Patents

Literature

32results about How to "Inexpensive, dependable and effective" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

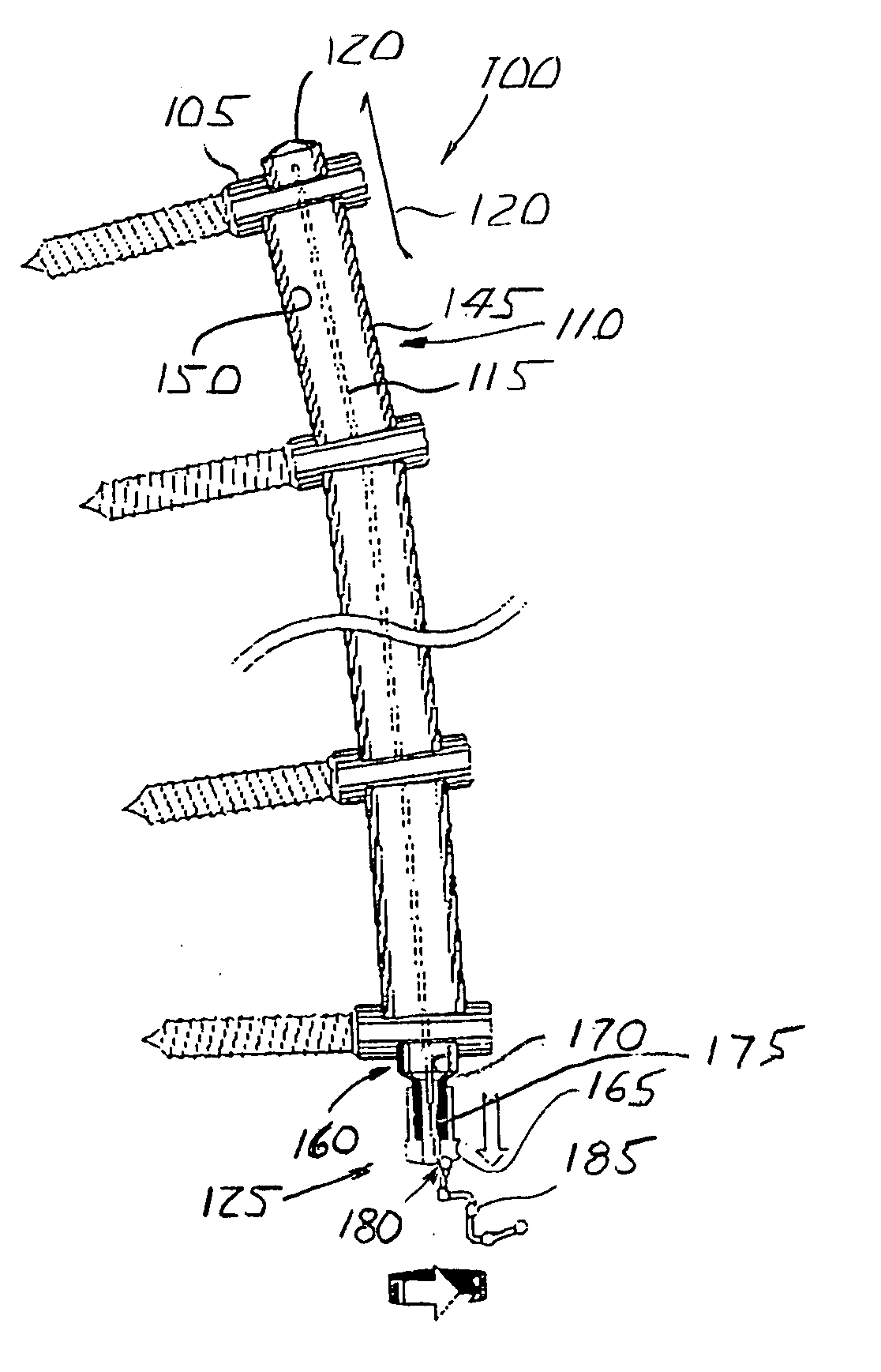

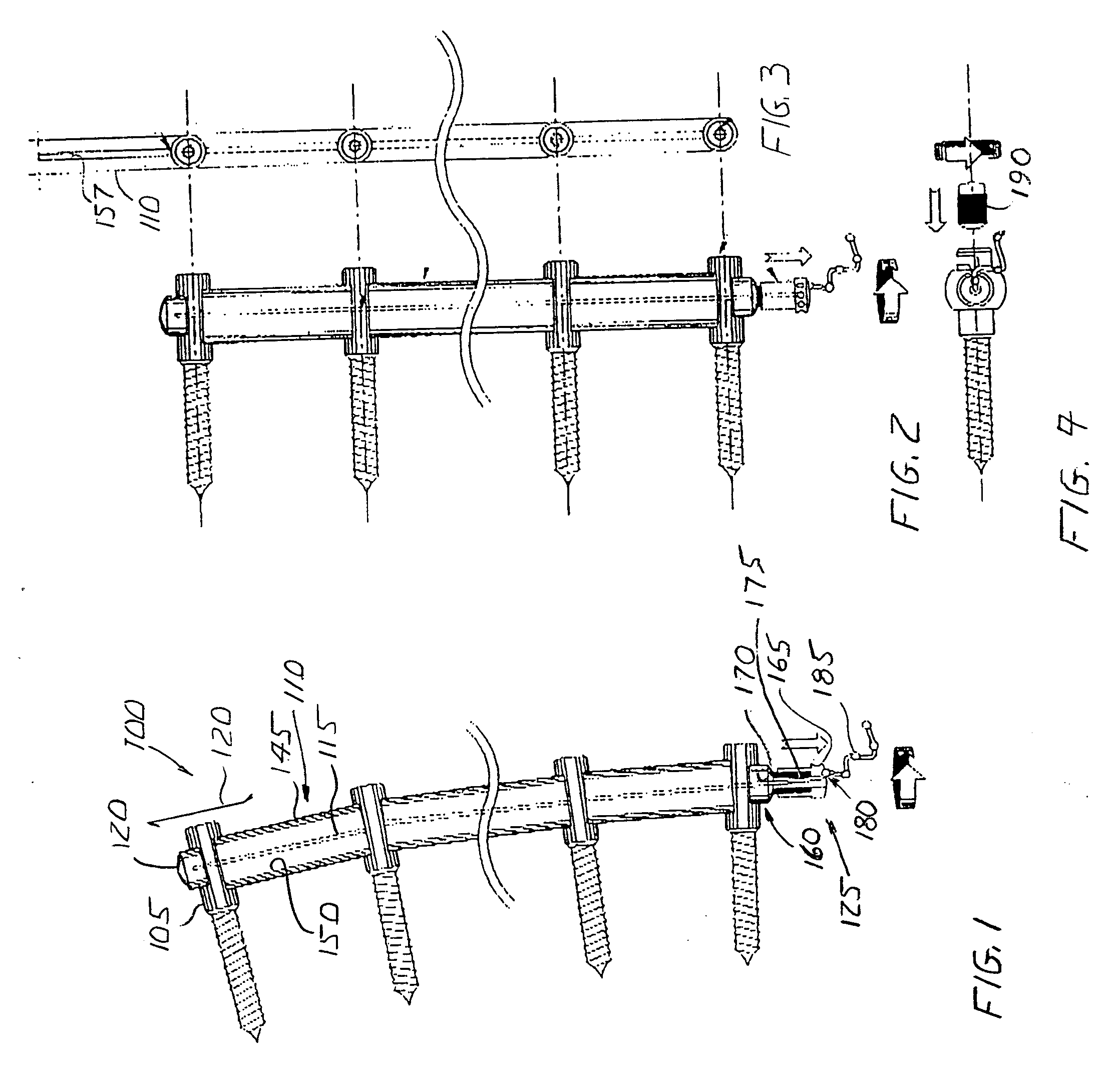

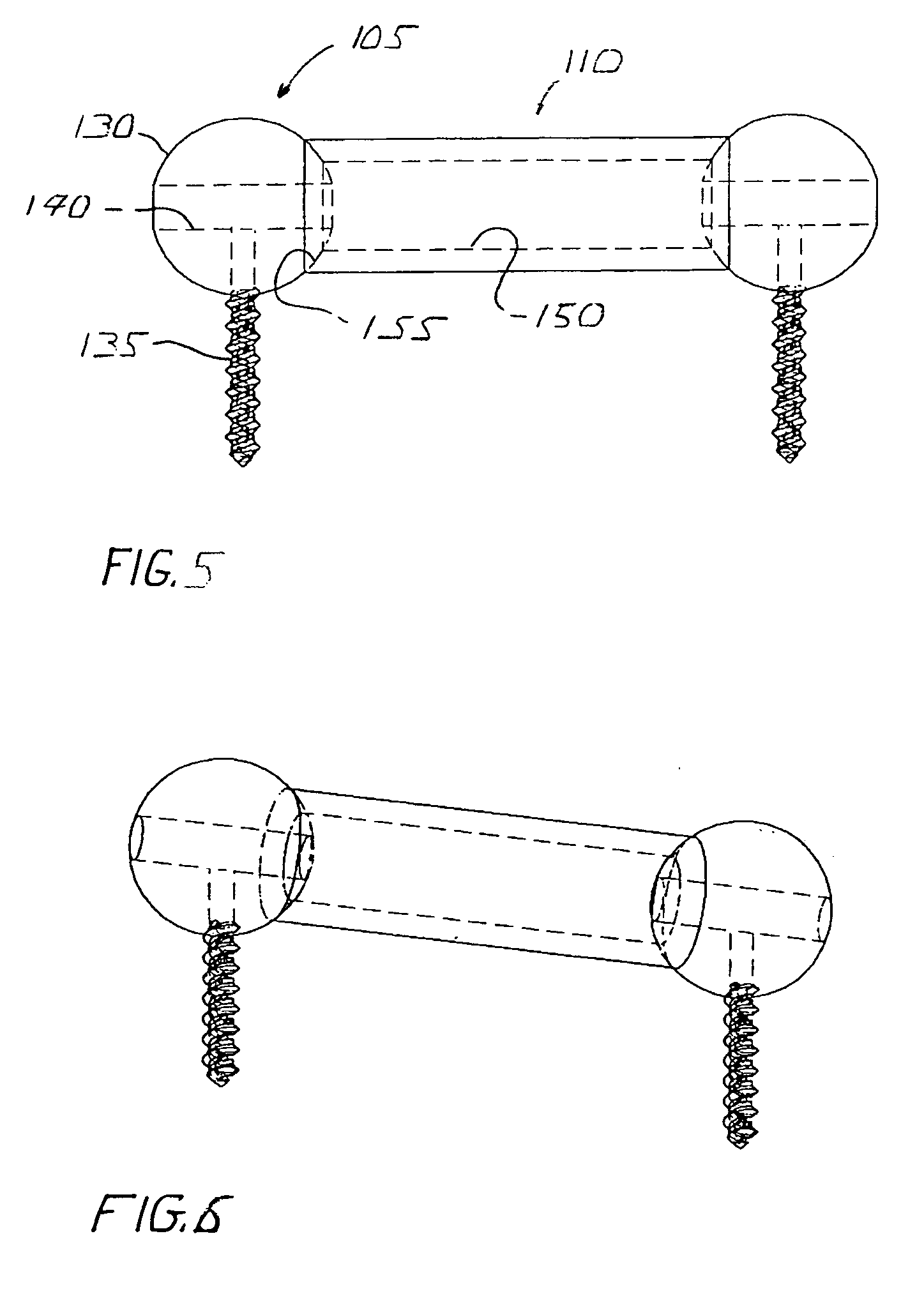

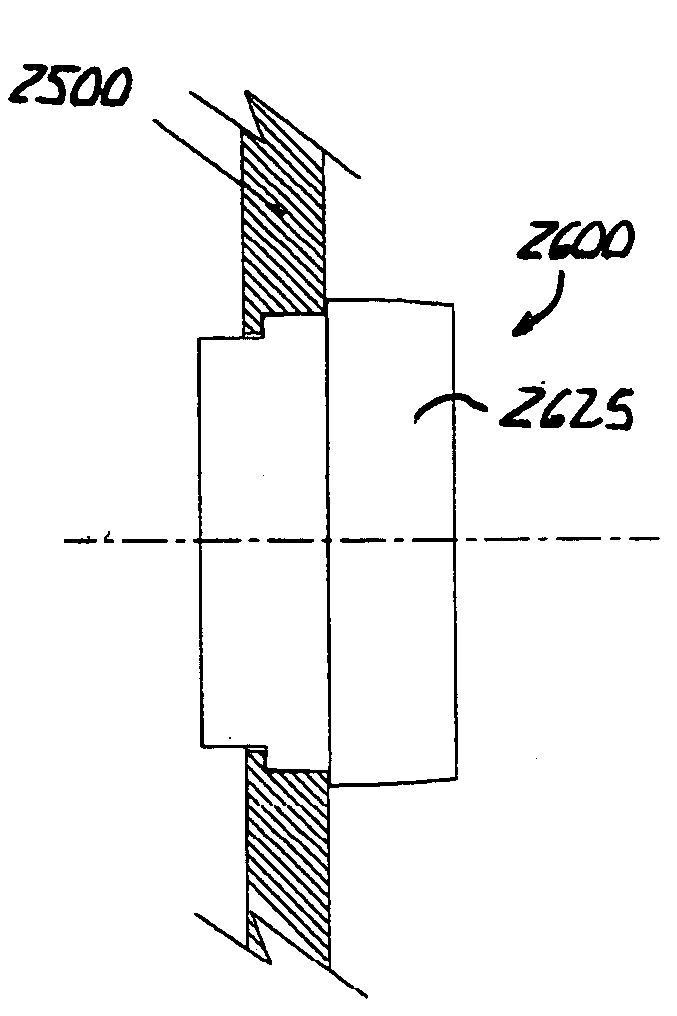

Apparatus for and method of aligning a spine

InactiveUS20060195090A1Easy to configureEasy to implantInternal osteosythesisJoint implantsEngineeringElectric cables

A plurality of pins attach to bone, such as a vertebra (not shown). Spacers interpose between pins. A cable extends through pins and spacers between a cap and an expansion sleeve. The expansion sleeve increases cable tension to restrict movement among pins and spacers.

Owner:SUDDABY LOUBERT

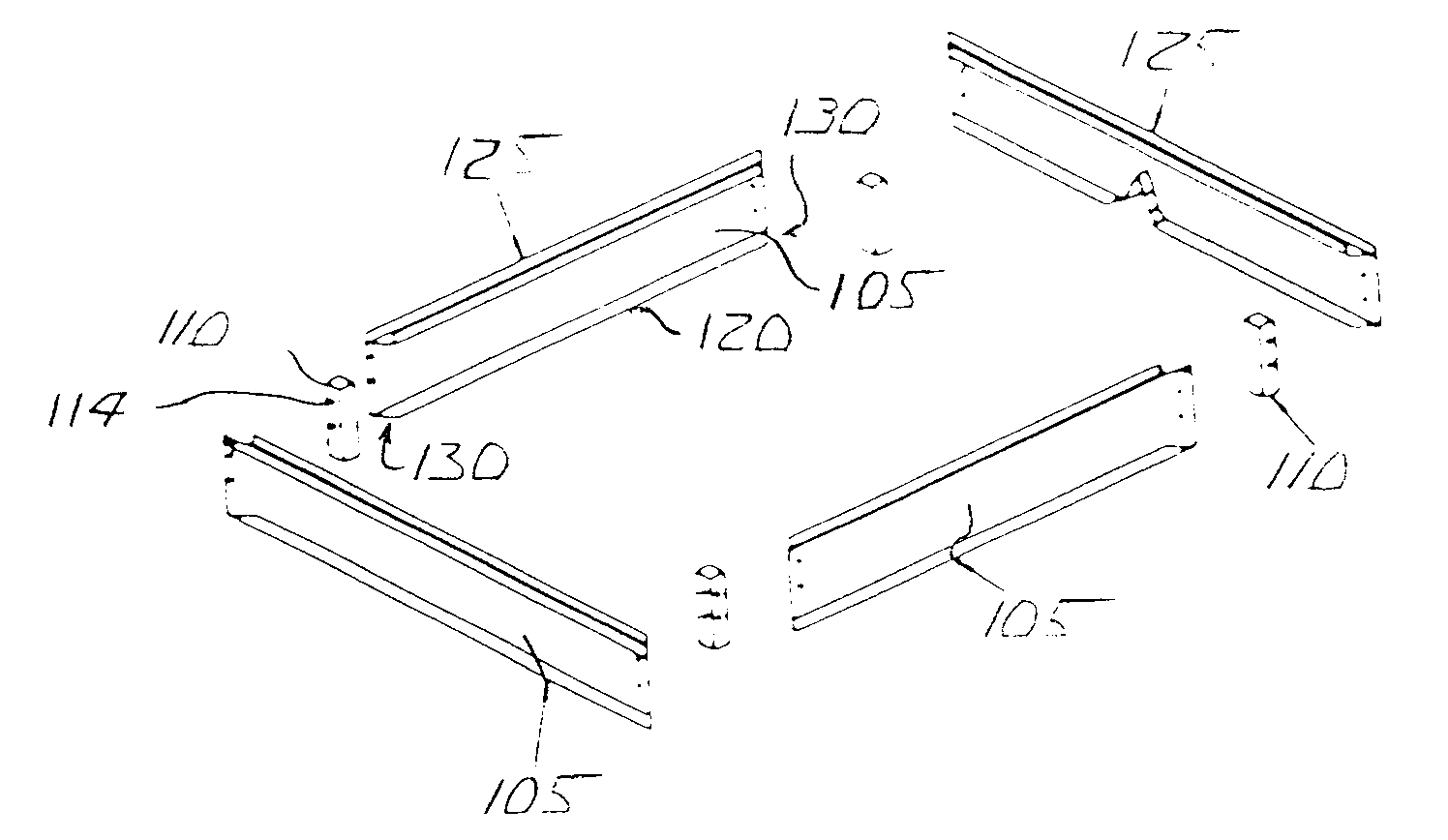

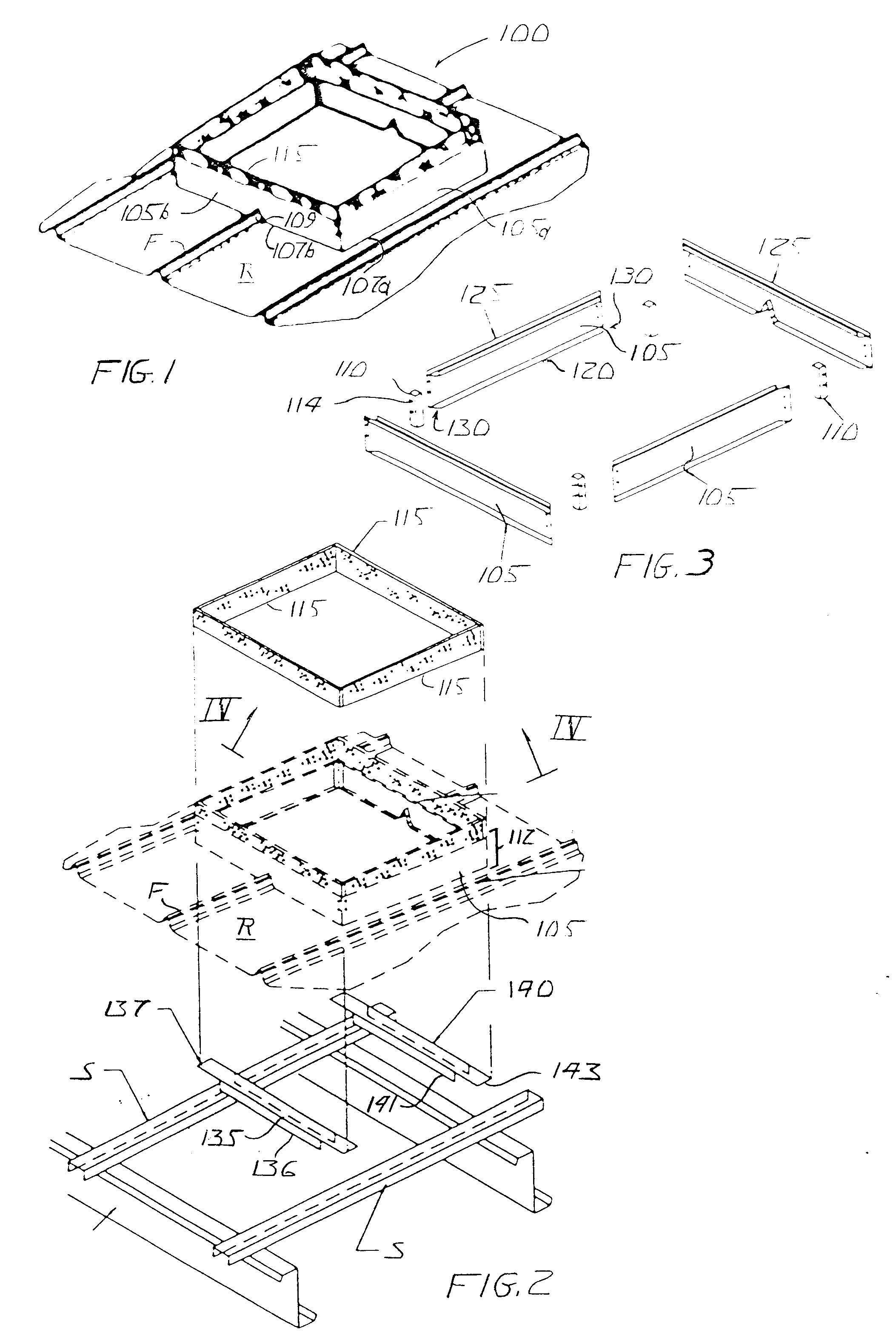

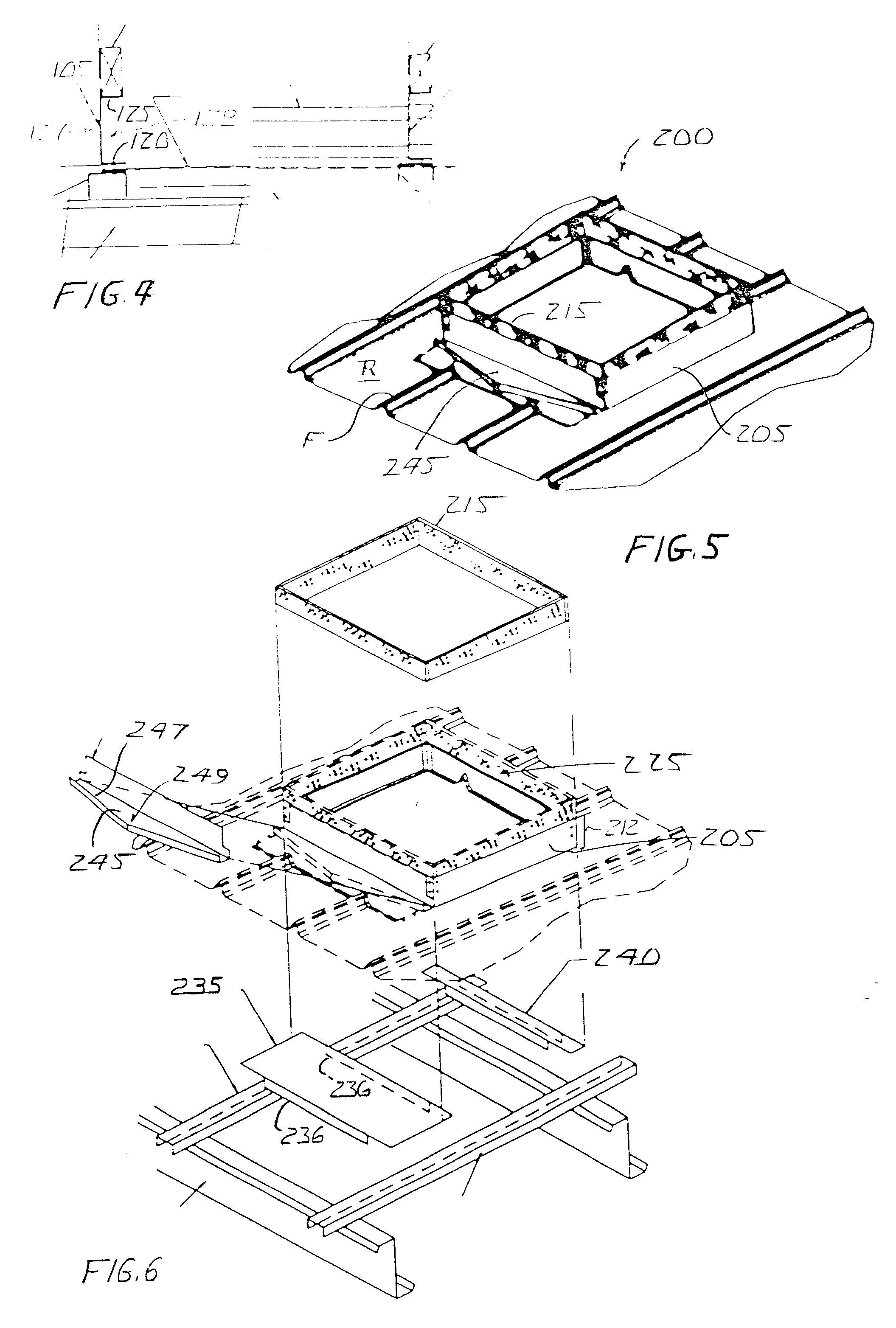

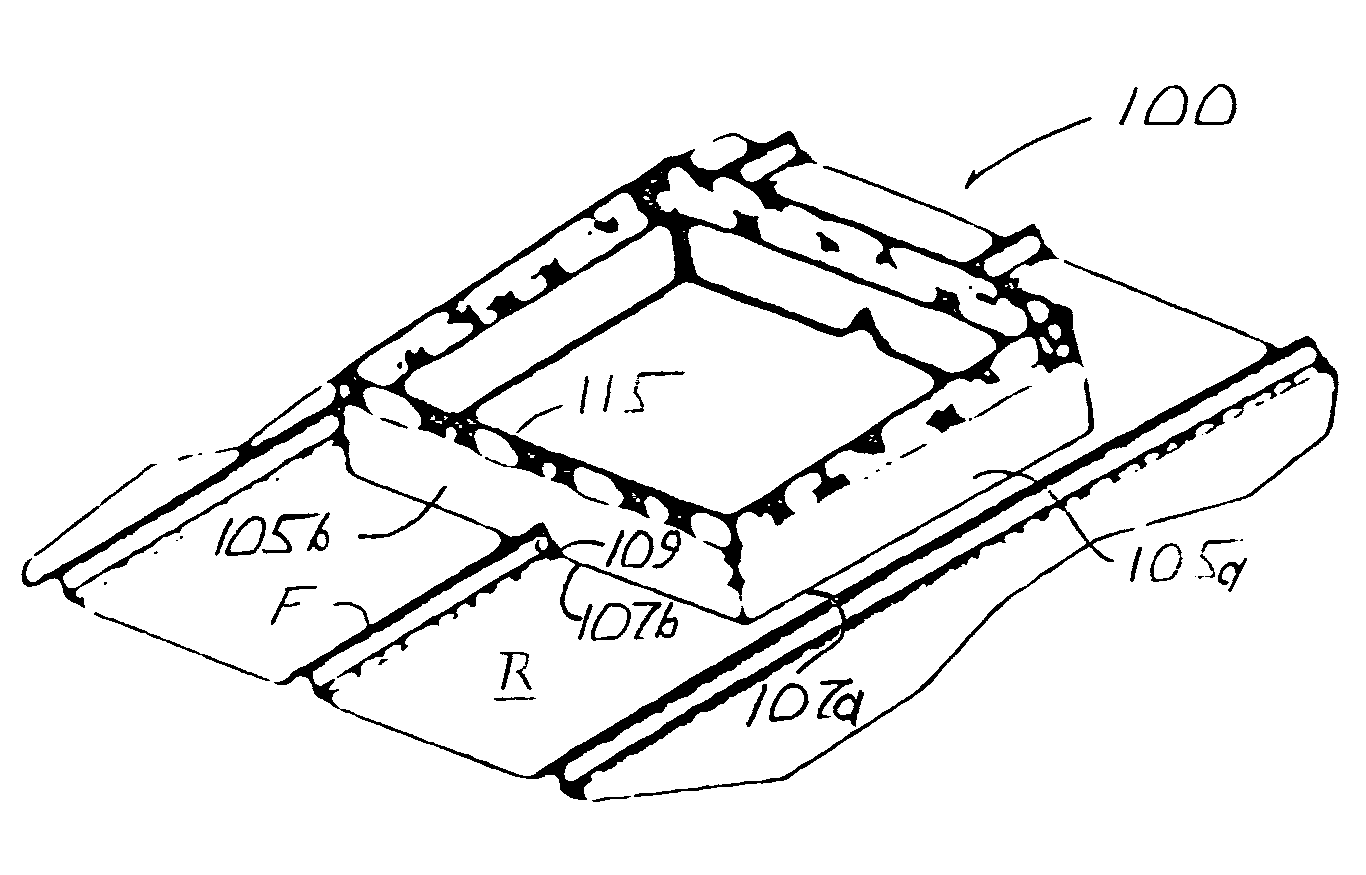

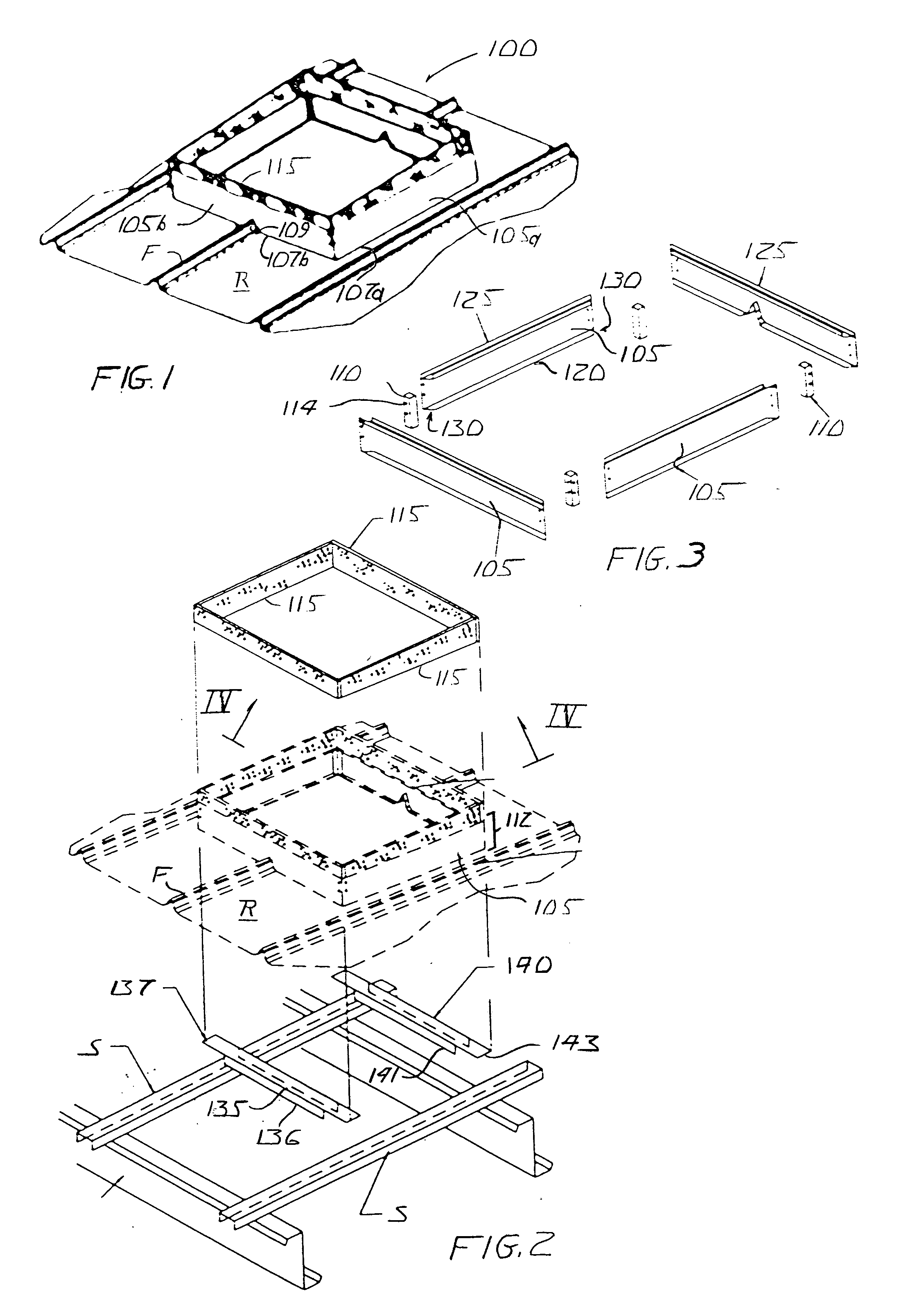

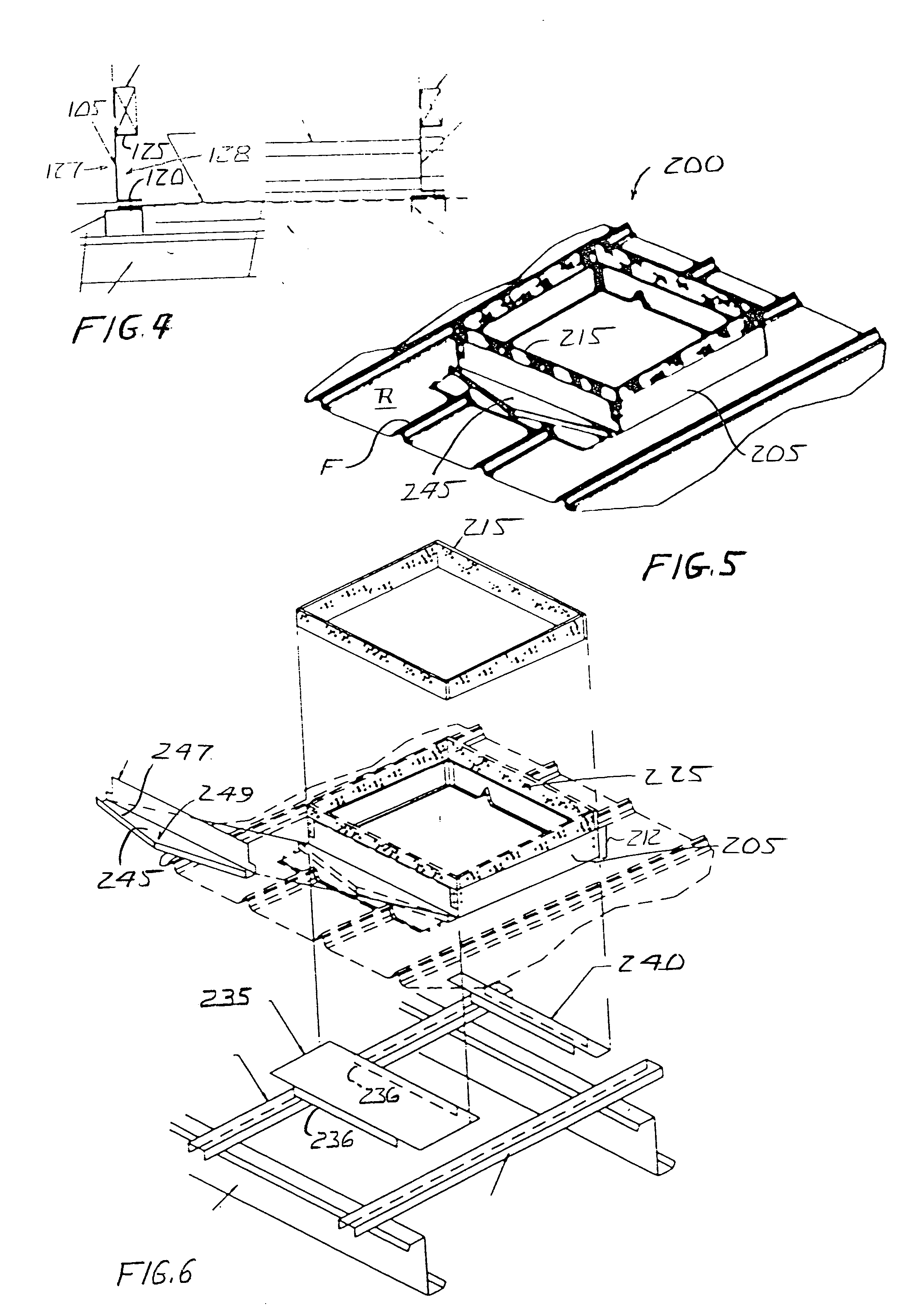

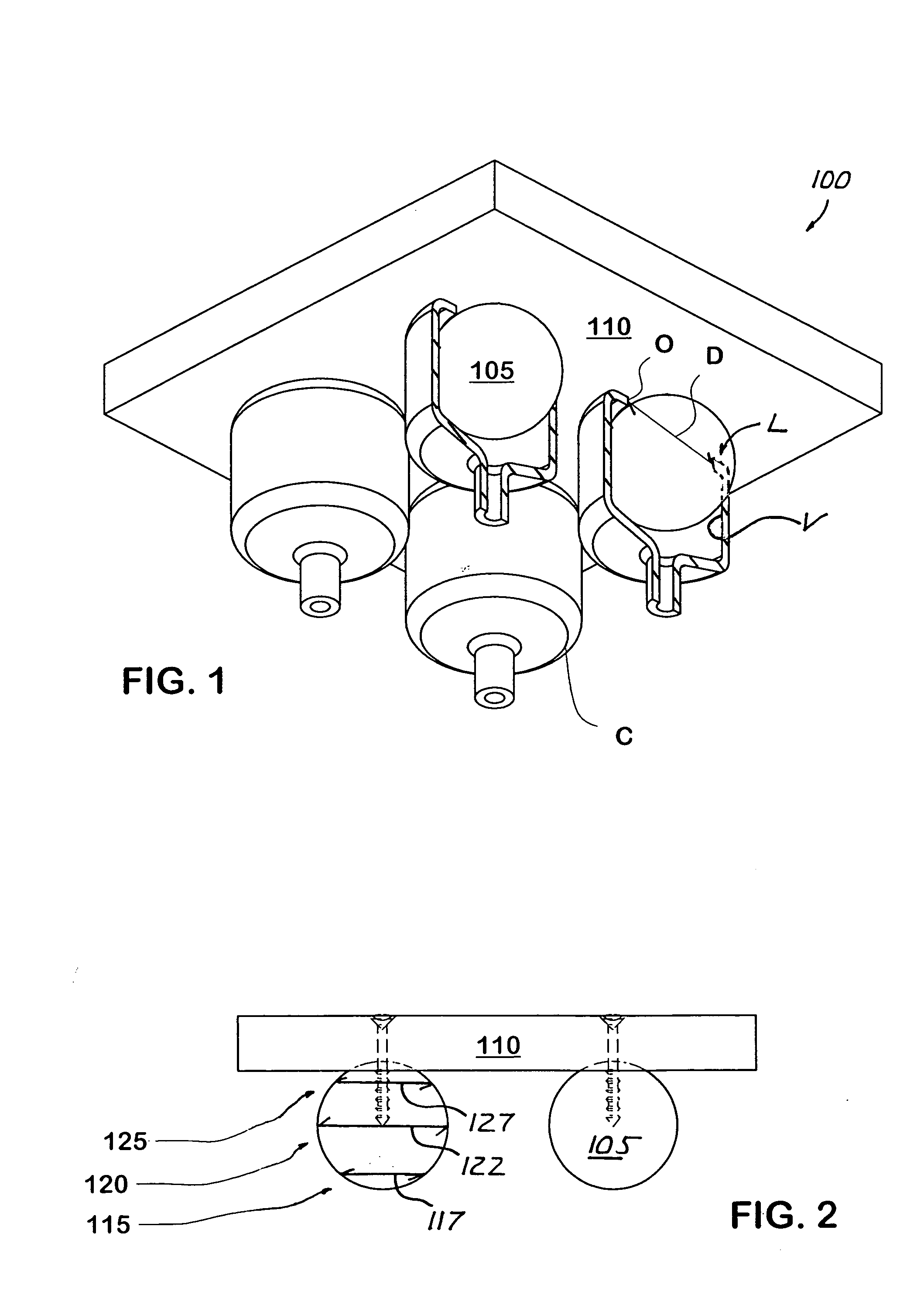

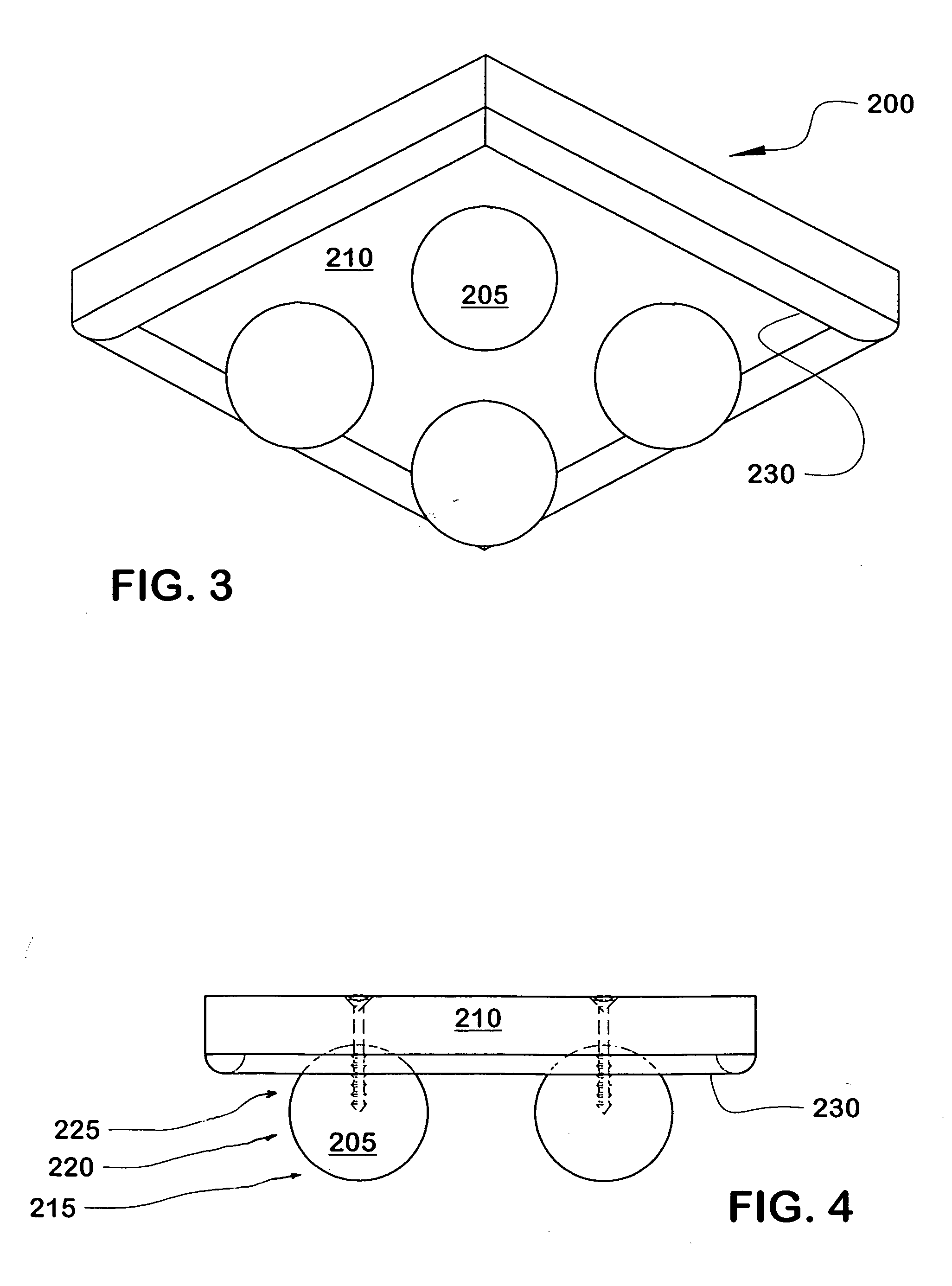

Knock-Down Roof Curb

InactiveUS20070094984A1Inexpensive, dependable and effectiveBuilding roofsRoof coveringStructural engineeringMetal cutting

A roof curb is shipped in a disassembled state to an installer who assembles, sizes, locates and configures the curb to accommodate slope on any roof without welding or metal cutting. The curb includes an aluminum walls, each having a channel for receiving the bottom edge of a board, which may be taper cut according to the pitch of the roof to provide a level surface for supporting an appliance. Methods of making and installing the roof curb also are disclosed.

