Cutting oil and preparation method thereof

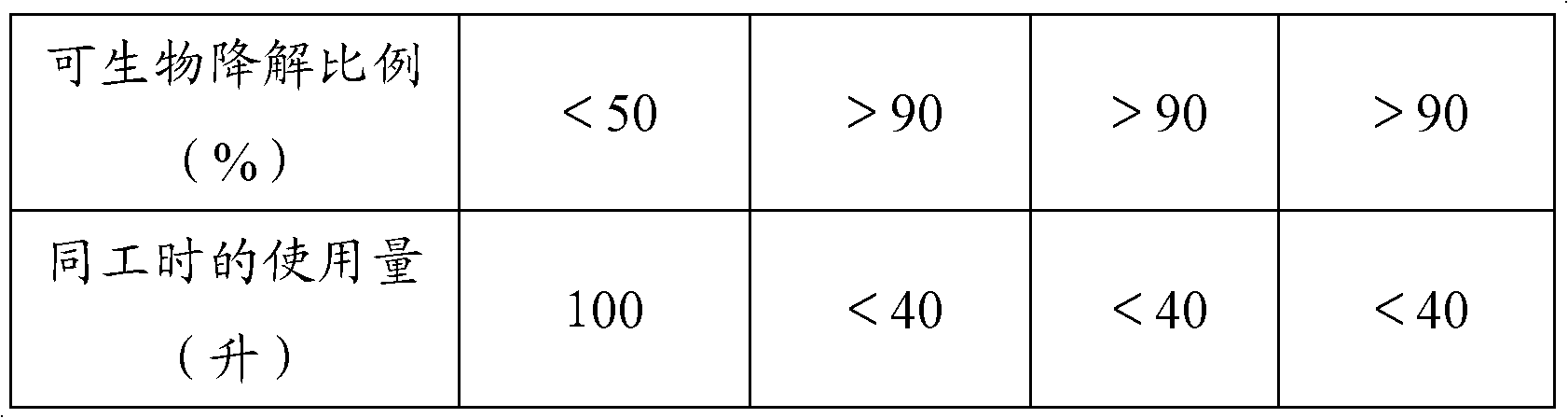

A cutting oil and vegetable oil technology, applied in the field of lubricating oil, can solve the problems of ecological environment pollution, poor biodegradation performance and high ecological toxicity, and achieve the effect of reducing waste liquid discharge, reducing usage and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

