Buckling type LED drive power supply box and production method thereof

A technology of LED driving and manufacturing method, applied in the field of power supply box, can solve the problems of no heat resistance and corrosion resistance of power supply box, single use, no production method of power supply box, etc., and achieves good protection effect, high production efficiency, and reduction of raw materials. Effect of drying waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

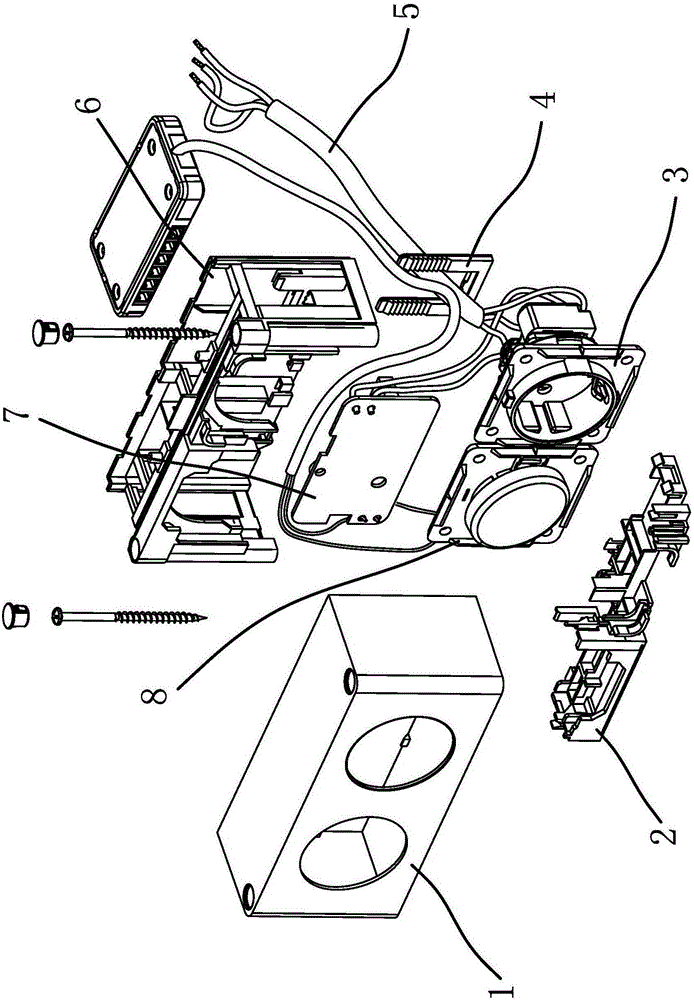

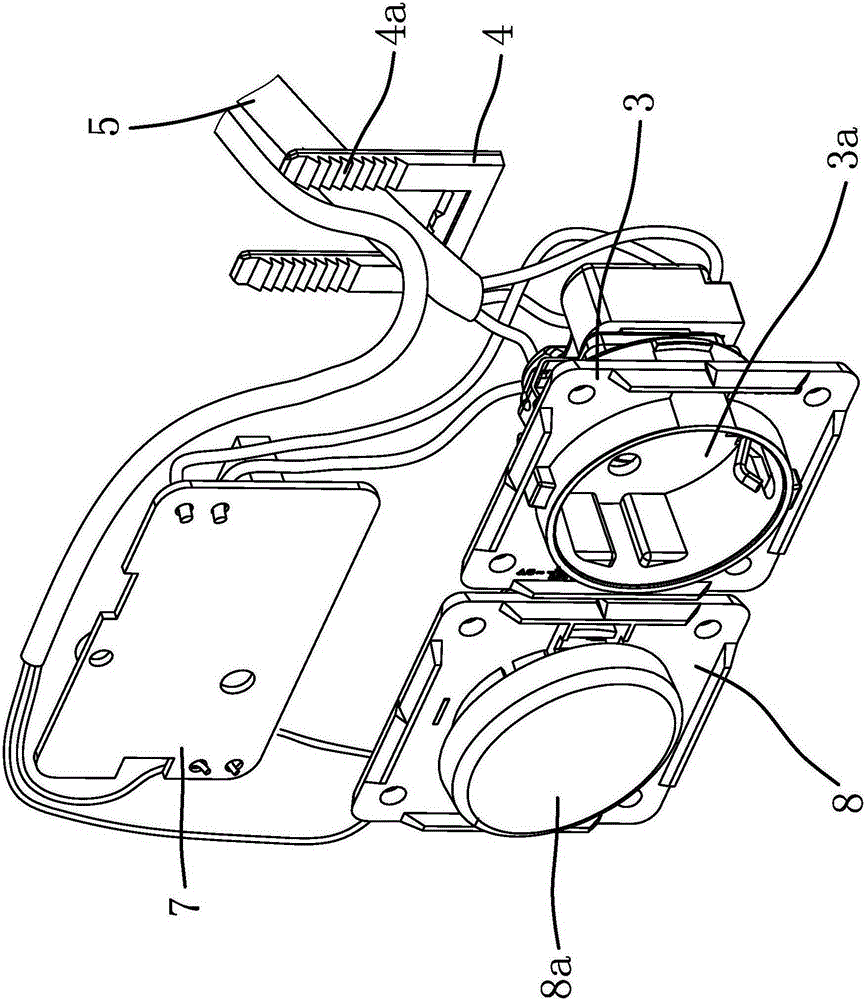

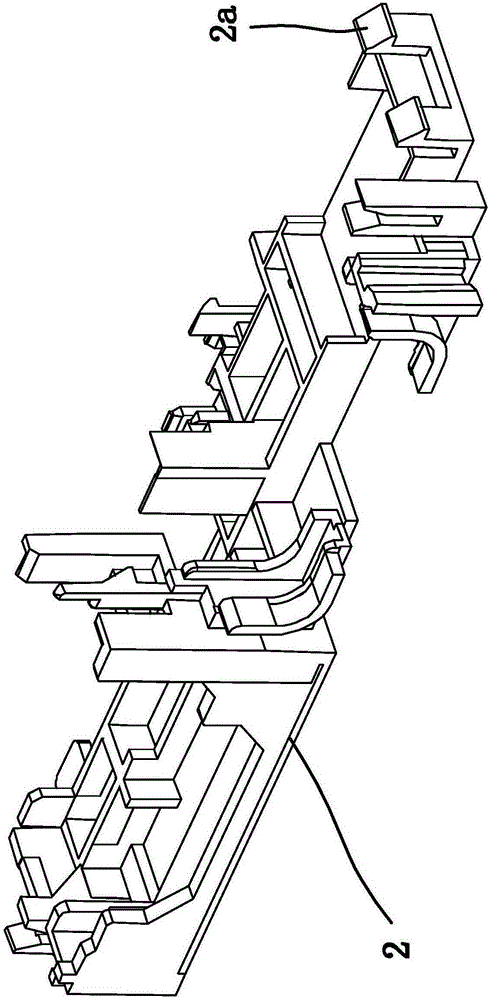

[0043] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the snap-on LED drive power supply box includes an outer box body 1 and an inner box body. One end of the outer box body 1 has an opening, and the other end of the outer box body 1 has a first through hole 1b and a second through hole 1c. The box body is clamped in the outer box body 1 through the opening, and the inner box body includes a large frame 6 and a small frame 2. One side of the large frame 6 is a cover plate 6b; the cover plate 6b is provided with an outlet hole 6b1 for the power supply line 5 to pass through ; With this structure, the wire 5 can be passed through the large frame 6 through the outlet hole 6b1; the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com