Automatic hoisting device for large-scale hood gate

An automatic lifting and mainframe technology, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as low efficiency, difficult use, meeting heads, etc., and achieve high efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

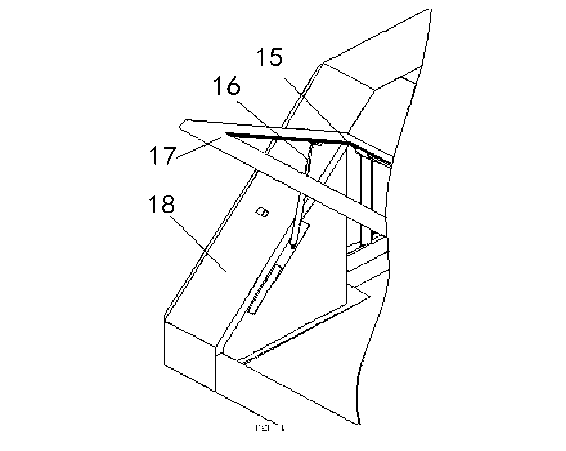

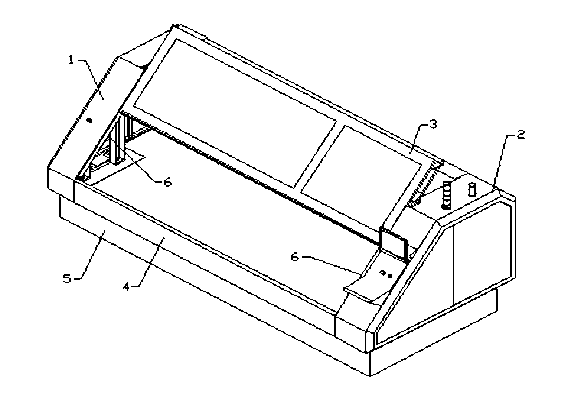

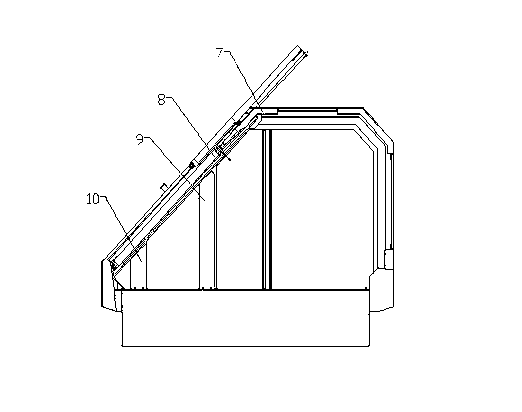

[0024] like figure 2 , image 3 , Figure 4 The shown large-scale hood door automatic lifting device is composed of the following components: a left column assembly 1, a right column assembly 2, a lifting cylinder assembly 8 installed on the column, the connecting parts of the left and right column assemblies, Rail assembly 11 , door frame assembly 3 , safety brake assembly 12 , buffer assembly 14 . The left column 1 and the right column 2 are fixed on the machine tool table 5 by screws, and the front top plate 7 and the front baffle 4 in the connection assembly connect the left column 1 and the right column 2 as a whole, which increases the rigidity of the entire hood column. and stability. The hinge support in the cylinder assembly 8 is installed on the cylinder mounting plate of the column, the cylinder block is supported by the upper brackets on the left and right columns, and the shaft extension ends of the cylinder are fixed on the U-shaped grooves on both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com