Manufacturing method of ultrathin glass adapter plate

A production method and ultra-thin glass technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of affecting etching efficiency and reducing etching rate, achieve fewer process steps, improve reliability and speed , The effect of process cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

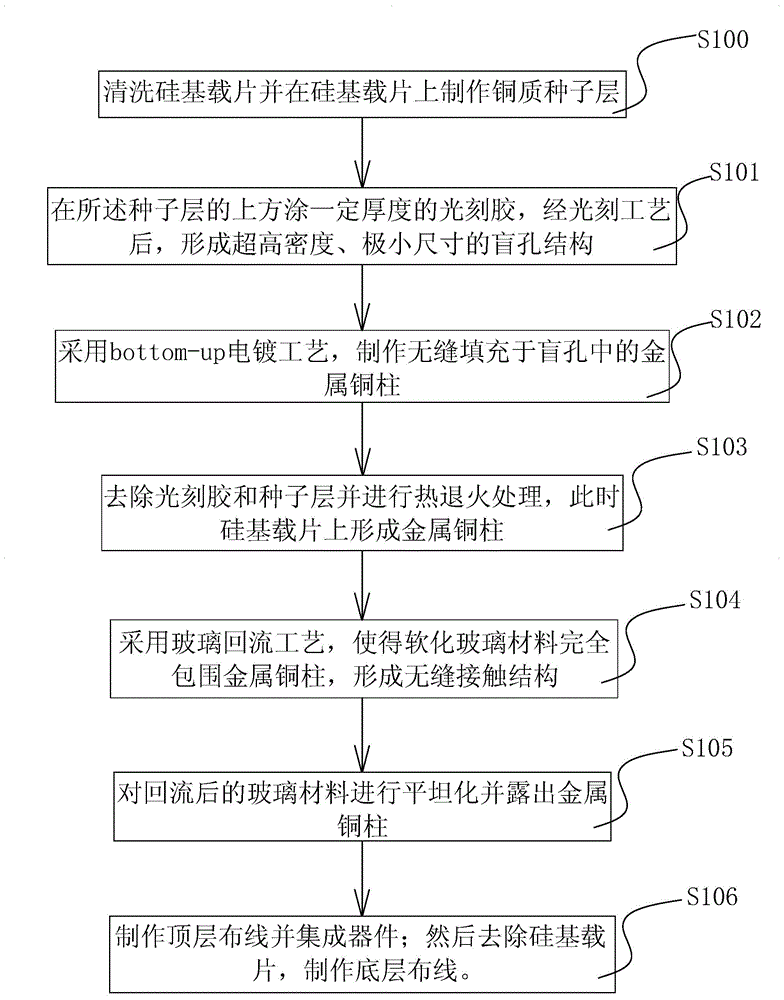

[0042] see Figure 1 to Figure 8 As shown, in this embodiment, a method for manufacturing an ultra-thin glass adapter plate includes the following steps:

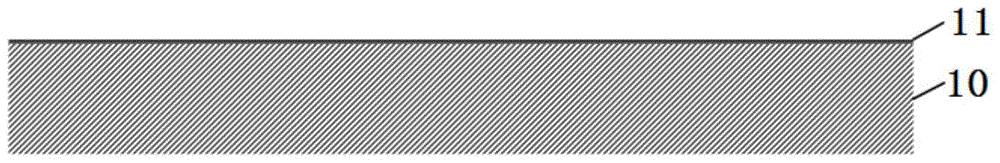

[0043] S100: slide cleaning and making seed layer: as figure 2 As shown, the silicon-based carrier 10 is cleaned, and after cleaning, a 200-500nm seed layer 11 is fabricated on the silicon-based carrier 10 by an electroless copper plating process;

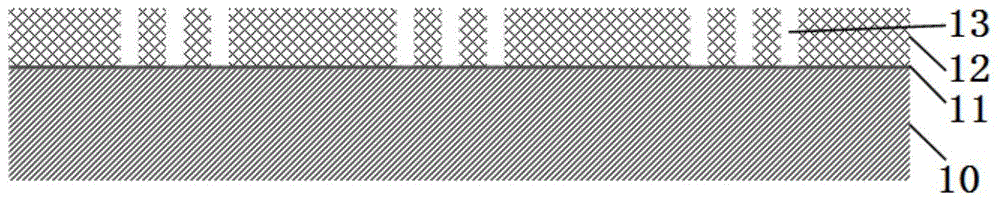

[0044] S101: Apply a certain thickness of photoresist 12 on the top of the seed layer 11, and form an ultra-high-density, extremely small-sized blind hole 13 structure after a photolithography process, such as image 3 shown;

[0045] S102: using a bottom-up (bottom-up) electroplating process to manufacture metal copper pillars 14 seamlessly filled in blind holes 13, such as Figure 4 shown;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com