Environment-friendly metal cutting liquid and preparing method thereof

A metal cutting fluid and green metal technology, applied in the field of metal cutting, can solve the problems of interference of water-soluble anti-rust agent and anti-rust effect, and achieve the effect of good emulsification stability, excellent cleaning performance and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of the green metal cutting fluid of the present invention is described below.

[0054] The preparation method of the green metal cutting fluid of the present invention comprises: adding anionic surfactant and extreme pressure agent to base oil and heating to 50-60°C, stirring evenly and stopping heating, adding defoamer, bactericide and compound anti-foaming agent The composition of the rust agent and water are continuously stirred at a speed of 60r / min, then the non-ionic surfactant and coupling agent are added in sequence, and stirred until the appearance is clear and transparent, that is, the green metal cutting fluid is obtained.

Embodiment 1

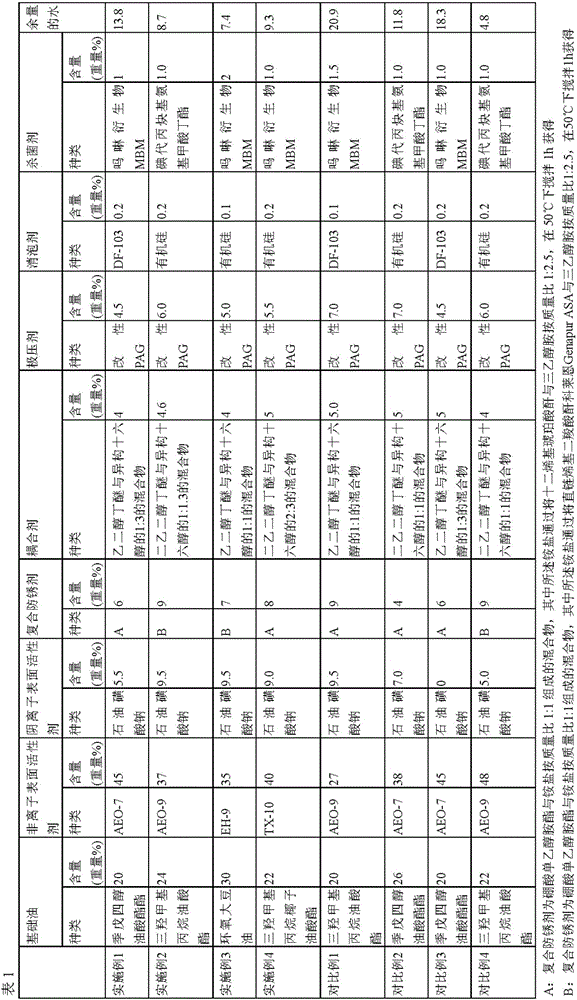

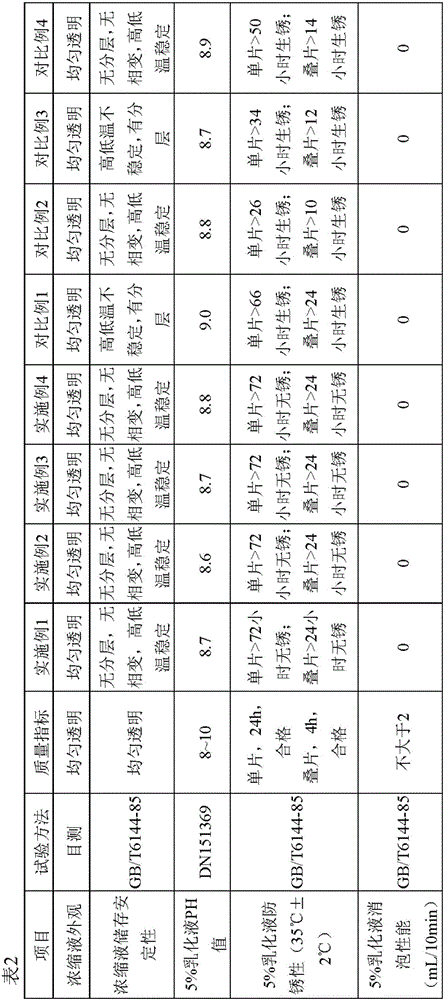

[0057] The composition and content of the green metal cutting fluid of this embodiment are shown in Table 1.

[0058] The preparation method of the green type metal cutting fluid of the present embodiment comprises the following steps:

[0059] (1) 20 g of pentaerythritol oleate (PETO-A) (Liaocheng Ruijie Chemical Co., Ltd., the same below), 5.5 g of anionic surfactant sodium petroleum sulfonate (Shanghai Boda Chemical Co., Ltd., the same below), extreme pressure Add 4.5g of anion-modified polyether PAG (Nanjing Gutian Chemical Co., Ltd., the same below) into the glass, heat to 50°C, and stop heating after stirring evenly.

[0060] (2) Add boric acid monoethanolamine ester (Shanghai Zhenwei Chemical Co., Ltd., the same below) and amine salt in a mass ratio of 1:1 mixture 6g, fungicide morpholine derivative MBM 1g (Suzhou Kaimeisi Chemical Materials Co., Ltd. company, the same below), polyether defoamer (DF-103) 0.2g (Nanjing Gutian Chemical Co., Ltd., the same below) and wate...

Embodiment 2

[0063] The composition and content of the green metal cutting fluid of this embodiment are shown in Table 1.

[0064] The preparation method of the green metal cutting fluid of the present embodiment comprises the following steps:

[0065] (1) Put 24g of trimethylolpropane oleate (Liaocheng Ruijie Chemical Co., Ltd., the same below), 9.5g of anionic surfactant sodium petroleum sulfonate, and 6.0g of extreme pressure agent anionic modified polyether PAG into a glass cup , heated to 50°C, and stopped heating after stirring evenly.

[0066] (2) Add 9 g of a mixture of monoethanolamine borate and amine salt at a mass ratio of 1:1, and 1.0 g of bactericide iodopropynyl butyl carbamate (Suzhou Kaimeisi Chemical Materials Co., Ltd., the same below), Organosilicon defoamer 0.2g (Shanghai Suokai Industrial Co., Ltd., the same below) and water 8.7g, and continuously stirred with the rotating speed of 60r / min; ASA (Shanghai Suokai Industrial Co., Ltd., the same below) and triethanolami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com