Owner:BLUESCOPE BUILDINGS NORTH AMERICA

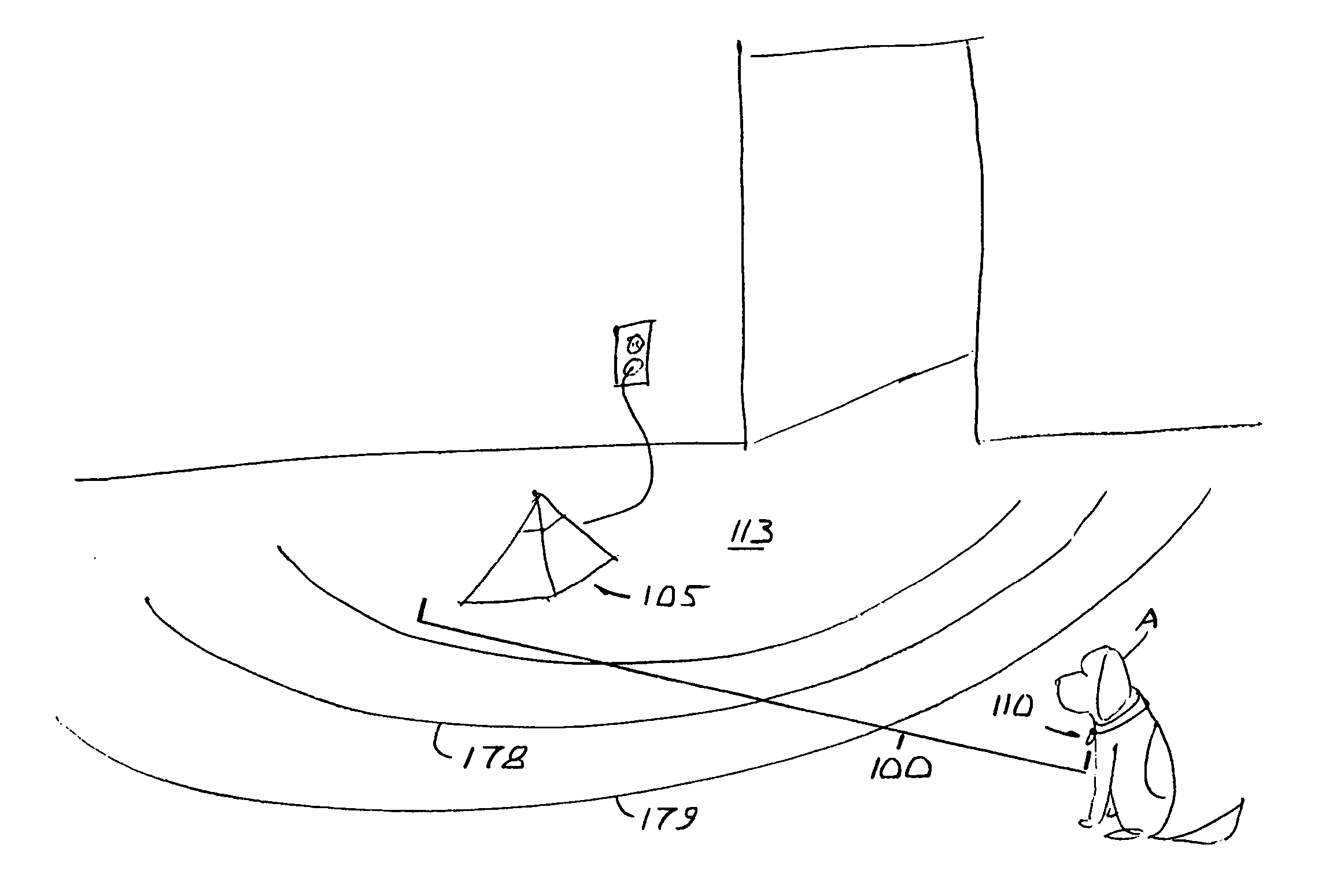

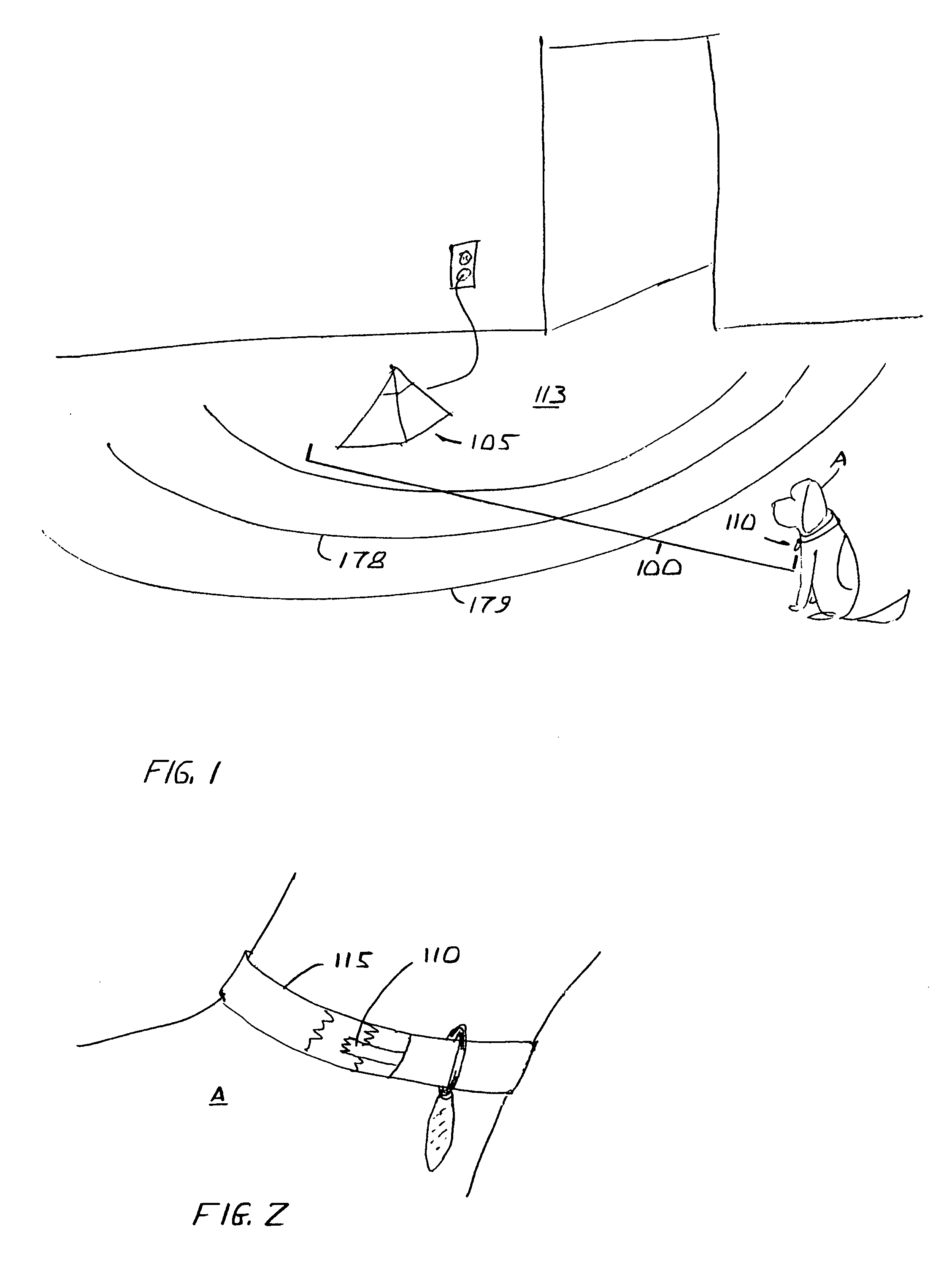

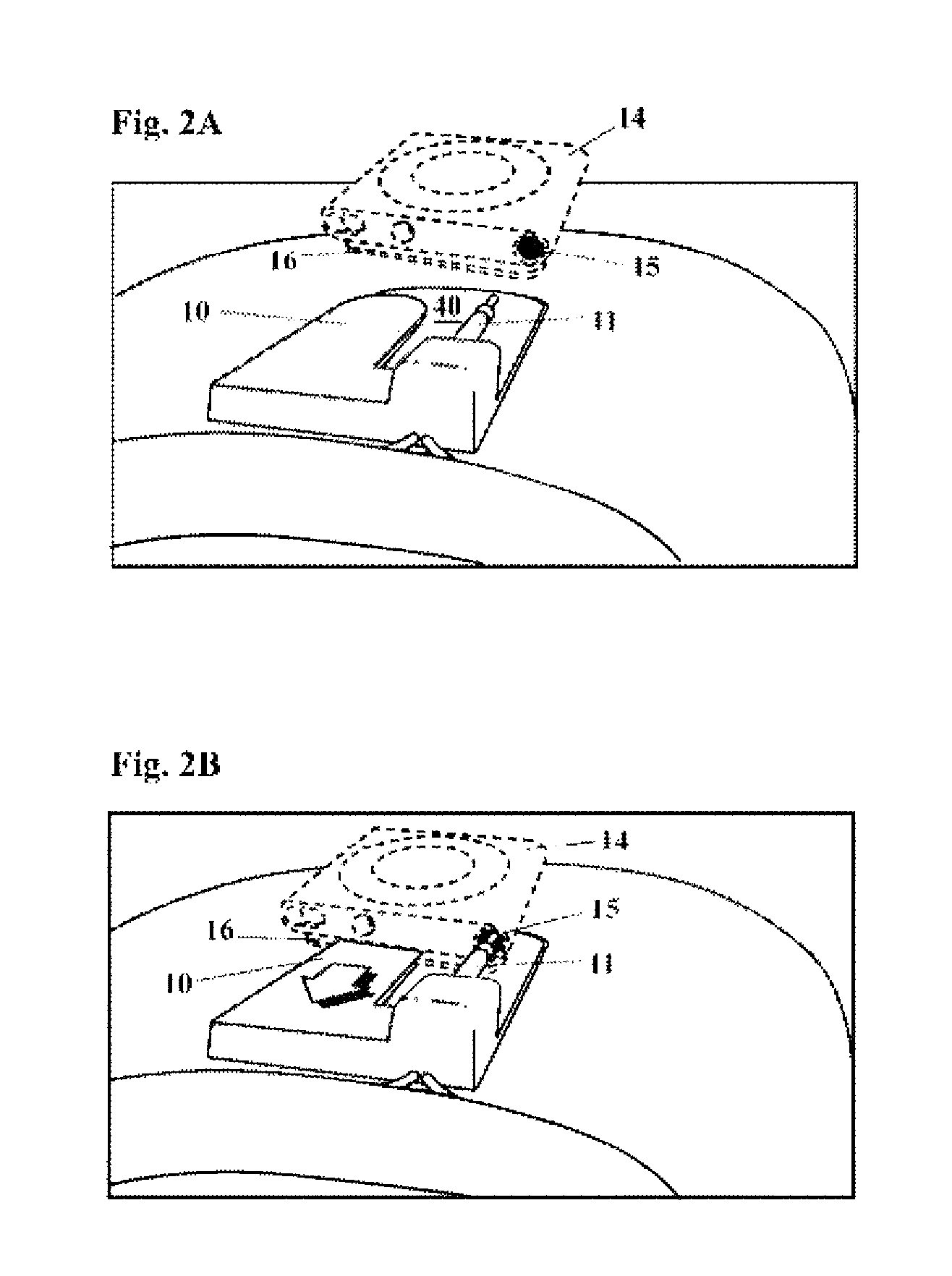

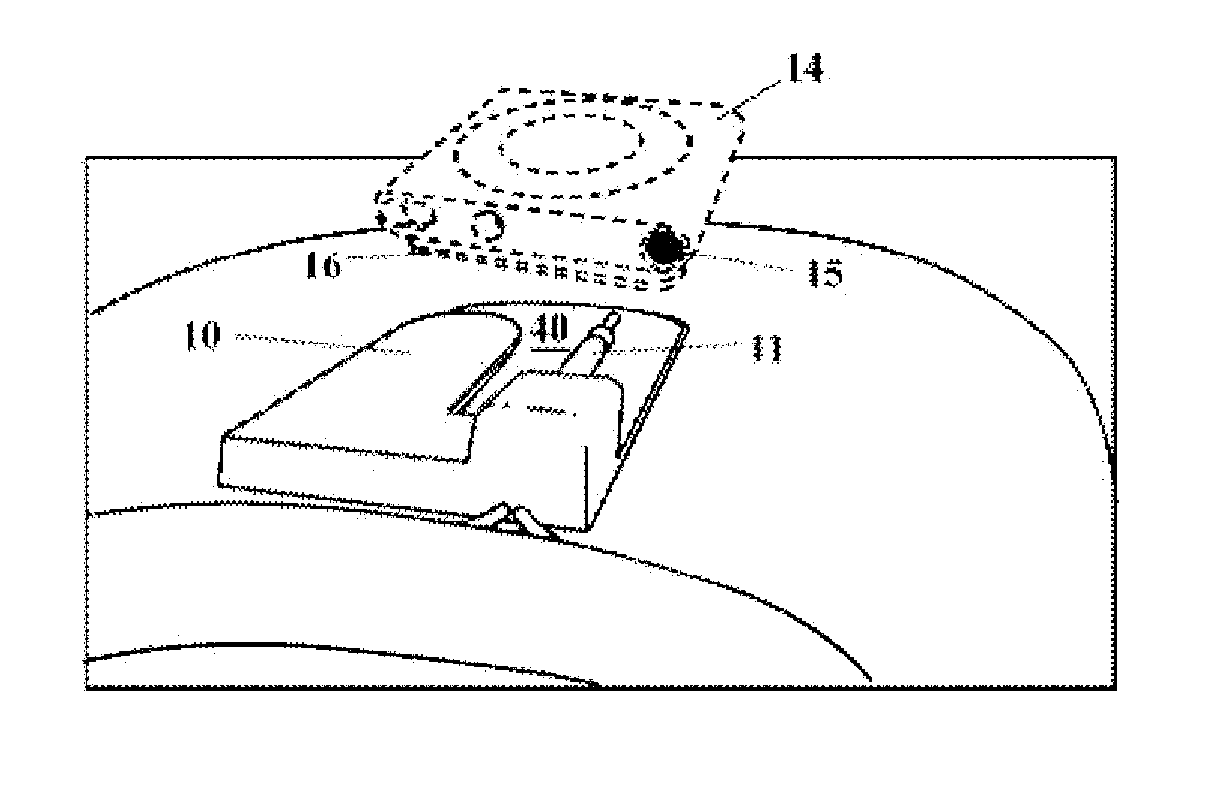

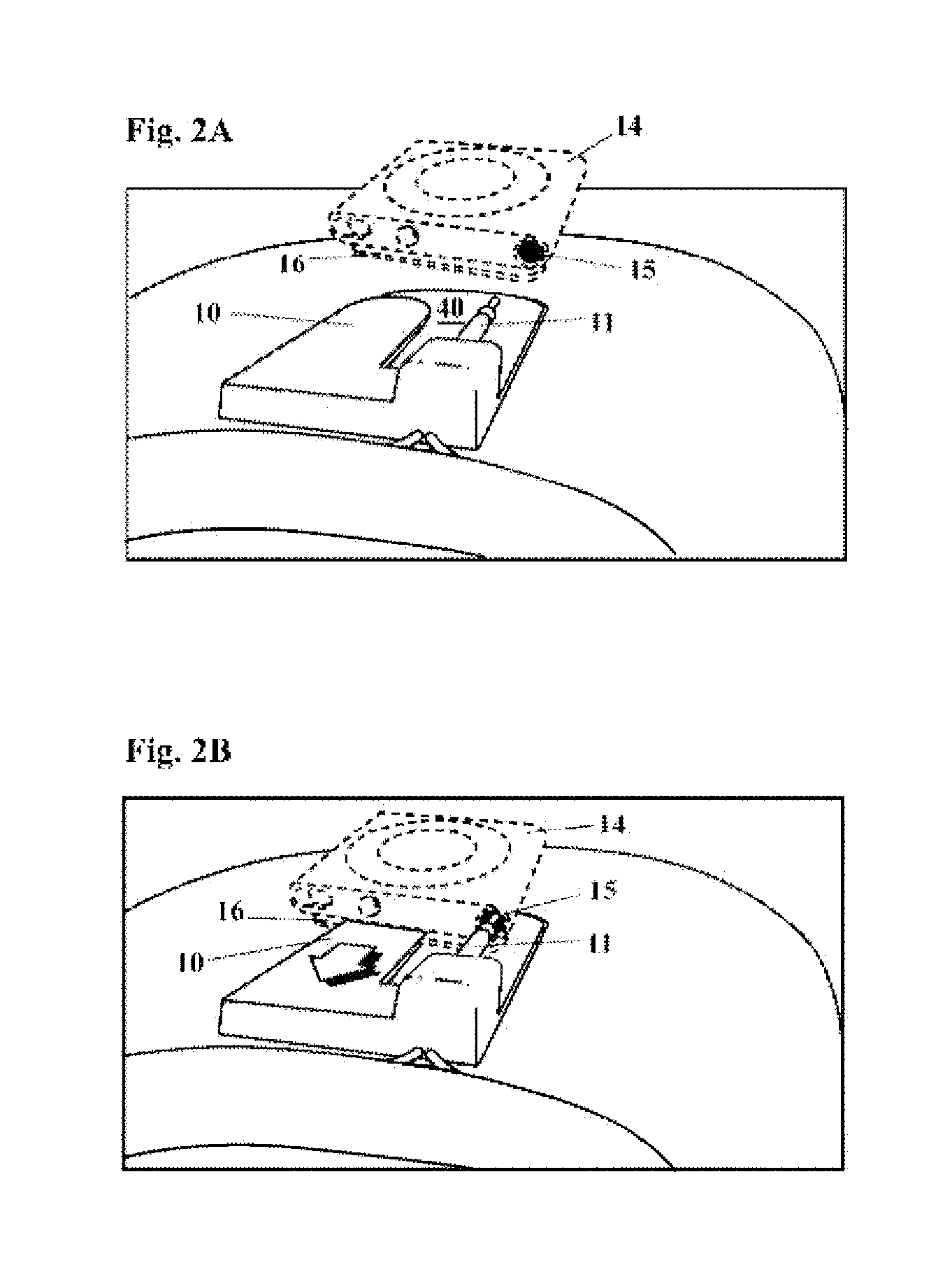

Pet containment apparatus and method

An electronic containment apparatus for and method of controlling the movement of an animal relative to a protected area employs magnetic fields for designating exclusion or containment areas within a household. The animal is provided with a collar, which includes a magnetic marker designed to perturb a magnetic field produced by an exclusion unit's magnetic field generator. The exclusion unit produces stimuli to which the animal responds, but to which humans do not respond.

Owner:VIGGIANO GREGORY R

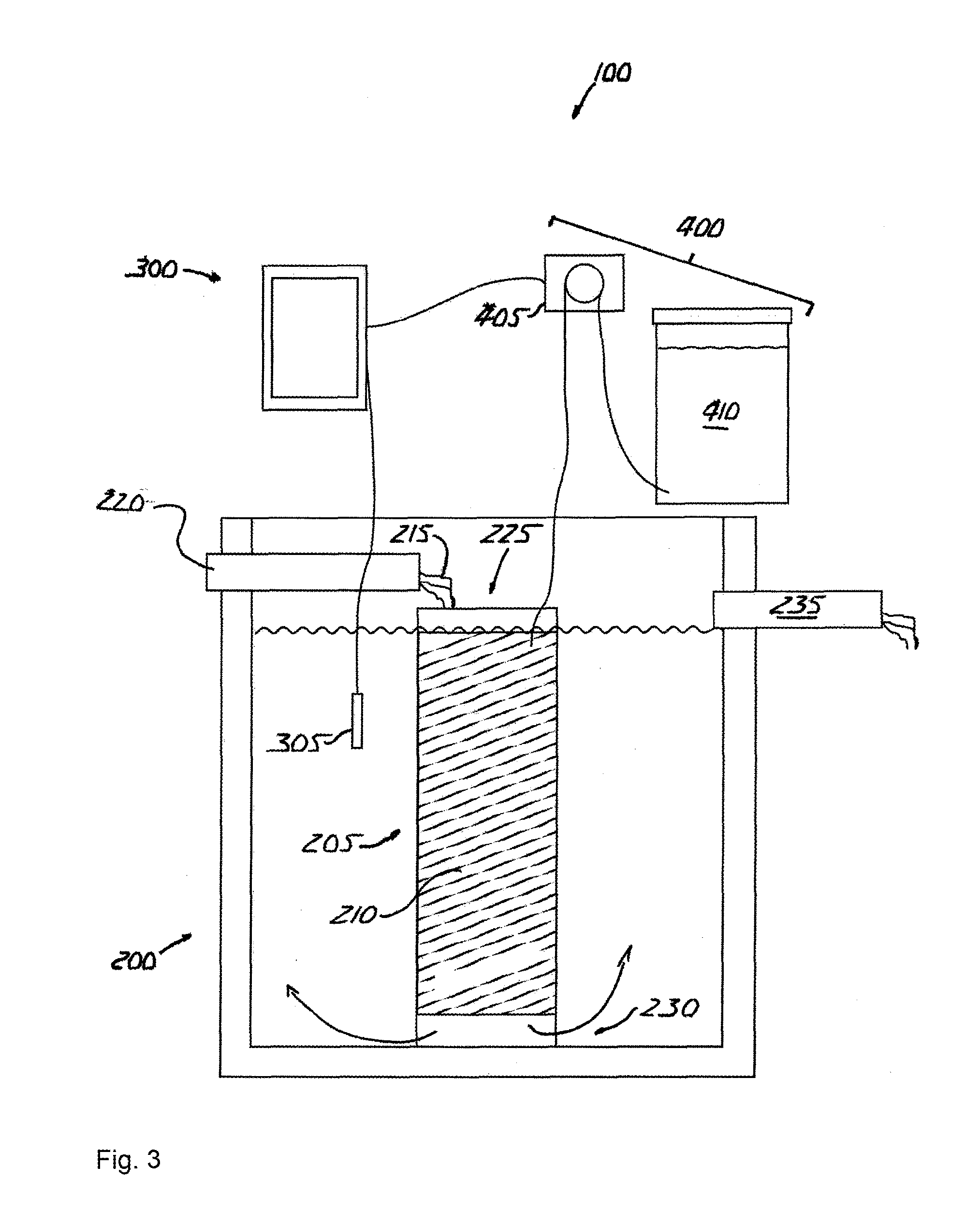

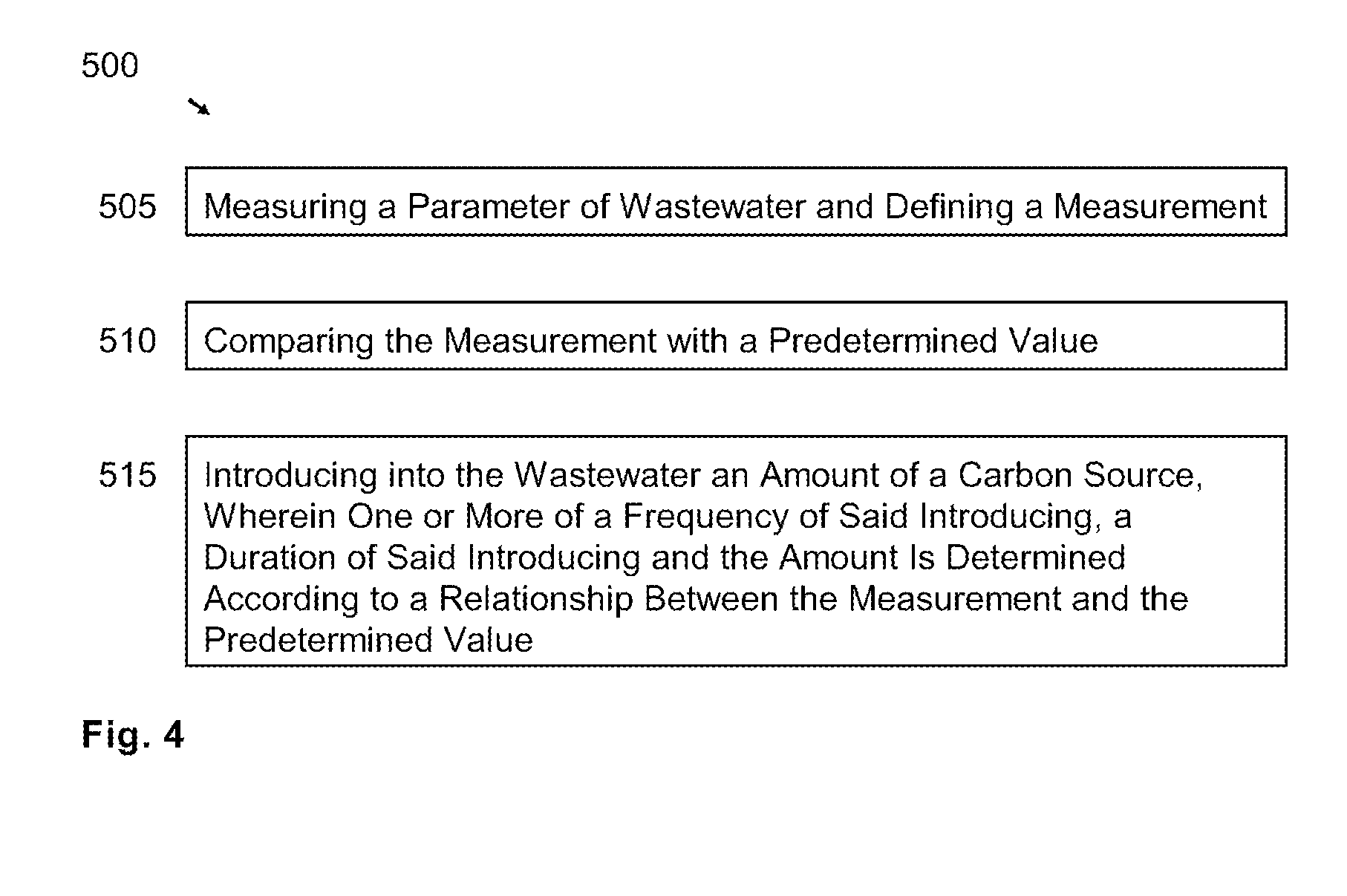

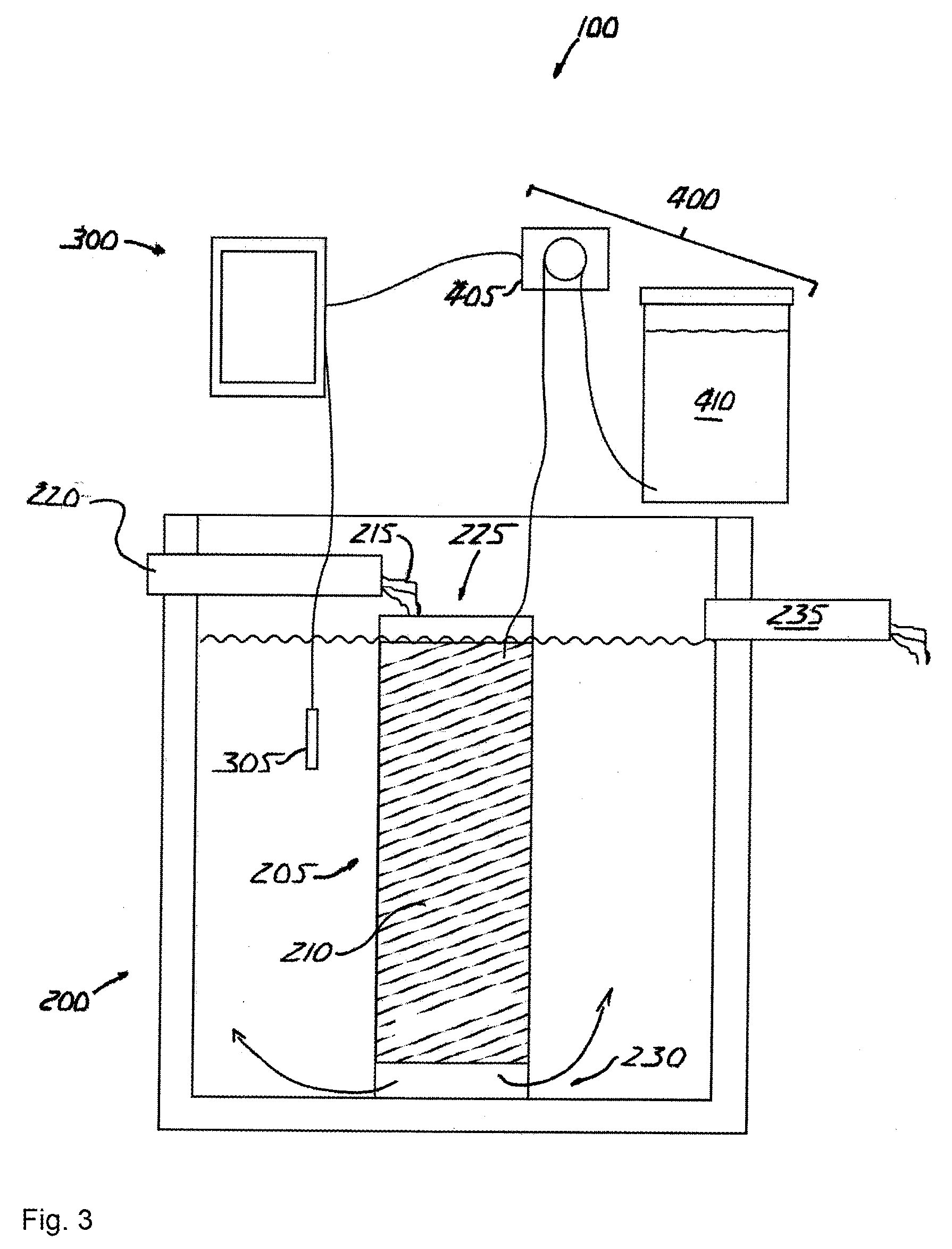

Compound for denitrifying wastewater

InactiveUS20100163484A1High activityInexpensive, dependable and effectiveEsterified saccharide compoundsSugar derivativesNitrateWastewater

Disclosed is a method of denitrifying a solution including introducing into the solution an amount of a carbon source within a duration and at a frequency so that indigenous heterotrophic bacteria deplete dissolved oxygen in the solution and decompose oxygen from nitrate in the solution to obtain its combined oxygen. Related apparatuses and compounds also are disclosed.

Owner:HOOT AEROBIC SYST

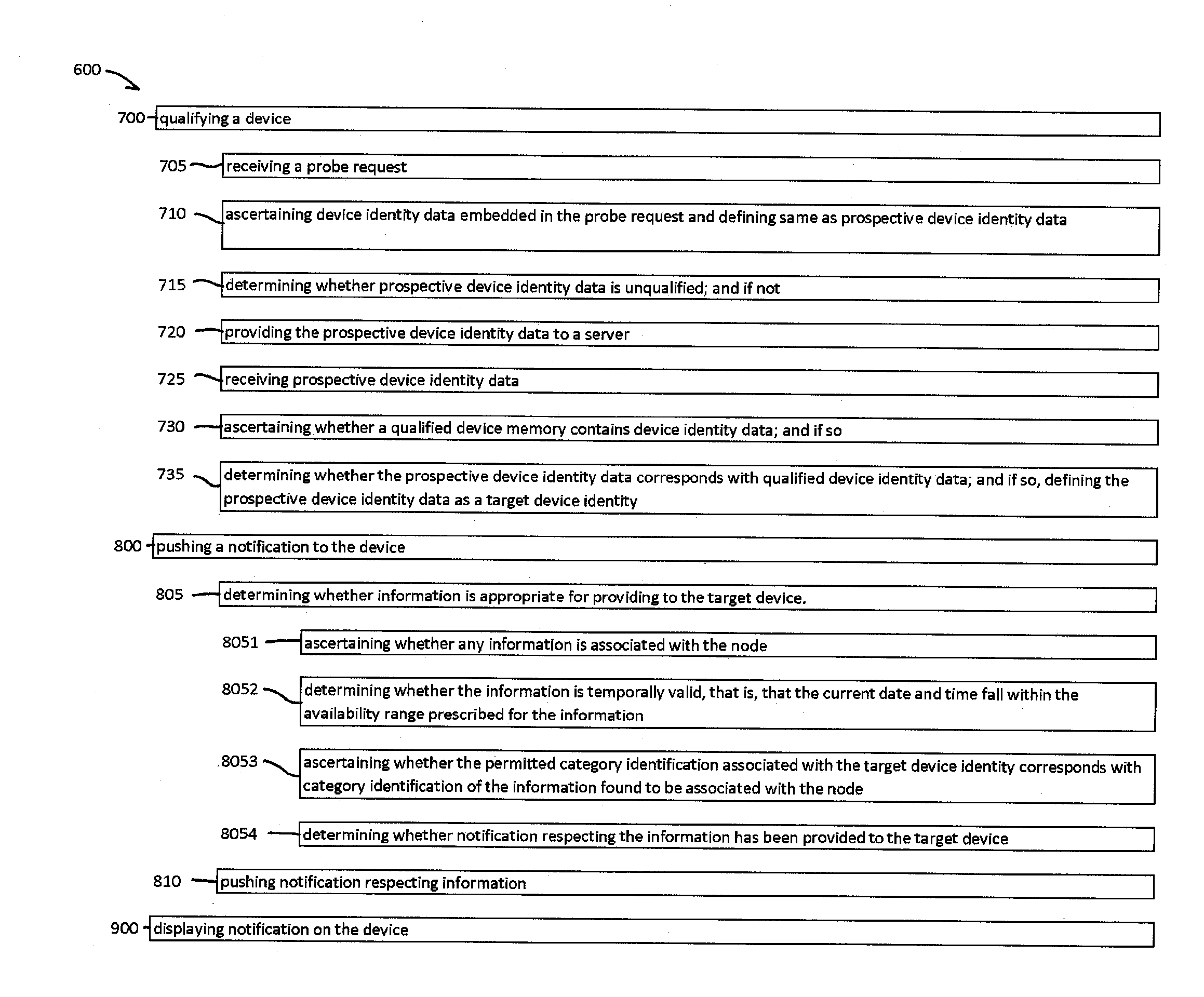

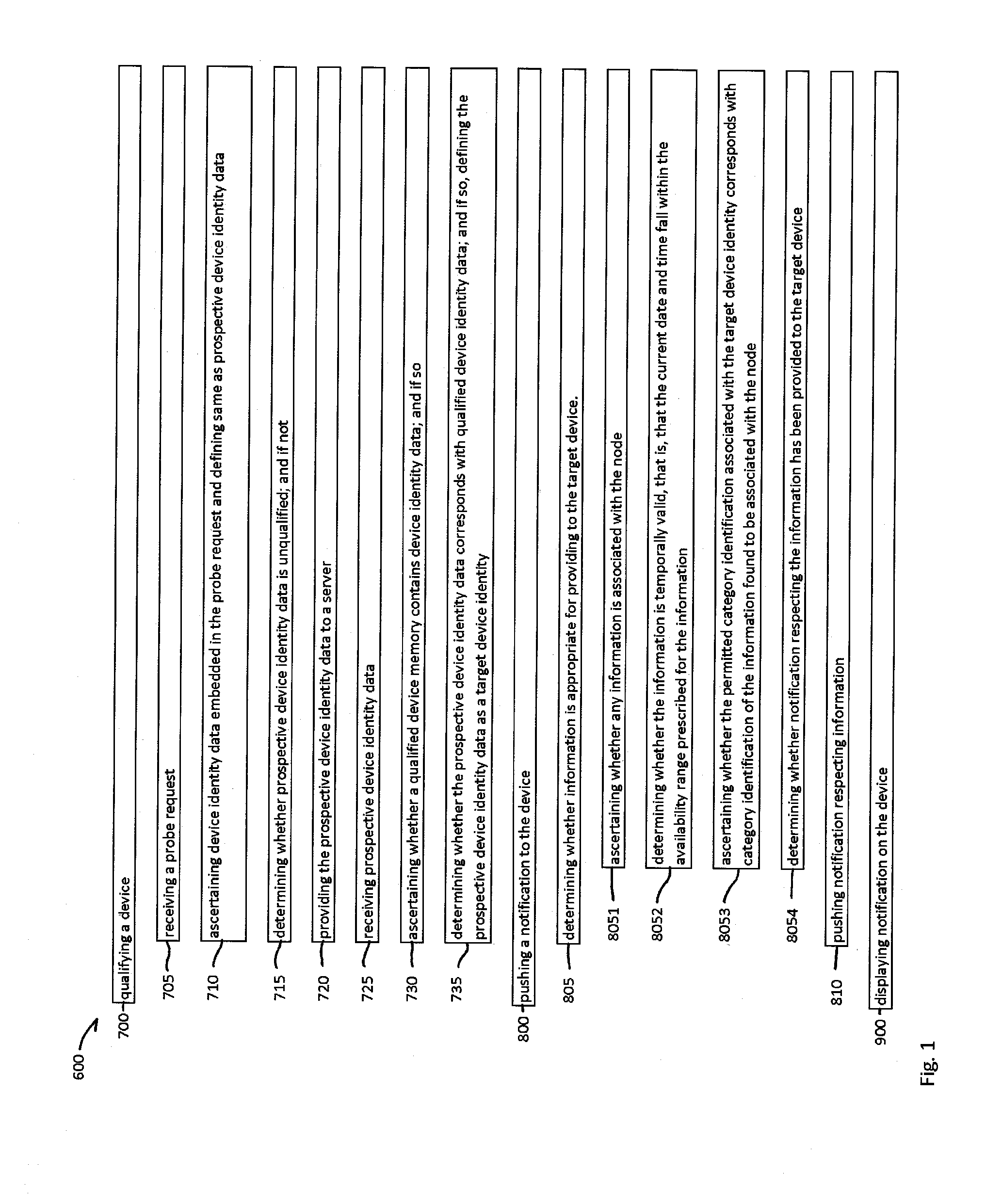

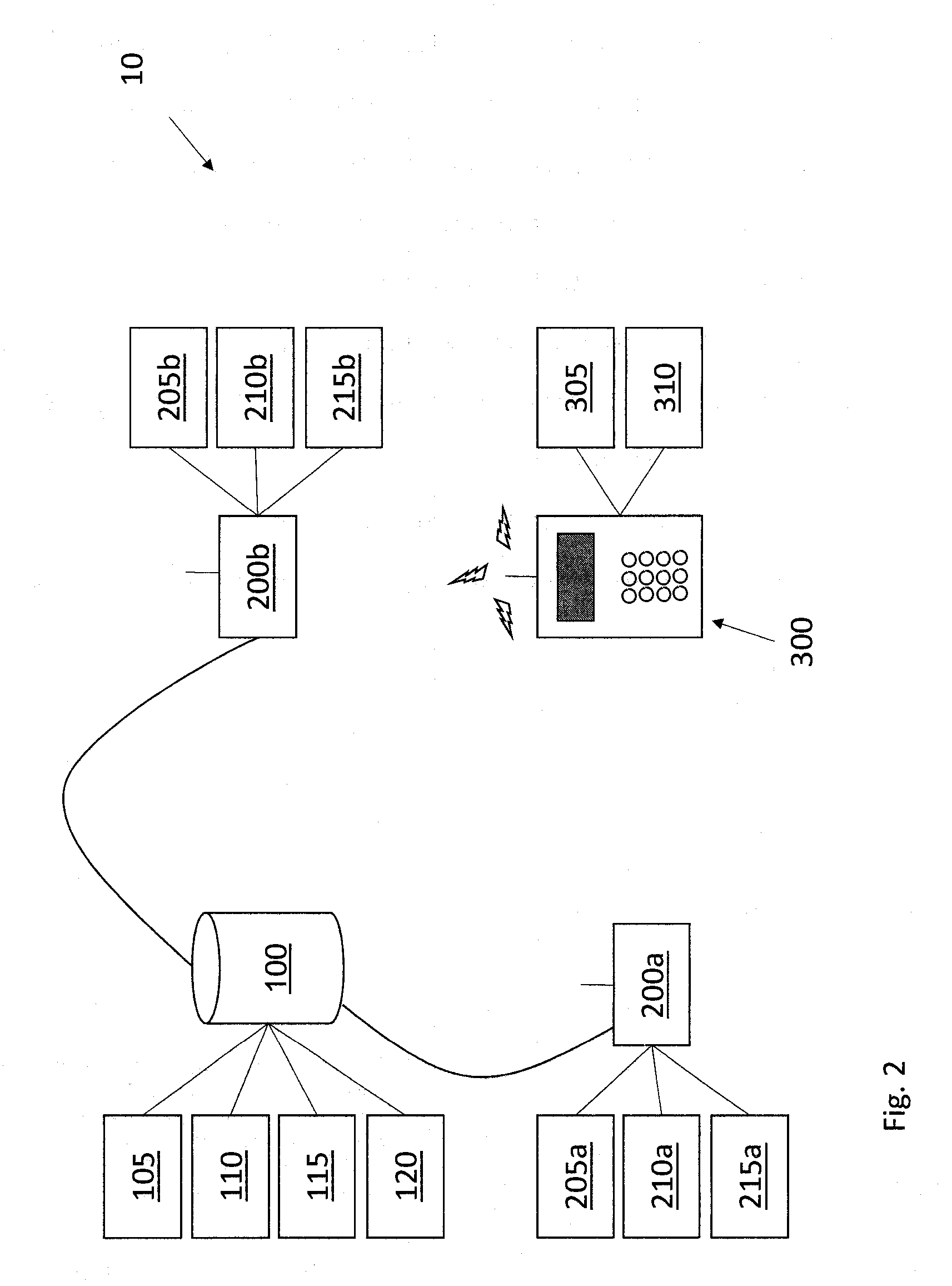

System, Method and Apparatuses for Qualifying Mobile Devices and Providing Information Thereto

InactiveUS20150220993A1Inexpensive, dependable and effectiveTransmissionMarketingInternet privacyMobile device

Disclosed is a method of qualifying mobile devices and providing information thereto including: receiving a probe request; ascertaining mobile device identity data embedded in the probe request and defining a prospective device identity data; determining whether the prospective device identity data are unqualified; and if not, providing the prospective device identity data to a push server. Apparatuses and systems for performing the method are disclosed as well.

