Producing method of eight-ingredient dried bean curd

A production method and Babaodou technology, applied in dairy products, cheese substitutes, applications, etc., can solve the problems of many hidden dangers in quality and safety, unstable product taste, and high production cost, so as to ensure product quality and safety and reduce initial colonies. The content of the content, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

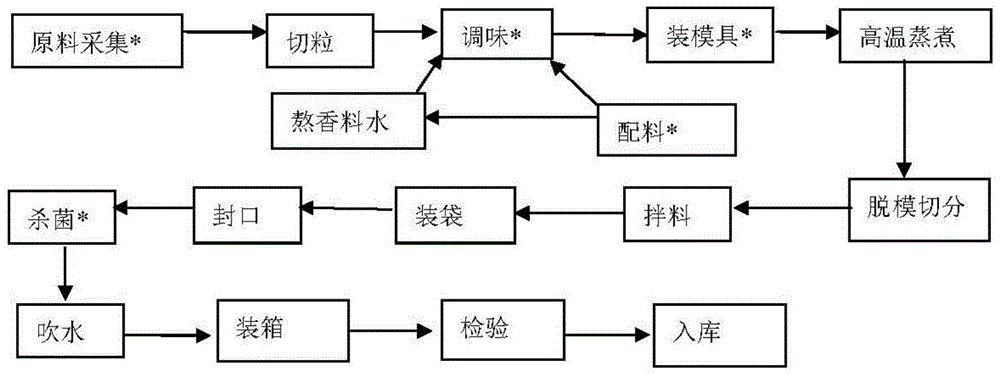

[0053] Such as figure 2 Shown is the process flow diagram of the eight-treasure dried bean curd production method of the present invention. The production method of Babao dried tofu in this embodiment includes the following steps: raw material collection → dicing → seasoning → mold loading → high temperature cooking → demoulding and cutting → mixing ingredients → bagging → sealing → sterilization → blowing water → boxing → Inspection → storage.

[0054] Wherein, in the raw material collection process, dried soybeans are collected as raw materials after being made into tofu by grinding soybeans, and the dried soybeans have a water content of 51% by mass.

[0055] In the dicing process, the dried tofu is cut into granules of a predetermined size, and the size of the granules is 5mm×5mm×5mm.

[0056] In described seasoning operation, comprise the steps:

[0057]1) Boil the flavored water, use the spice bag to cook the spice water; in the spice bag, the mass percentages of eac...

Embodiment 2

[0066] Such as figure 2 Shown is the process flow diagram of the eight-treasure dried bean curd production method of the present invention. The production method of Babao dried tofu in this embodiment includes the following steps: raw material collection → dicing → seasoning → mold loading → high temperature cooking → demoulding and cutting → mixing ingredients → bagging → sealing → sterilization → blowing water → boxing → Inspection → storage.

[0067] Wherein, in the raw material collection process, dried soybeans are collected as raw materials after being made into tofu by grinding soybeans, and the dried soybeans have a water content of 59% by mass.

[0068] In the dicing step, the dried tofu is cut into granules of a predetermined size, and the size of the granules is 3mm×3mm×3mm.

[0069] In described seasoning operation, comprise the steps:

[0070] 1) Boil the flavored water, use the spice bag to cook the spice water; in the spice bag, the mass percentages of each ...

Embodiment 3

[0079] Such as figure 2 Shown is the process flow diagram of the eight-treasure dried bean curd production method of the present invention. The production method of Babao dried tofu in this embodiment includes the following steps: raw material collection → dicing → seasoning → mold loading → high temperature cooking → demoulding and cutting → mixing ingredients → bagging → sealing → sterilization → blowing water → boxing → Inspection → storage.

[0080] Wherein, in the raw material collection process, dried soybeans are collected as raw materials after being made into tofu by refining soybeans, and the dried soybeans have a water content of 55% by mass.

[0081] In the dicing process, the dried bean curd is cut into granules of a predetermined size, and the size of the granules is 7mm×7mm×7mm.

[0082] In described seasoning operation, comprise the steps:

[0083] 1) Boil the flavored water, use the spice pack to boil the spice water; in the spice pack, the mass percentage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com