Manufacturing method of oil-immersed transformer

A technology of oil-immersed transformer and manufacturing method, which is applied in inductance/transformer/magnet manufacturing, coil manufacturing, packaging/impregnation, etc., can solve the problems of inability to mass production and slow production speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

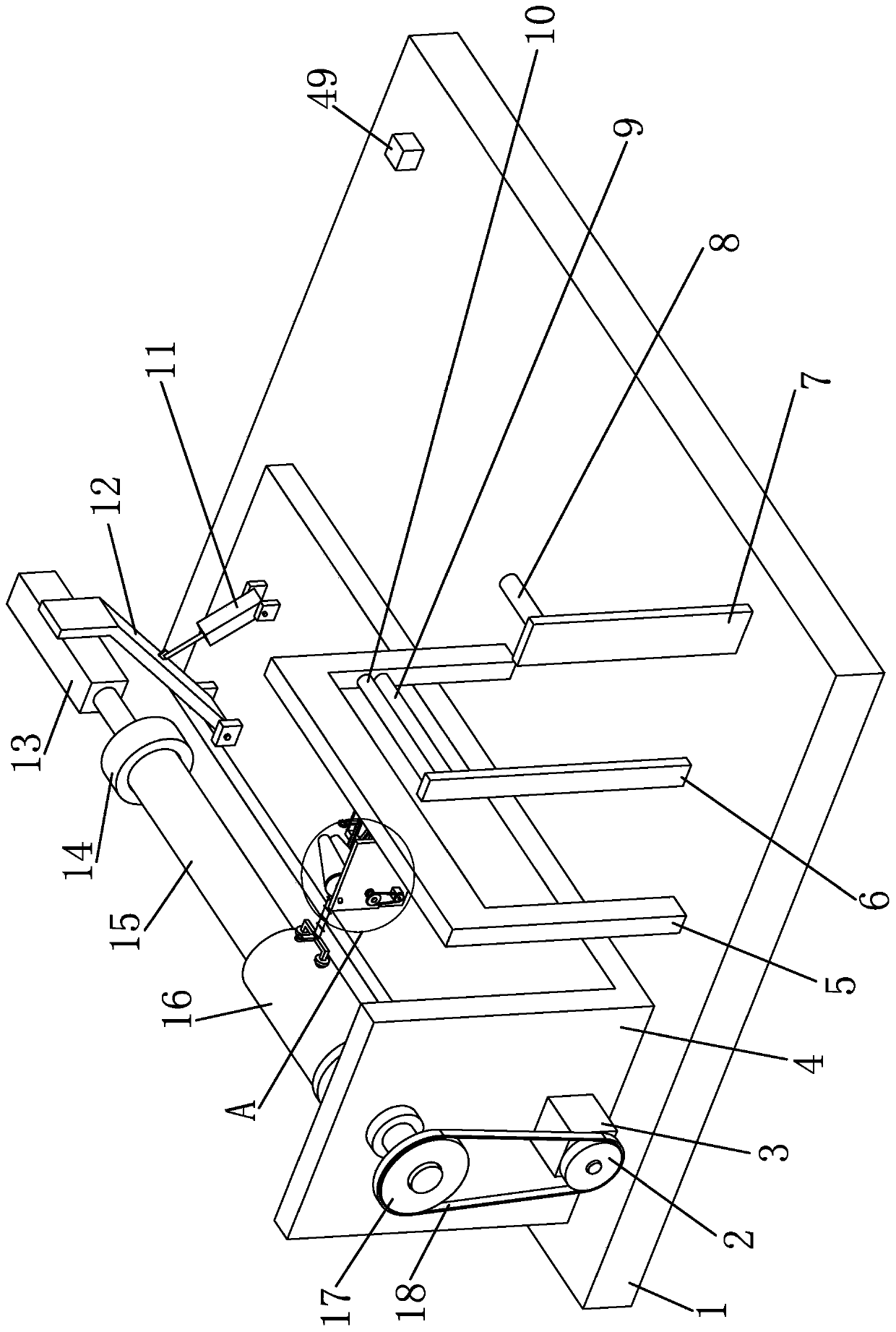

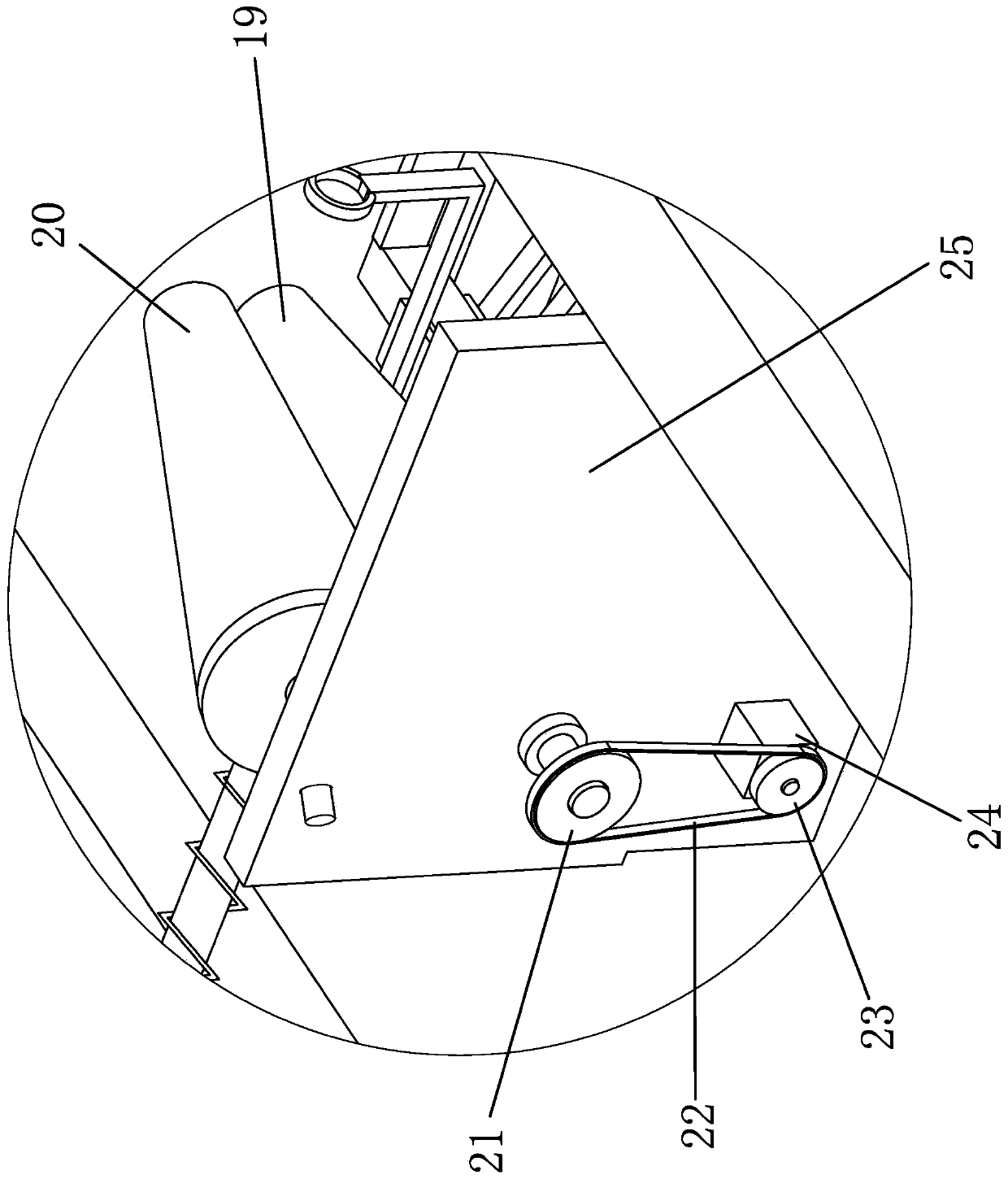

