Metal cutting fluid containing graphene dispersion solution and preparation method thereof

A graphene dispersion, metal cutting fluid technology, applied in the petroleum industry, additives, lubricating compositions and other directions, can solve the problems of poor lubricating performance, low cost, pollute the external environment and working environment, etc., to improve lubricating performance, stable The effect of dispersing and improving friction and wear behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

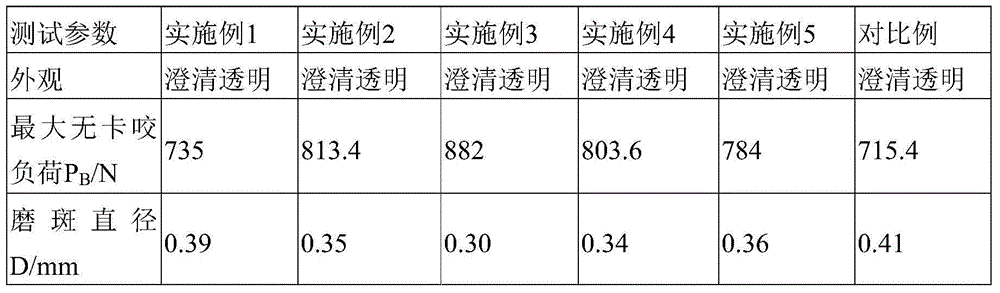

Examples

preparation example Construction

[0053] The preparation method of above-mentioned lubricity additive graphene dispersion liquid specifically comprises the steps:

[0054] (1) Adopt improved Hummers method to prepare graphene oxide (this method is the method recorded in the document "Dispersion of graphene sheets in organic solvent supported by ionic interactions"), then disperse graphene oxide into deionized water, prepare into an aqueous solution, preferably ultrasonically prepared into an aqueous solution, the concentration of the aqueous solution is 0.05-0.20 grams / 100 milliliters, preferably 0.08-0.18 grams / 100 milliliters, more preferably 0.15 grams / 100 milliliters, then add urotropine, the urotropine The amount added is 0.01-0.15 grams, preferably 0.05-0.15 grams, more preferably 0.075 grams, based on 100 milliliters of aqueous solution, at 100-110 ° C, preferably 100 ° C under reflux reaction for 8-15 hours, preferably 12 hours, to obtain graphene dispersion liquid mother liquor. Preferably, the mass ...

preparation example 1

[0071] Get 0.15 grams of graphene oxide prepared by the Hummers method that has removed residual ions through dialysis, it is formulated as an aqueous solution of 100 milliliters, and urotropine is added, and the mass ratio of graphene oxide and urotropine is 2:1 , stirred and refluxed at 100°C for 12 hours, and cooled. Add 0.01 gram of sodium dodecylbenzenesulfonate to the above-mentioned graphene dispersion mother liquor, and ultrasonically treat for 0.5 h to obtain a uniformly dispersed graphene dispersion.

[0072] Reference Example 1 of Graphene Dispersion Liquid

[0073] Get 0.15 grams of graphene oxide prepared by the Hummers method that has removed residual ions through dialysis, it is mixed with 100 milliliters of aqueous solution, add urotropine, by graphene oxide and urotropine mass ratio is 2:1 , stirred and refluxed at 100°C for 12 hours, and cooled. 0.01 gram of sodium lauryl sulfate was added to the above-mentioned graphene dispersion liquid, and ultrasonic tr...

Embodiment 1

[0078] The synthetic metal cutting fluid containing graphene dispersion liquid, calculated by weight percentage, its raw material composition and content are as follows:

[0079] Lubricity additive: 0.2%

[0080] Rust inhibitor: 7%

[0081] Corrosion inhibitor: 0.3%

[0082] Anti-hard water agent: 0.1%

[0083] Lubricant: 15%

[0084] The remainder is water;

[0085] Described lubricity additive is graphene dispersion liquid;

[0086] Described antirust agent is that sodium gluconate, borax, triethanolamine form mixture by the mass ratio of 6:7:8;

[0087] Described corrosion inhibitor is benzotriazole;

[0088] Described antihard water agent is ethylenediaminetetraacetic acid;

[0089] Described lubricant is polyethylene glycol;

[0090] Above-mentioned lubricity additive graphene dispersion liquid is prepared by the manufacturing method comprising the following steps:

[0091] (1) Graphene oxide was prepared by the improved Hummers method (as described in the docume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com