Owner:BENTE ROBERT

Knock-down roof curb

InactiveUS20060070315A1Inexpensive, dependable and effectiveBuilding roofsRoof coveringEngineeringCorrosion resistant

A standardized, corrosion-resistant roof curb that can be shipped in a disassembled state, which an installer may assemble, size, locate and configure to provide an appropriate roof slope on any roof without welding, includes a panel and an extrusion configured to receive the panel, wherein the panel is trimmed according to the pitch of the roof. Methods of making and installing the roof curb also are disclosed.

Owner:BUTLER MFG

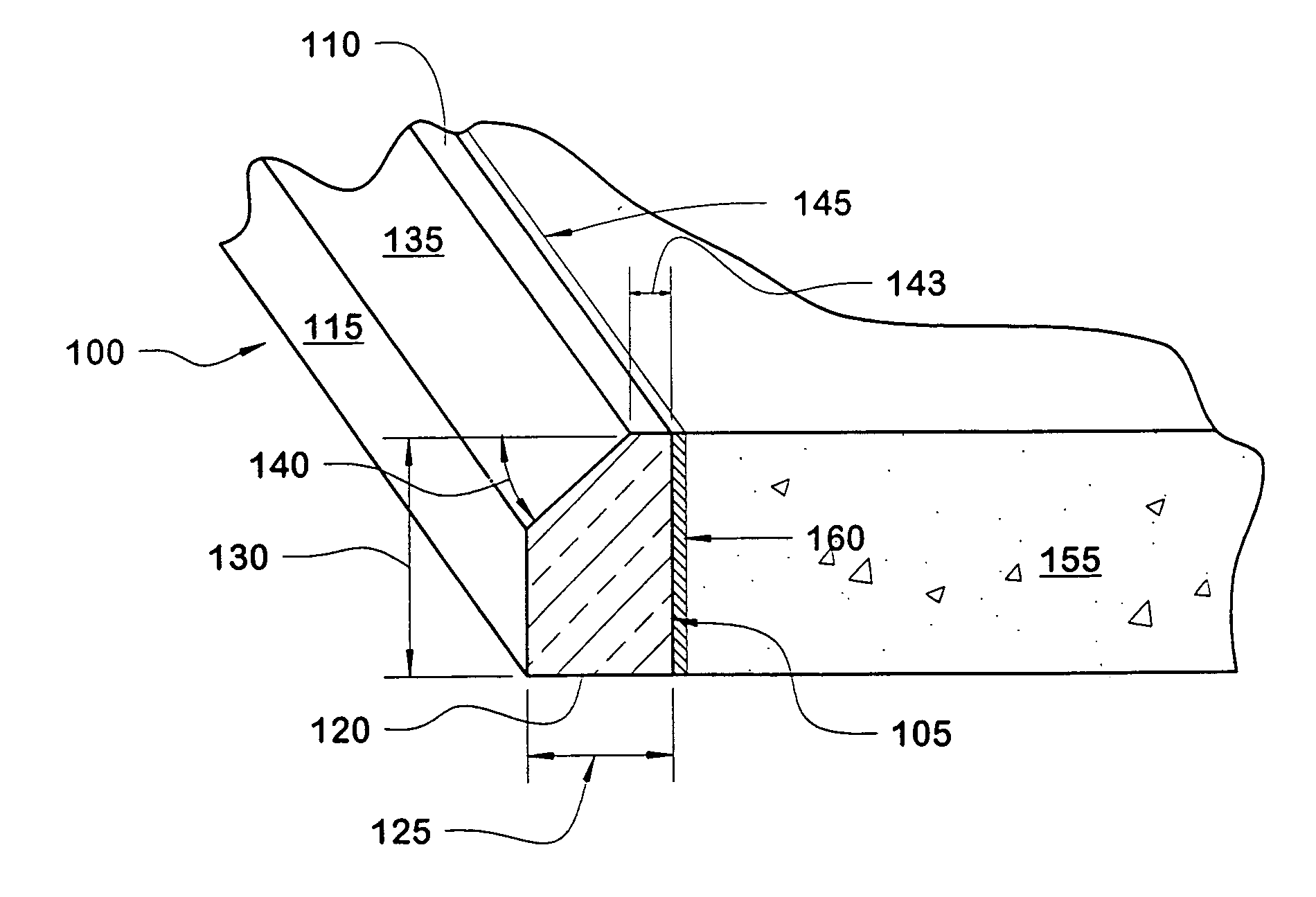

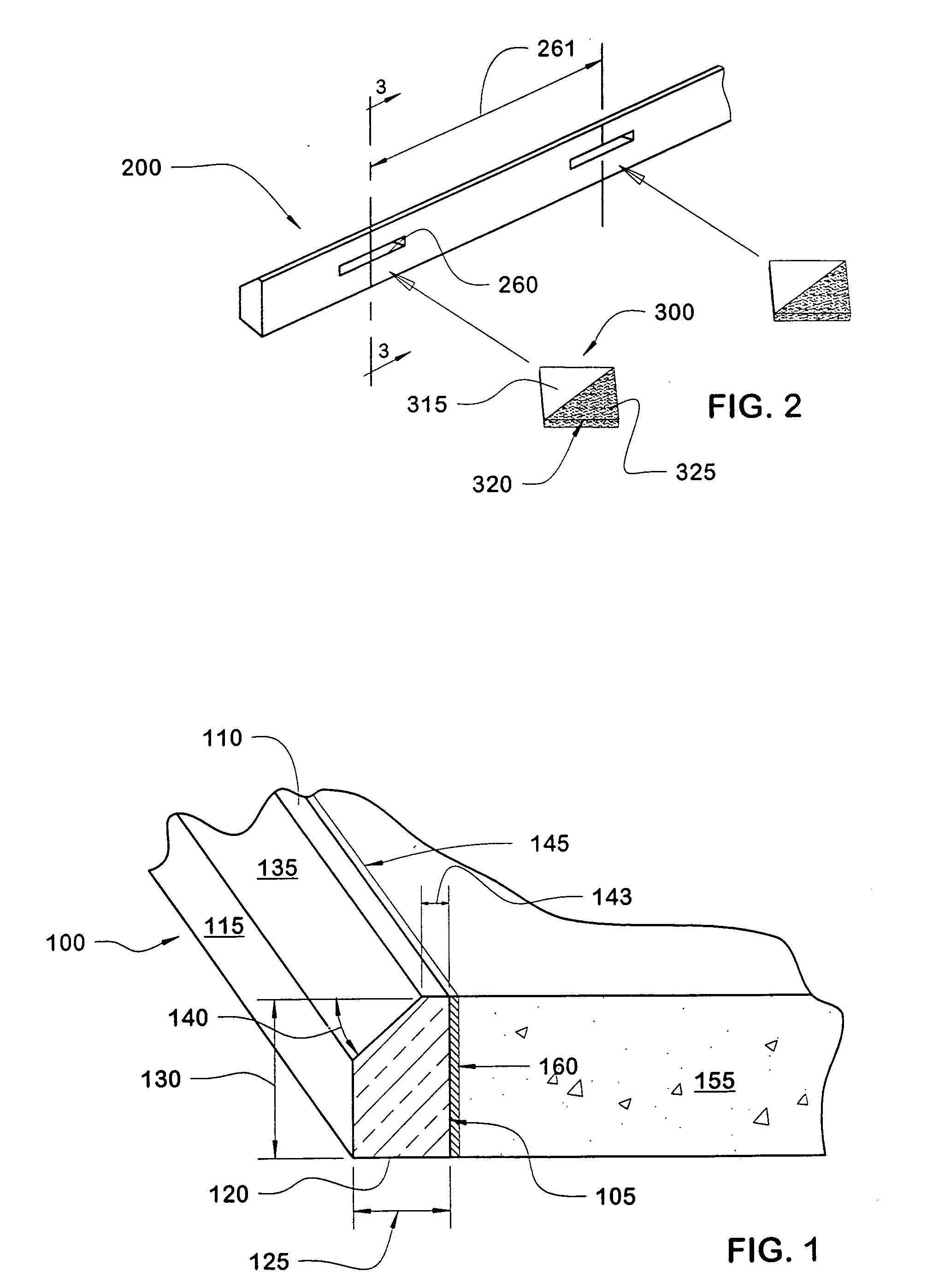

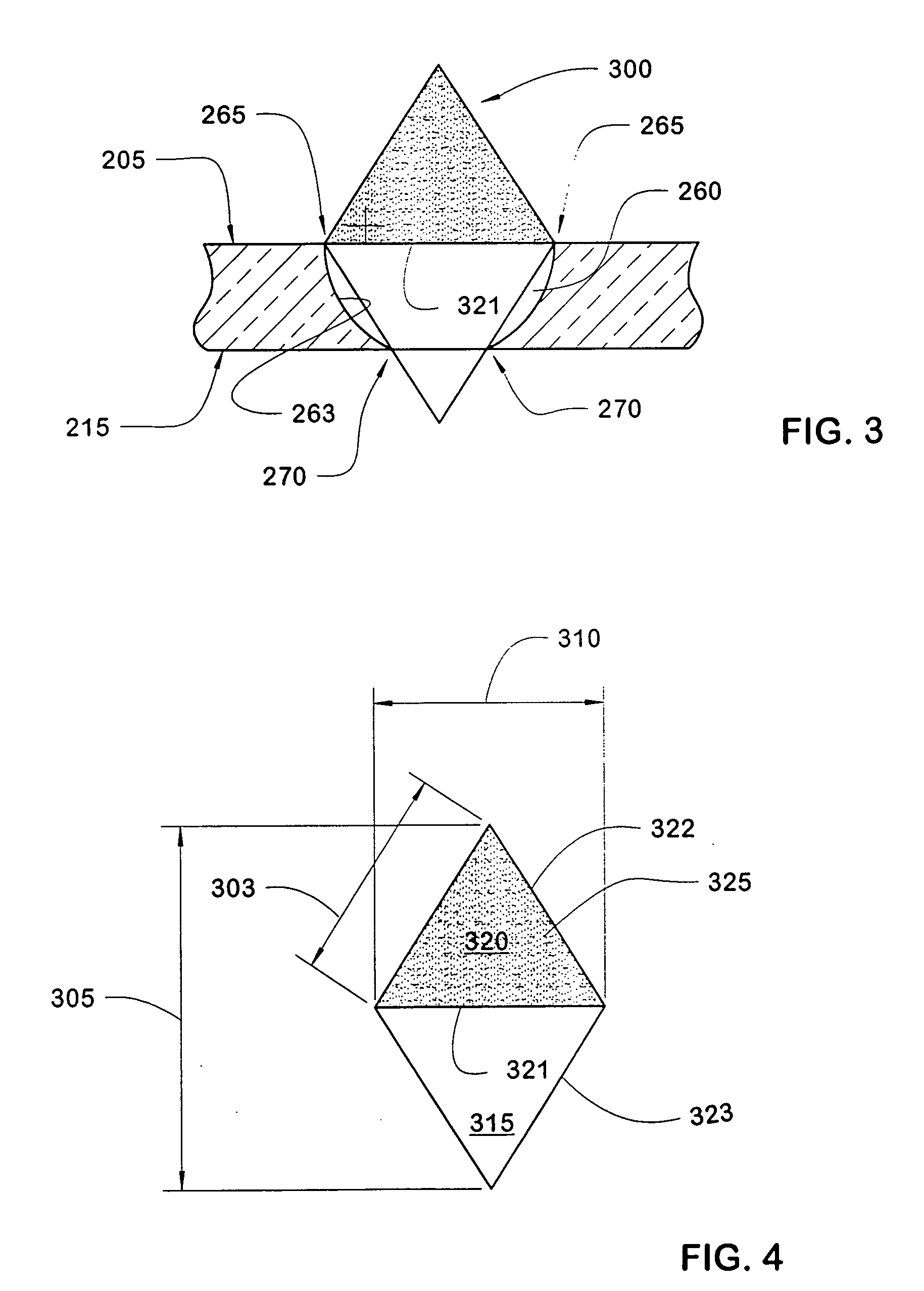

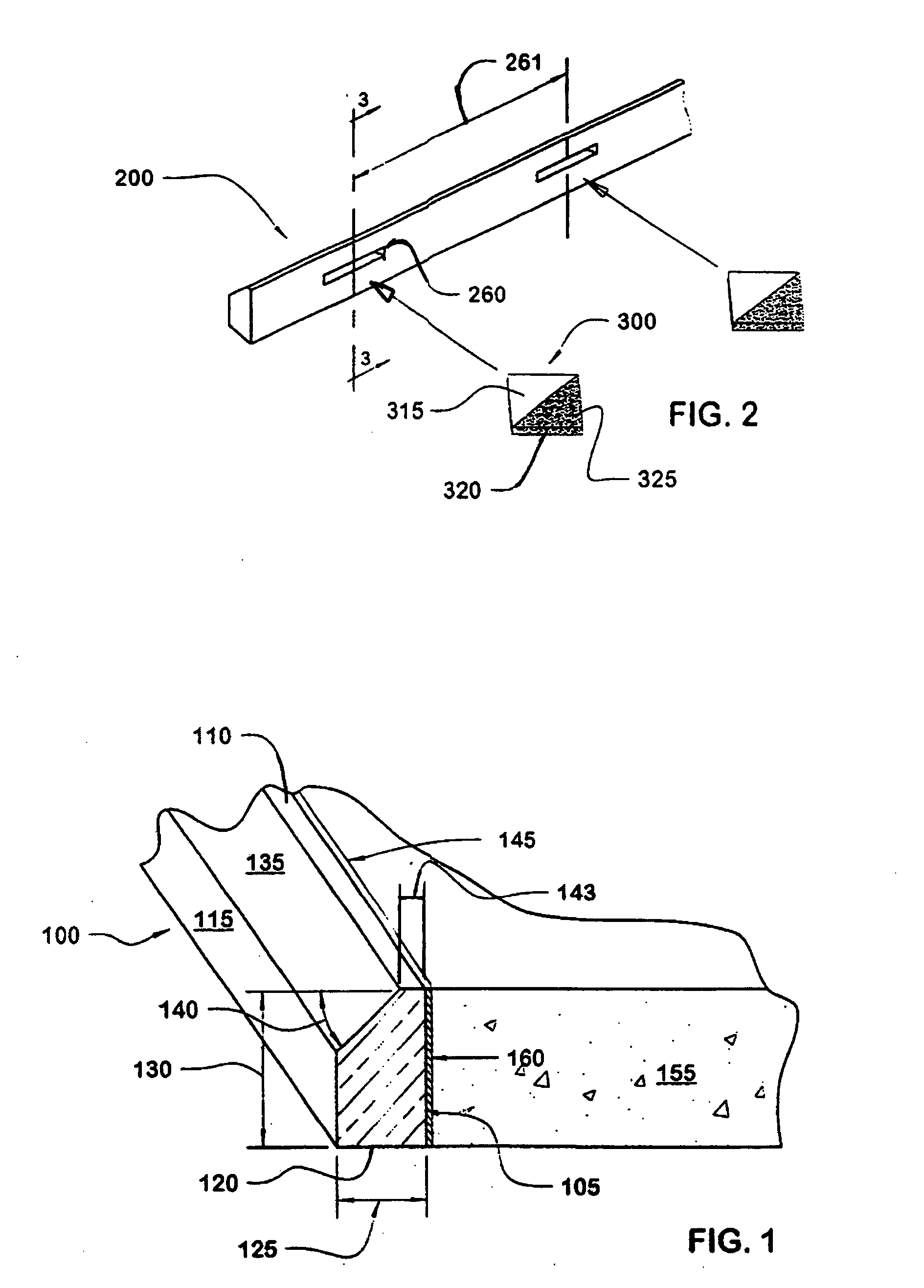

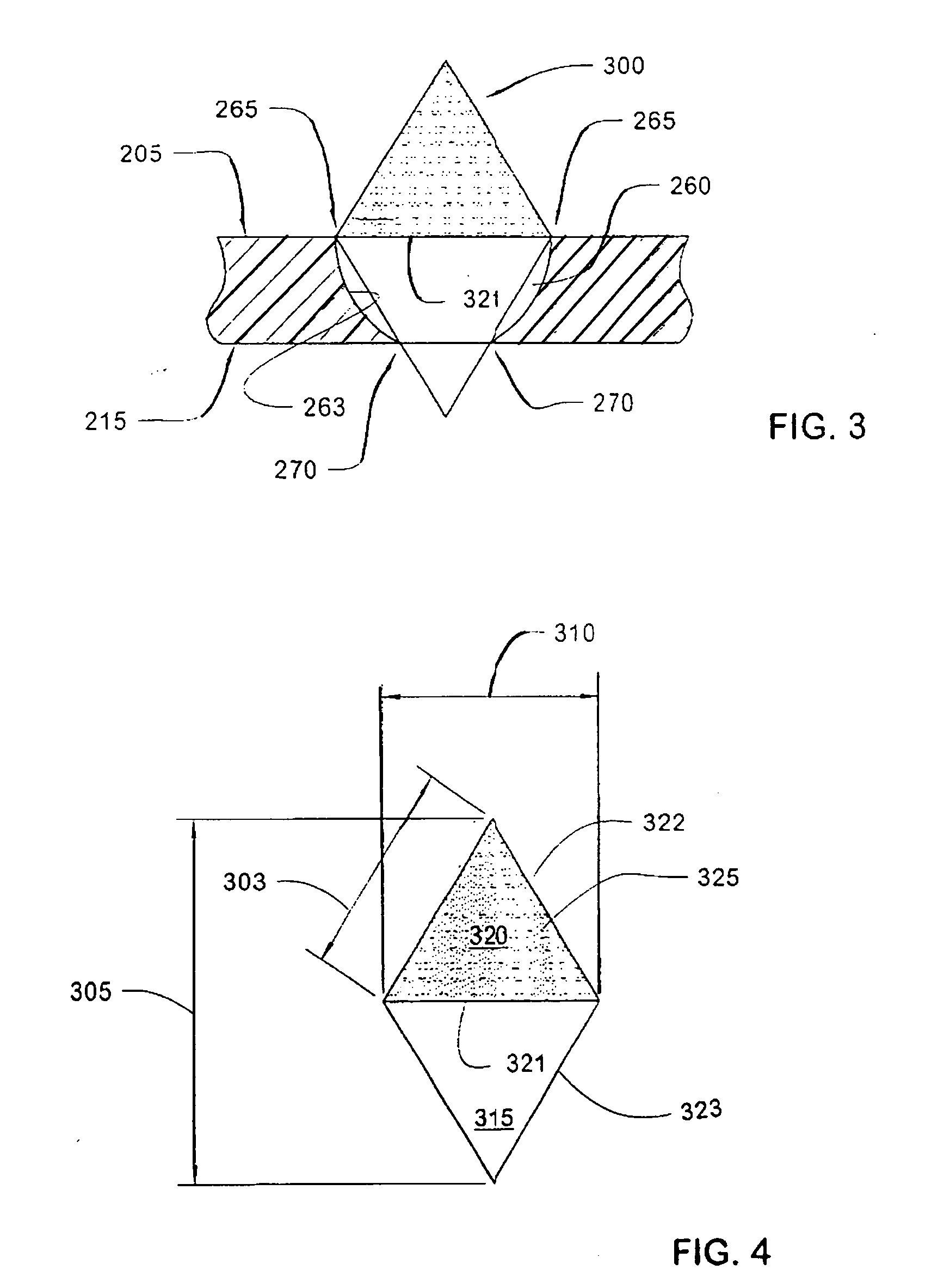

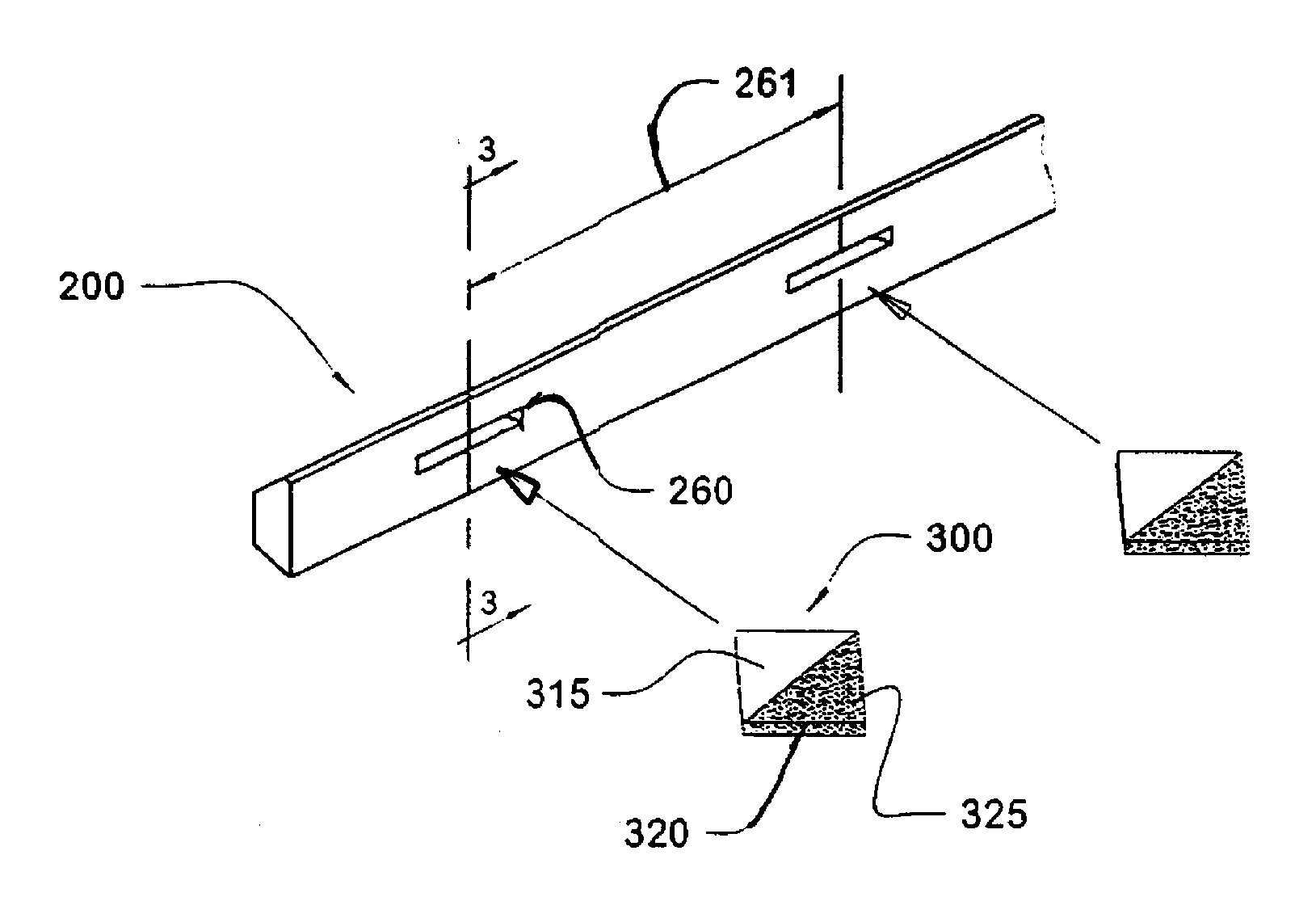

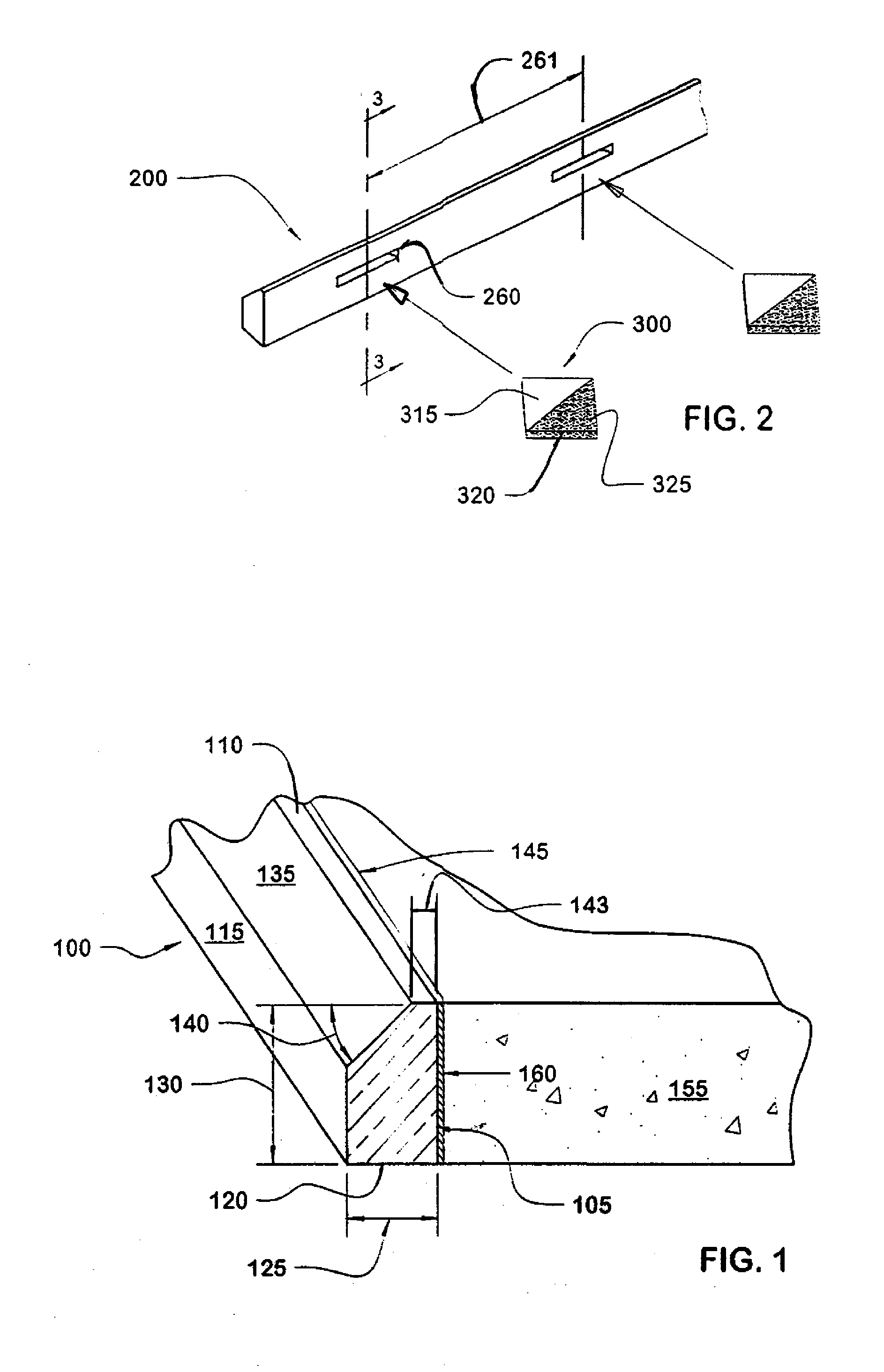

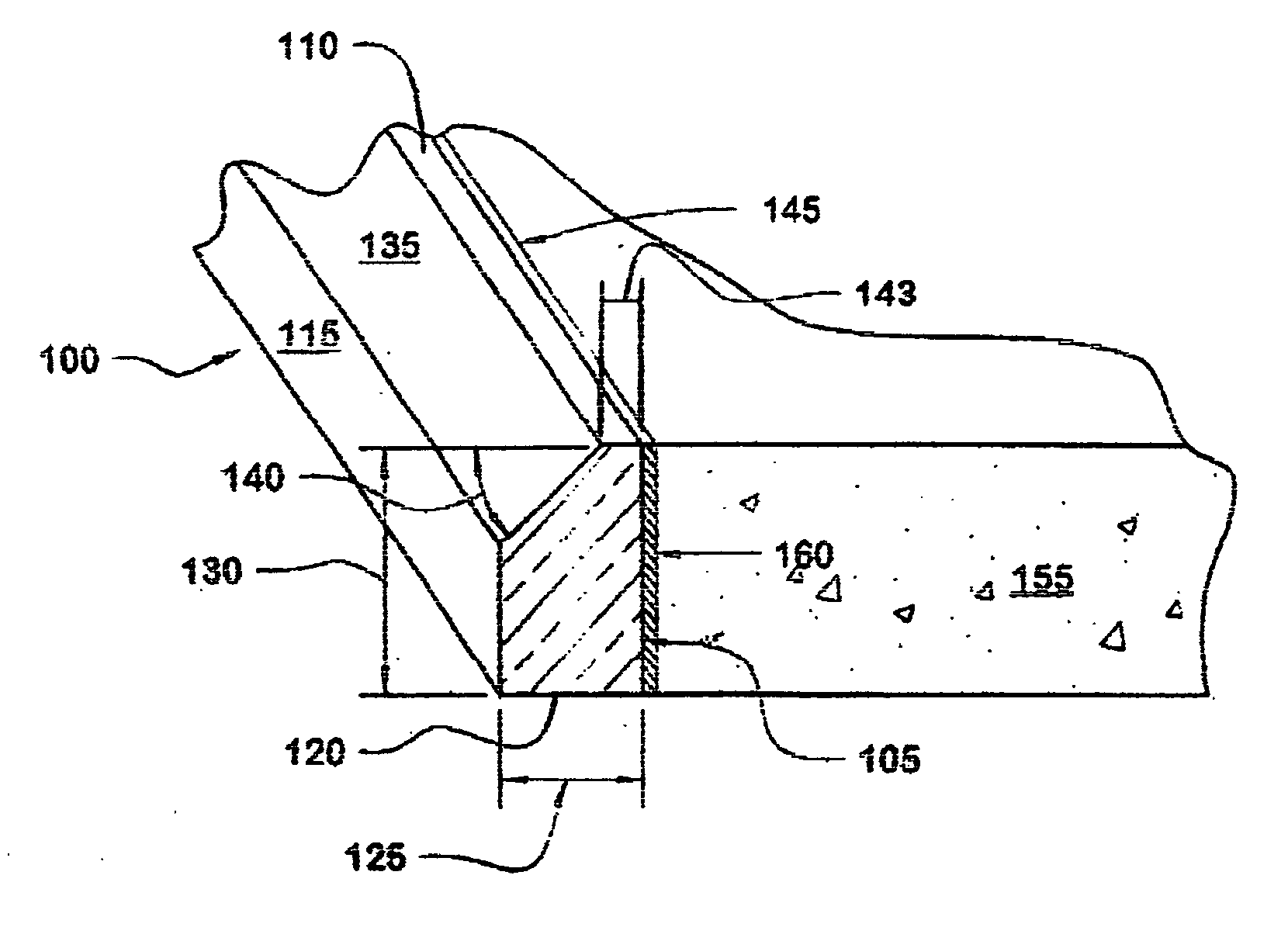

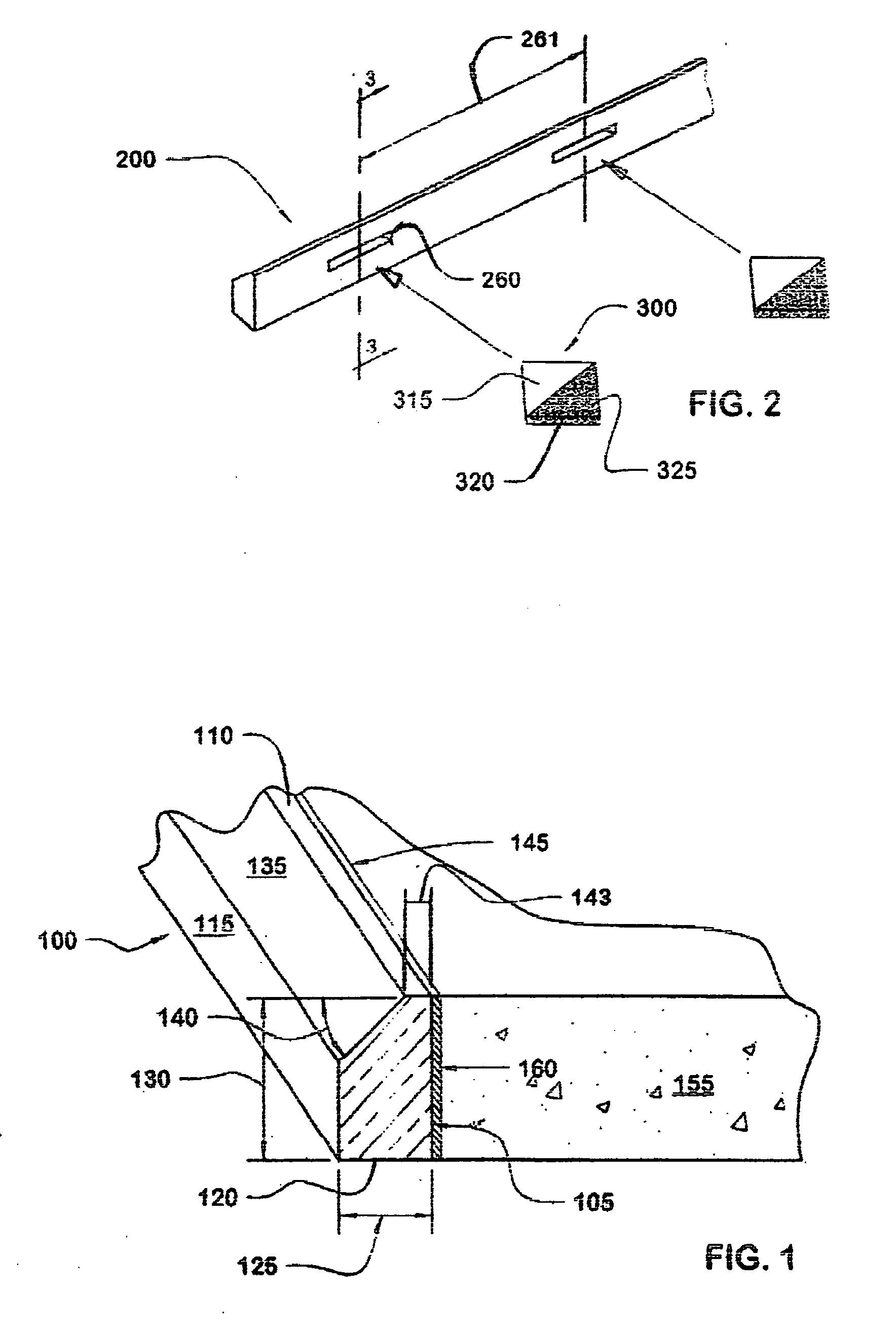

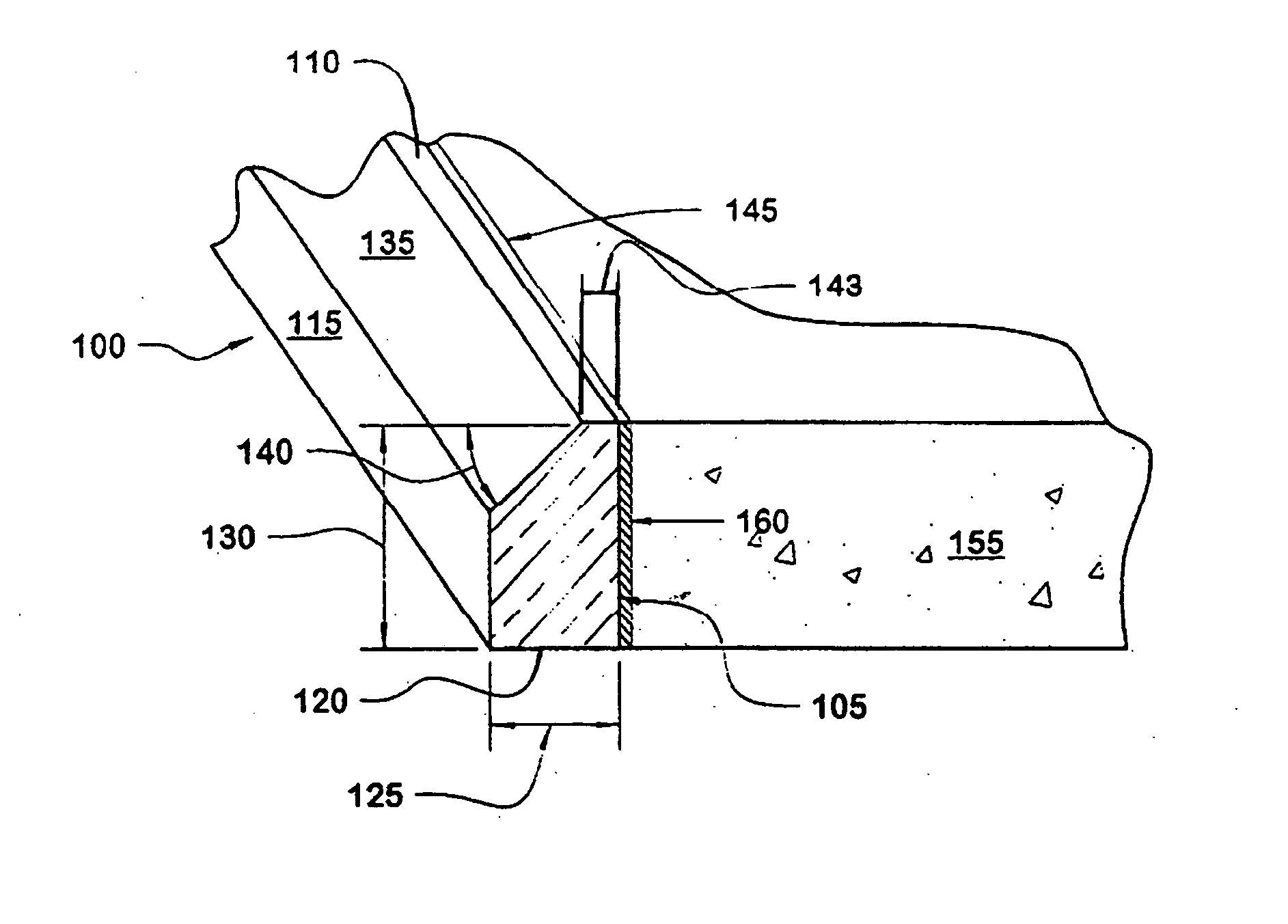

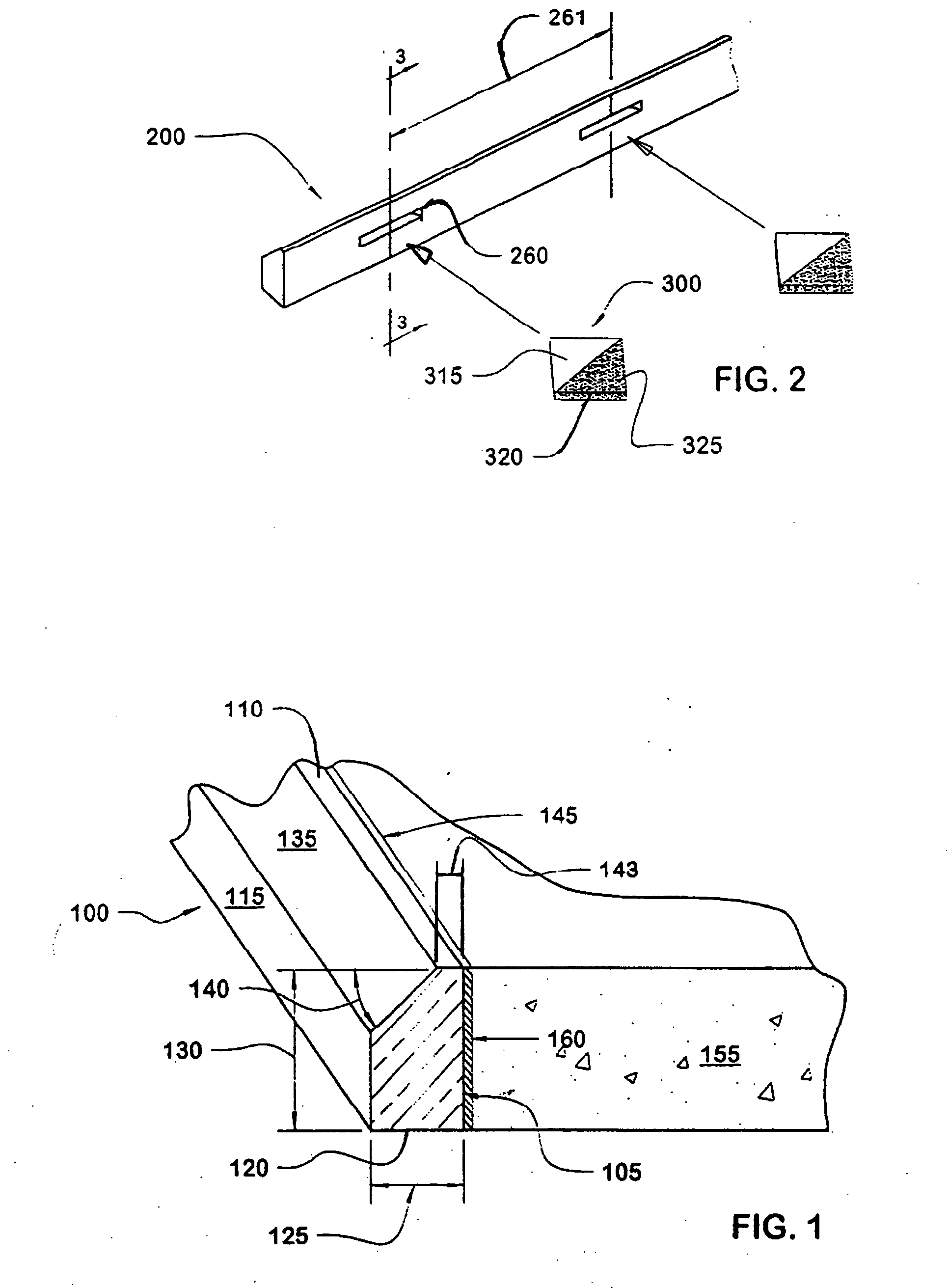

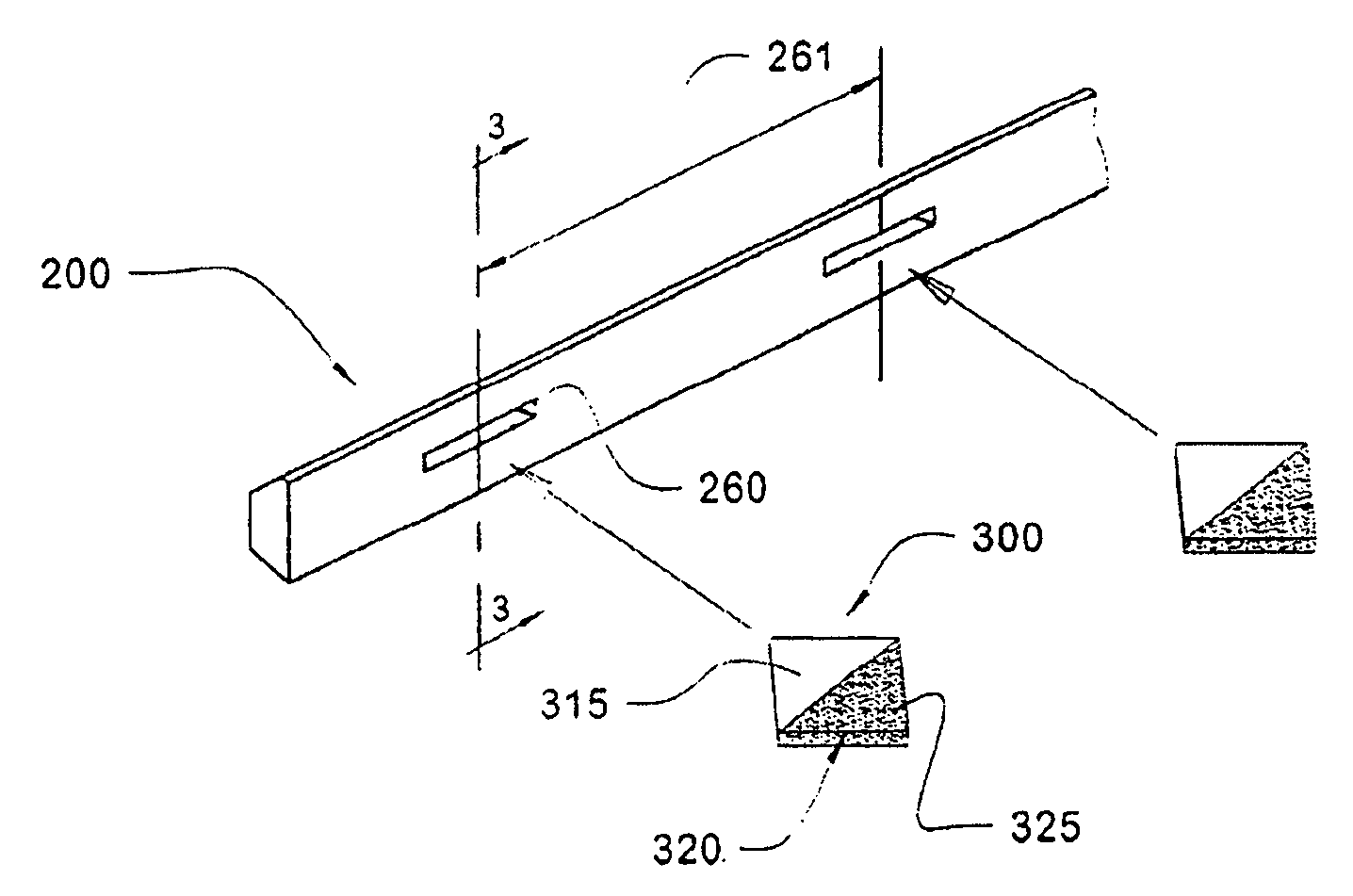

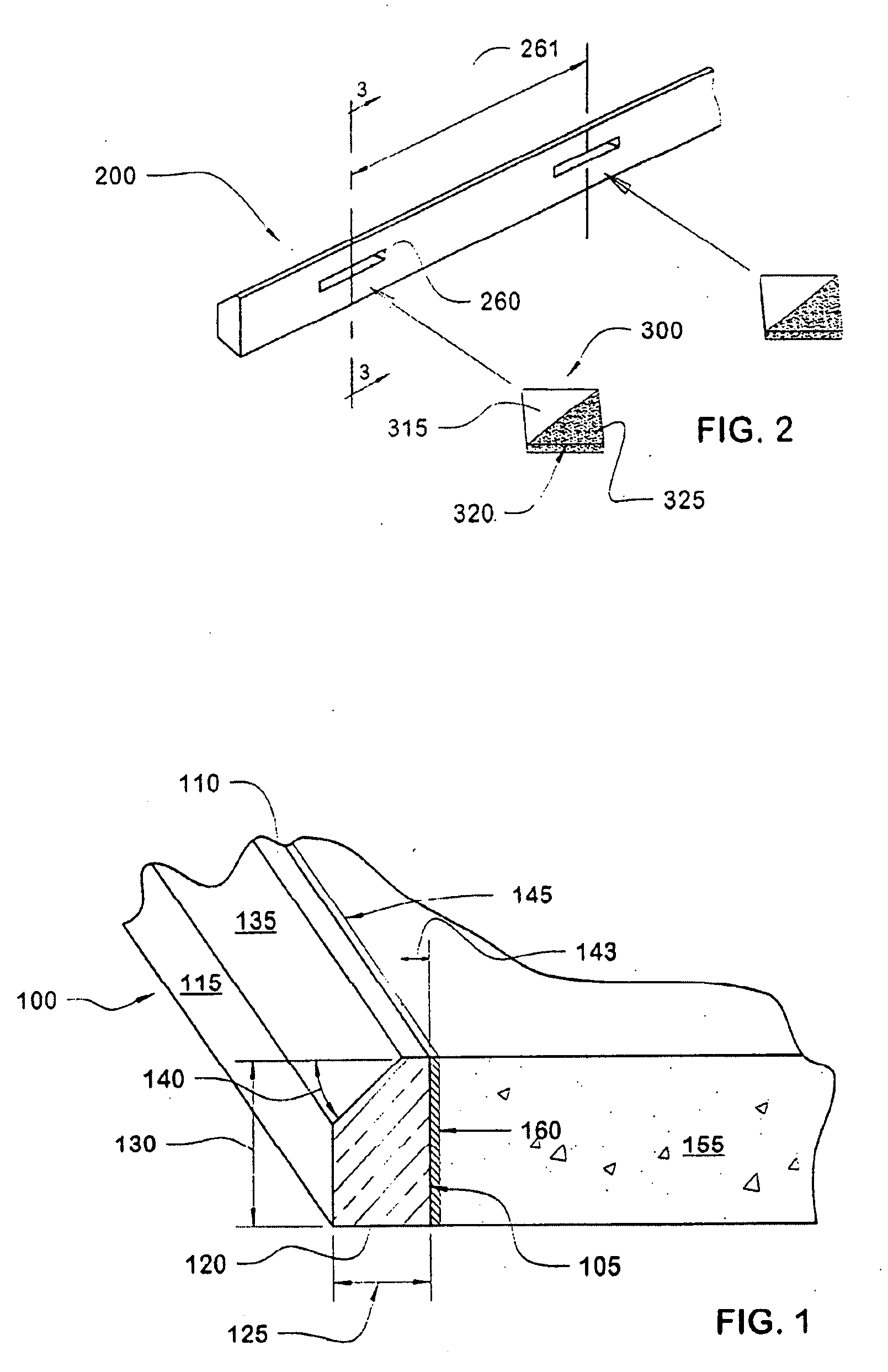

