Manufacturing method of simple hoisting tool for factory building roof purline

The technology of a hoisting tool and a manufacturing method is applied in the field of manufacturing a simple hoisting tool for purlins on the roof of a factory building, which can solve the problems of complex structure of the hoisting device, low hoisting efficiency, inconvenient production and use, etc., and achieve simple structure of the device, small and exquisite hoisting tools, and easy production. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

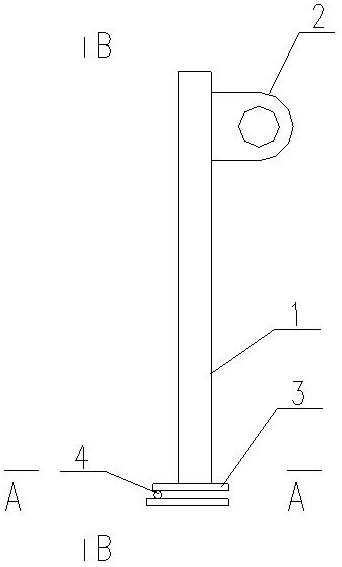

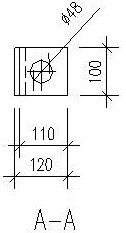

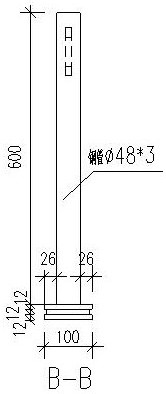

[0028] see now figure 1 , figure 1 It is a structural schematic diagram of the lifting tool of the embodiment of the present invention, figure 2 for figure 1 The sectional view of A-A in, image 3 for figure 1 Sectional view of B-B in middle.

[0029] The manufacturing method of the simple hoisting tool for factory roof purlins of the present invention is used for factory roof girders that have been erected successfully. It is mainly aimed at the hoisting conditions where the purlins cannot be hoisted by machinery on site and the purlins are manually hoisted. The manufacturing method of the hoisting tool includes the following steps:

[0030] a. Determine the shape and size of the spreader according to the design, and make the spreader pole 1. The spreader pole is a steel pipe, and the length of the steel pipe is 600mm;

[0031] b. Make the lifting lug, the lifting lug 2 is a rectangular steel plate, the rectangular steel plate is centered with a through hole, one side o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com