Method for improving mechanical property of Ti48Zr20Nb12Cu5Be15 by using magnetic field

A technology of ti48zr20nb12cu5be15 and magnetic field is applied in the field of titanium-based amorphous composite materials and its preparation, which can solve the problems of high process parameter control requirements, complicated operation and high additional cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

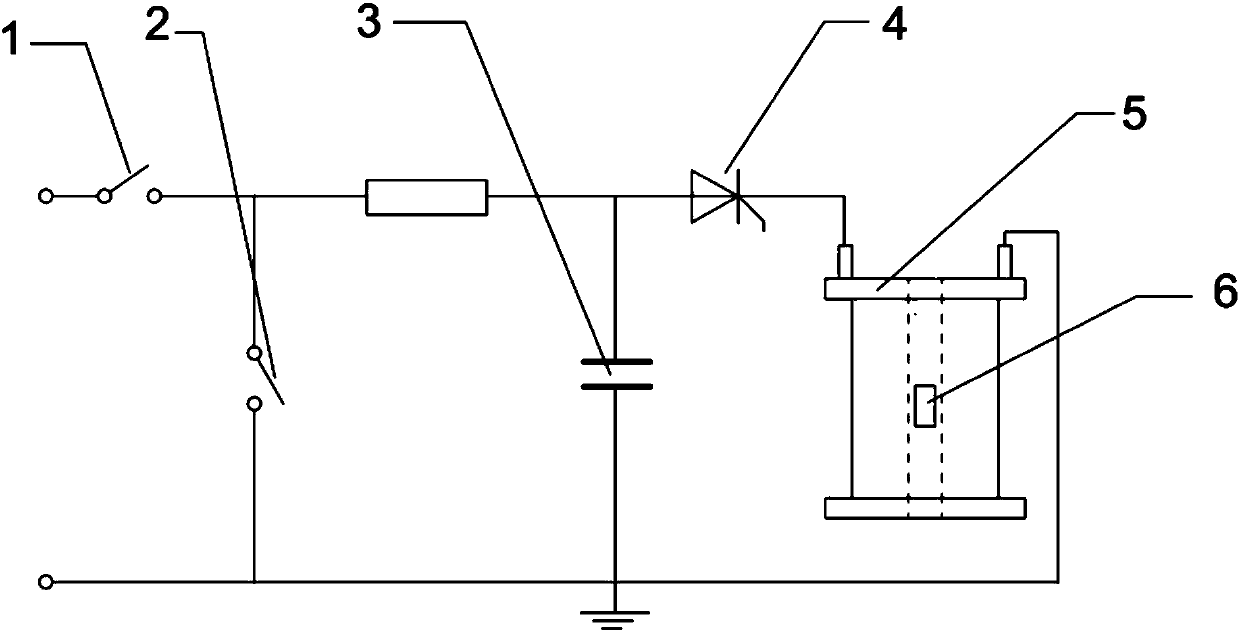

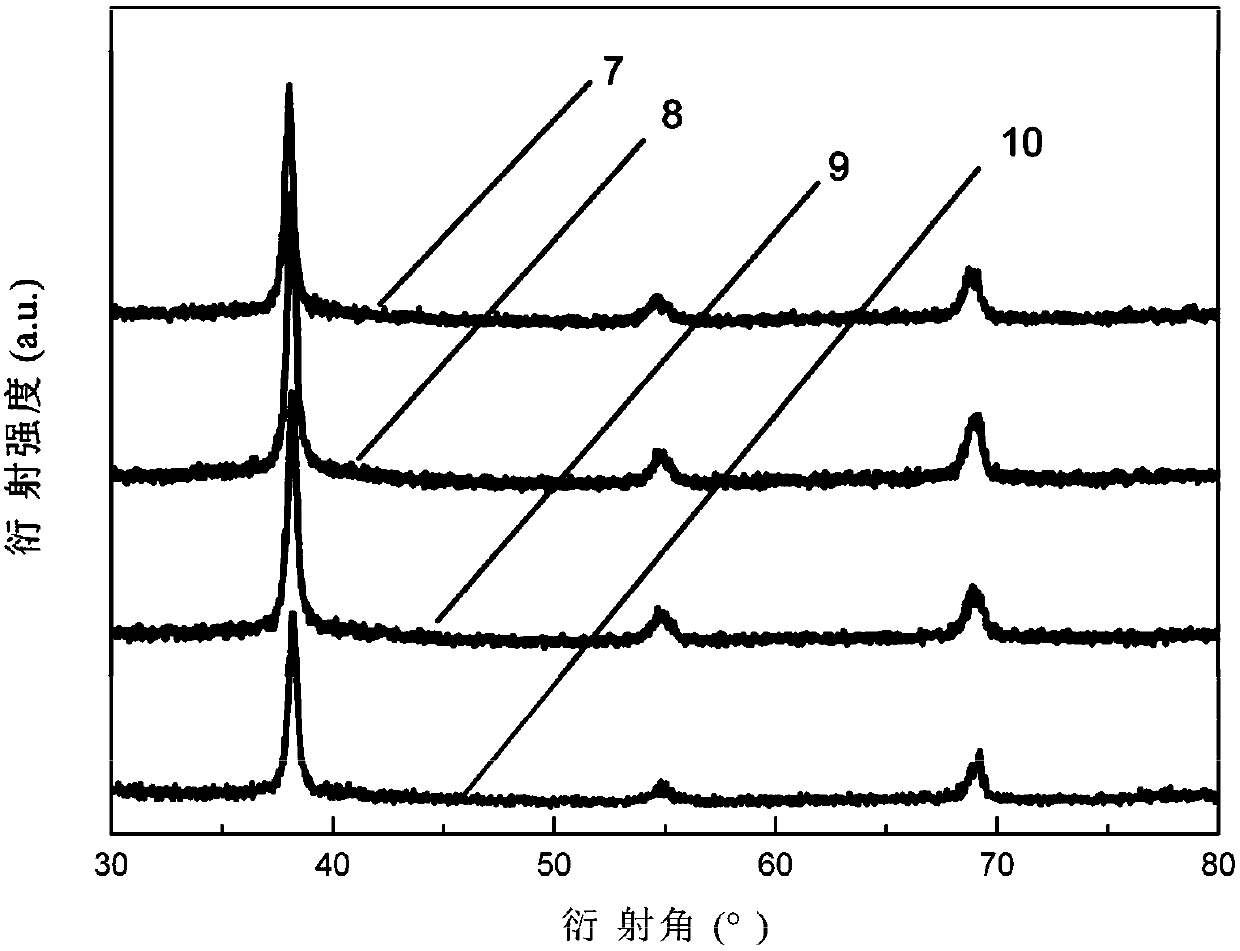

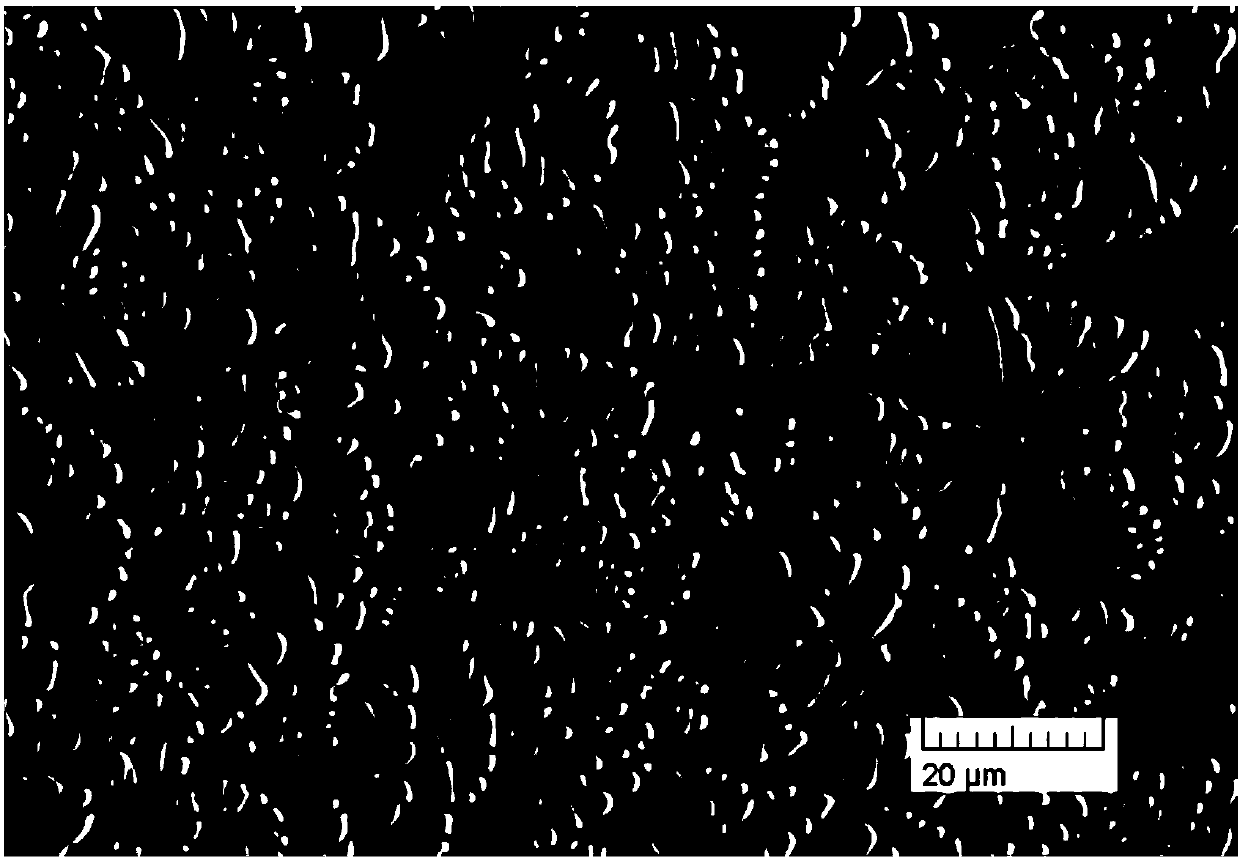

[0026] The present embodiment is a kind of utilizing pulsed magnetic field to process Ti 48 Zr 20 Nb 12 Cu 5 be 15 A titanium-based amorphous composite material, a method for improving its mechanical properties.

[0027] The titanium-based amorphous composite material described in this implementation example is composed of Ti, Zr, Nb, Cu, Be, and the atomic percentage of the titanium-based amorphous composite material is Ti 48 Zr 20 Nb 12 Cu 5 be 15 , the pulsed magnetic field intensity used is 10T, and the number of pulses is 5 times.