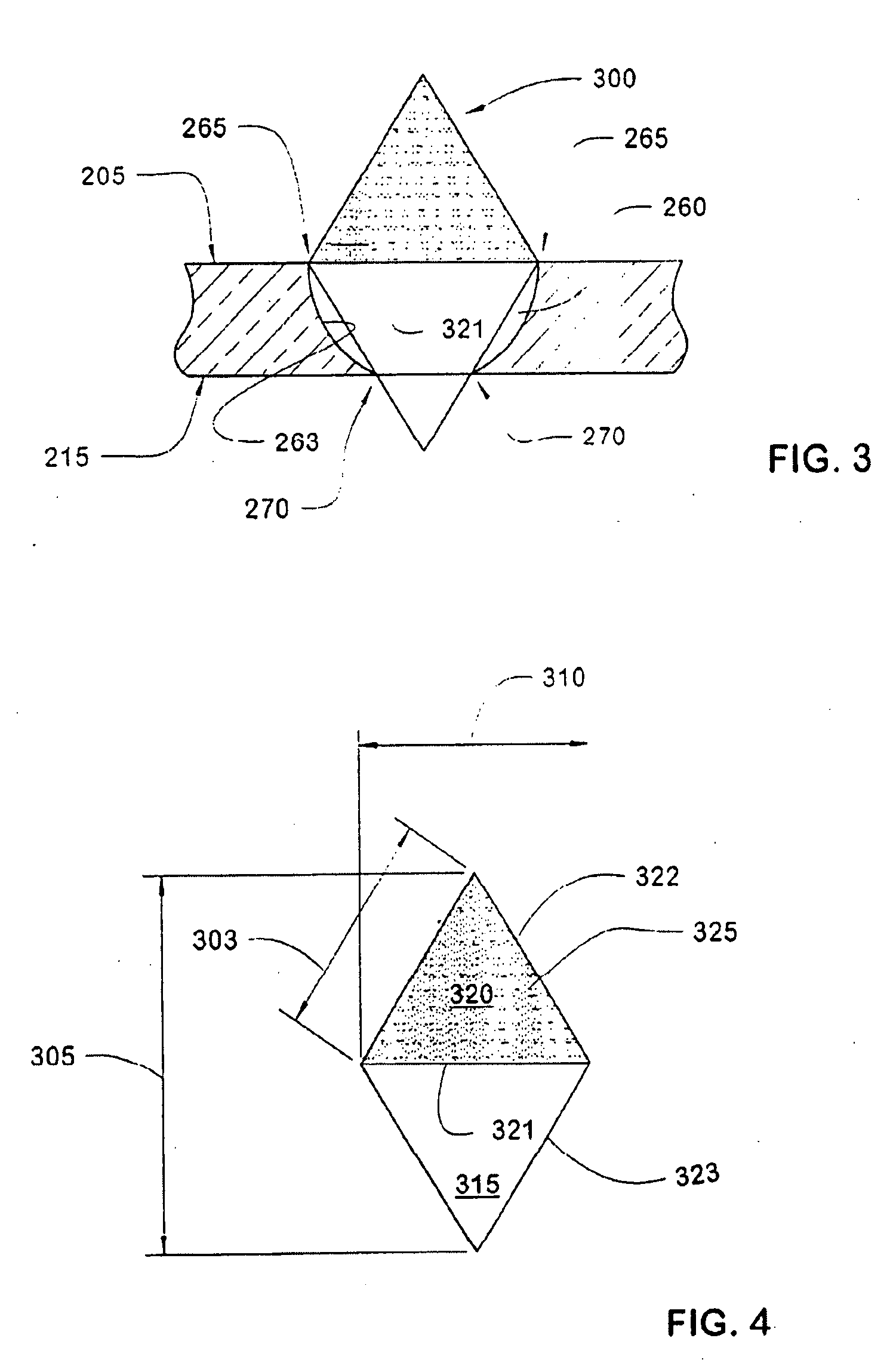

Method of forming concrete and an apparatus for transferring loads between concrete slabs

ActiveUS20060177267A1Inexpensive, dependable and effectiveStrutsSingle unit pavingsEngineeringMechanical engineering

Owner:E Z FORM

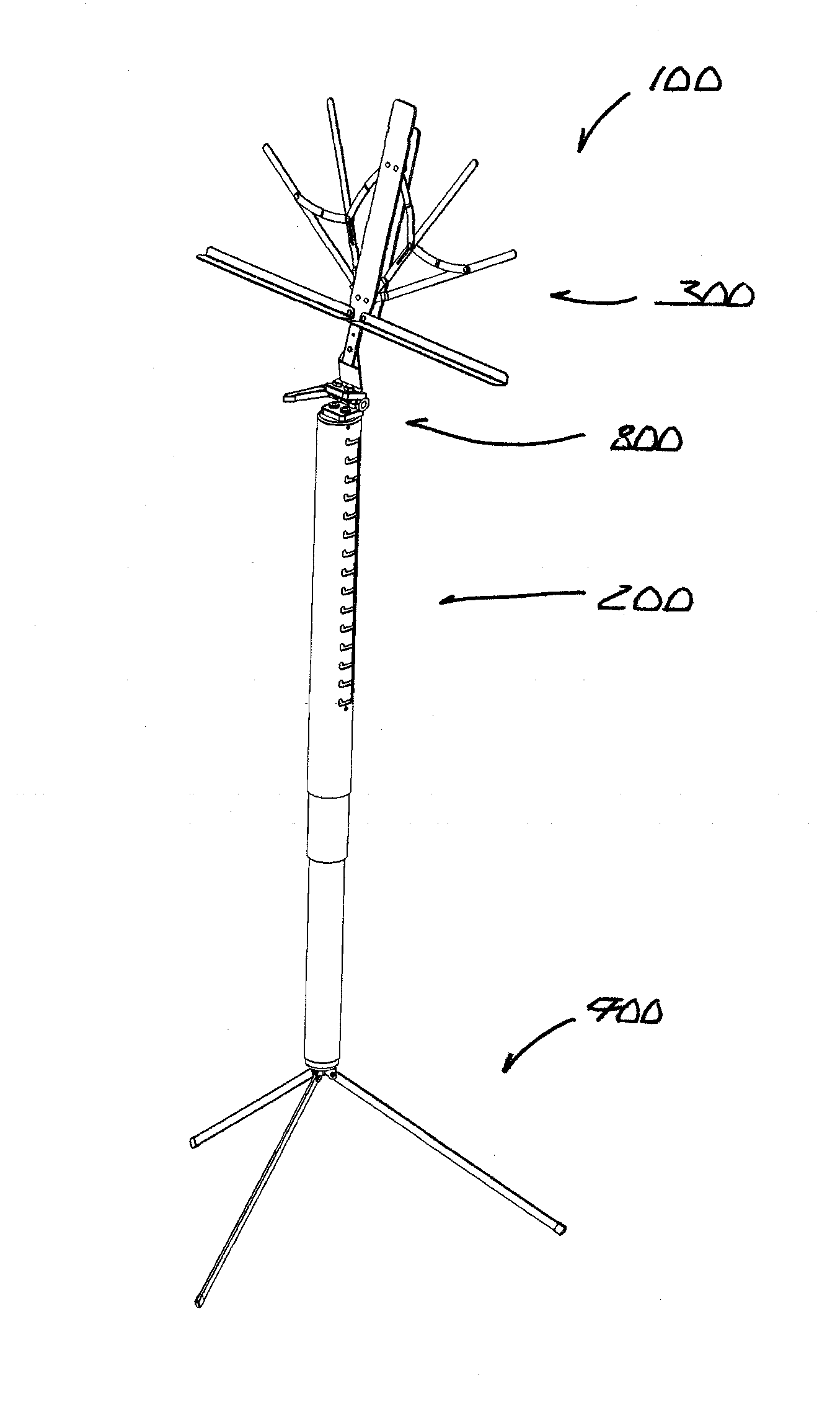

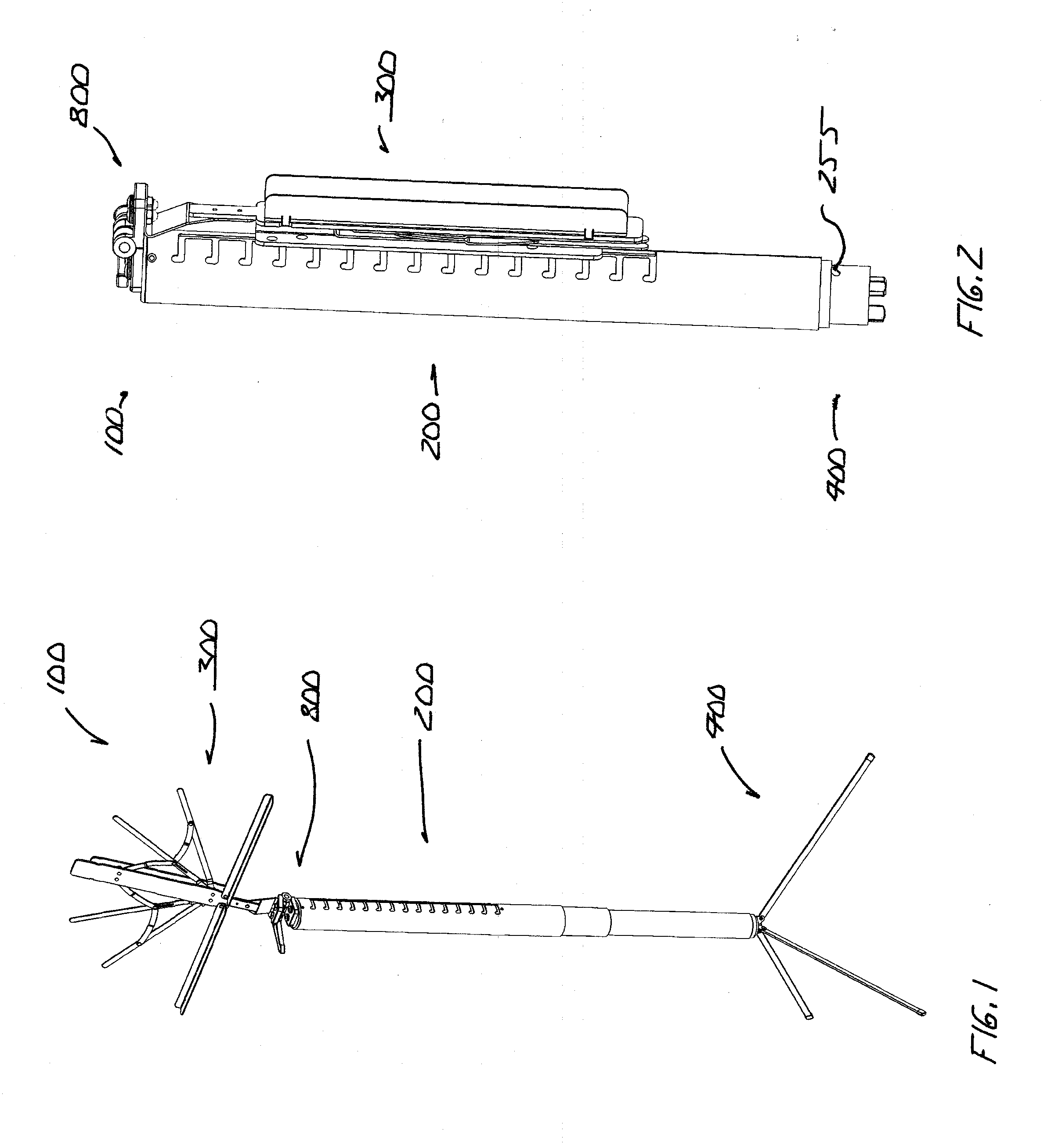

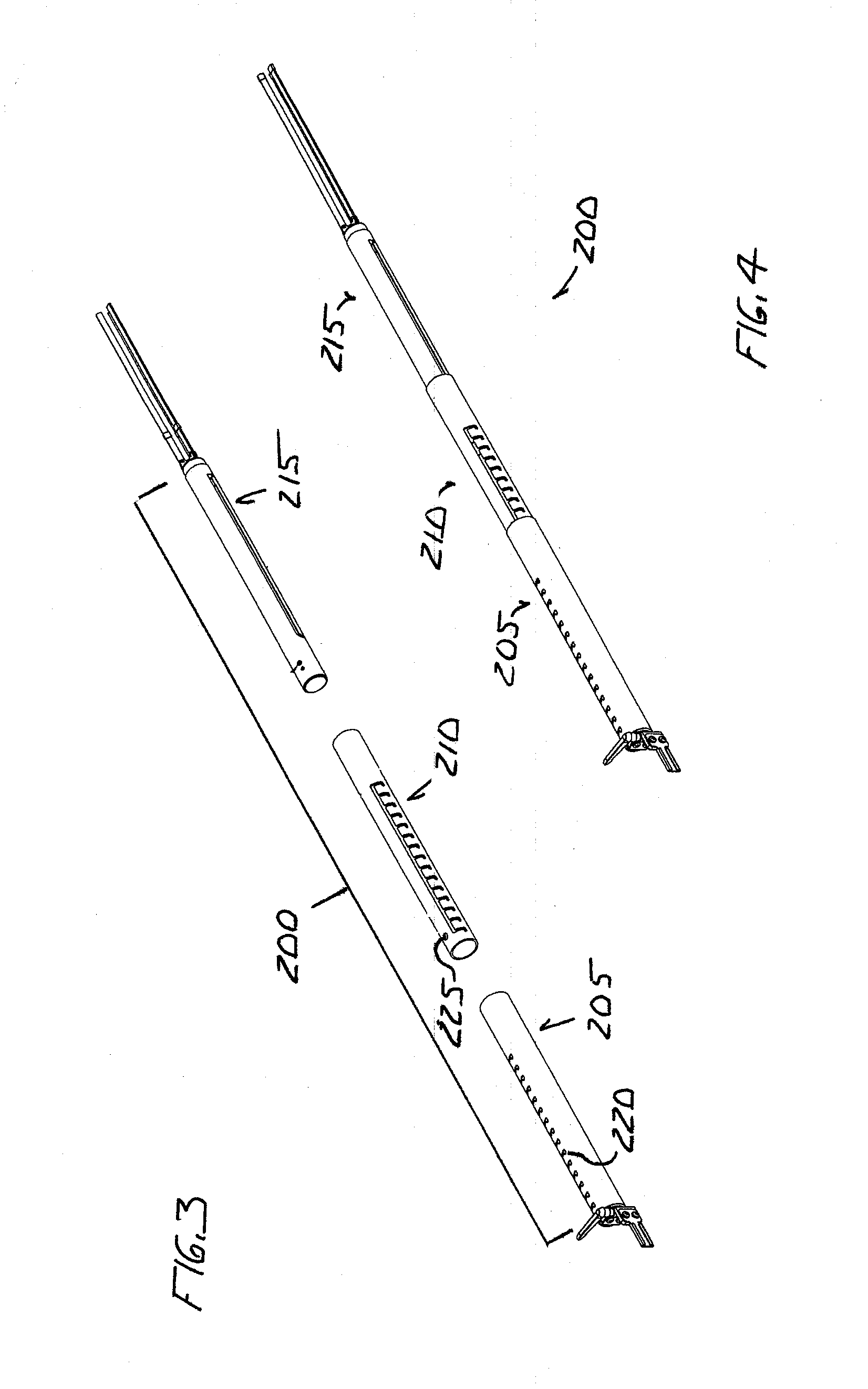

Music Stand and Rack, Pedestal and Hinge Therefor

InactiveUS20140252196A1Inhibition of translationInexpensive, dependable and effectivePulpitsLecternsEngineeringMusic stand

Disclosed is a music stand that includes a column with a first segment having at least one positional slot and a second segment having a protrusion configured to be received in each of the positional slots. When the protrusion is received in one of the positional slots, the protrusion can prevent relative translation of the first segment and the second segment in at least one direction, thereby defining a unique extension. The music stand also includes a support selected from a rack and a pedestal that is fixed relative to said column.

