5; ball milling for 24 hours, after mixing evenly, discharge the material, dry it at 100°C; then briquette at 500~800°C Calcined for 2 hours to synthesize two single-phase ceramic powders respectively, grind the synthesized above-mentioned ceramic materials with a mortar and pass through a 40-mesh sieve, then weigh the two single-phase powders according to the two-phase co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com