EVA heat treatment method of waste crystalline silicon solar cell module

A technology of solar cells and heat treatment methods, applied in waste treatment, electronic waste recycling, solid waste removal, etc., can solve problems such as high cost, volatile organic solvents, environmental hazards, etc., to shorten the processing cycle, avoid environmental pollution, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

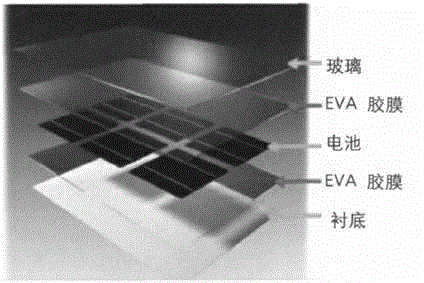

[0027] A kind of waste crystalline silicon solar cell module EVA heat treatment method, described method comprises the following steps:

[0028] a. Pretreatment

[0029] Firstly, pretreatment is carried out, and the waste crystalline silicon solar panel is heated on an electric heating plate to remove the TPT backsheet on the back;

[0030] b. Pyrolysis treatment

[0031] Put the battery plate without TPT into the quartz tube, then put it into the tube furnace, feed gas into the system, start to heat up, and keep it for a period of time after rising to a certain temperature, and take out the separated glass after the pyrolysis furnace cools down and batteries.

[0032] Further, the heating temperature in step a is 100° C. to 150° C., and the heating time is 3 minutes to 10 minutes.

[0033] Further, the gas described in step b is nitrogen or air.

[0034] Further, the specific temperature described in step b is 540°C to 580°C.

[0035] Further, after the temperature is ra...

Embodiment 2

[0038] This embodiment is an optimized solution based on the embodiment 1, and provides a method for heat treatment of waste crystalline silicon solar cell module EVA. For the parts in this embodiment that are the same as those in Embodiment 1, please refer to the content disclosed in Embodiment 1 for understanding, and the content disclosed in Embodiment 1 should also be regarded as the content of this embodiment, and will not be described repeatedly here.

[0039] This embodiment is a specific process of heat-treating EVA in a nitrogen atmosphere.

[0040] First, put the solar panel into an oven, bake it at 70°C for 10 days, and then heat it on a 140°C electric heating plate for 5 minutes to remove the TPT backsheet on the back.

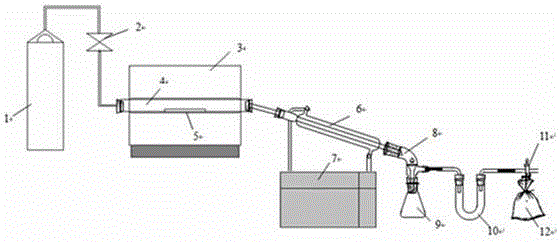

[0041] Put the TPT-removed cell plate into a quartz tube and put it into a tube furnace. according to figure 2 way to connect. Introduce high-purity nitrogen into the system, the gas flow rate is 65ml / min, start heating after purging for 15 min...

Embodiment 3

[0043] This embodiment is an optimized solution based on the embodiment 1, and provides a method for heat treatment of waste crystalline silicon solar cell module EVA. For the parts in this embodiment that are the same as those in Embodiment 1, please refer to the content disclosed in Embodiment 1 for understanding, and the content disclosed in Embodiment 1 should also be regarded as the content of this embodiment, and will not be described repeatedly here.

[0044] This embodiment is a specific process of heat-treating EVA in an air atmosphere.

[0045] First, put the solar panel into an oven, bake it at 70°C for 10 days, and then heat it on a 140°C electric heating plate for 5 minutes to remove the TPT backsheet on the back.

[0046] Put the TPT-removed cell plate into a quartz tube and put it into a tube furnace. according to figure 1 way to connect. Use an air pump to feed air into the system, the gas flow rate is 70ml / min, start heating after purging for 15 minutes, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com