Owner:ABADY JASON

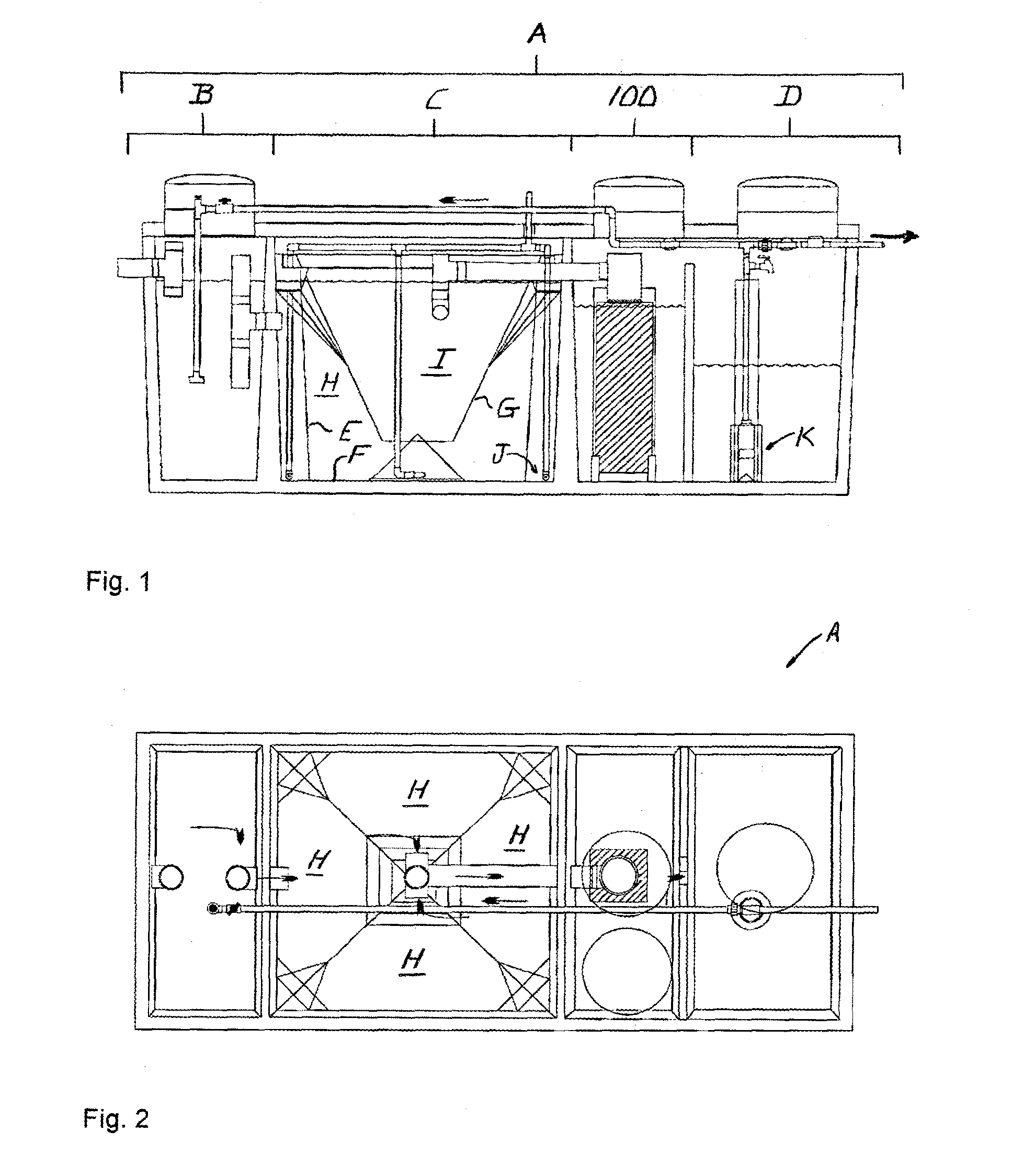

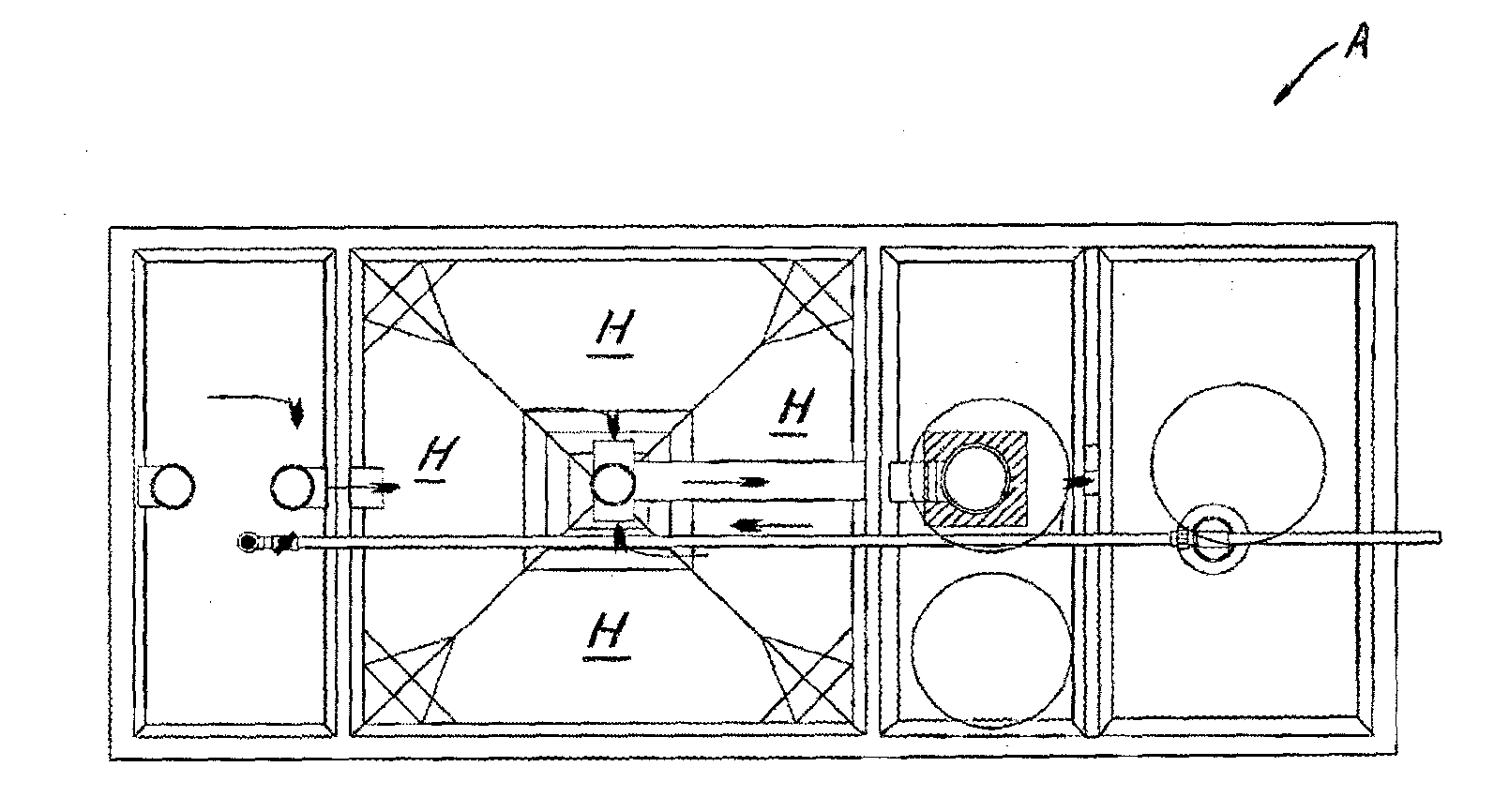

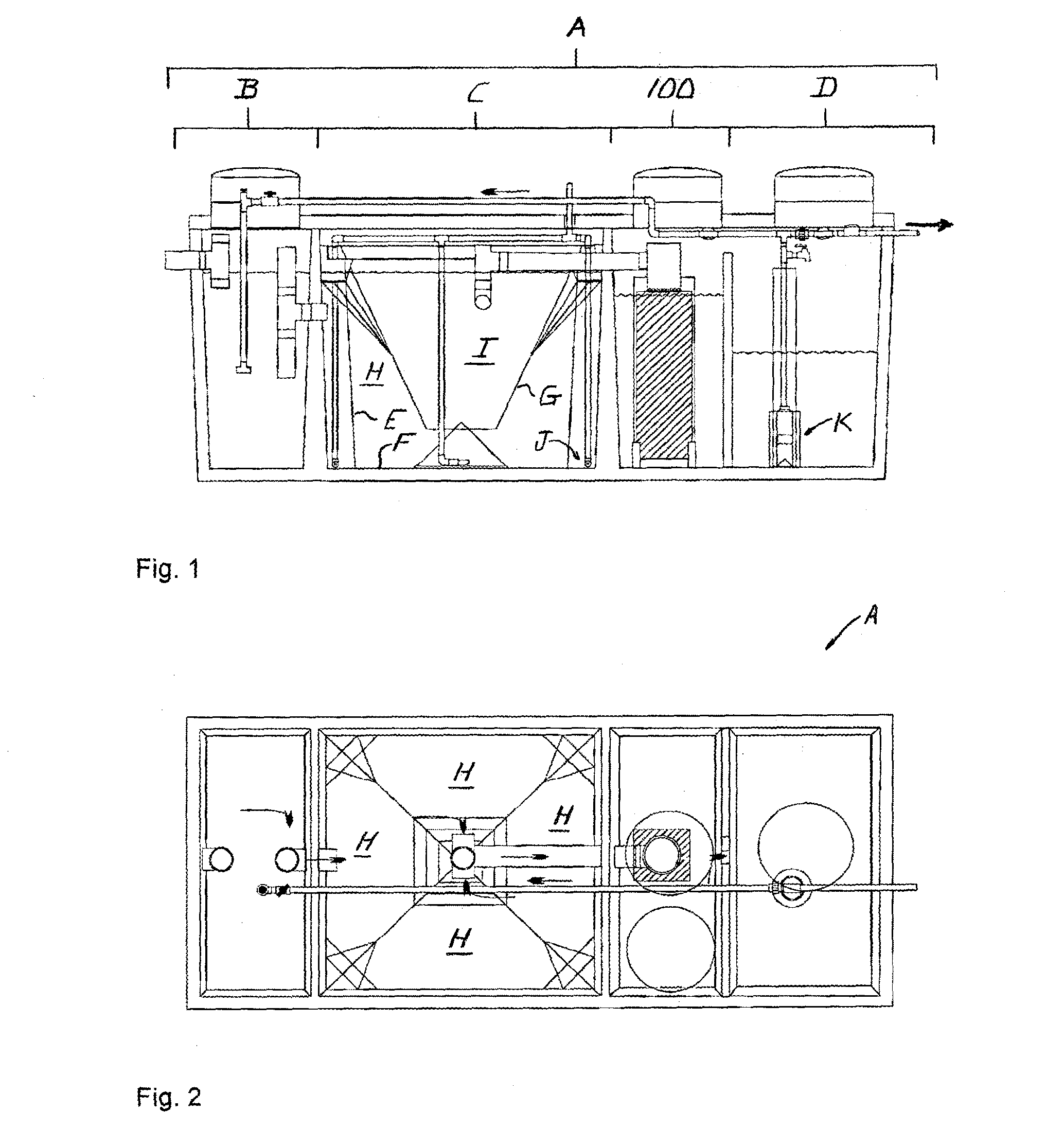

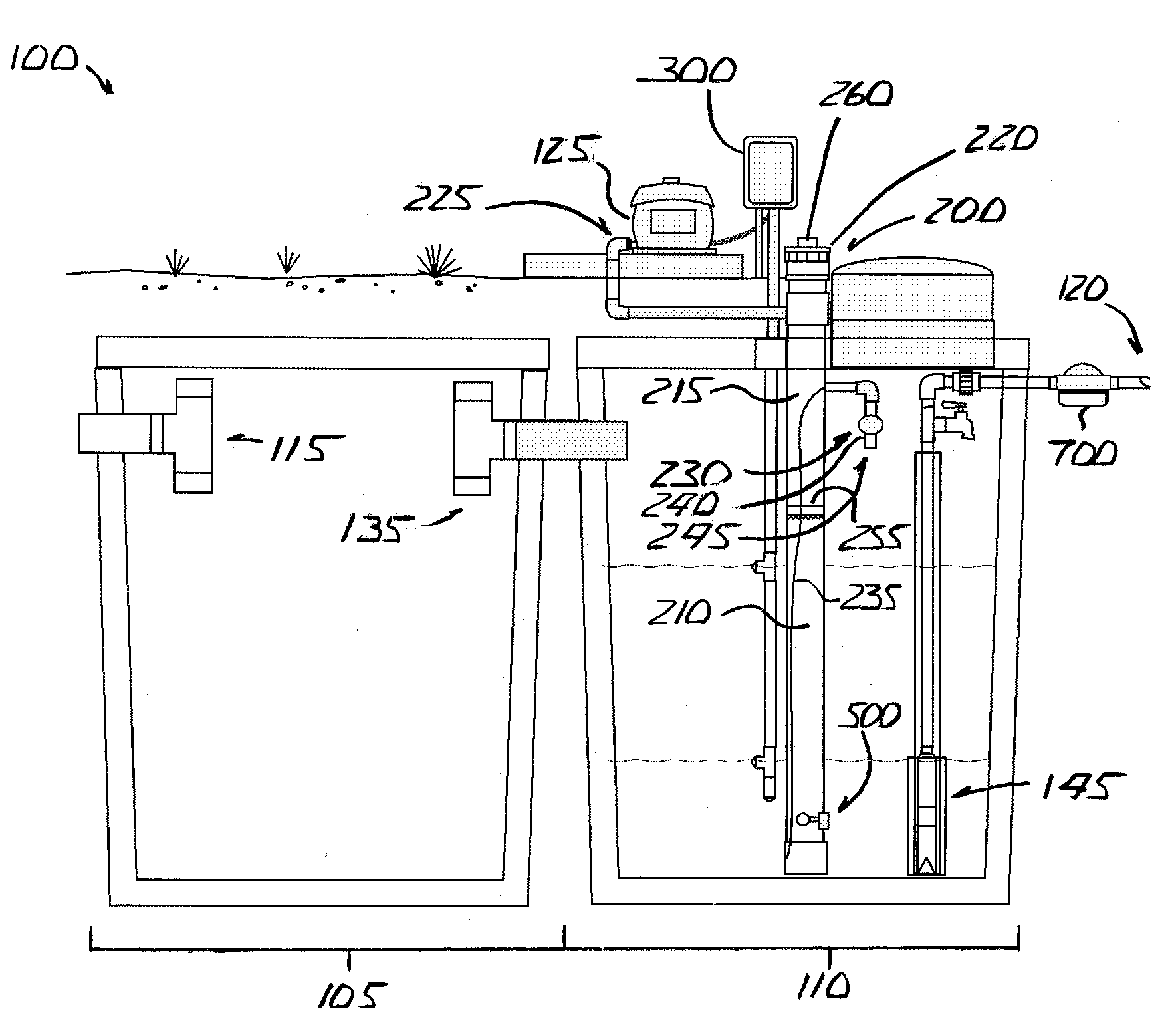

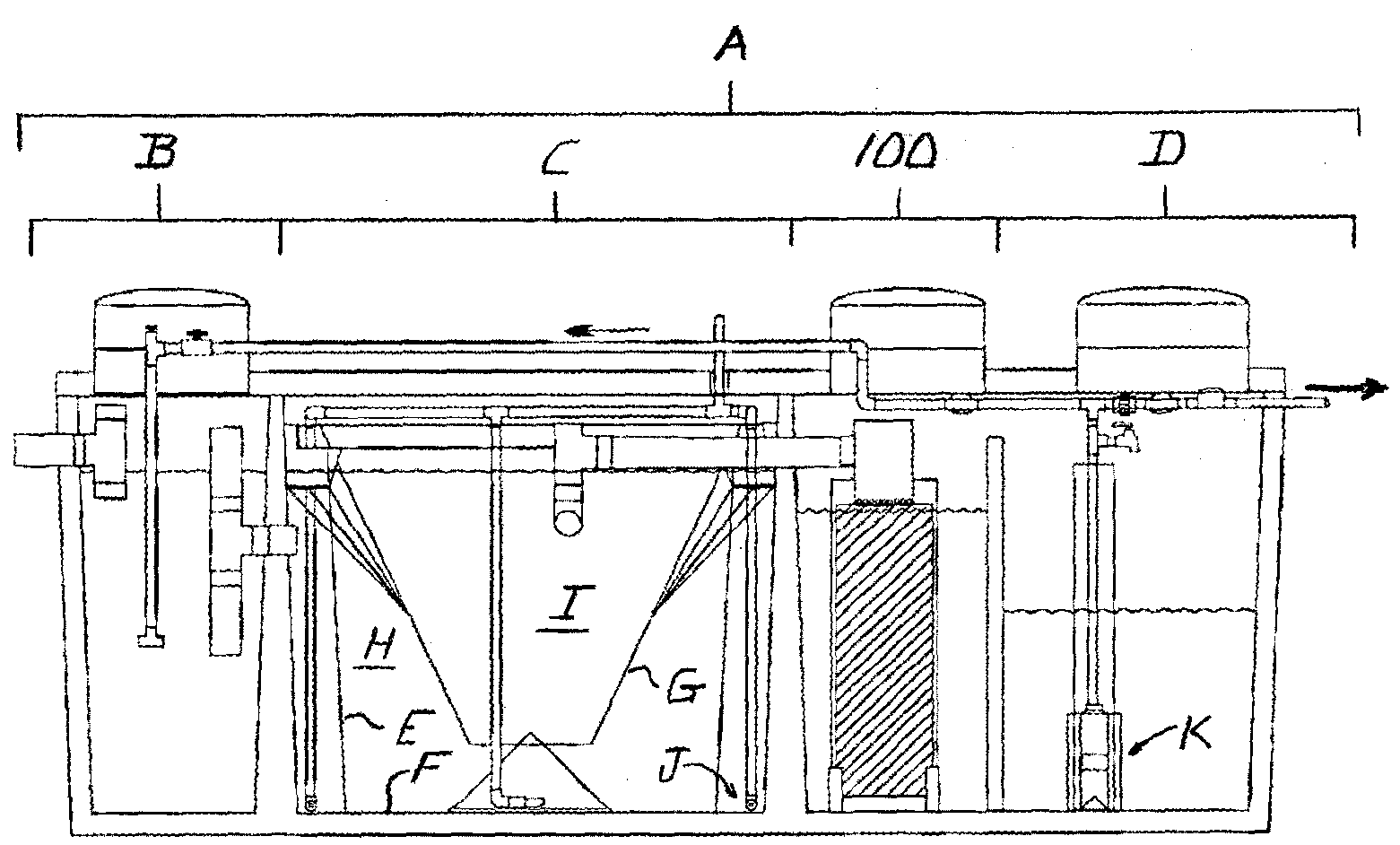

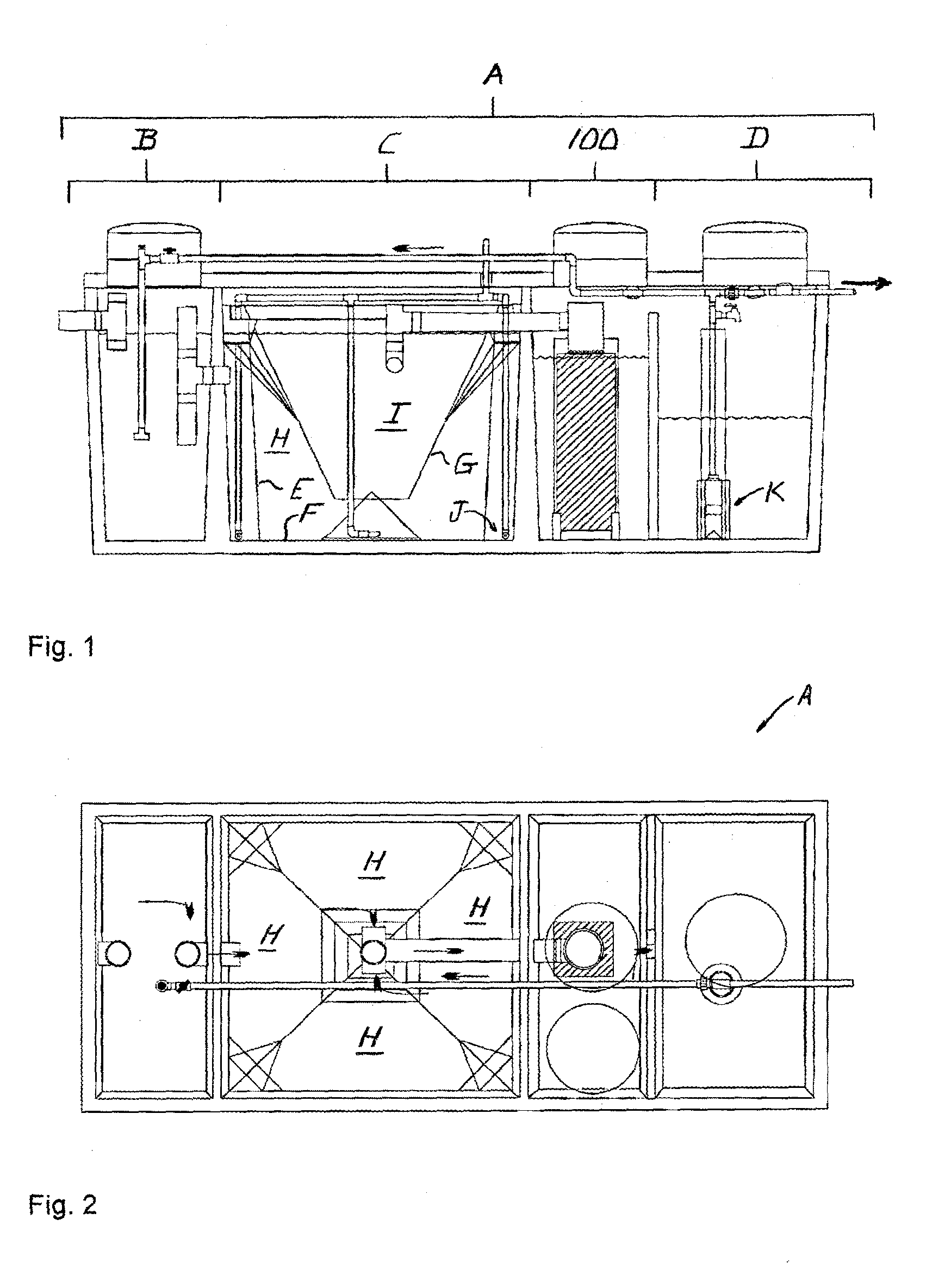

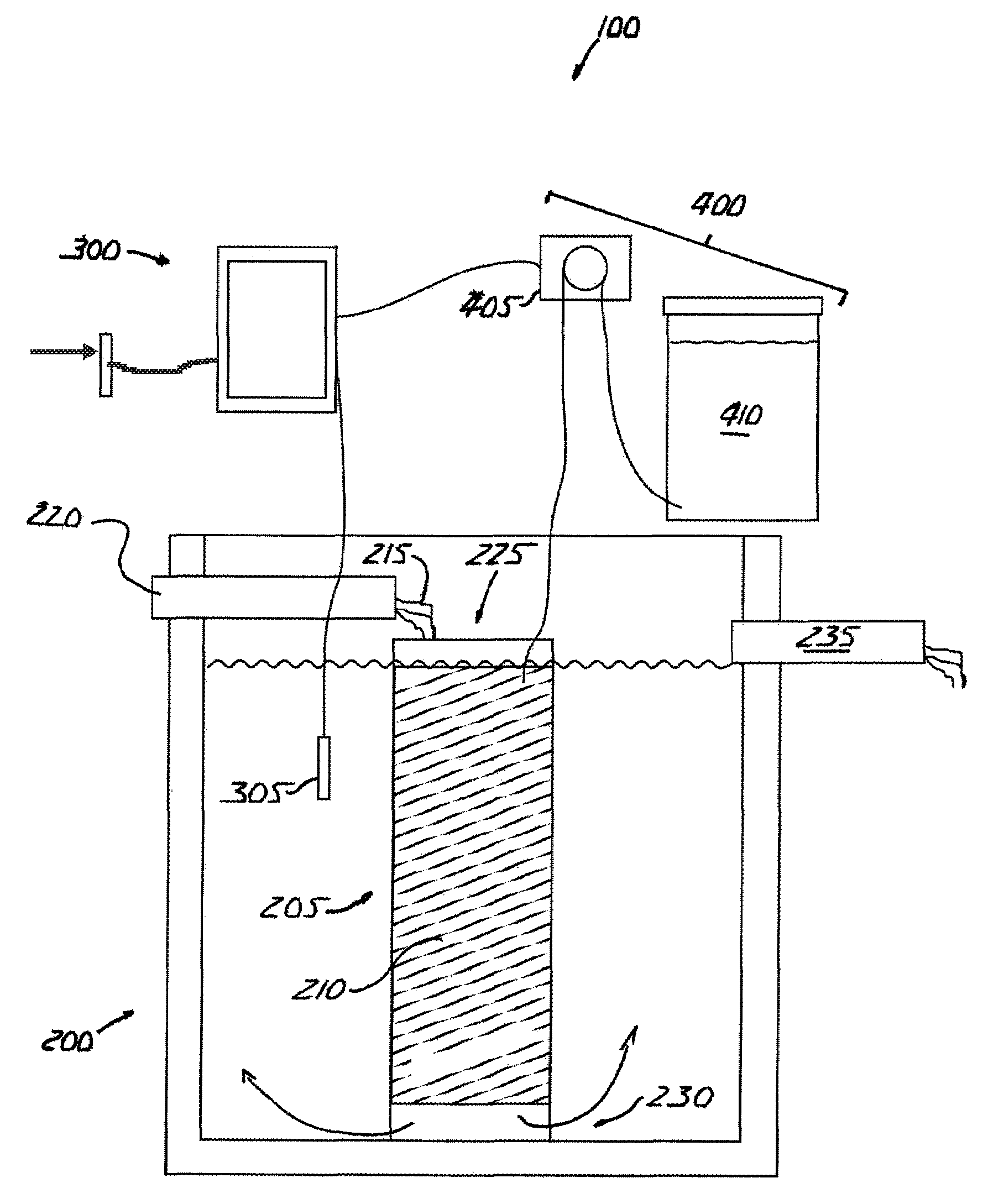

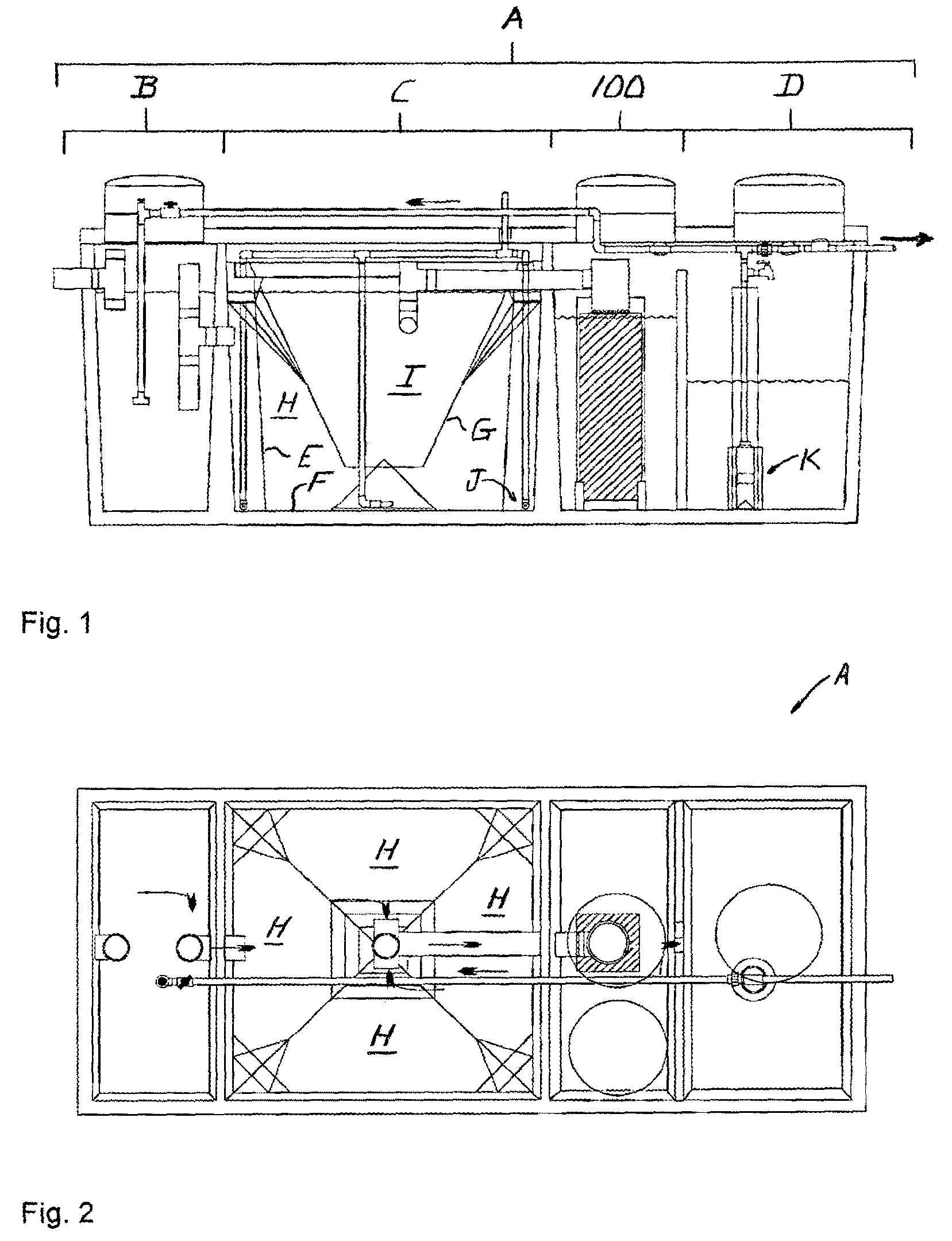

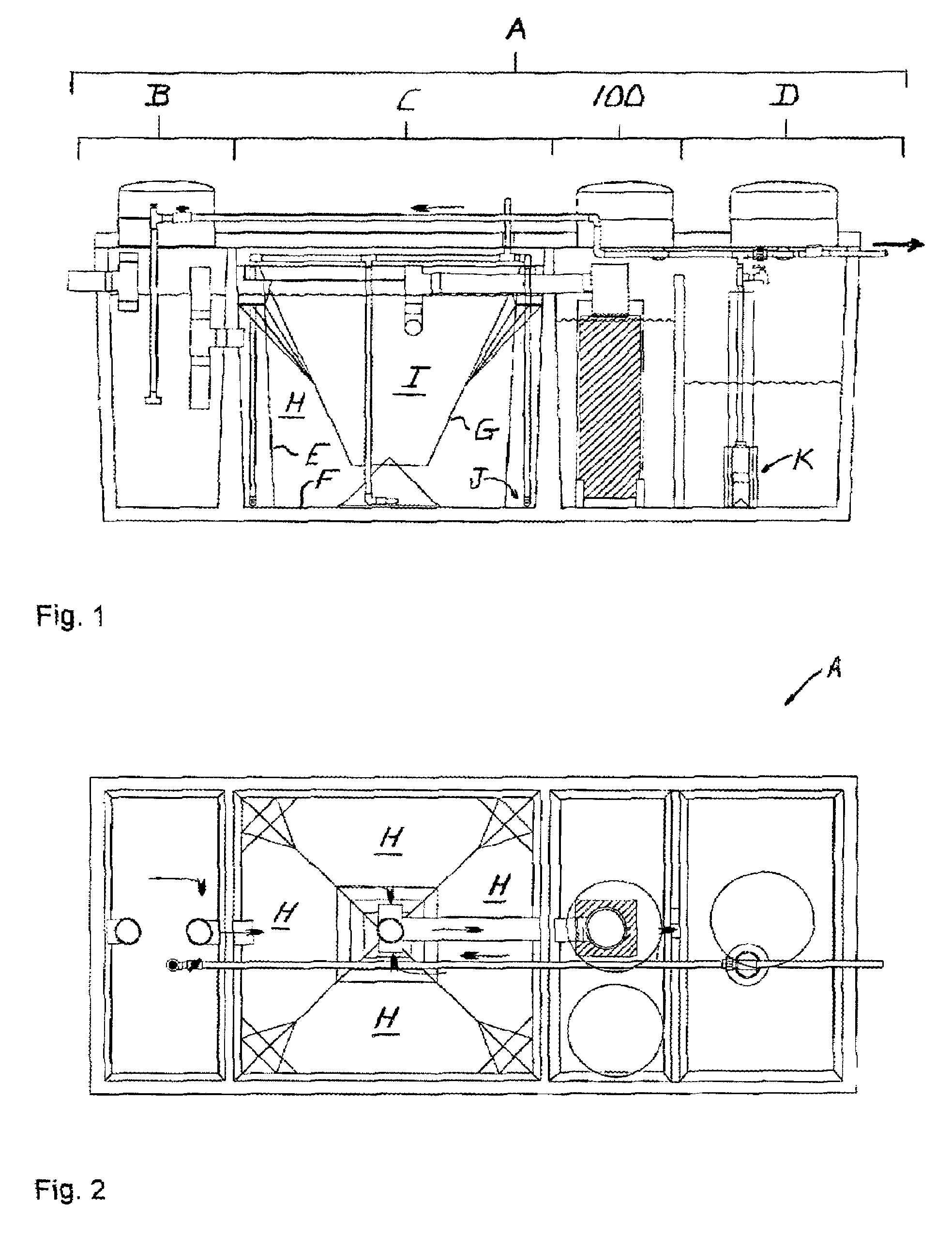

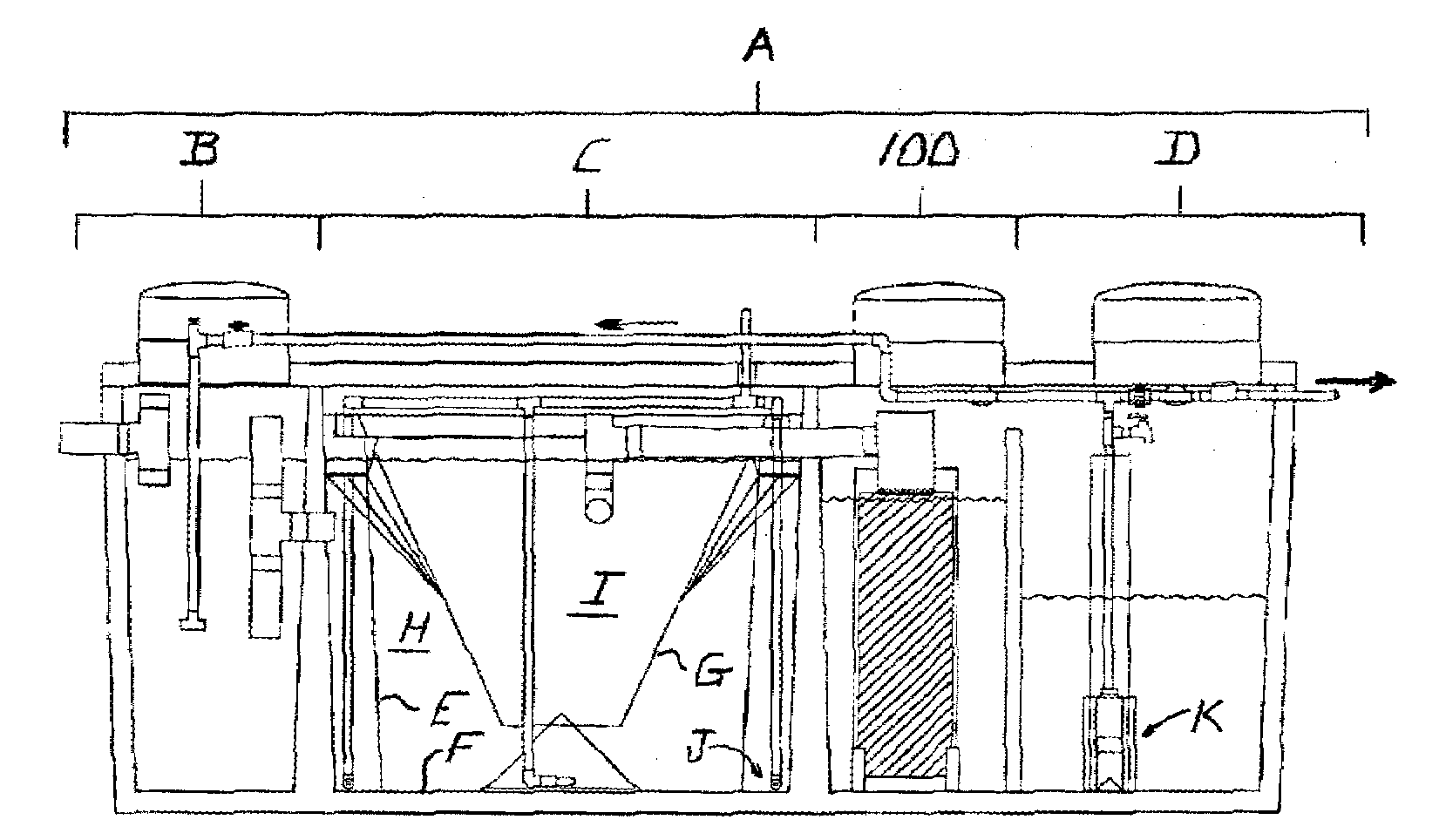

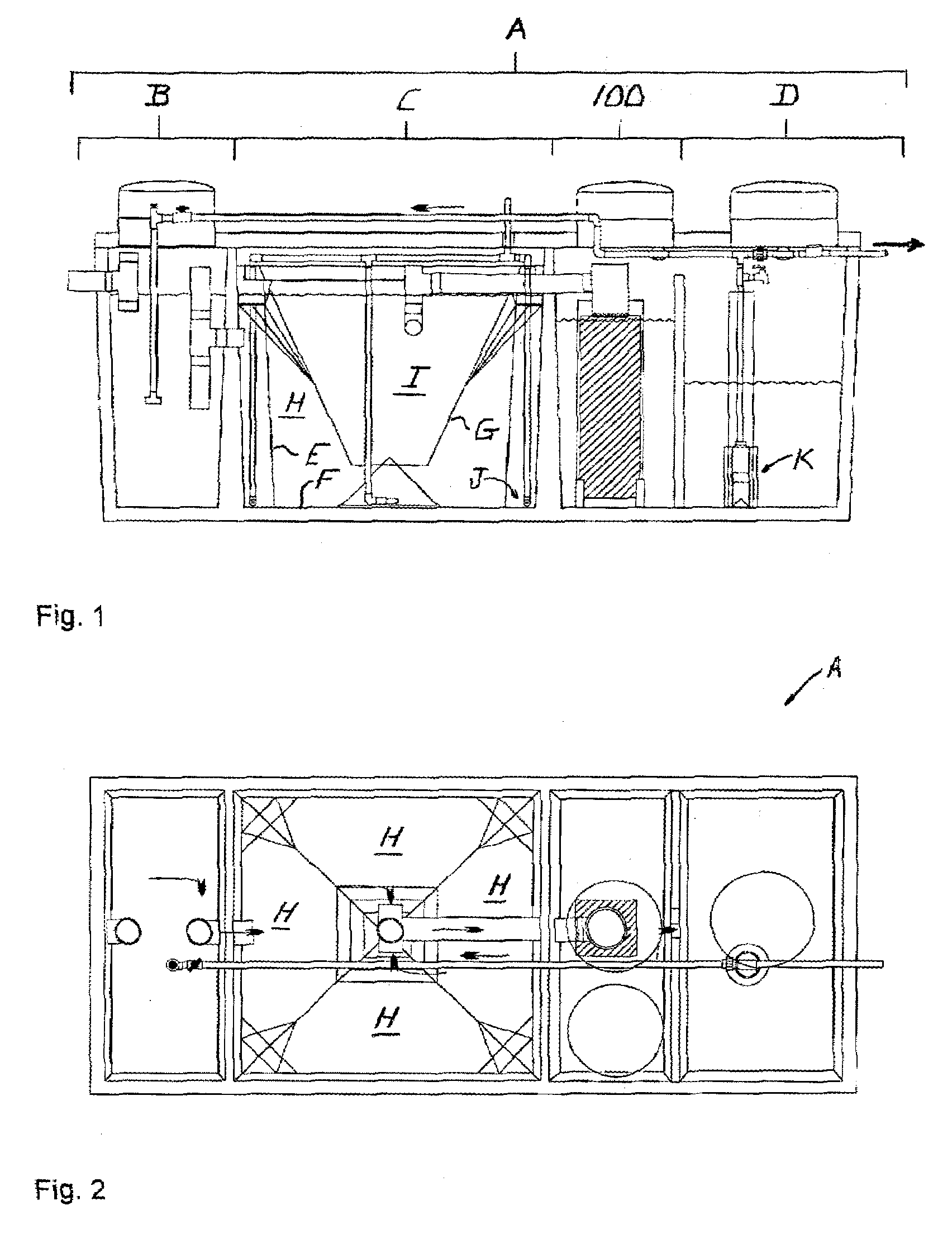

Apparatus For Denitrifying Wastewater

ActiveUS20090211957A1High activityInexpensive, dependable and effectiveWater treatment parameter controlBiological treatment regulationNitratePolyethylene glycol

Disclosed is an apparatus for denitrifying a solution that includes a denitrification tank configured to receive a portion of the solution for a period of time. Controlling an amount, duration and frequency of introduction of polyethylene glycol into the solution promotes indigenous heterotrophic bacteria depleting dissolved oxygen in the solution and obtaining oxygen from nitrate in the solution.

Owner:HOOT AEROBIC SYST

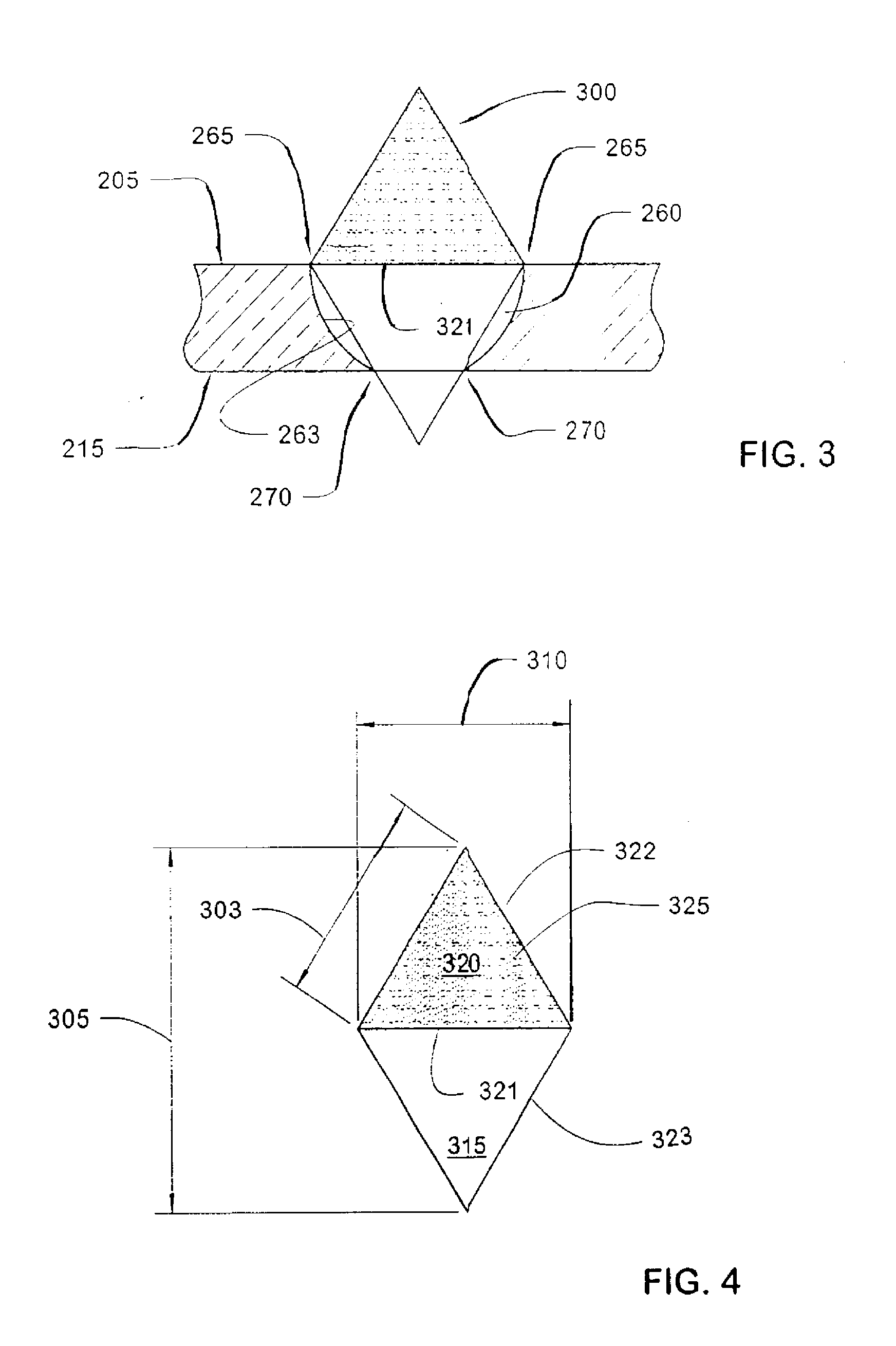

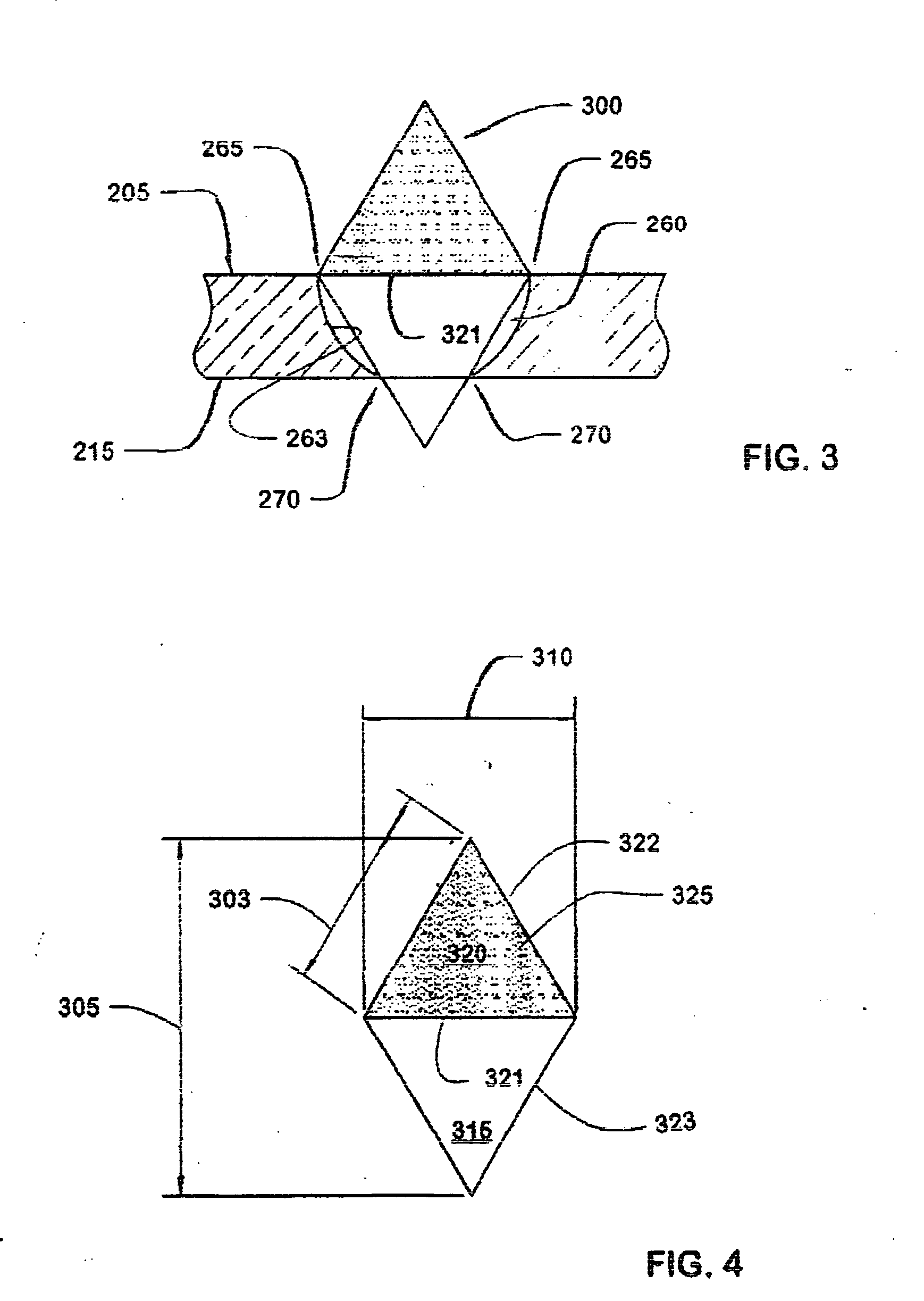

Method of forming concrete and an apparatus for transferring loads between concrete slabs