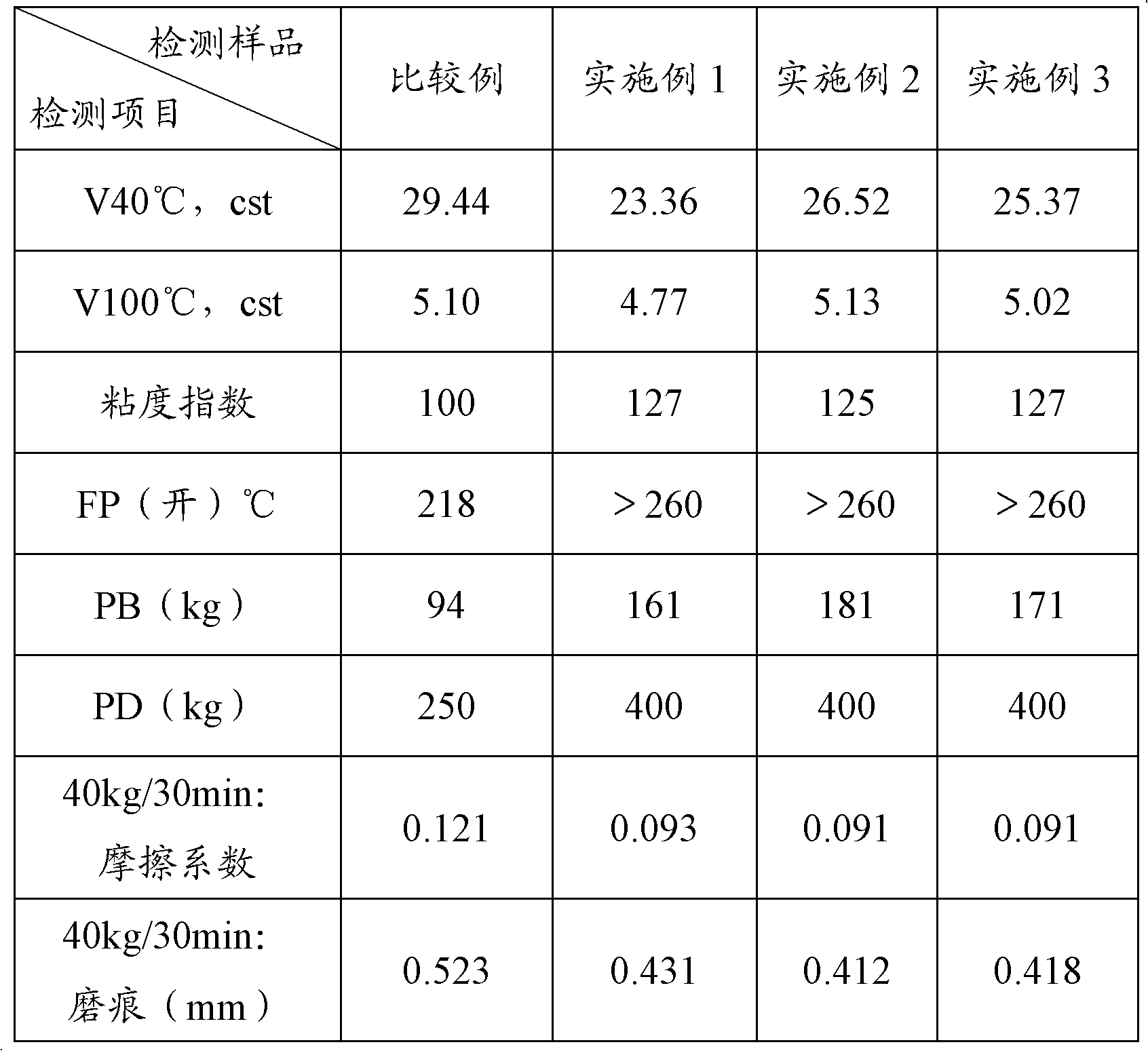

Examples

preparation example Construction

[0037] The present invention also provides a kind of preparation method of cutting oil, comprises the following steps:

[0038] a) Putting synthetic ester and vegetable oil into a blending kettle to mix and stir;

[0039] b) Stir the base oil obtained in a) to 60°C to 100°C, add antioxidant, anti-rust agent, extreme pressure anti-wear agent and metal deactivator, stir, then lower the temperature to below 50°C, stop stir;

[0040] The weight percentage of each component is: 20%-40% of synthetic ester, 60%-80% of vegetable oil, 0%-3% of antioxidant, 0%-2% of anti-rust agent, 1%-5% of extreme pressure and anti-wear agent , metal deactivator 0% ~ 1%;

[0041] c) filtering the oil product obtained in b) to obtain a cutting oil product.

Embodiment 1

[0043] a) 30% by weight of synthetic ester and 65.3% of rapeseed oil are mixed and stirred in a blending kettle, wherein the synthetic ester consists of trimethylolpropane triolein, isooctyl stearate, and isooctyl oleate Octyl esters are mixed according to the mass ratio of 3:1:1;

[0044] b) Heat and stir the base oil obtained in a), heat up to 70°C, add 1% of 2,6-di-tert-butyl-p-cresol, 0.6% of rust inhibitor, 3% of trialkyl phosphate and 0.1 % of benzotriazole derivatives, stirred, then cooled to 40°C, and stopped stirring, wherein the rust inhibitor was mixed with dodecenylsuccinic acid semi-fat and ammonium salt type rust inhibitor according to the mass ratio of 4:1 made;

[0045] c) filtering the oil product obtained in b) to obtain a cutting oil product.

Embodiment 2

[0047] a) 25% by weight of synthetic ester and 65.6% of vegetable oil are mixed and stirred in a blending tank, wherein the synthetic ester consists of trimethylolpropane triolein, isooctyl stearate, and isooctyl oleate It is mixed according to the mass ratio of 2:1:1.5; the vegetable oil is prepared by mixing rapeseed oil and oxidized rapeseed oil according to the mass ratio of 8:2;

[0048] b) Heat and stir the base oil obtained in a), heat up to 80°C, add 3% L57 octyl / butyl diphenylamine, 1.2% rust inhibitor, 5% phosphorus nitrogen complex and 0.2% methyl Benzotriazole derivatives, stirring, then cooling down to 45°C, and stopping stirring, wherein the antirust agent is mixed with dodecenylsuccinic acid semifat and ammonium salt type antirust composite agent according to the mass ratio of 3:1 made;

[0049] c) filtering the oil product obtained in b) to obtain a cutting oil product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com