[0028] The specific process of the method for improving the mechanical properties of titanium-based amorphous composite materials by pulsed magnetic field treatment described in this embodiment is as follows:

[0029] The first step, Ti 48 Zr 20 Nb 12 Cu 5 be 15 Surface insulation treatment. Ti will be prepared using existing technology 48 Zr 20 Nb 12 Cu 5 be 15 The titanium-based amorphous composite material is tightly wra...

Embodiment 2

[0036] The Ti described in this implementation example 48 Zr 20 Nb 12 Cu 5 be 15 The pulsed magnetic field intensity used is 10T, and the number of pulses is 10 times.

[0037] The pulsed magnetic field treatment described in this embodiment improves Ti 48 Zr 20 Nb 12 Cu 5 be 15 The specific process of the method of mechanical properties is as follows:

[0038] The first step, Ti 48 Zr 20 Nb 12 Cu 5 be 15 Surface insulation treatment. Ti will be prepared using existing technology 48 Zr 20 Nb 12 Cu 5 be 15 The titanium-based amorphous composite material is tightly wrapped with polyimide high-temperature insulating tape with a temperature resistance of 280°C, so that no exposed metal surface can be left, so that the titanium-based amorphous composite material is completely insulated from the electromagnetic induction coil of the pulsed magnetic field processing equipment. This prevents short circuits from occurring during subsequent discharges.

[0039] The ...

Embodiment 3

[0045] The present embodiment is a kind of utilizing pulsed magnetic field to process Ti 48 Zr 20 Nb 12 Cu 5 be 15 , to improve its mechanical properties.

[0046] The titanium-based amorphous composite material described in this implementation example is composed of Ti, Zr, Nb, Cu, Be, and the atomic percentage of the titanium-based amorphous composite material is Ti 48 Zr 20 Nb 12 Cu 5 be 15 , the pulsed magnetic field intensity used is 10T, and the number of pulses is 20 times.

[0047] The specific process of the method for improving the mechanical properties of titanium-based amorphous composite materials by pulsed magnetic field treatment described in this embodiment is as follows:

[0048] The first step is the surface insulation treatment of the titanium-based amorphous composite material. Ti will be prepared using existing technology 48 Zr 20 Nb 12 Cu 5 be 15 The titanium-based amorphous composite material is tightly wrapped with polyimide high-temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com