[0044] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

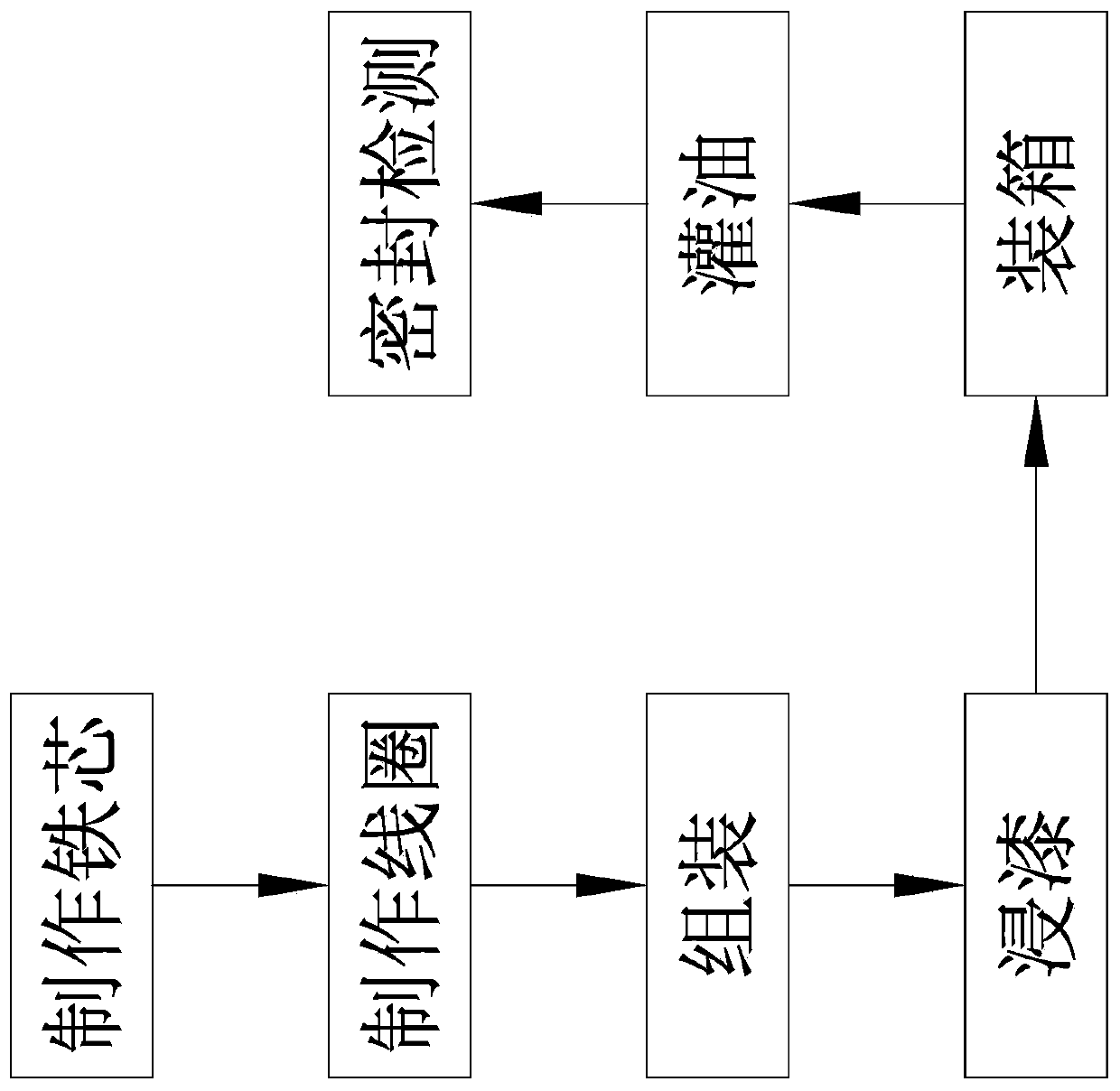

[0045] like Figure 1-Figure 6 As shown, the manufacturing method of the oil-immersed transformer includes the following steps:

[0046] a. Manufacture of the iron core: Slitting and cross-shearing the coil material, and stacking the obtained silicon steel sheets to obtain the iron core;

[0047] b. Making coils: Winding the wires through winding equipment to make coils;

[0048] c. Assembling: Assemble the iron core and the coil into one body to make a semi-finished product;

[0049] d. Impregnation: the semi-finished product is impregnated by the impregnation device;

[0050] e. Packing: put the semi-finished product into the fuel tank and fix it;

[0051] f, oil filling: carry out vacuum oil filling process to the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com