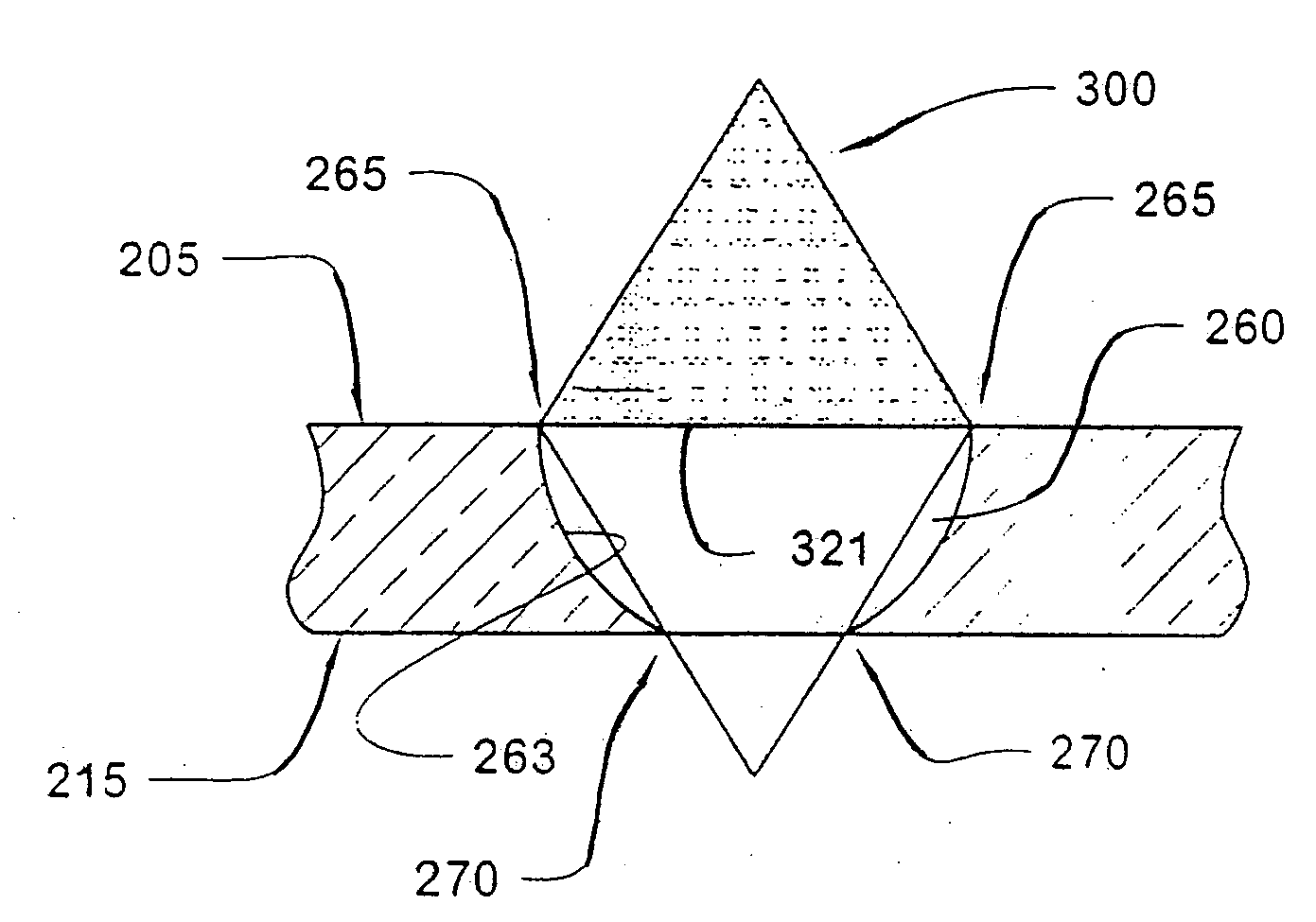

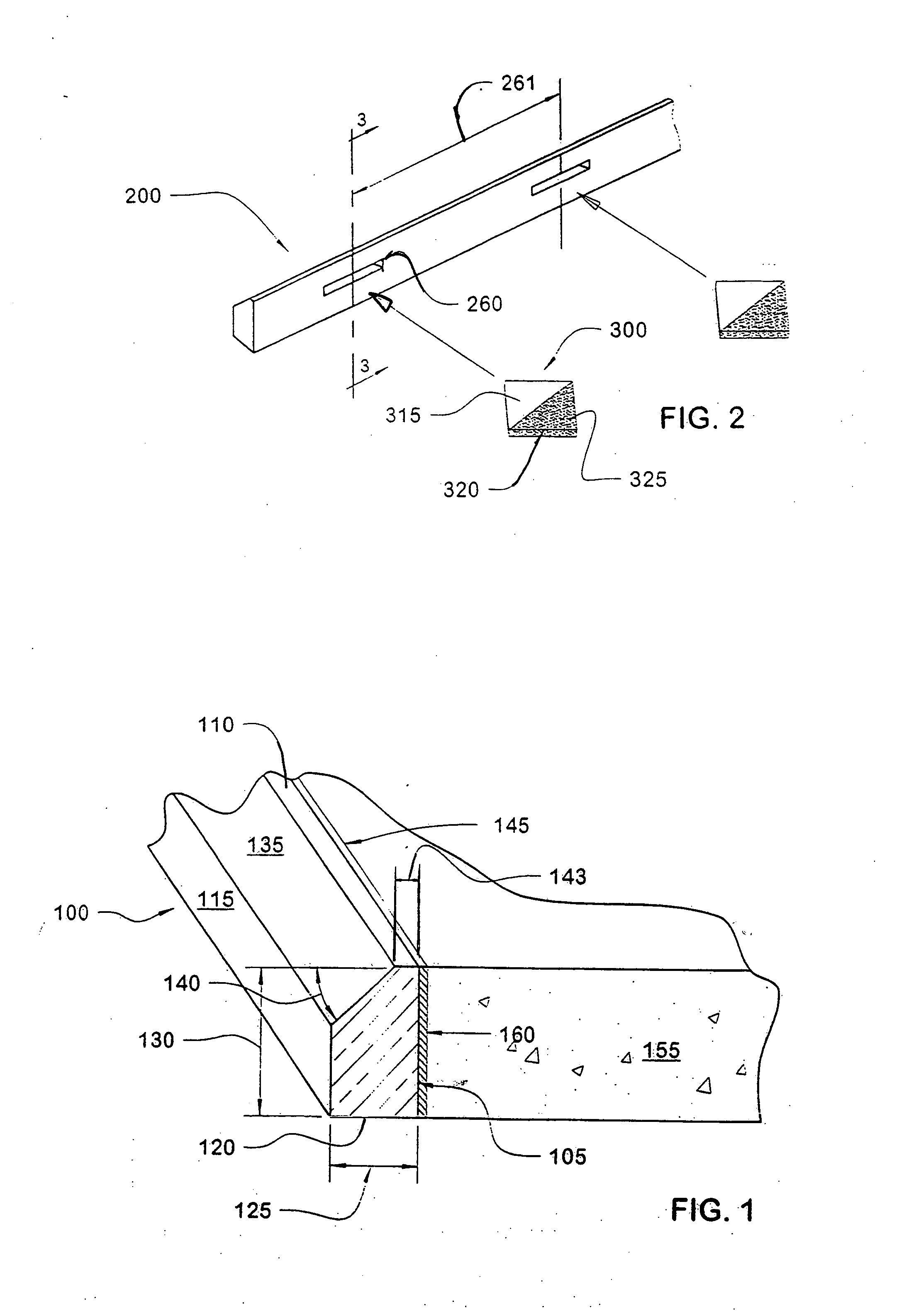

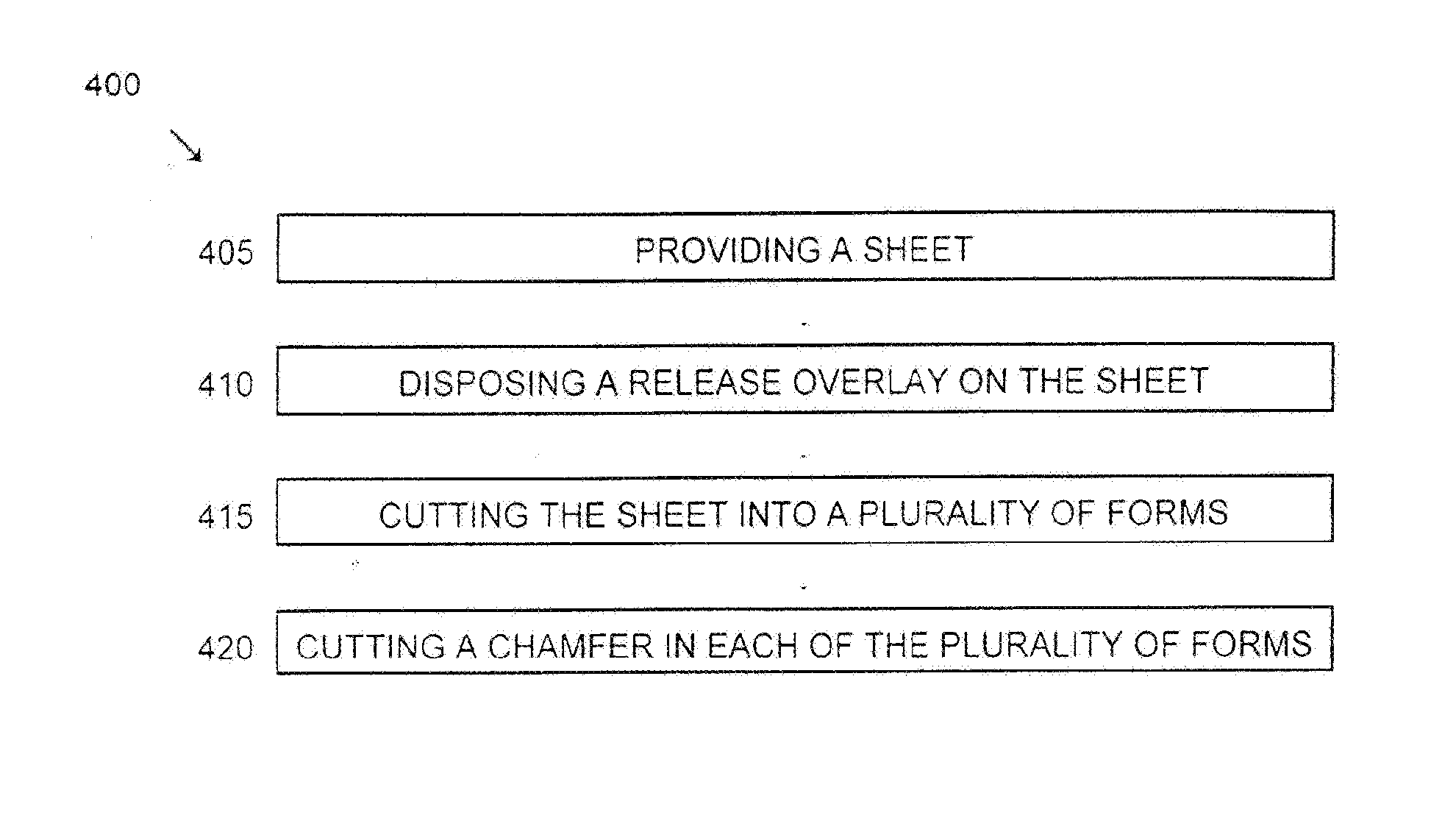

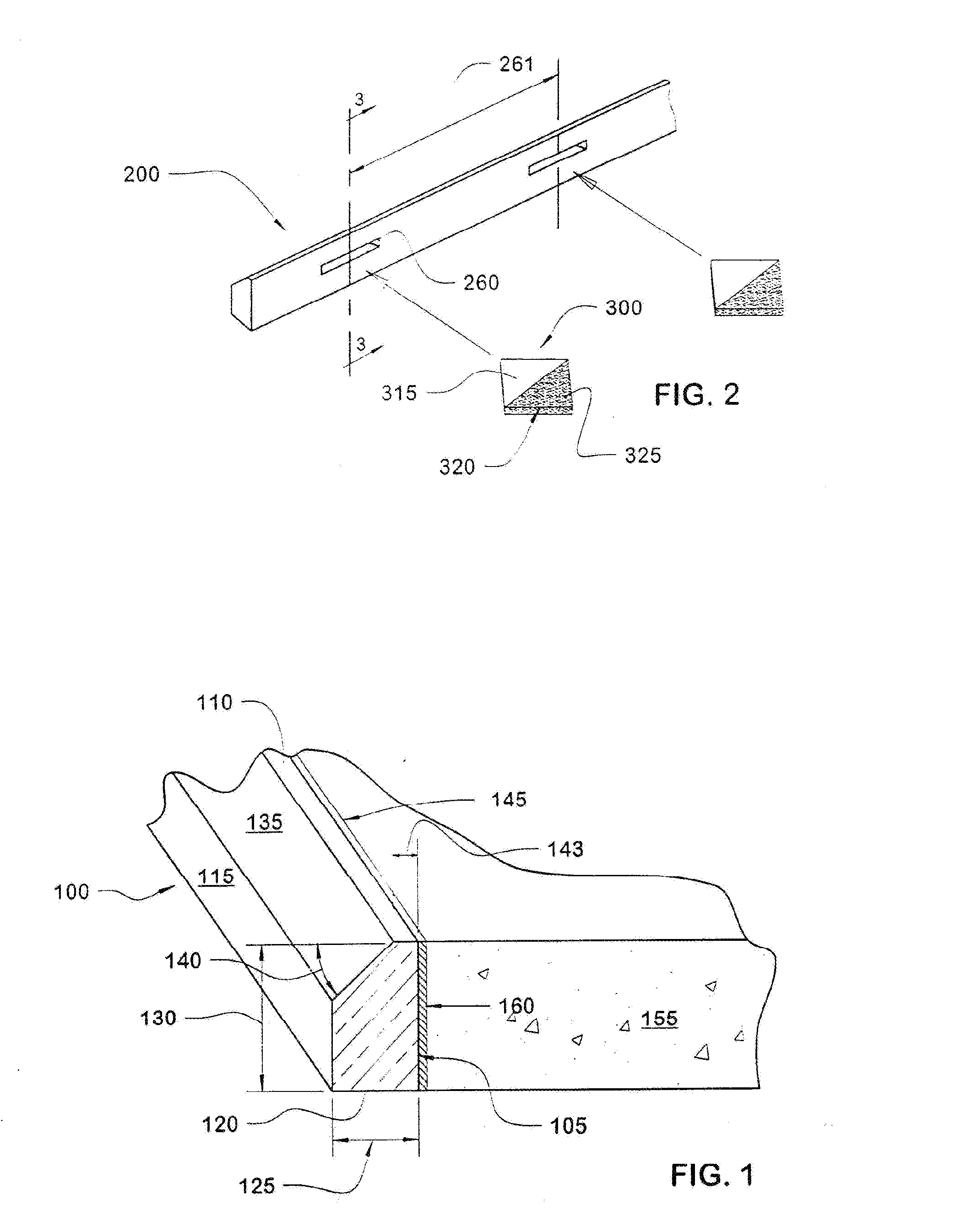

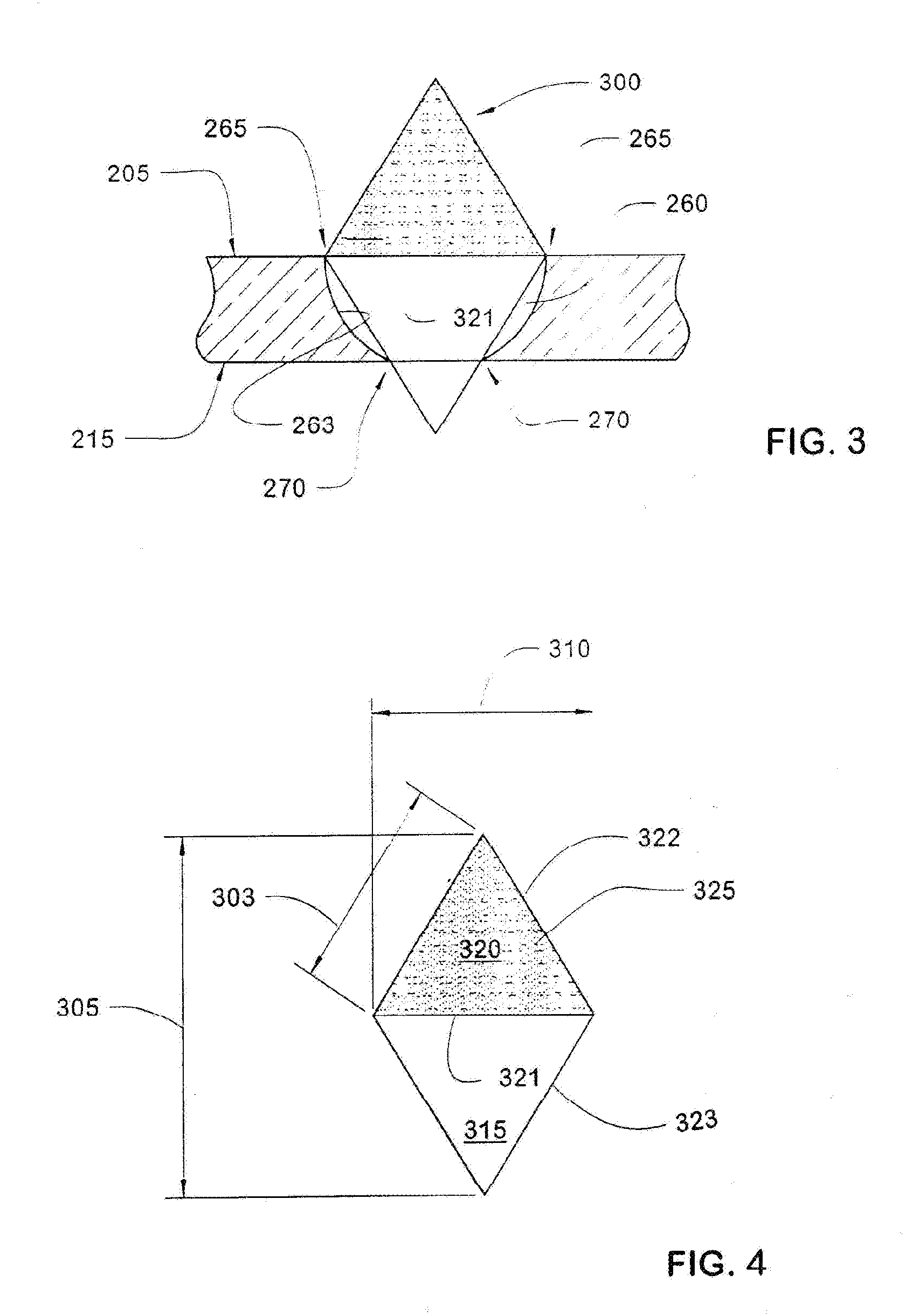

InactiveUS20050166531A1Inexpensive, dependable and effectiveStrutsPaving detailsMultiple formsStructural engineering

An apparatus for forming concrete includes a form having a slot configured to closely receive a plate. The slot is defined by one or more annular surfaces having central axes perpendicular to a direction in which the slot receives the plate. A method for forming same includes providing a sheet of form material; disposing a release layer on the sheet; cutting the sheet into a plurality of forms having a predetermined form height; and cutting a slot in each of each of the plurality of forms. Another apparatus for forming concrete includes a plate having a first portion and a second portion. A coating is disposed on the first portion. When disposed in a joint defined by a first volume of concrete and a second volume of concrete, the first volume of concrete adheres only to the coating and the second volume of concrete adheres only to the second portion. A method for forming concrete includes providing a plate having a coated first portion and a second portion; providing a form having a slot configured to closely receive the second portion; inserting the second portion in the slot; positioning the form to receive concrete; pouring a volume of concrete on the form and the first portion; curing the volume of concrete and defining cured concrete; and removing the form from the cured concrete. The plate remains in the cured concrete.

Owner:E Z FORM

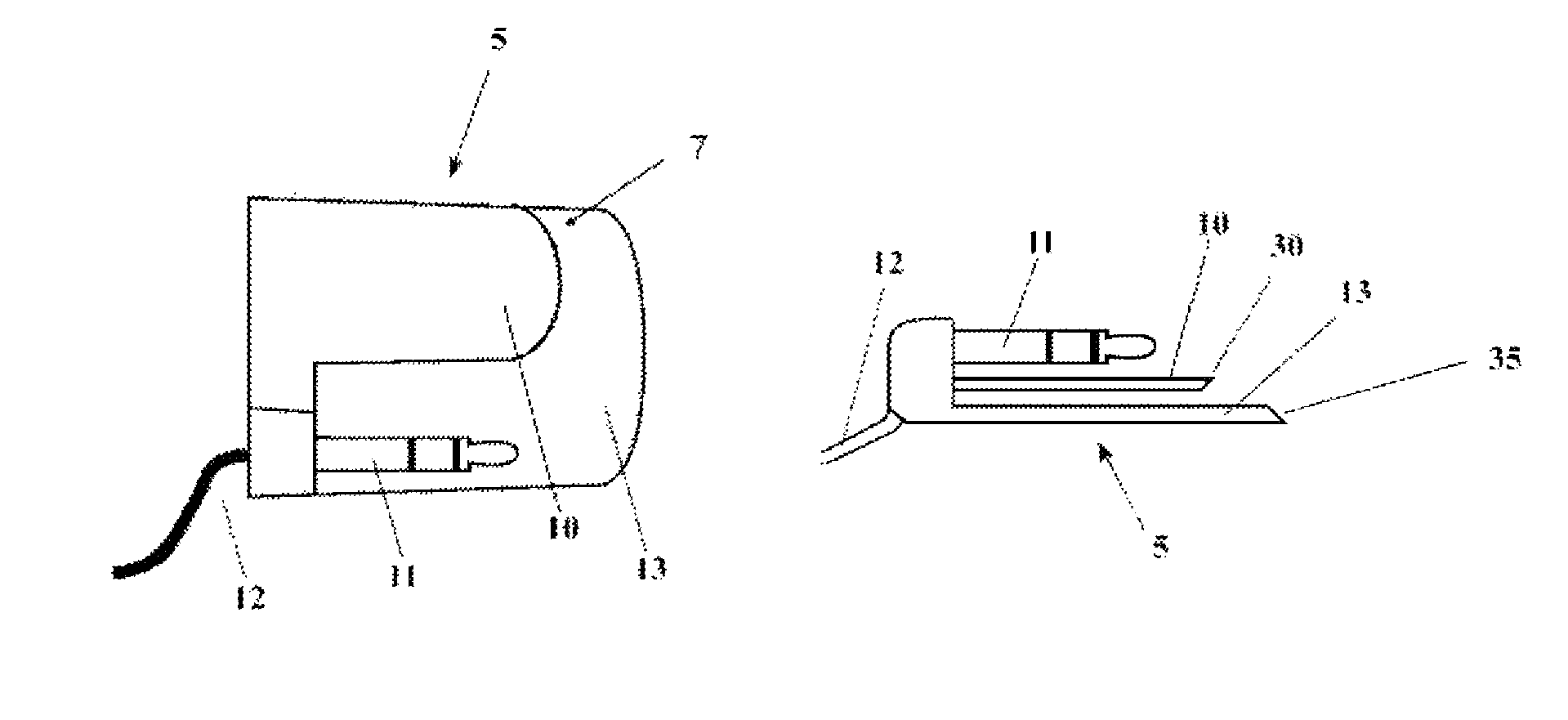

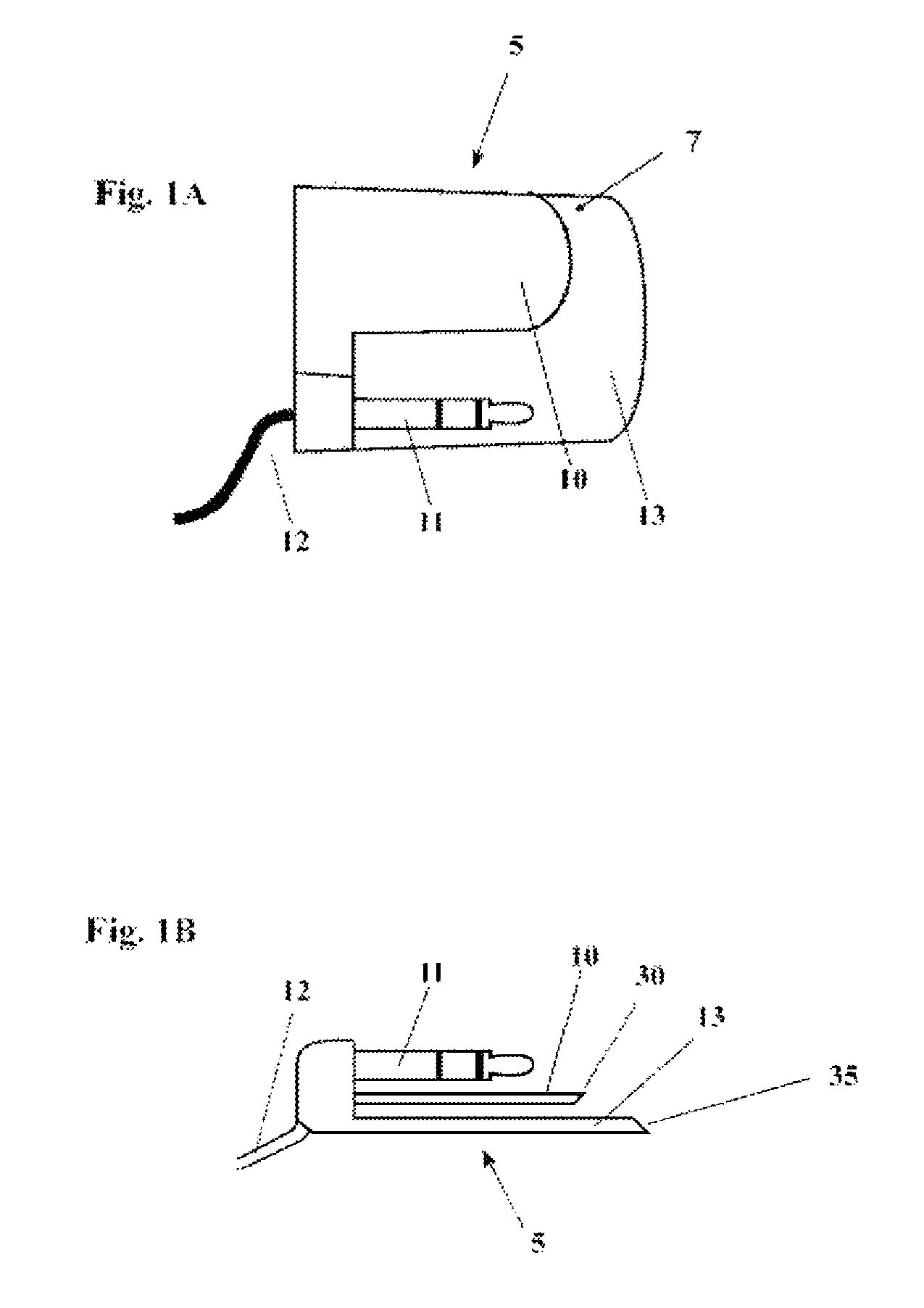

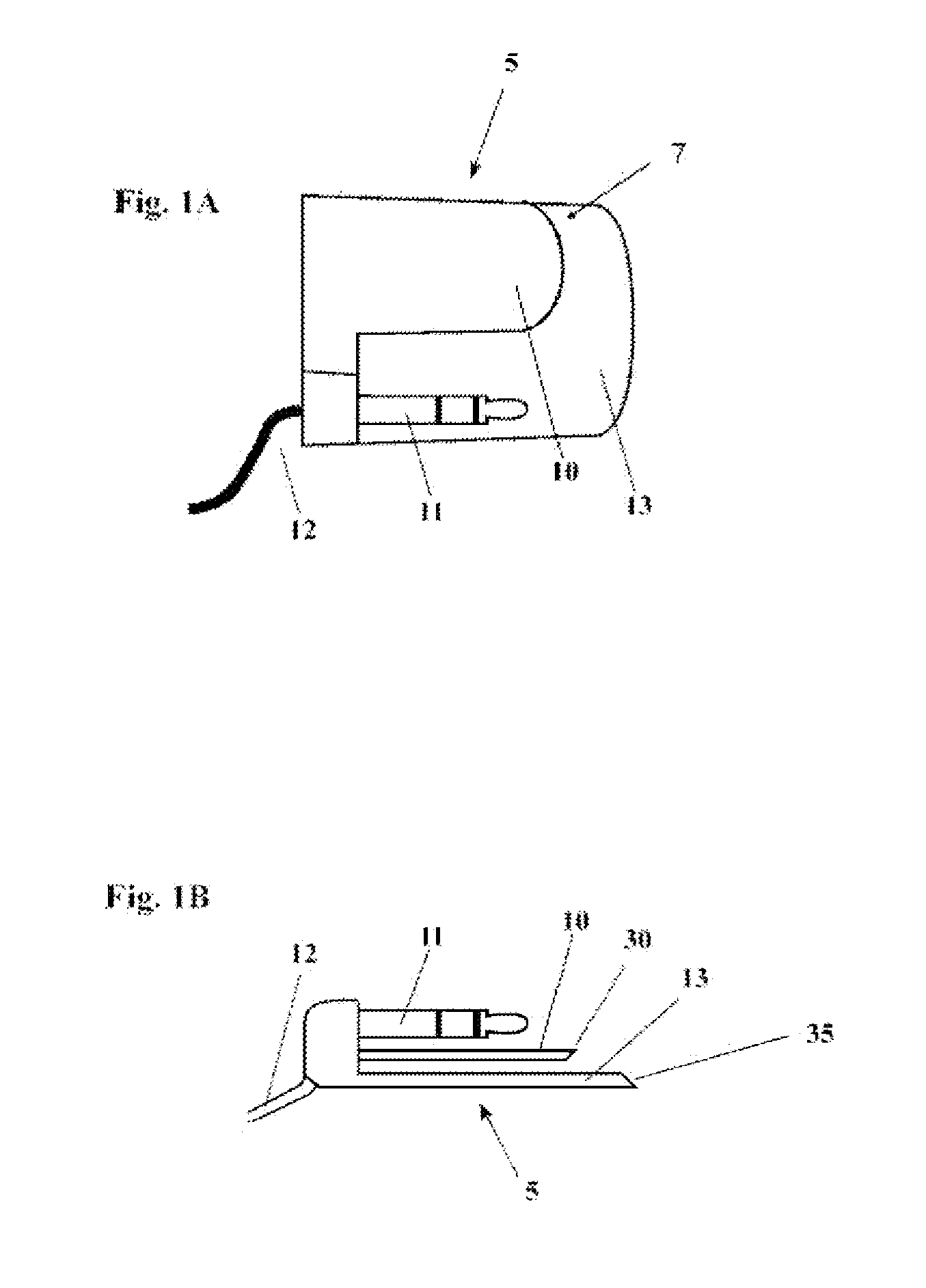

Apparatus for mounting an audio player

InactiveUS8611075B2Easy to installInexpensive, dependable and effectiveTravelling carriersHoldersElectrical connectionEngineering

Disclosed is a mounting dock with an integral jack for digital audio players, preferably that incorporate a built-in clip, including, but not limited to the iPod Shuffle® and iPod Nano® manufactured by Apple, Inc. The dock includes a tapered and beveled mounting stem that inserts into the audio player's clip and a jack that inserts into and provides electrical connection with the audio player's audio port. The stem and jack are positioned and aligned so as to enable simultaneous mounting and electrical connection with the audio player, thereby effecting connection with a desired output device, such as earphones, with one hand in a single motion.

Owner:CARTER ZANE

Apparatus for forming concrete and transferring loads between concrete slabs

InactiveUS20070196170A1Inexpensive, dependable and effectiveSingle unit pavingsPaving detailsStructural engineering

Owner:E Z FORM

Apparatus for Forming Concrete and Transferring Loads Between Concrete Slabs

InactiveUS20070204558A1Inexpensive, dependable and effectiveStrutsSingle unit pavingsEngineeringMechanical engineering

