Horizontal electroplating production line for circuit boards

A technology for electroplating production lines and circuit boards, applied in the electrolysis process, electrolysis components, etc., can solve the problems of too much waste water, no electroplating, and large environmental pollution, and achieve the effect of reducing costs and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

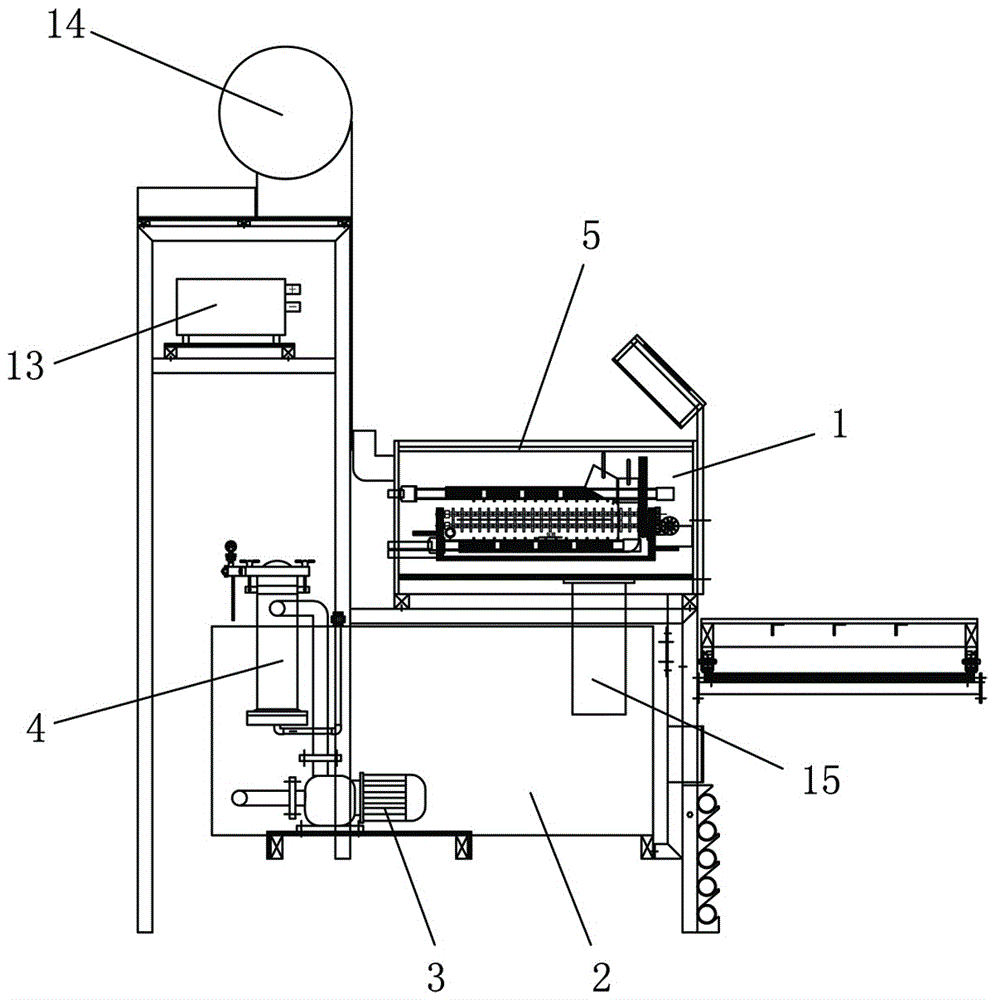

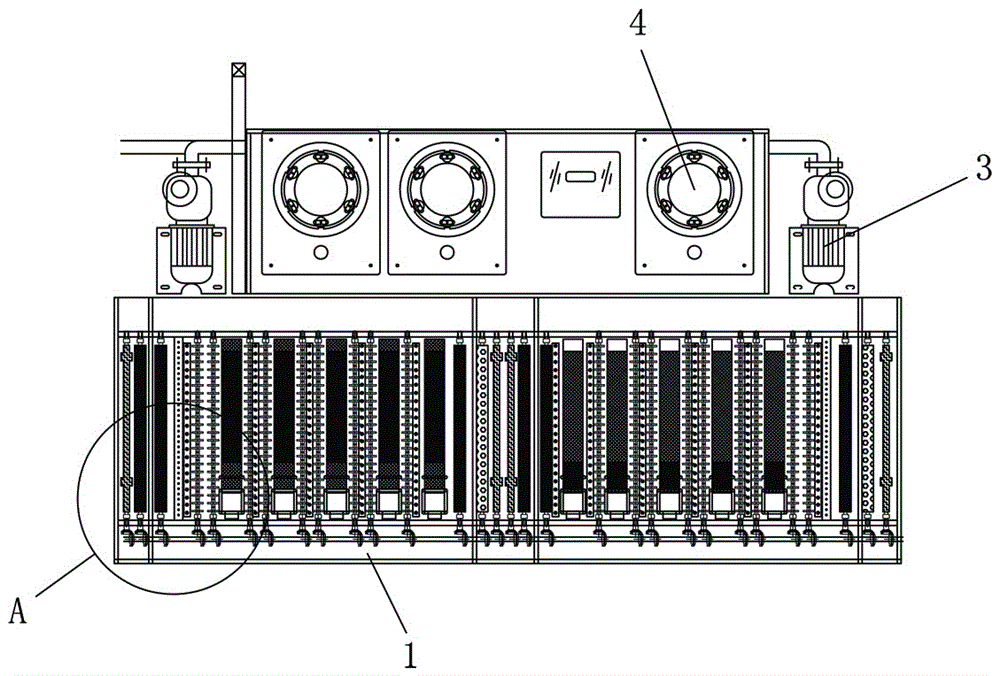

[0031] Combine below Figure 1-4 The technical solution provided by the present invention is described in more detail.

[0032] see Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a circuit board horizontal electroplating production line, including: a cleaning device, an electroplating device and a dehumidification device.

