Method for manufacturing faucet shell

A manufacturing method and faucet technology, applied in the field of faucets, can solve the problems of reduced workload of workers, time-consuming and laborious processing, etc., and achieve the effects of simplifying processing, improving processing efficiency and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

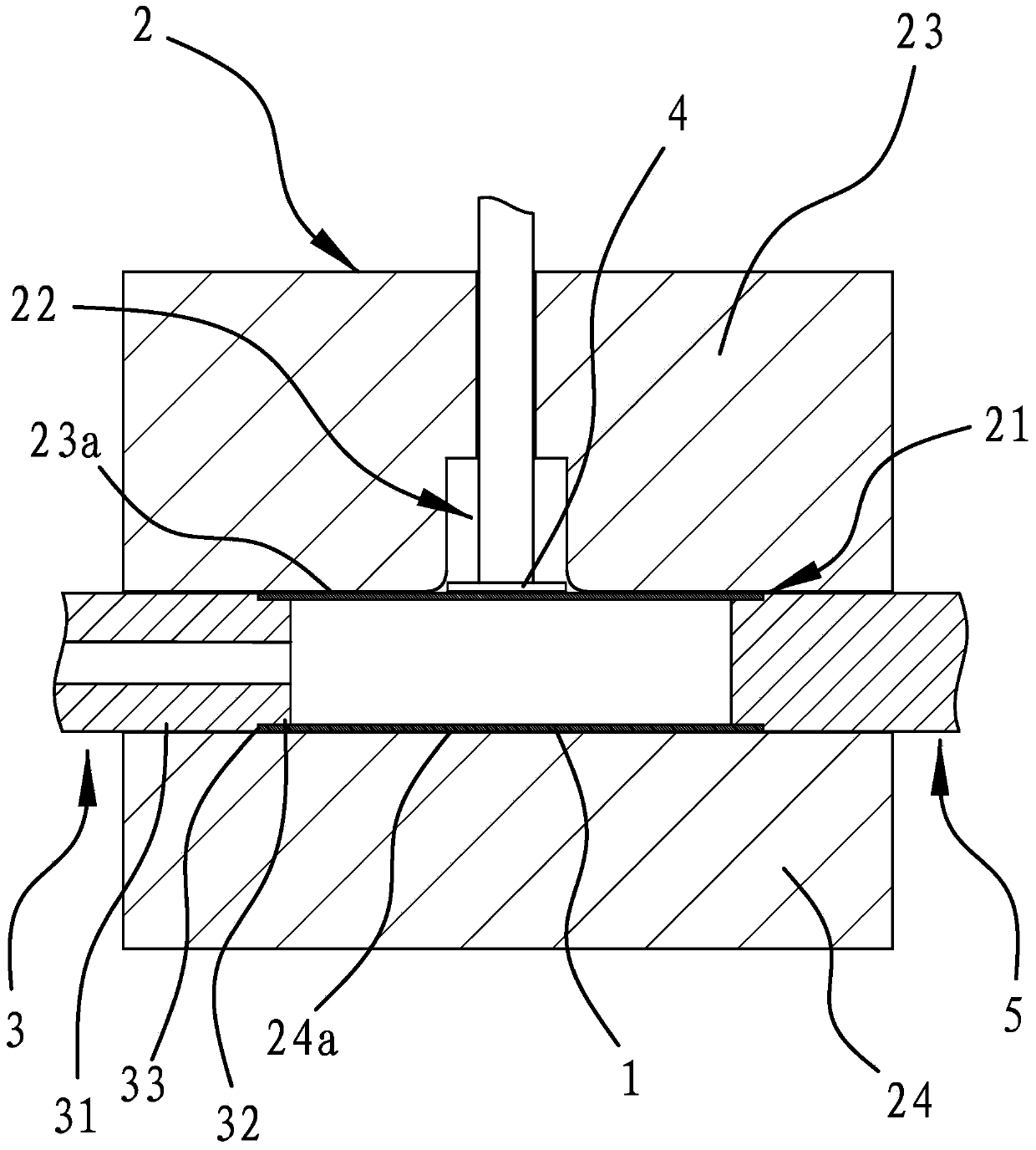

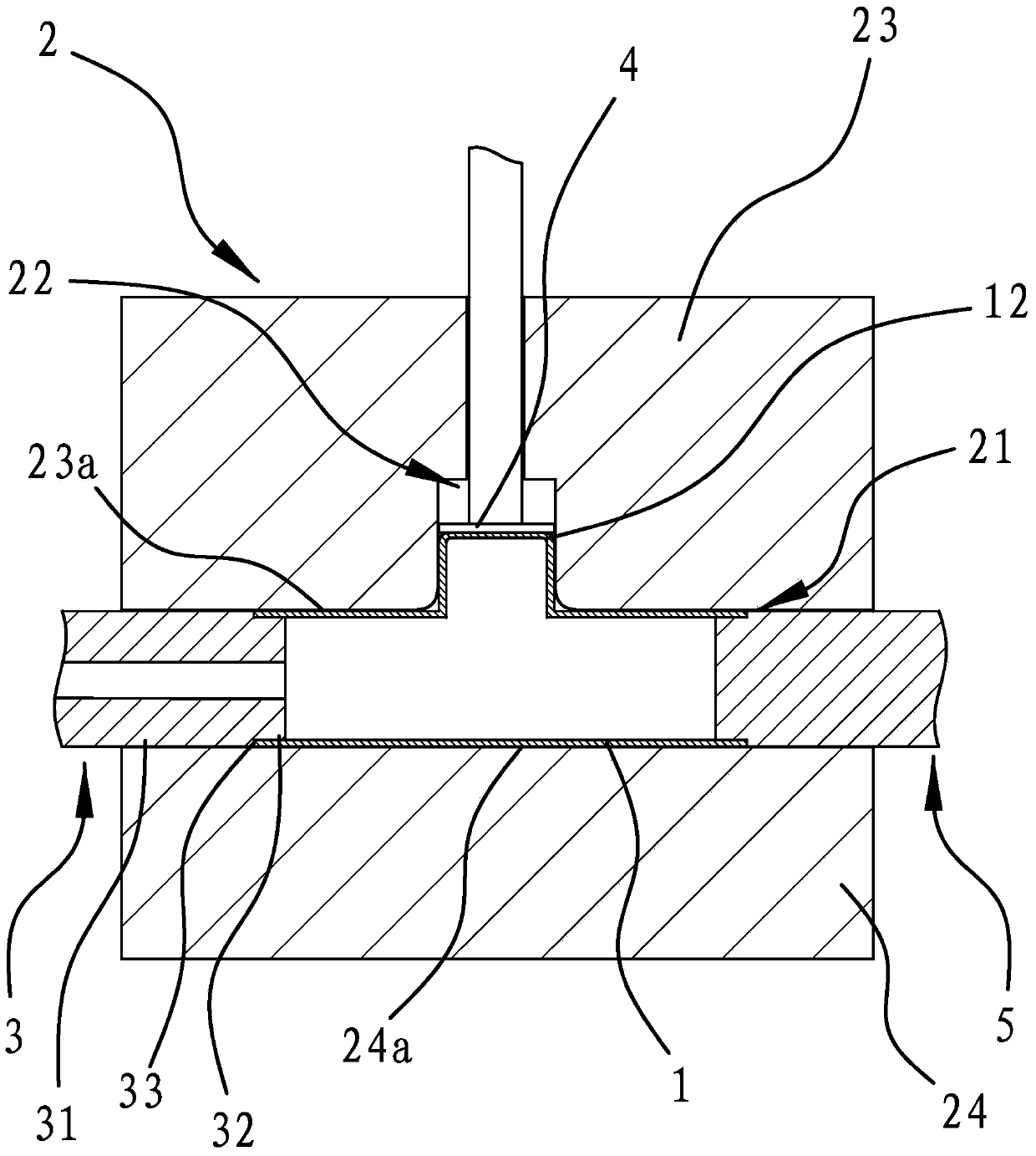

[0039] Such as Figure 1 to Figure 5 Shown, the manufacture method of faucet shell comprises the following steps:

[0040] A. Processing preparation: prepare the metal pipe 1 of the required length and the mold 2 with a cavity 21 that matches the shape of the metal pipe 1 inside, and the side of the cavity 21 in the mold 2 also has a cavity 21. The forming cavity 22;

[0041] In this embodiment, the metal tube 1 is an equal-diameter tube made of brass or stainless steel, which can be cut from a longer metal tube 1 raw material, or can be purchased directly, and the metal tube 1 obtained by cutting can be processed first. Tempering treatment to relieve internal stress of the metal pipe. Both the cavity 21 and the forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com