Owner:CARROLL MICHAEL E

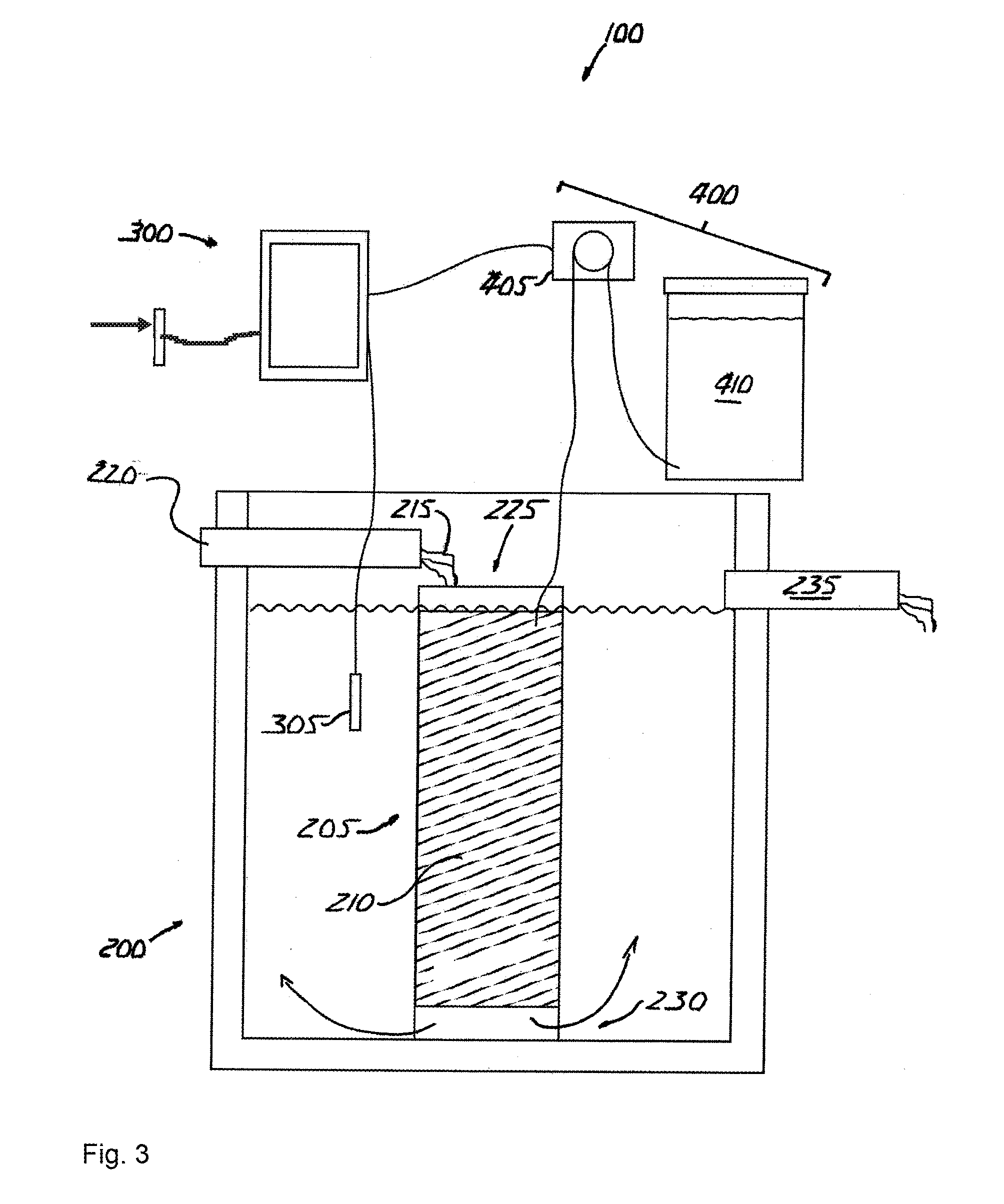

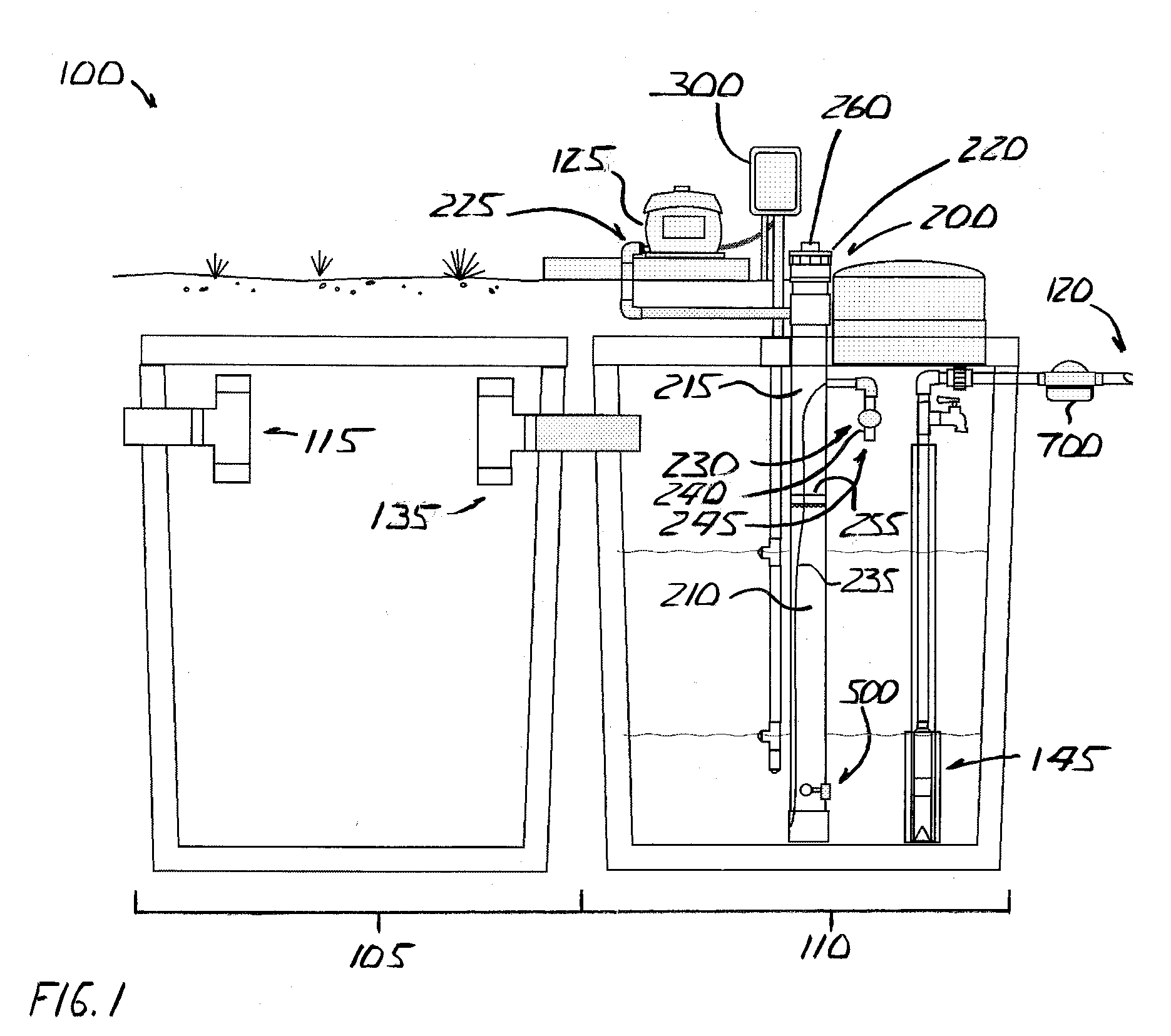

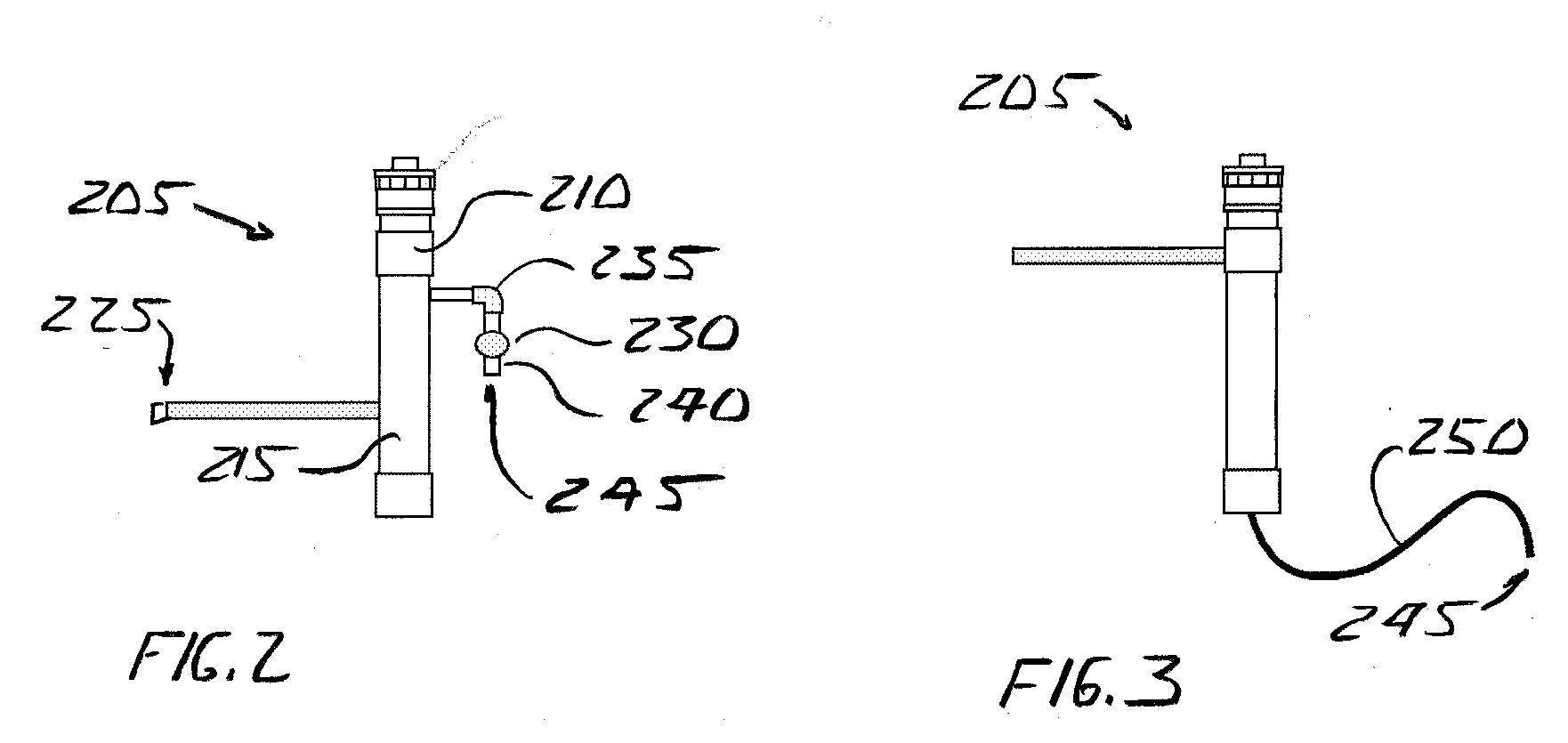

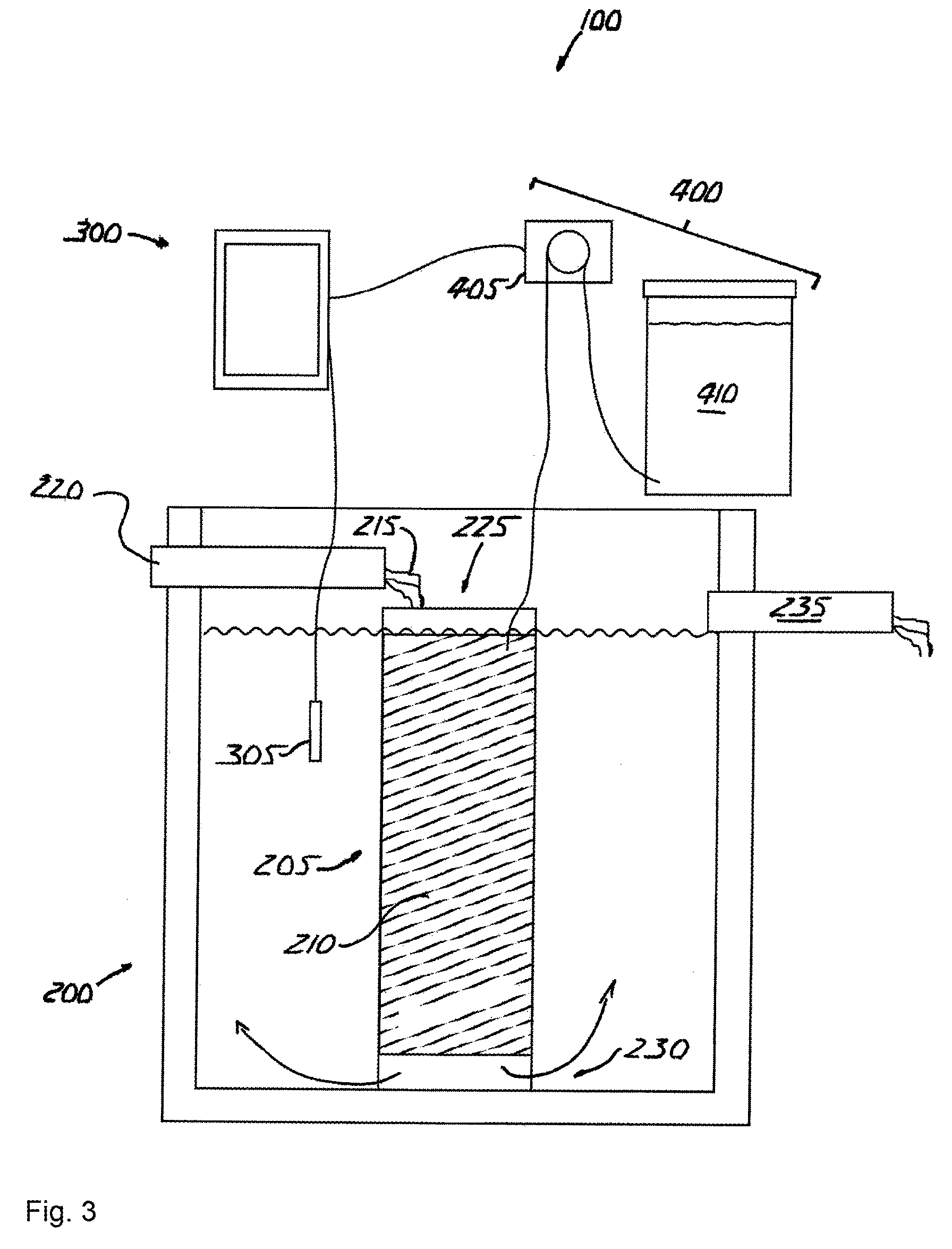

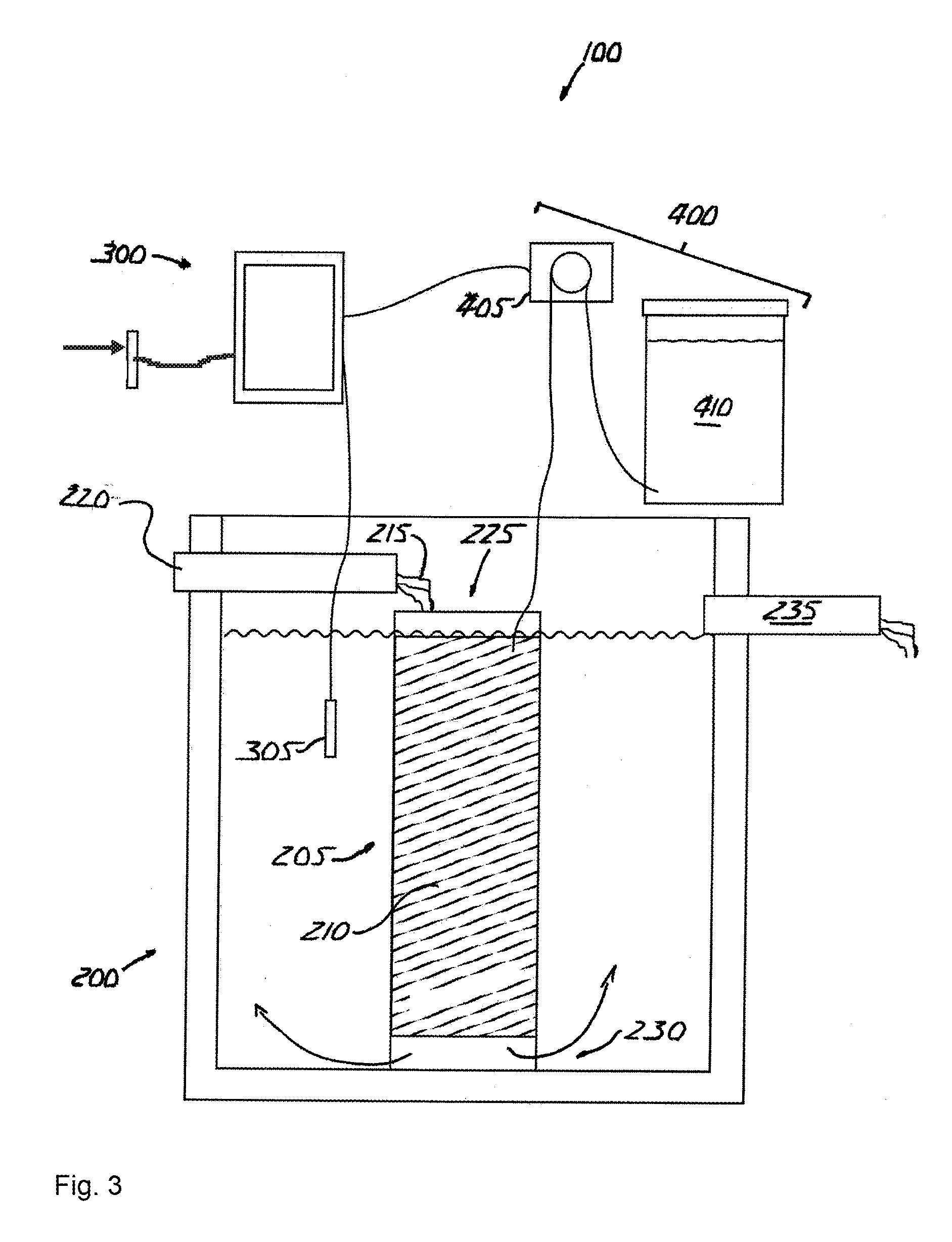

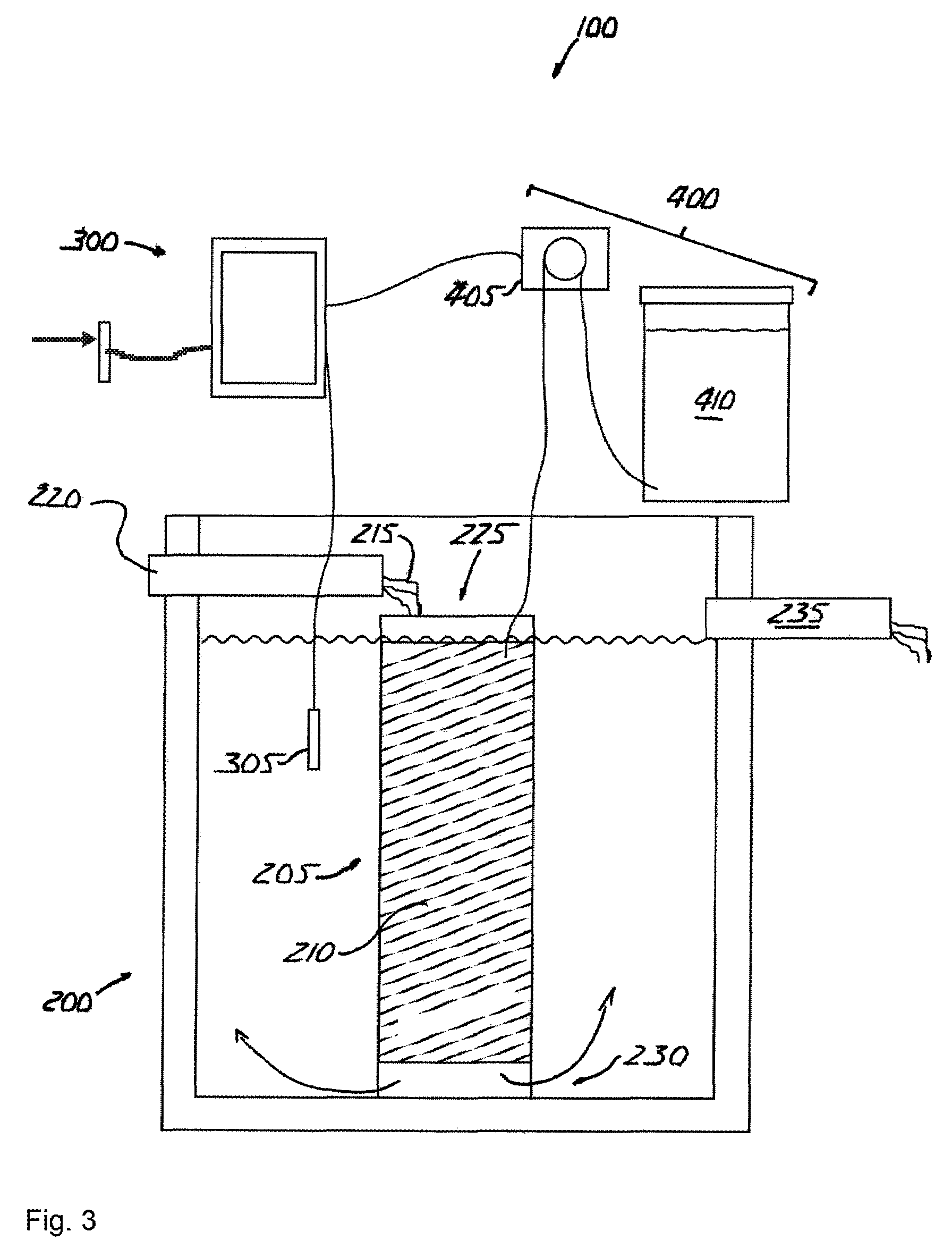

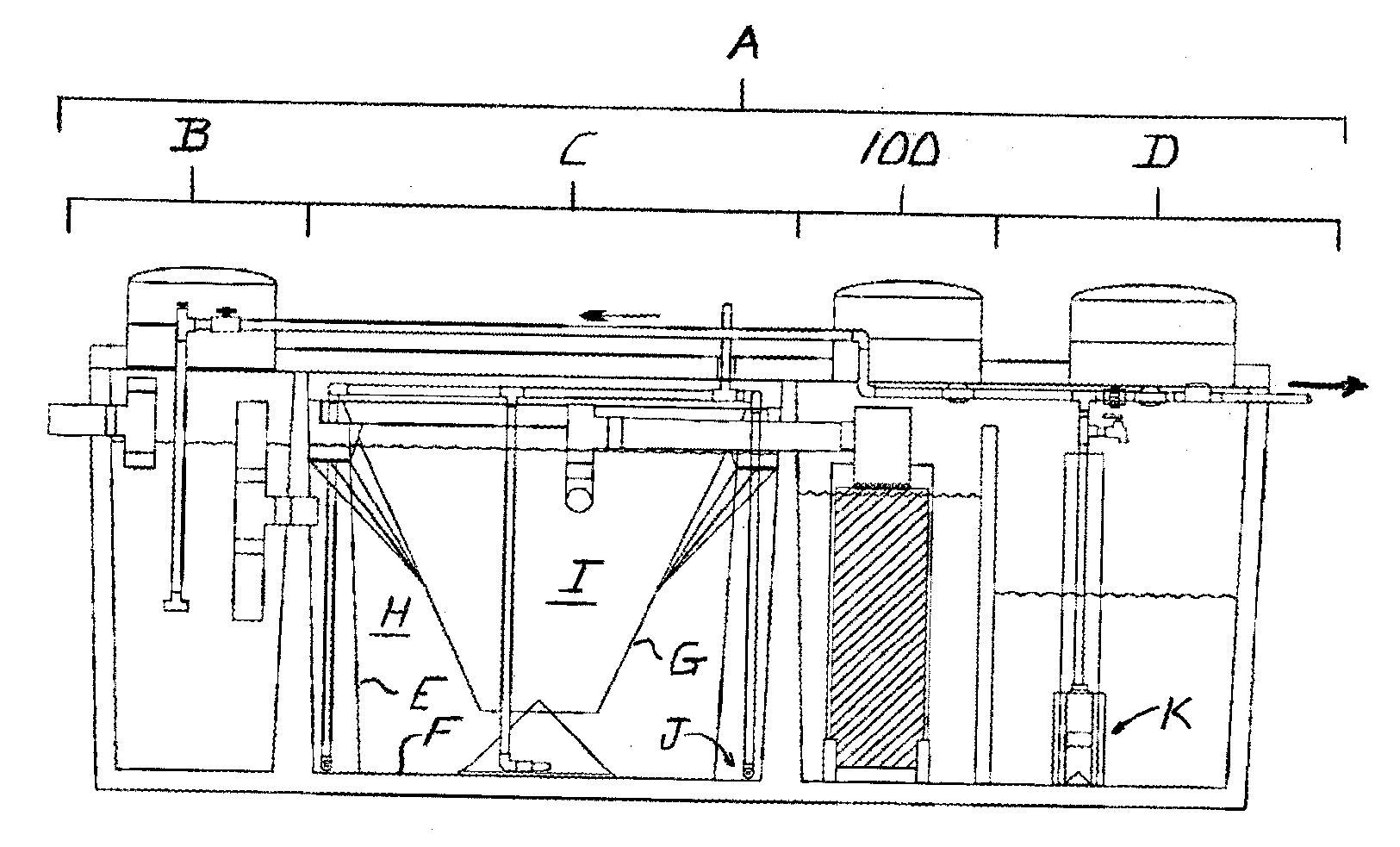

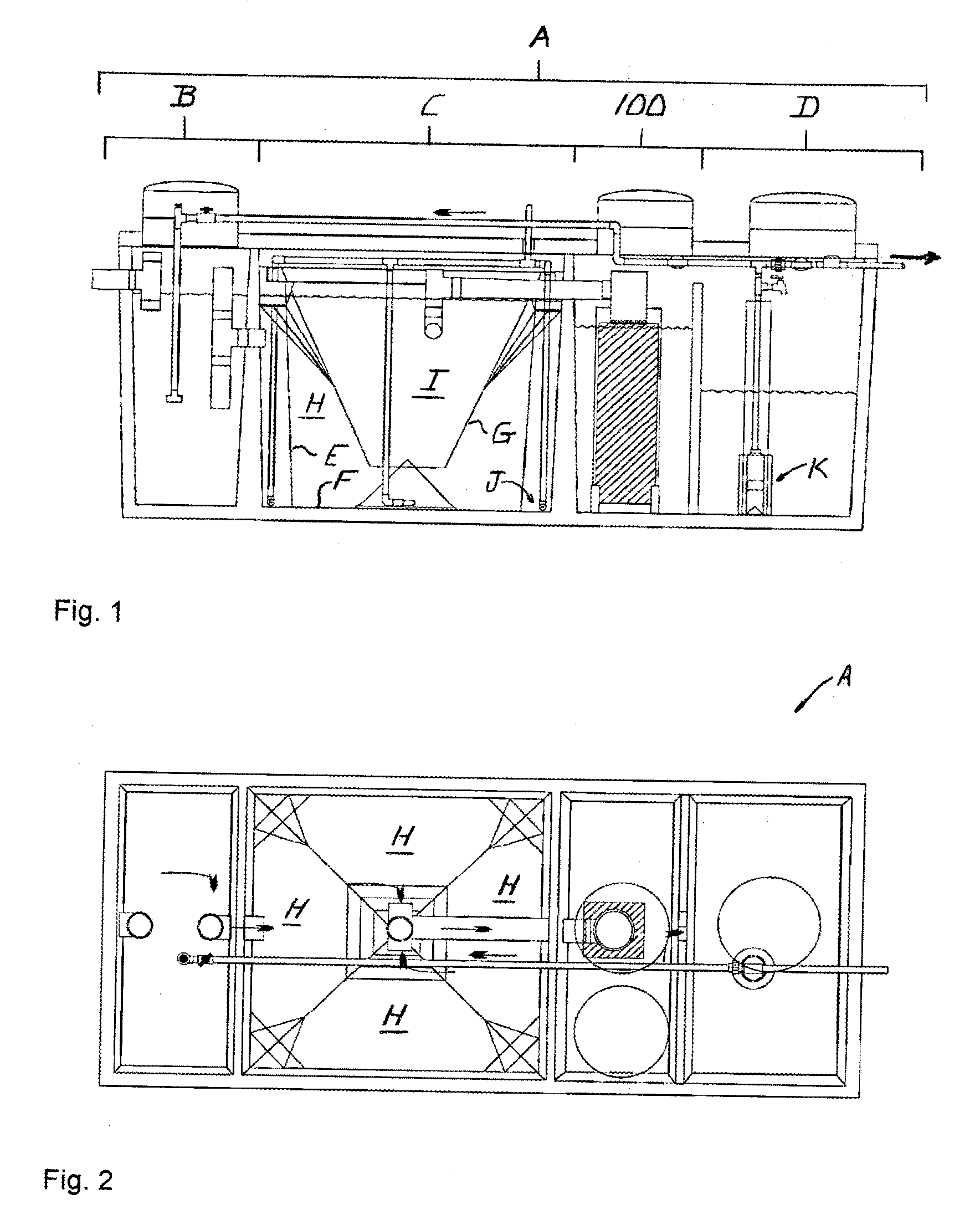

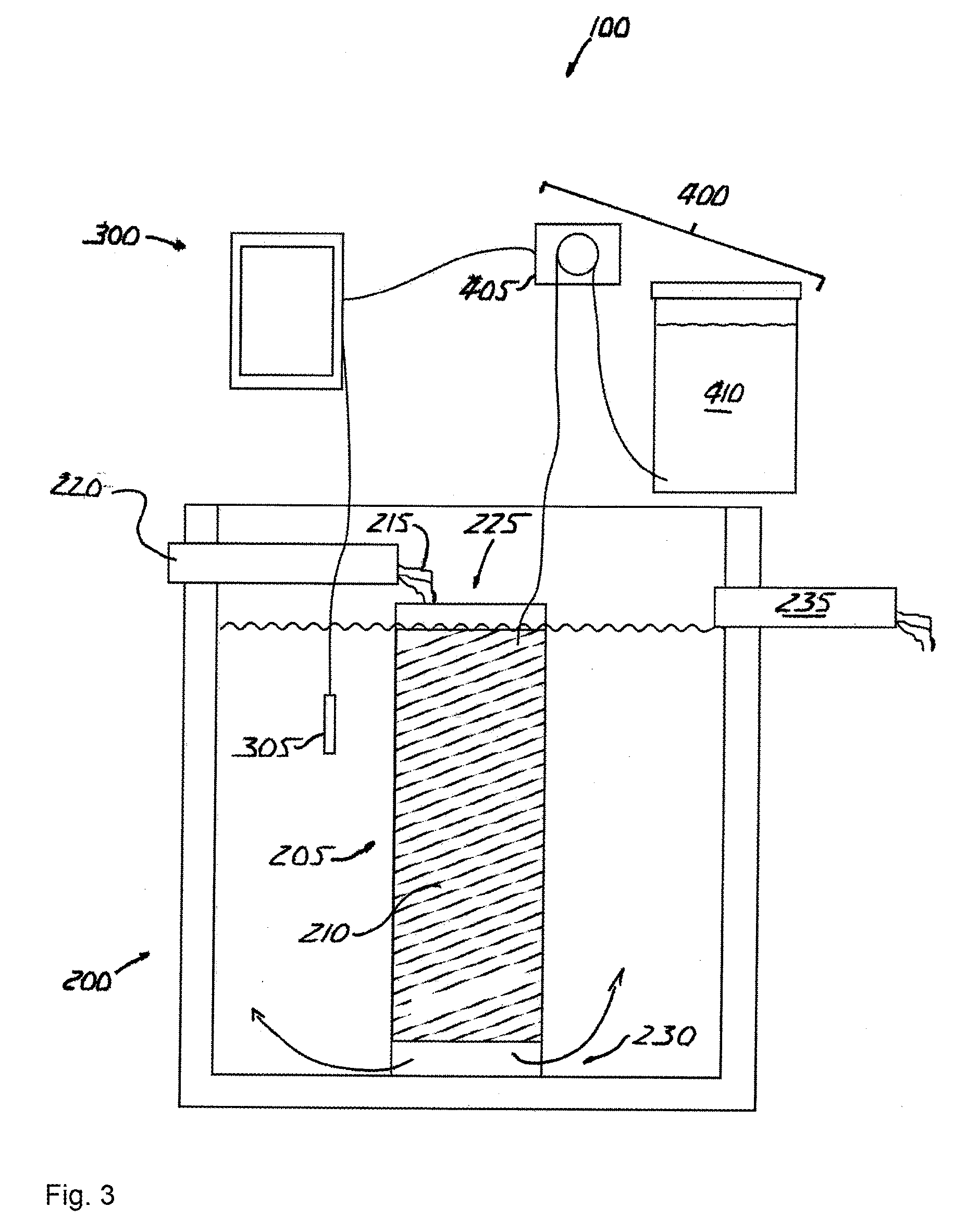

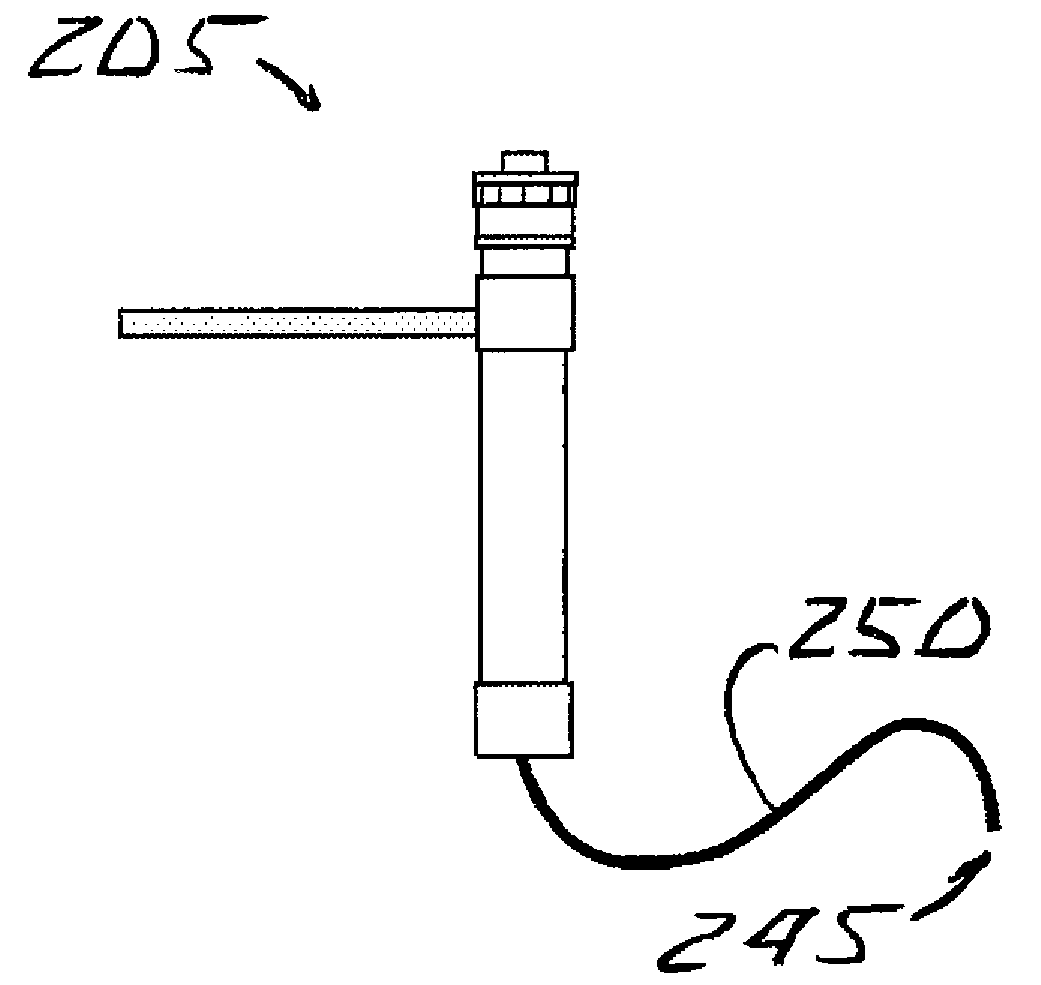

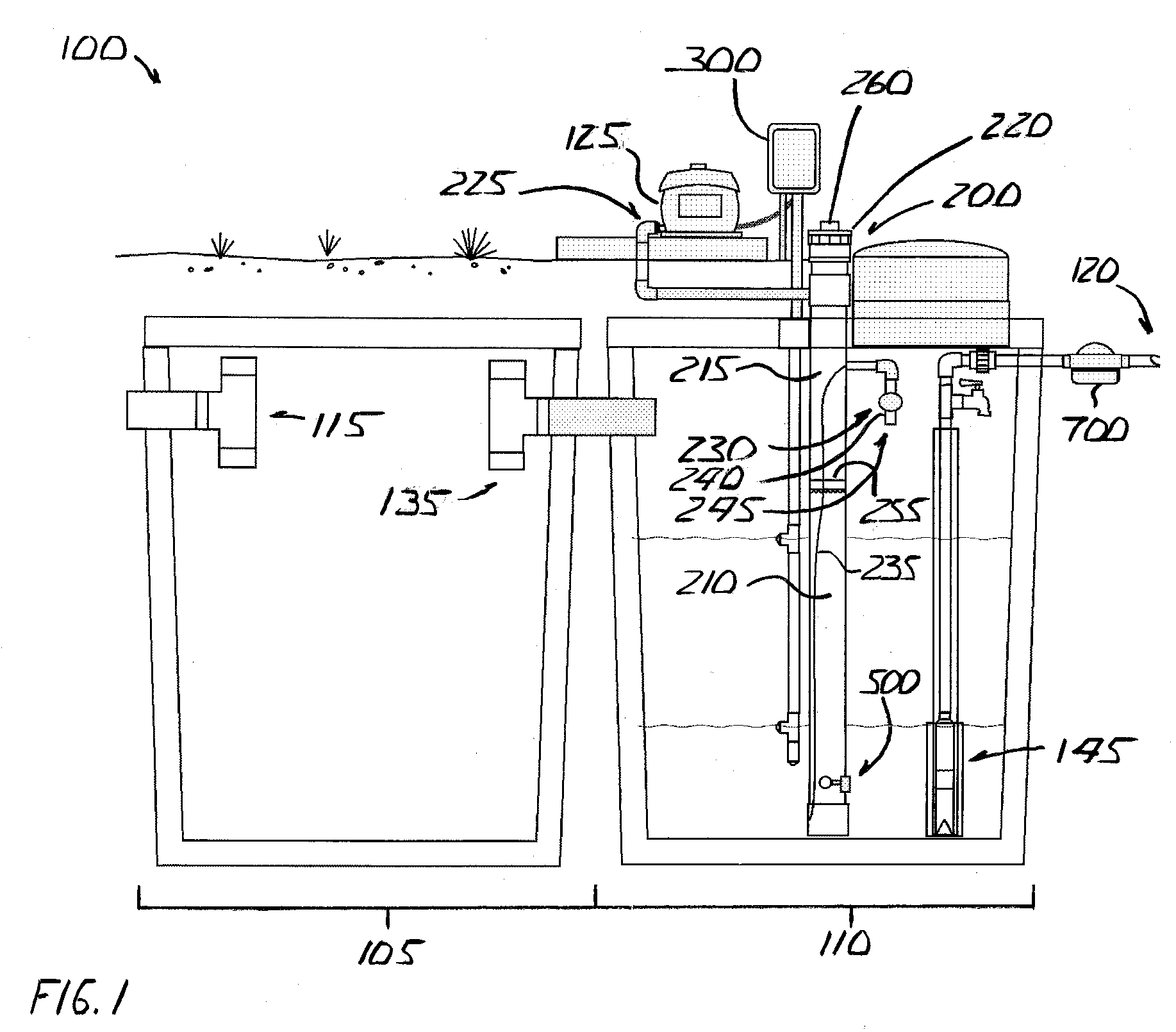

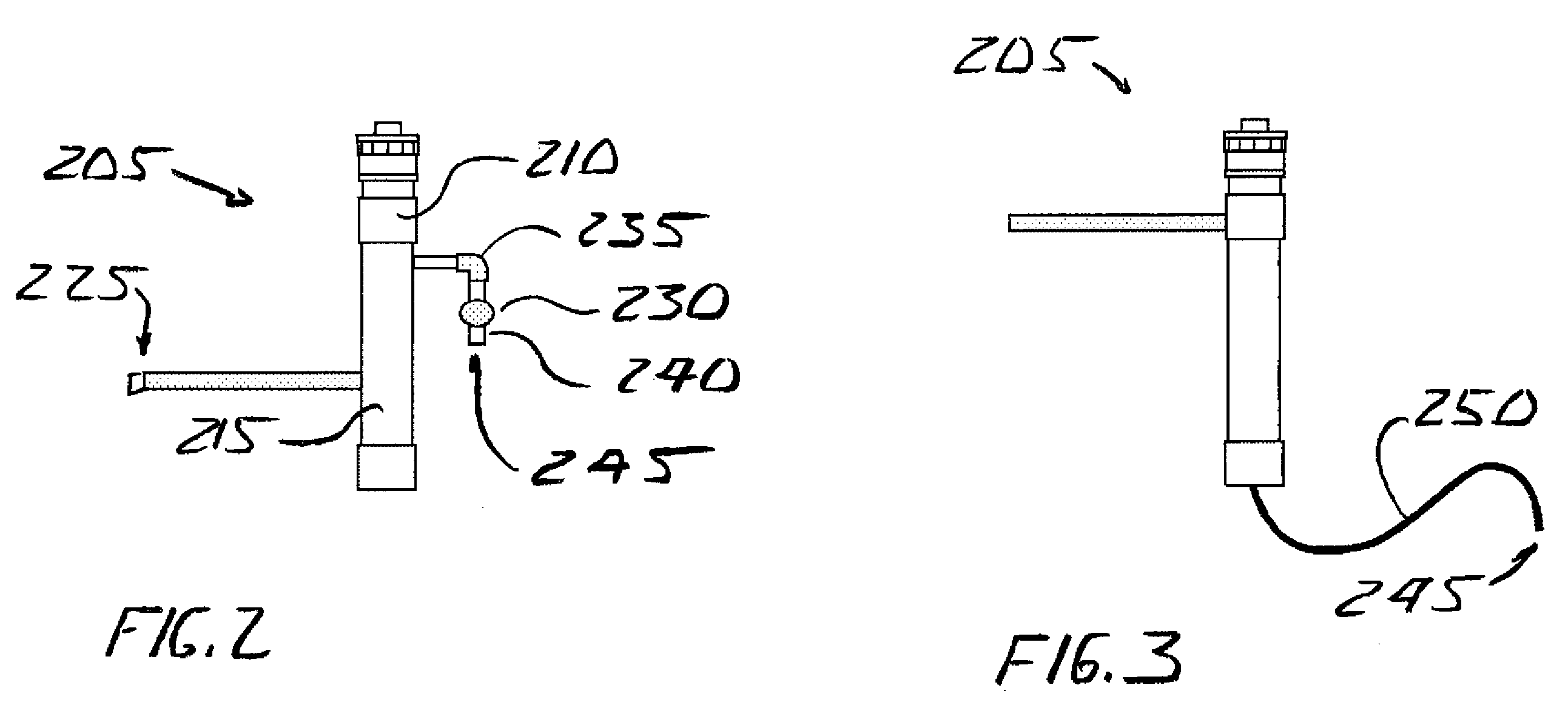

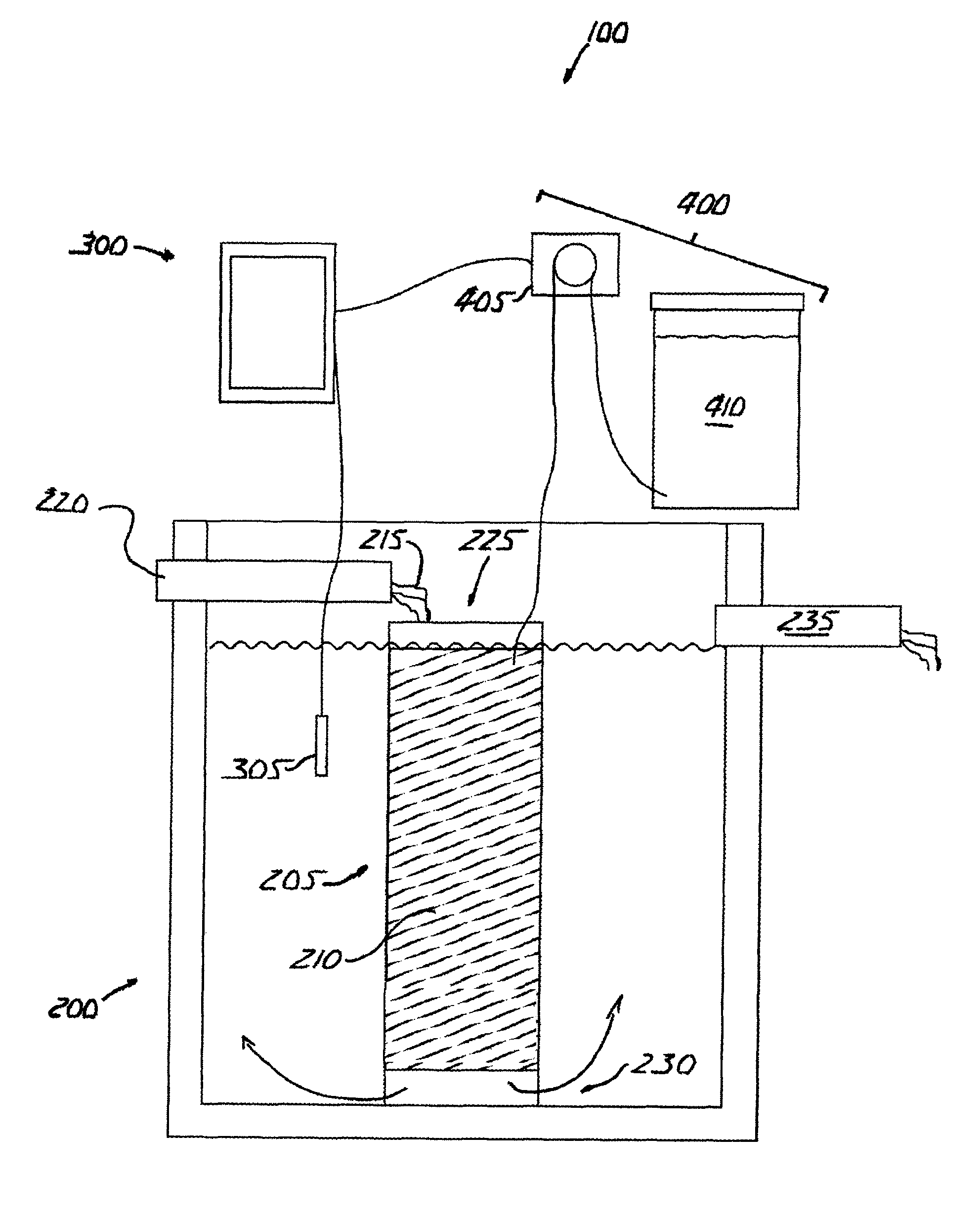

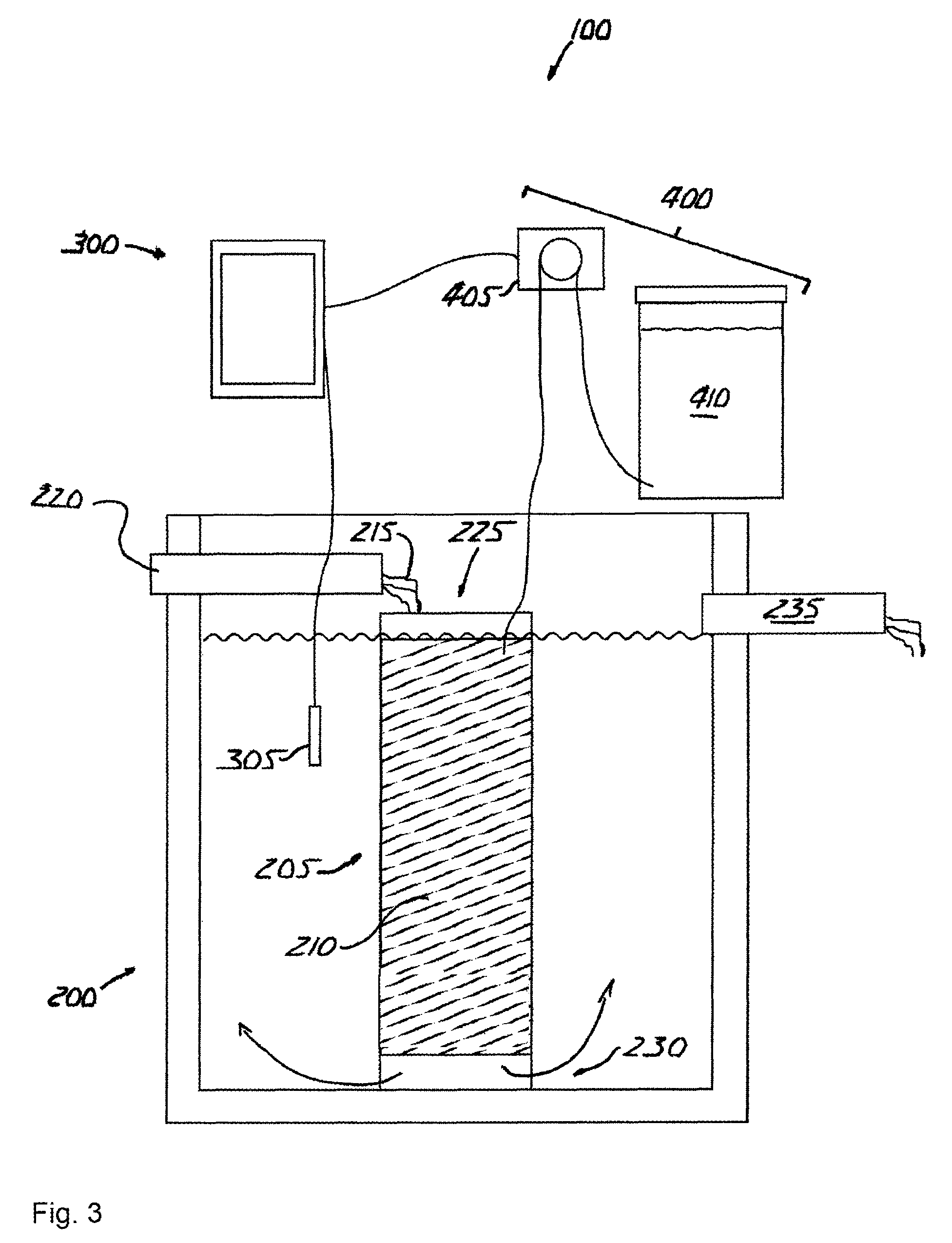

Apparatus for and Method of Dosing a Wastewater Treatment System

InactiveUS20080083674A1Inexpensive, dependable and effectiveWater treatment parameter controlSpecific water treatment objectivesTreatment systemWastewater disposal

A reservoir is configured to receive a first fluid, and has an inlet configured to receive a second fluid and an outlet. Second fluid received in the reservoir drives a corresponding amount of first fluid out of the outlet and into the wastewater treatment system. A method also is disclosed.

Owner:HOOT AEROBIC SYST

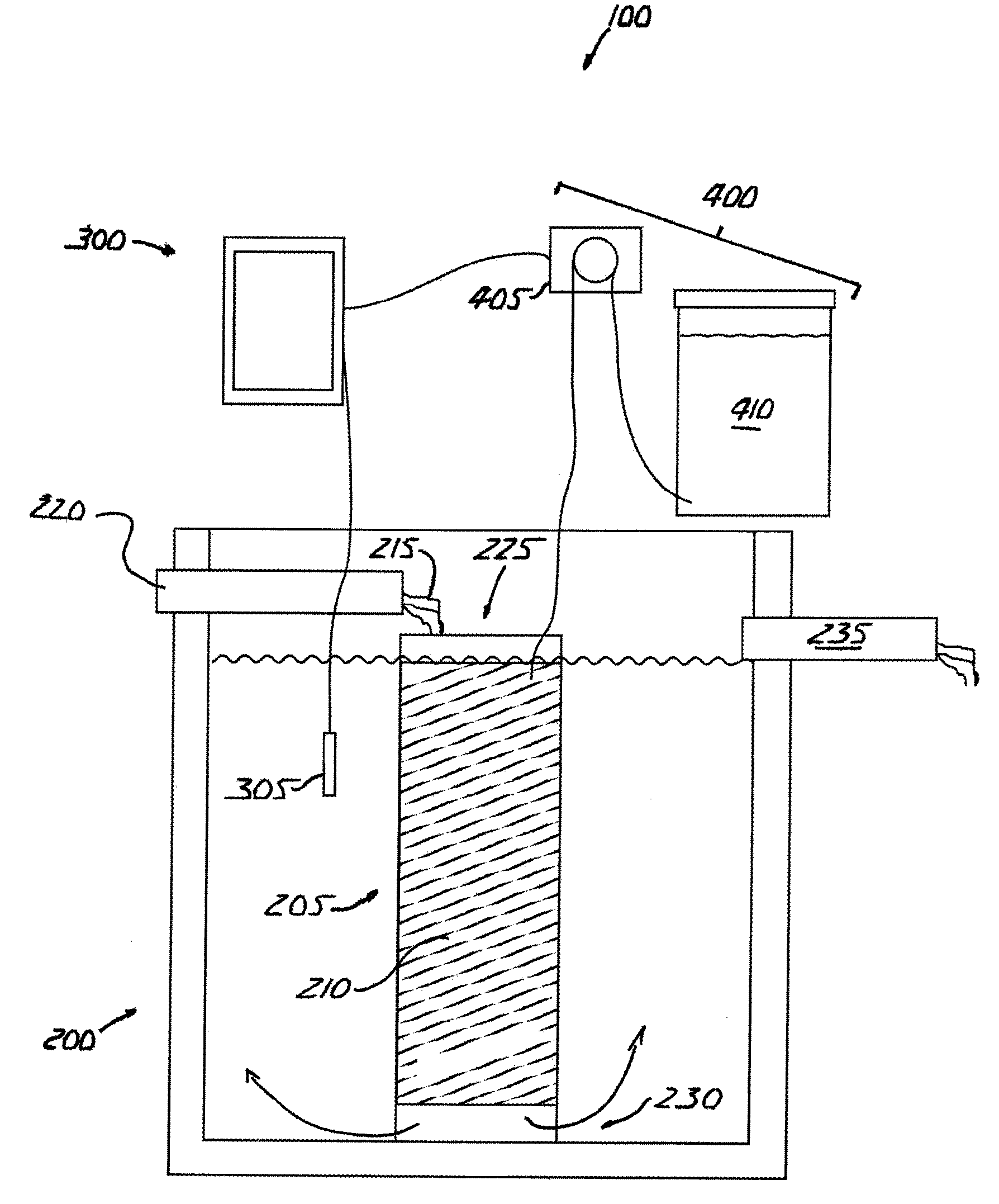

Apparatus for denitrifying wastewater

ActiveUS7544292B2High activityInexpensive, dependable and effectiveWater treatment parameter controlOther chemical processesNitrateWastewater

Owner:CORMIER TROY L

Apparatus For Denitrifying Wastewater

ActiveUS20090211954A1High activityInexpensive, dependable and effectiveWater treatment parameter controlOther chemical processesNitratePolyethylene glycol

Disclosed is an apparatus for denitrifying a solution that includes a denitrification tank configured to receive a portion of the solution for a period of time. Controlling an amount, duration and frequency of introduction of polyethylene glycol into the solution promotes indigenous heterotrophic bacteria depleting dissolved oxygen in the solution and obtaining oxygen from nitrate in the solution.