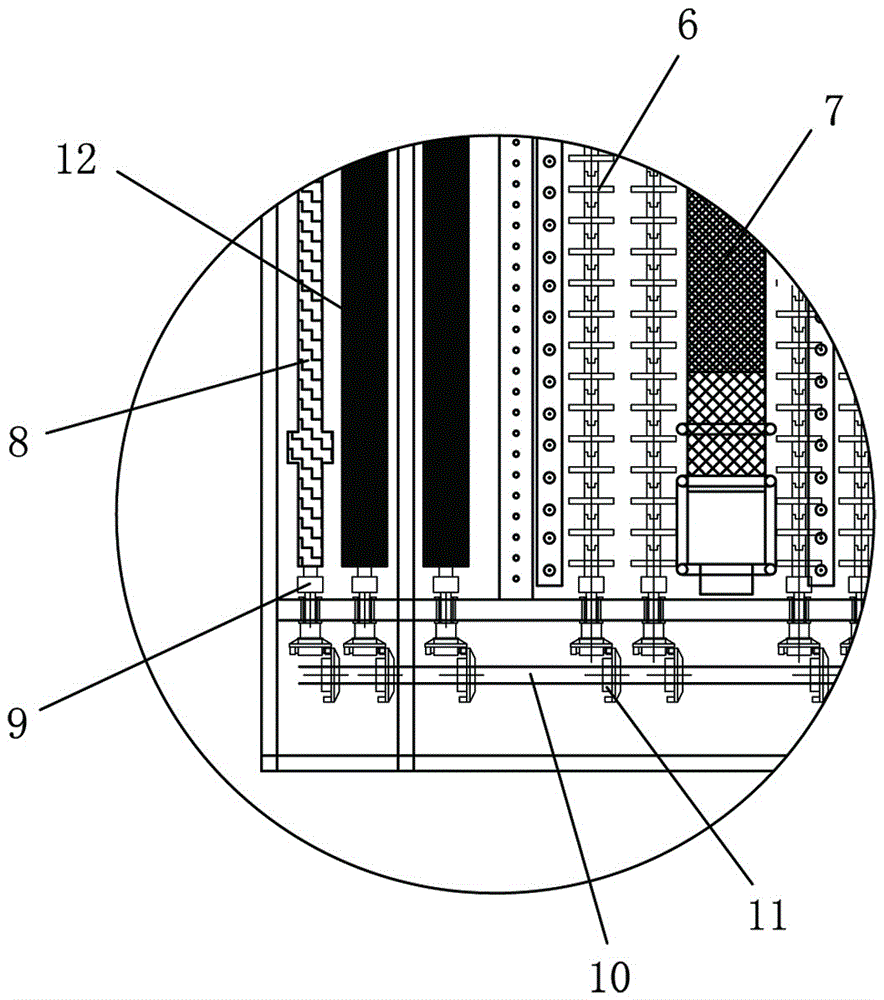

[0033] Wherein, the electroplating device includes a copper plating device and a tin plating device. Both the copper plating device and the tin plating device include an electroplating tank 1 , a rectifier 12 , a liquid medicine main tank 2 , a liquid medicine circulation pump 3 , a filtering barrel 4 and a liquid medicine nozzle 5 . There are eight conductive carbon rods 8, eight conductive wheels 9 and twenty titanium baskets 7 in the electroplating tank 1. The conductive carbon rods 8 correspond to the conductive wheels 9 one by one. The conductive carbon rods 8 use the conductive wheels 9 and the rectifiers 13 The ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com