Owner:HOOT AEROBIC SYST

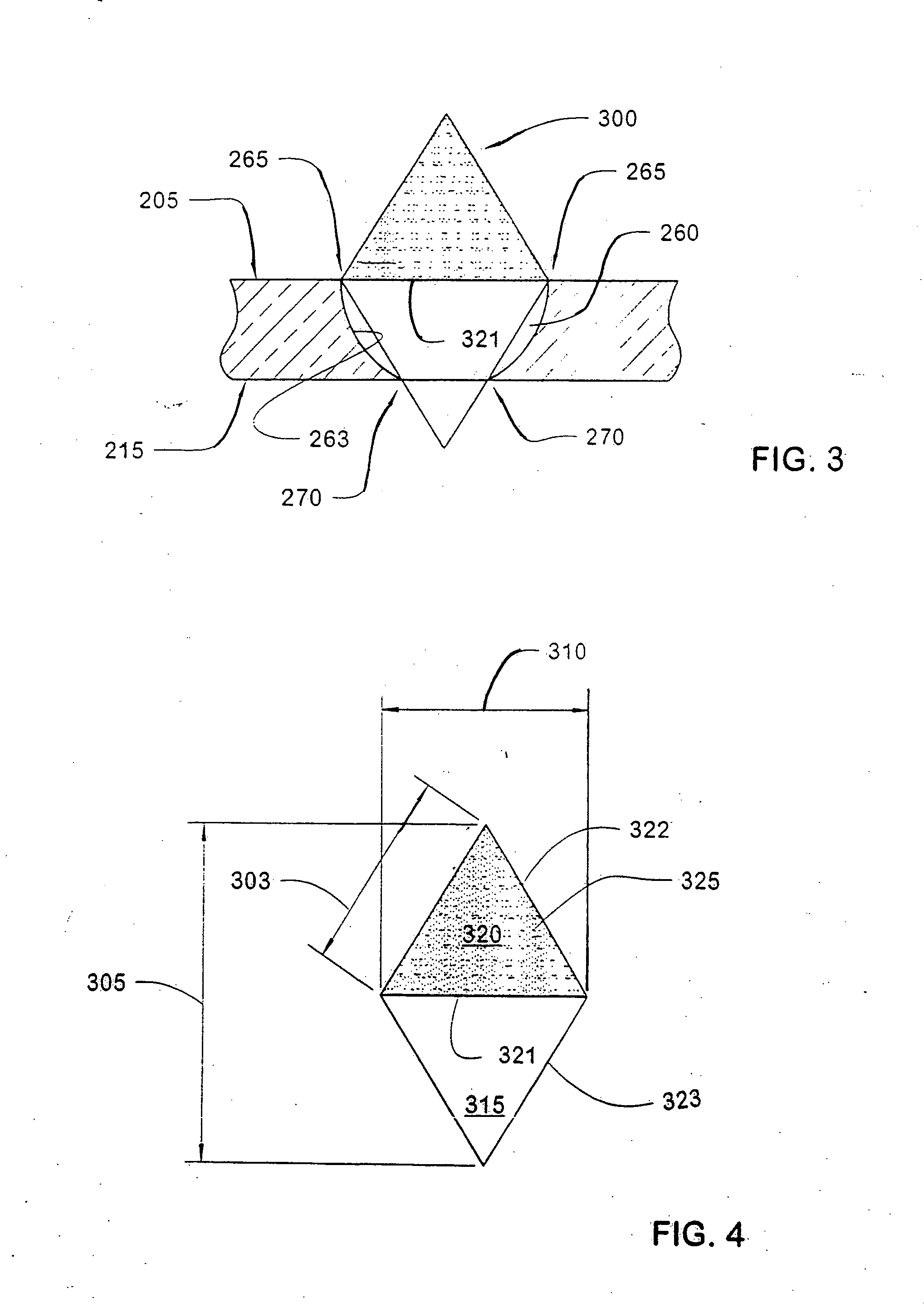

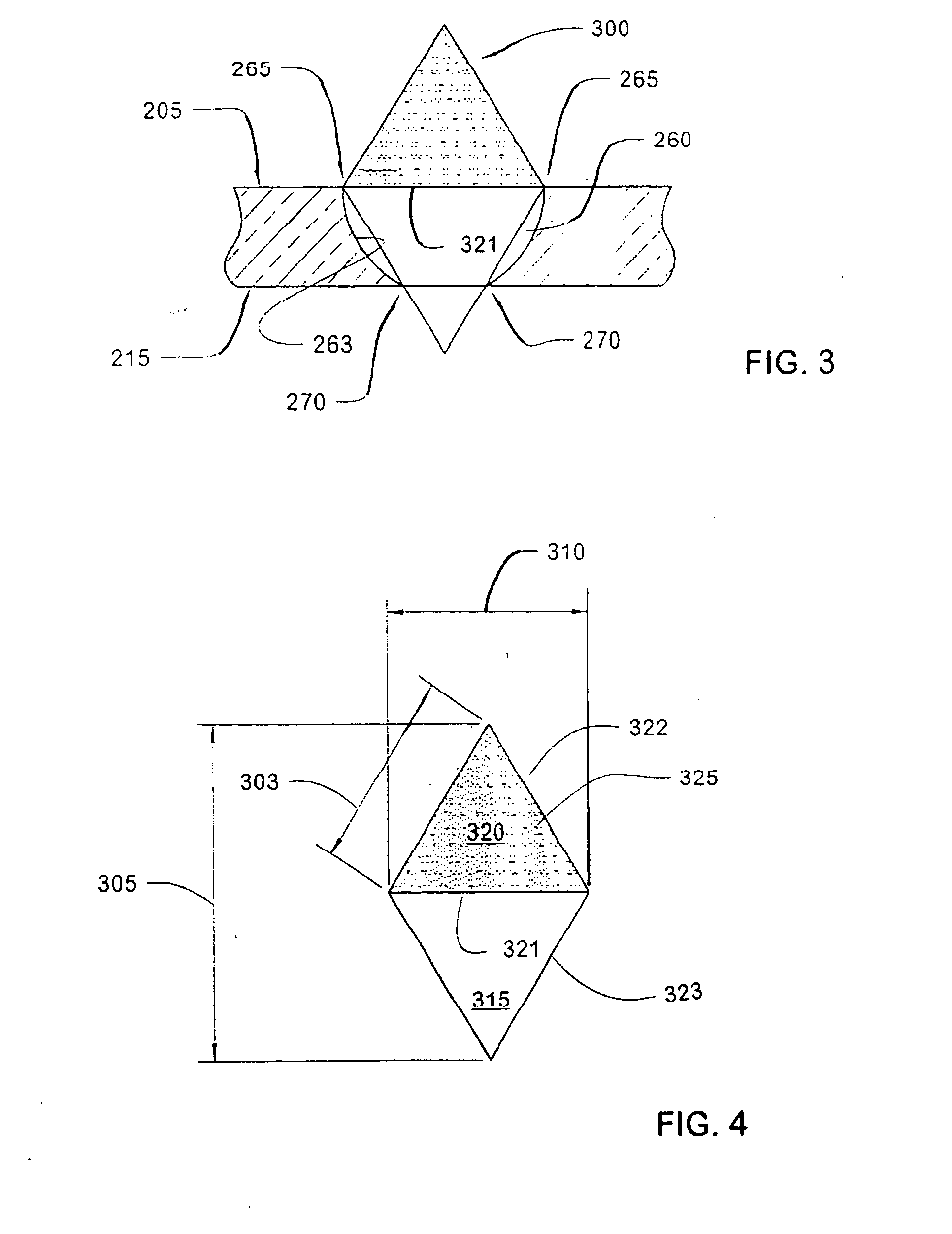

Apparatus for and method of forming concrete and transferring loads between concrete slabs

InactiveUS20060185316A1Inexpensive, dependable and effectivePaving detailsBuilding constructionsElastomerEngineering

An embodiment configured according to principles of the invention includes a plate defining a hexagon having a base parallel with joint between concrete slabs. Another embodiment includes a hexagon-shaped plate having an elastomer-coated first portion and a second portion, and a form having a slot configured to closely receive the second portion. A further embodiment includes a plate having compressive and / or resilient edge banding disposed on a plate edge that is not parallel to the joint. Apparatuses and methods for retro-fitting existing concrete stabs for transferring a load with a new adjacent concrete slab also are disclosed.

Owner:E Z FORM

Apparatus for denitrifying wastewater

ActiveUS7666300B2High activityInexpensive, dependable and effectiveWater treatment parameter controlOther chemical processesNitrateWastewater

Disclosed is an apparatus for denitrifying a solution that includes a denitrification tank configured to receive a portion of the solution for a period of time. Controlling an amount, duration and frequency of introduction of polyethylene glycol into the solution promotes indigenous heterotrophic bacteria depleting dissolved oxygen in the solution and obtaining oxygen from nitrate in the solution.

Owner:CORMIER TROY L

Apparatus for and method of forming concrete and transferring loads between concrete slabs

InactiveUS20060180950A1Inexpensive, dependable and effectiveIn situ pavingsSidewalk pavingsEngineeringStructural engineering

Owner:E Z FORM

Apparatus For And Method Of Denitrifying Wastewater

ActiveUS20080035538A1High activityInexpensive, dependable and effectiveWater treatment parameter controlOther chemical processesNitrateWastewater

Disclosed is a method of denitrifying a solution including introducing into the solution an amount of a carbon source within a duration and at a frequency so that indigenous heterotrophic bacteria deplete dissolved oxygen in the solution and decompose oxygen from nitrate in the solution to obtain its combined oxygen. Related apparatuses and compounds also are disclosed.

Owner:HOOT AEROBIC SYST

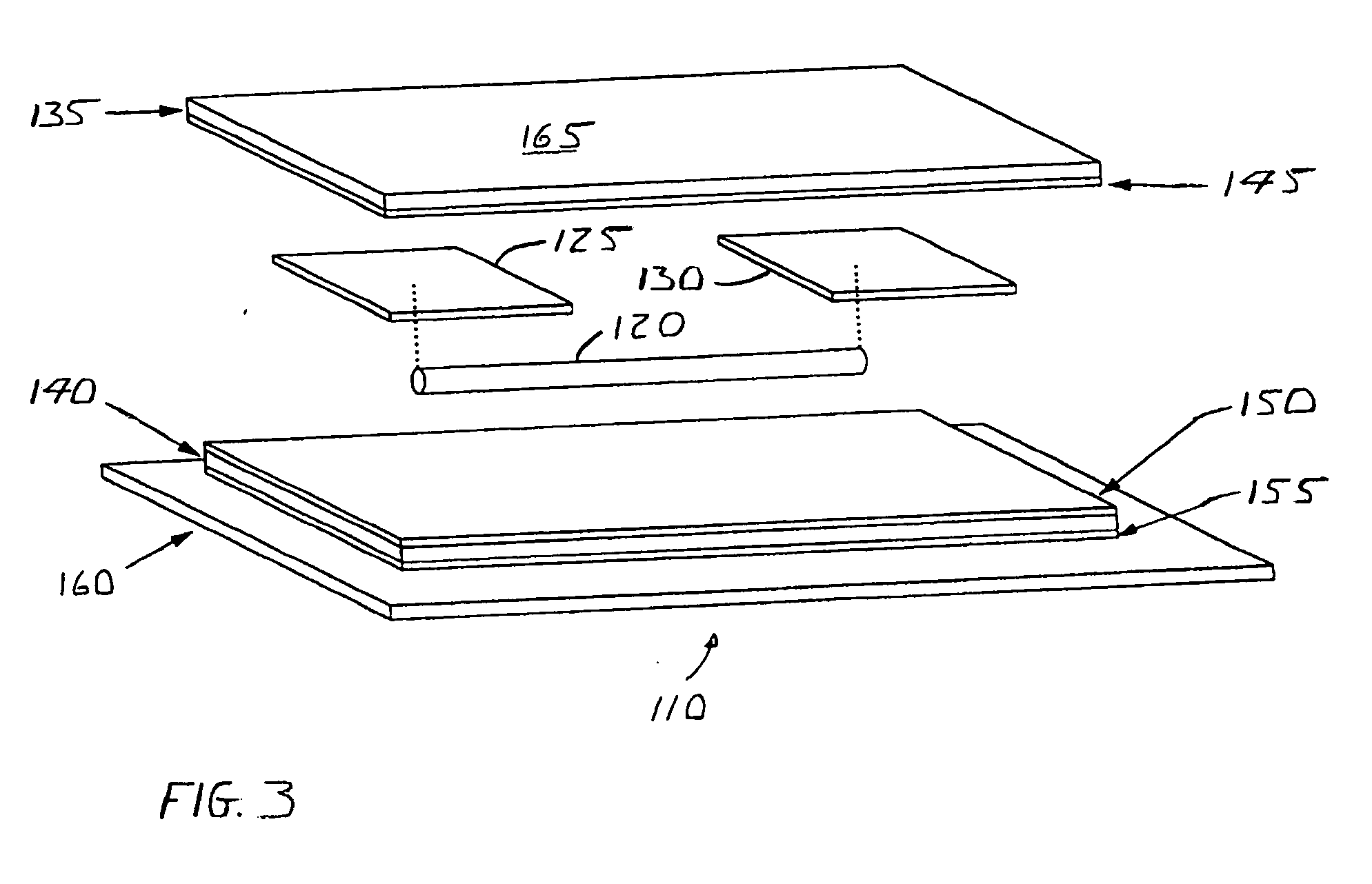

Apparatus for protecting against impact

InactiveUS20060269742A1Easy to transportQuick to useSpecial paperSynthetic resin layered productsEngineeringSecondary layer

Owner:MCTECH GROUP

Apparatus for Dosing a Wastewater Treatment System

InactiveUS20080083667A1Inexpensive, dependable and effectiveWater treatment parameter controlSpecific water treatment objectivesTreatment systemWastewater disposal

A reservoir is configured to receive a first fluid, and has an inlet configured to receive a second fluid and an outlet. Second fluid received in the reservoir drives a corresponding amount of first fluid out of the outlet and into the wastewater treatment system. A method also is disclosed.

Owner:CORMIER MURPHY J +4

Jetter cup holder

InactiveUS20060137616A1Avoid pollutionInexpensive, dependable and effectiveAnimal watering devicesCathetersEngineeringMechanical engineering

Owner:RUCKS CHAD

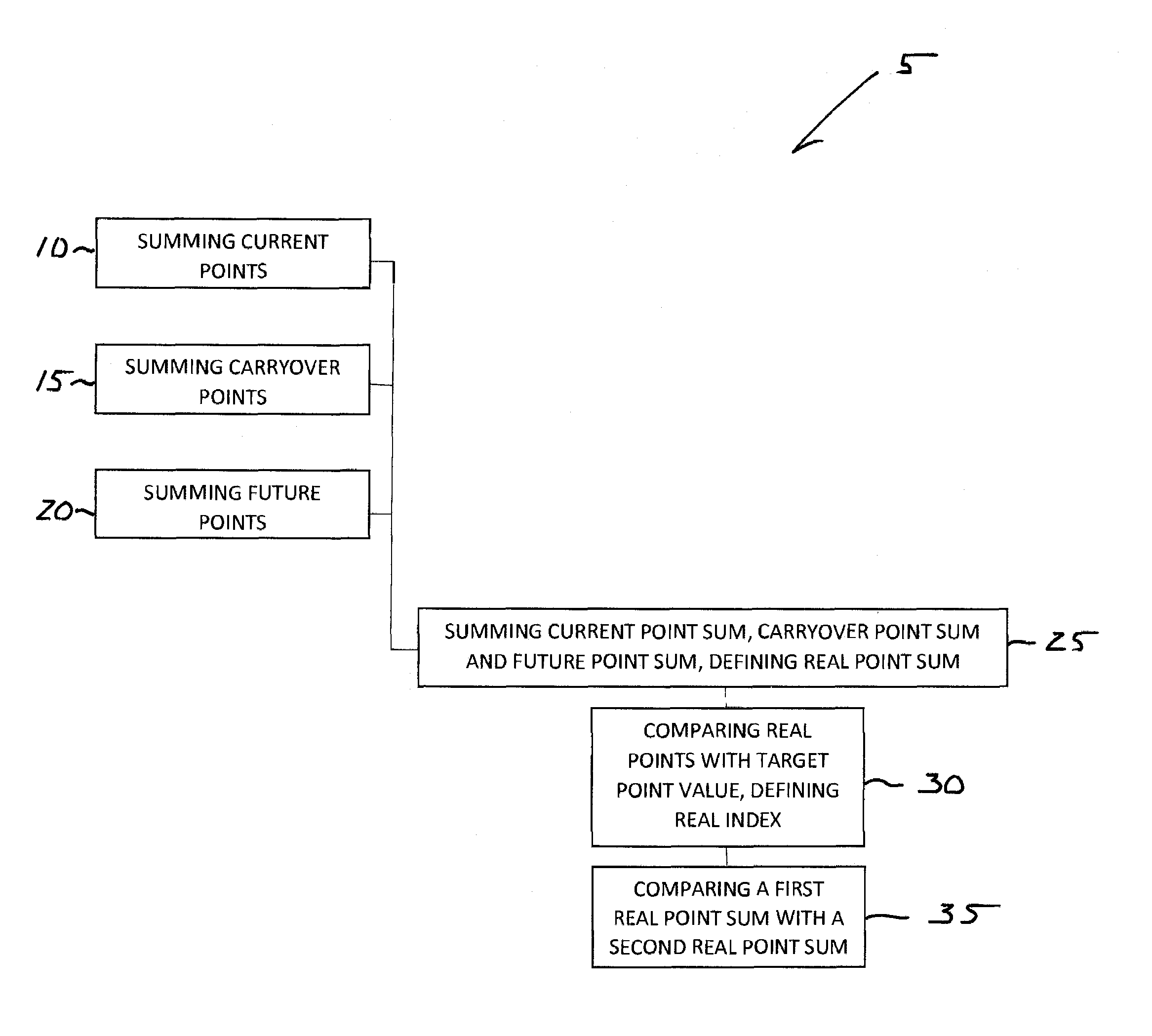

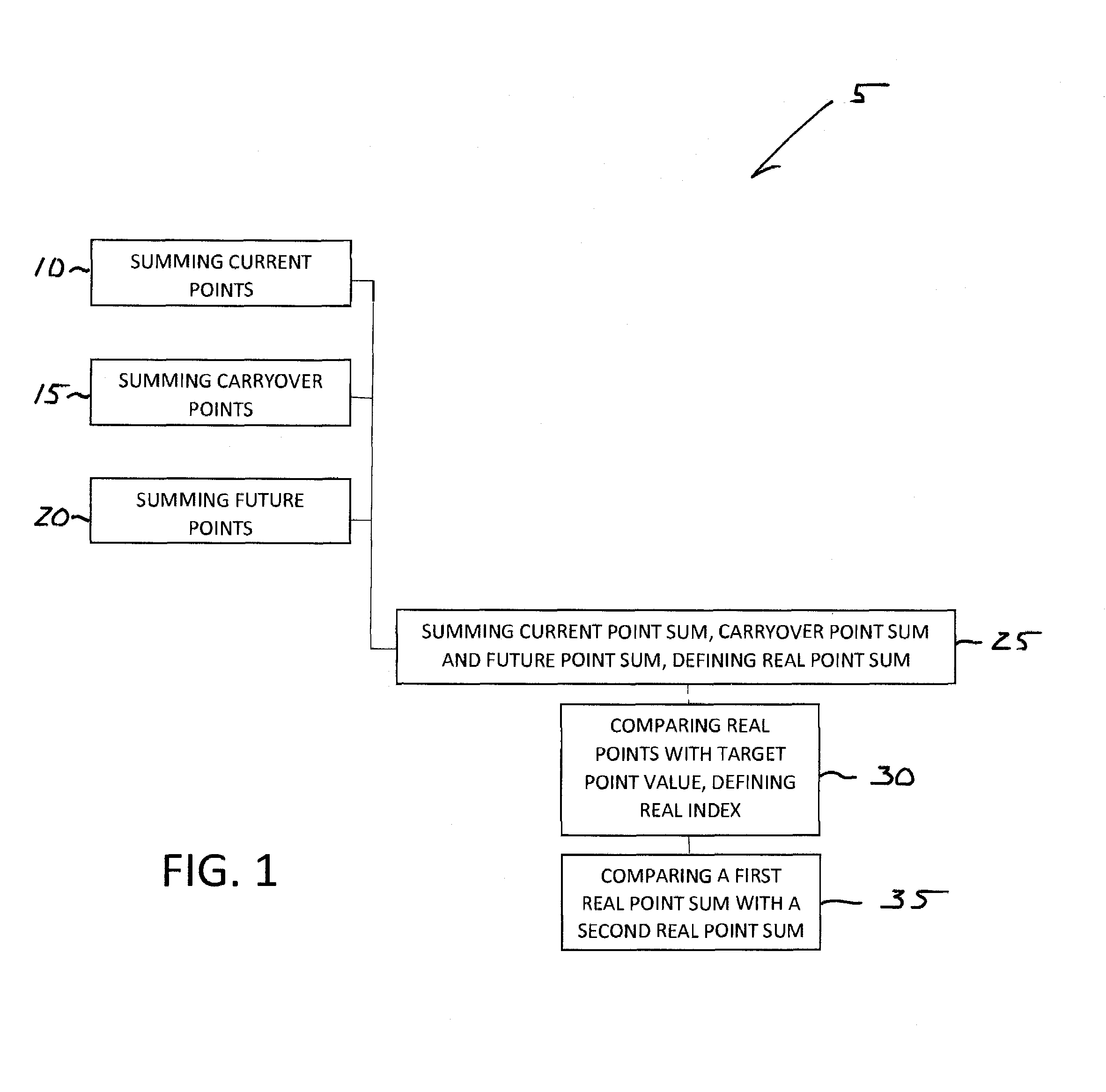

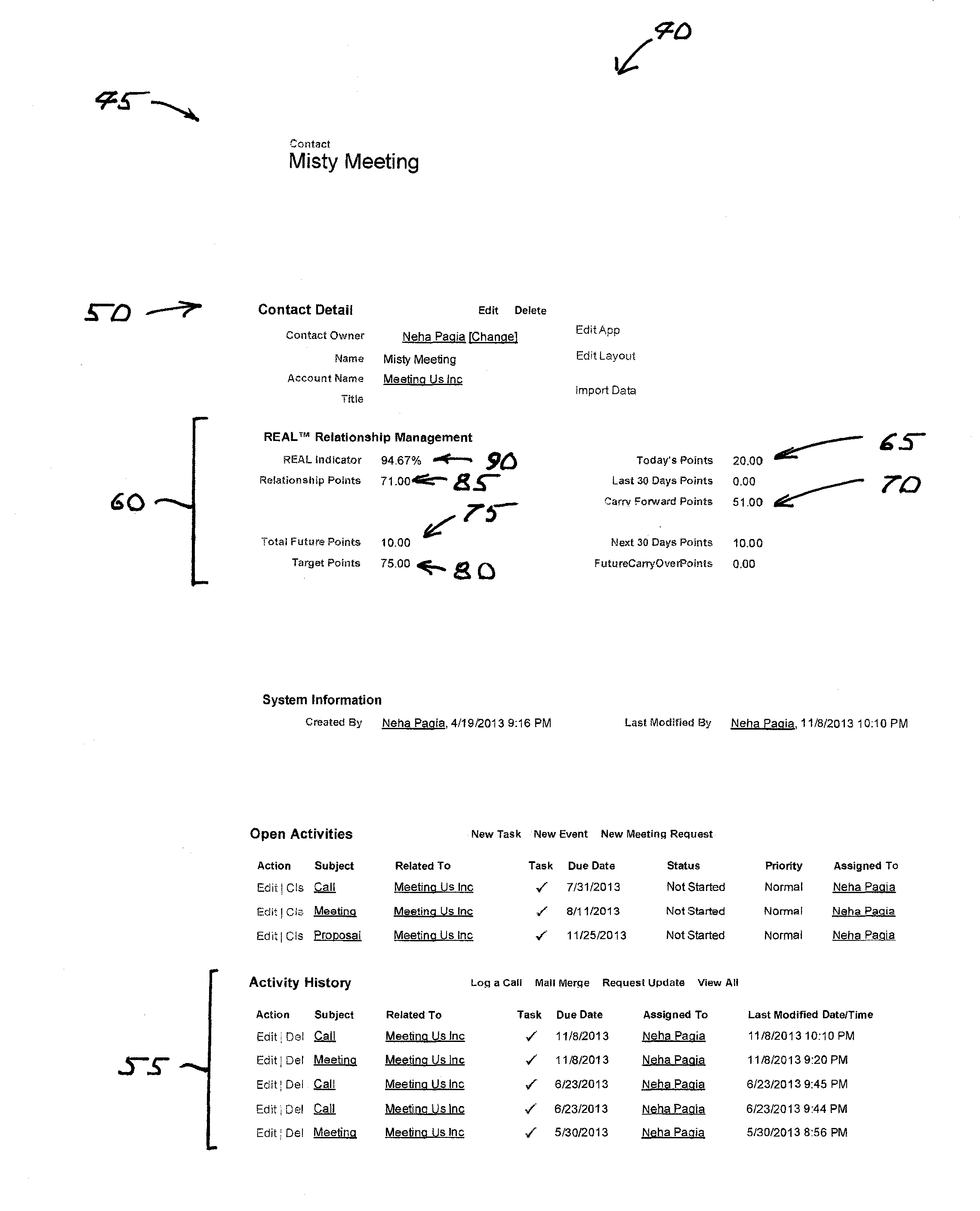

Method of Managing Customer Relationships

InactiveUS20140081716A1Inexpensive, dependable and effectiveCustomer relationshipResourcesActivity levelCurrent point

Described and depicted is a method for maintaining customer relationships that provides a true indicator of the health of a business relationship by quantifying the level of activity undertaken toward maintaining a relationship, according greater weight to favored and more recent and planned activities, which can be measured against a desired activity level. An embodiment configured according to principles of the invention includes: a first summing of points associated with activities completed within a first period of time and defining a carryover point sum; a second summing of points associated with activities completed within a second period of time and defining a current point sum; a third summing of points associated with activities scheduled within a third period of time and defining a future point sum; and a fourth summing of points comprising the current point sum, carryover point sum and future point sum, and defining a real point sum. The real point sum may be compared with a target point value to assess effort level expended in maintaining a relationship.

Owner:SPANBAUER SCOTT M

Method of Forming Concrete

InactiveUS20070272824A1Inexpensive, dependable and effectiveMouldsPaving detailsStructural engineeringMultiple forms

An apparatus for forming concrete includes a form having a slot configured to closely receive a plate. The slot is defined by one or more annular surfaces having central axes perpendicular to a direction in which the slot receives the plate. A method for forming same includes providing a sheet of form material; disposing a release layer on the sheet; cutting the sheet into a plurality of forms having a predetermined form height; and cutting a slot in each of each of the plurality of forms. Another apparatus for forming concrete includes a plate having a first portion and a second portion. A coating is disposed on the first portion. When disposed in a joint defined by a first volume of concrete and a second volume of concrete, the first volume of concrete adheres only to the coating and the second volume of concrete adheres only to the second portion. A method for forming concrete includes providing a plate having a coated first portion and a second portion; providing a form having a slot configured to closely receive the second portion; inserting the second portion in the slot; positioning the form to receive concrete; pouring a volume of concrete on the form and the first portion; curing the volume of concrete and defining cured concrete; and removing the form from the cured concrete. The plate remains in the cured concrete.

Owner:MCDONALD STEPHEN F

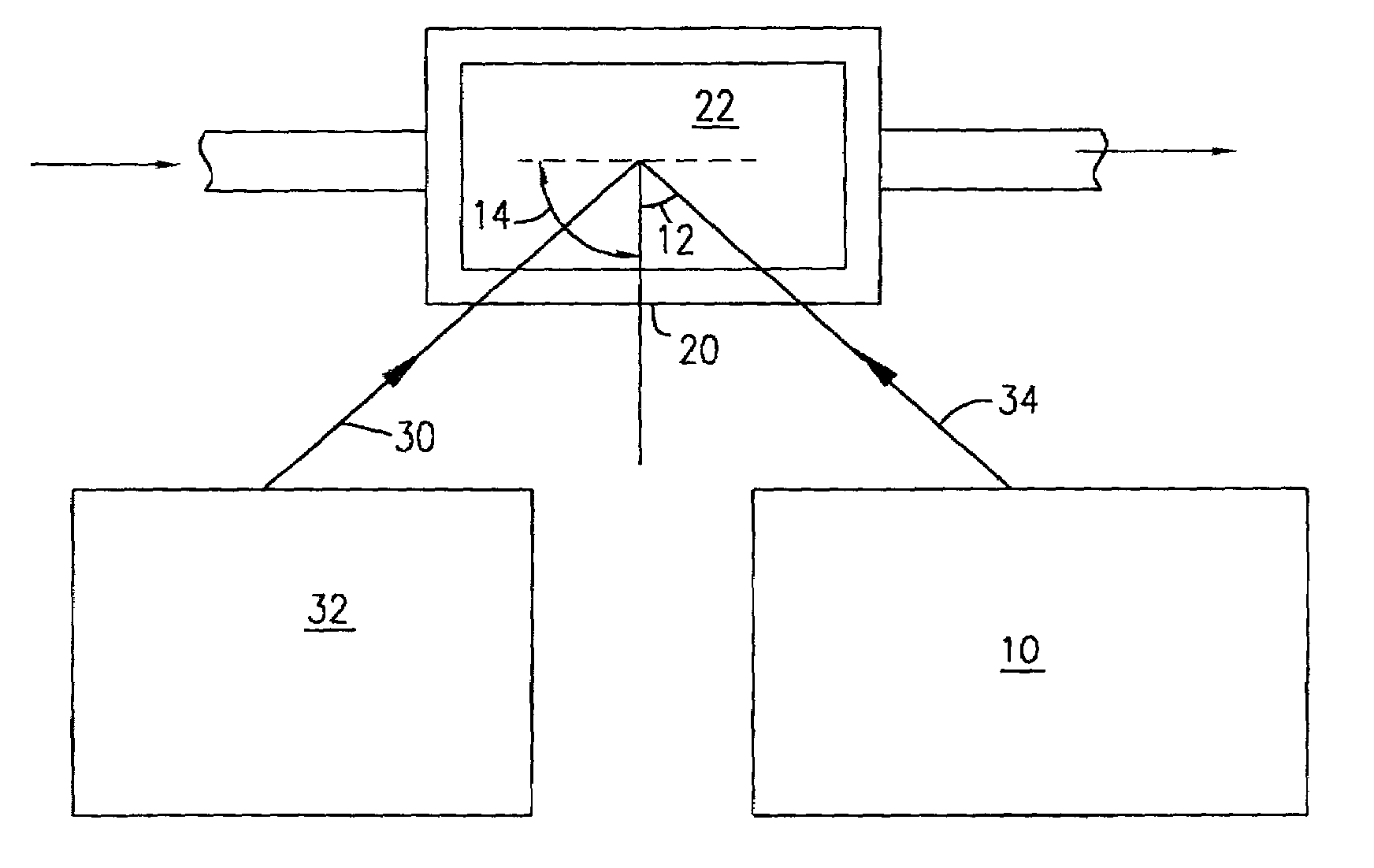

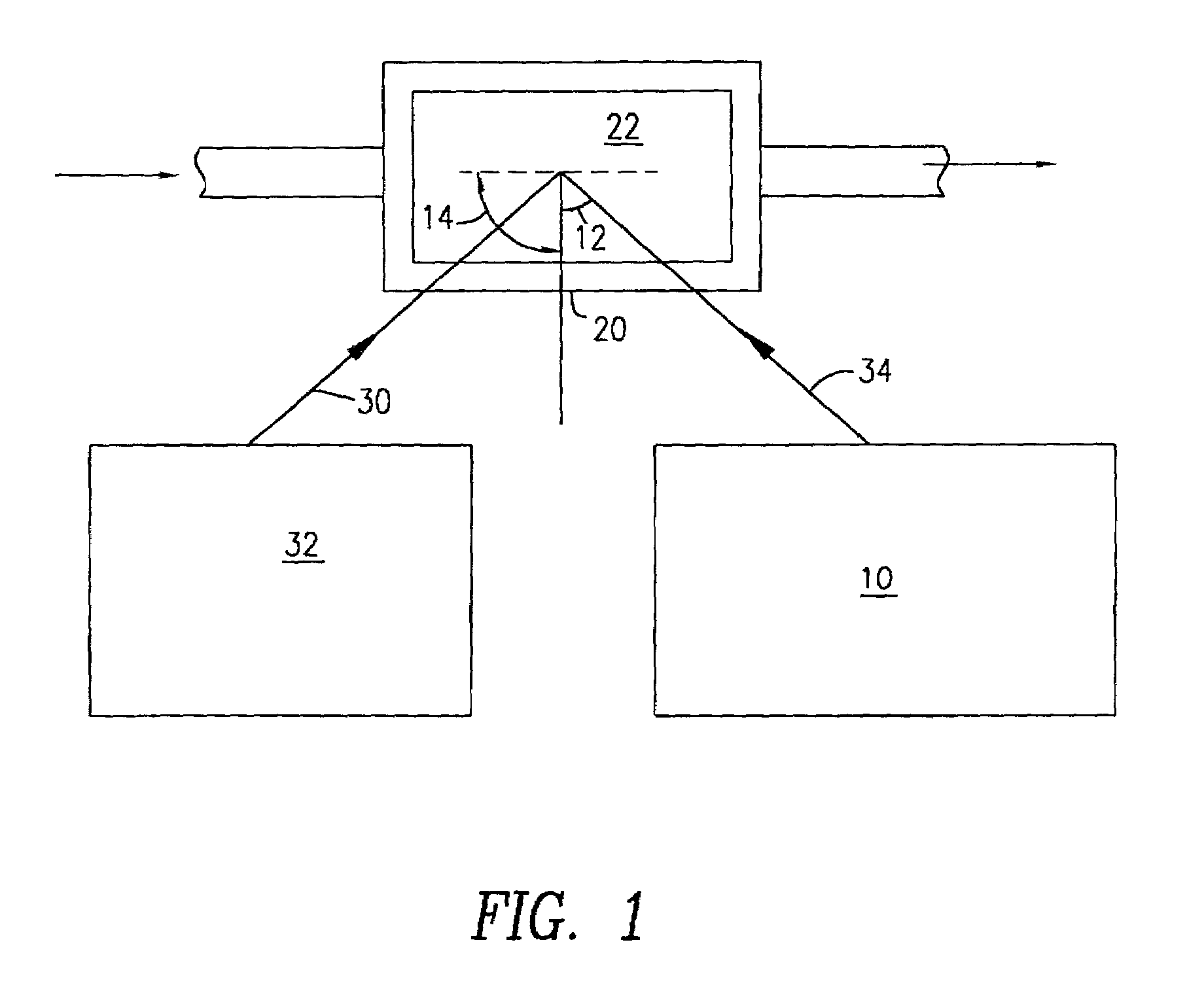

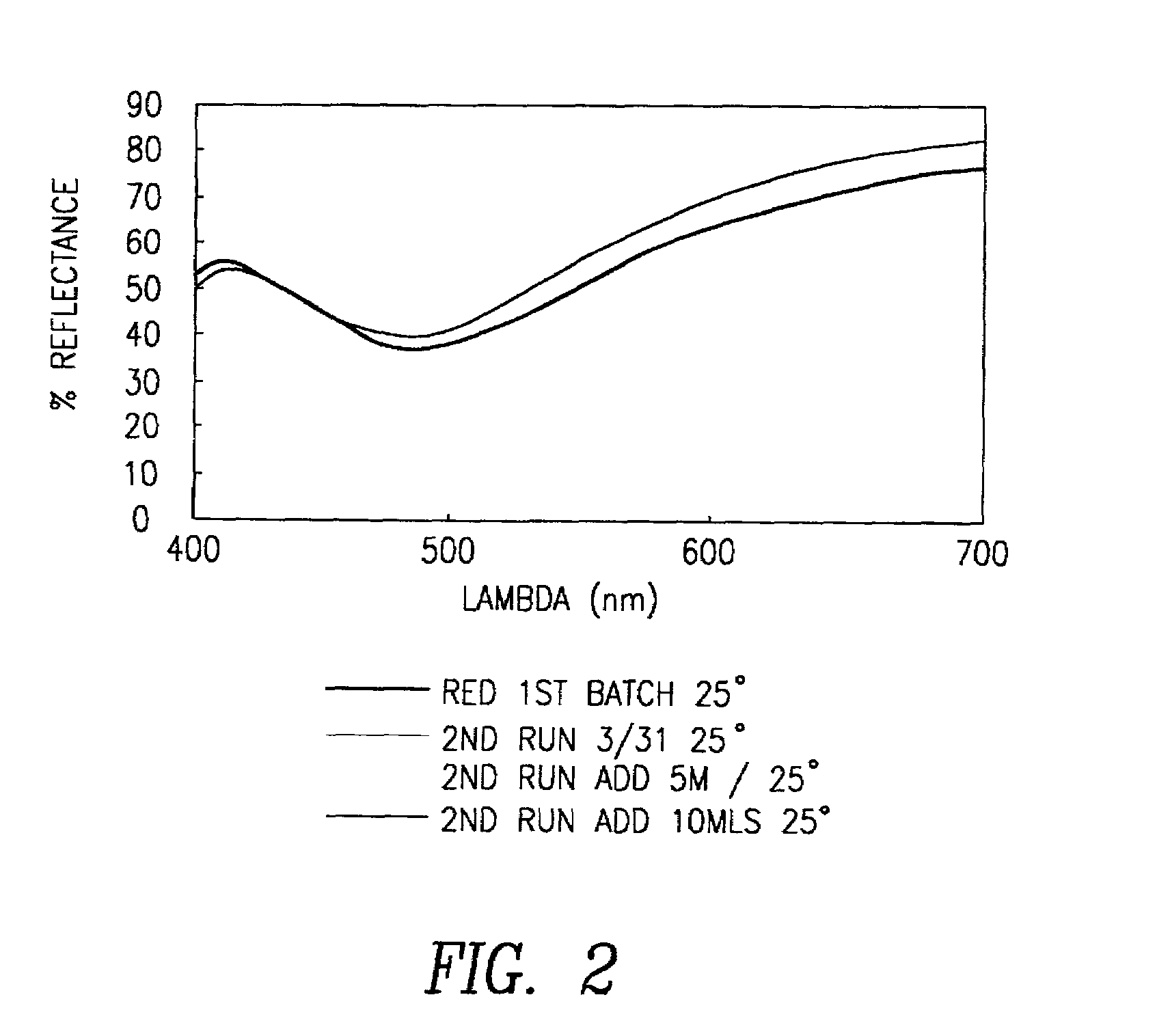

Automated reactor endpointing of platy interference effect pigments

InactiveUS6999167B2Increasing color-matched pigment outputReducing in-process testing timeRadiation pyrometryPhase-affecting property measurementsPigmentAnalytical chemistry

An apparatus and a method for objectively ascertaining a color match between a selected standard color and the color exhibited by an interference effect pigment during processing thereof and terminating the process upon achieving a match. The invention provides a spectrophotometer attached to a flow cell to monitor the color of a platy effect pigment to monitor pigment color and ascertain completion of the coating reaction process involved in interference pigment production.

Owner:ENGELHARD CORP

Method of denitrifying wastewater

ActiveUS8101081B2High activityInexpensive, dependable and effectiveWater treatment parameter controlGeneral water supply conservationNitrateWastewater

Disclosed is a method of denitrifying a solution including introducing into the solution an amount of a carbon source within a duration and at a frequency so that indigenous heterotrophic bacteria deplete dissolved oxygen in the solution and obtain oxygen from nitrate in the solution. Related apparatuses and compounds also are disclosed.

Owner:CORMIER TROY L

Method of Denitrifying Wastewater

ActiveUS20090236283A1High activityInexpensive, dependable and effectiveWater treatment parameter controlGeneral water supply conservationNitrateNitrogen

Disclosed is a method of denitrifying a solution including introducing into the solution an amount of a carbon source within a duration and at a frequency so that indigenous heterotrophic bacteria deplete dissolved oxygen in the solution and obtain oxygen from nitrate in the solution. Related apparatuses and compounds also are disclosed.

Owner:HOOT AEROBIC SYST

Apparatus for Mounting an Audio Player

InactiveUS20130201609A1Easy to installInexpensive, dependable and effectiveTravelling carriersHoldersElectrical connectionOutput device

Disclosed is a mounting dock with an integral jack for digital audio players, preferably that incorporate a built-in clip, including, but not limited to the iPod Shuffle® and iPod Nano® manufactured by Apple, Inc. The dock includes a tapered and beveled mounting stem that inserts into the audio player's clip and a jack that inserts into and provides electrical connection with the audio player's audio port. The stem and jack are positioned and aligned so as to enable simultaneous mounting and electrical connection with the audio player, thereby effecting connection with a desired output device, such as earphones, with one hand in a single motion.

Owner:CARTER ZANE

Method of Making an Apparatus for Forming Concrete

InactiveUS20070176075A1Inexpensive, dependable and effectiveStrutsIn situ pavingsMultiple formsEngineering

An apparatus for forming concrete includes a form having a slot configured to closely receive a plate. The slot is defined by one or more annular surfaces having central axes perpendicular to a direction in which the slot receives the plate. A method for forming same includes providing a sheet of form material; disposing a release layer on the sheet; cutting the sheet into a plurality of forms having a predetermined form height; and cutting a slot in each of each of the plurality of forms. Another apparatus for forming concrete includes a plate having a first portion and a second portion. A coating is disposed on the first portion. When disposed in a joint defined by a first volume of concrete and a second volume of concrete, the first volume of concrete adheres only to the coating and the second volume of concrete adheres only to the second portion. A method for forming concrete includes providing a plate having a coated first portion and a second portion; providing a form having a slot configured to closely receive the second portion; inserting the second portion in the slot; positioning the form to receive concrete; pouring a volume of concrete on the form and the first portion; curing the volume of concrete and defining cured concrete; and removing the form from the cured concrete. The plate remains in the cured concrete.

Owner:MCDONALD STEPHEN F

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com