Improved production method for pillowcase

A production method and pillow case technology, applied in the cutting of pillows, textile materials, bed sheets, etc., can solve the problems that the manufacturing method is too simple, the pillow case fabric does not have antibacterial, antistatic, flame retardant, single function, etc., to achieve strong functionality , Continuous and uninterrupted sewing operation, fast positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

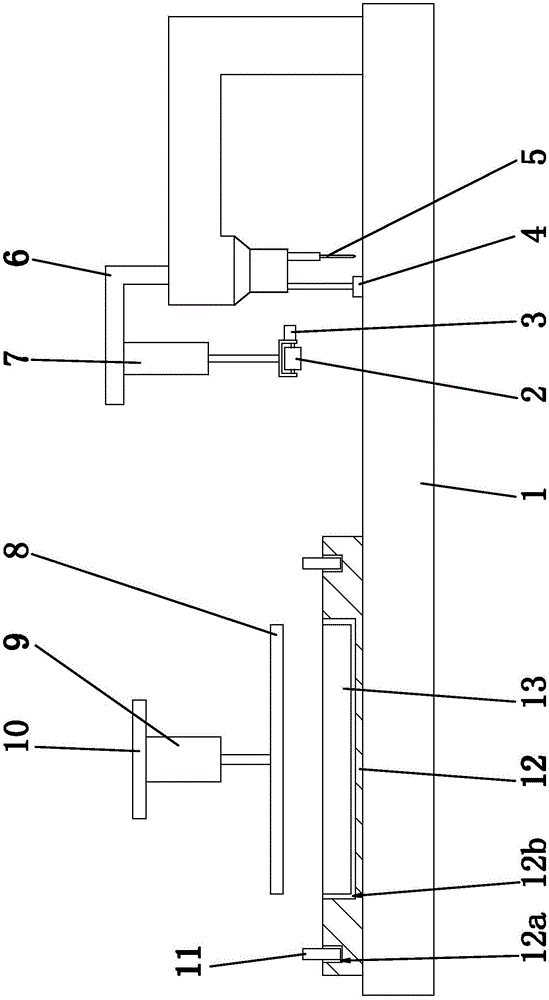

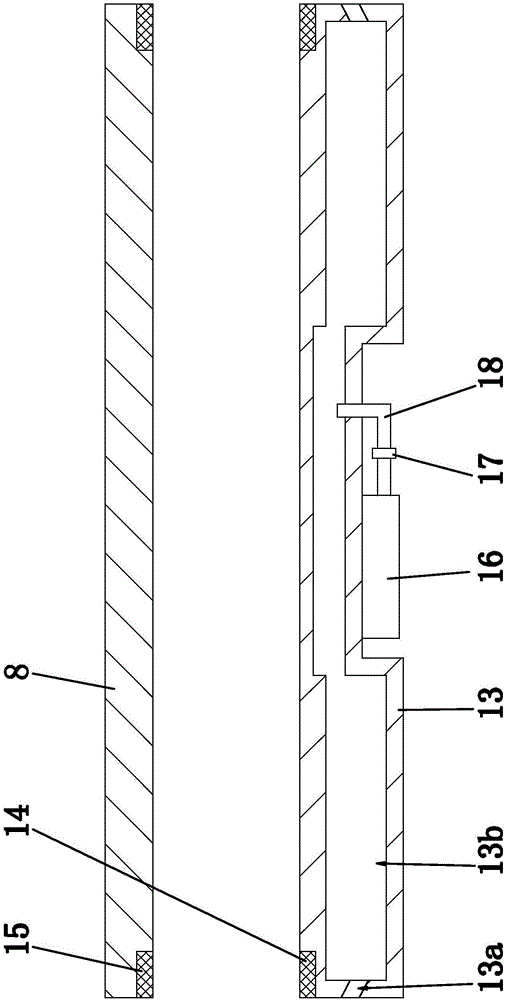

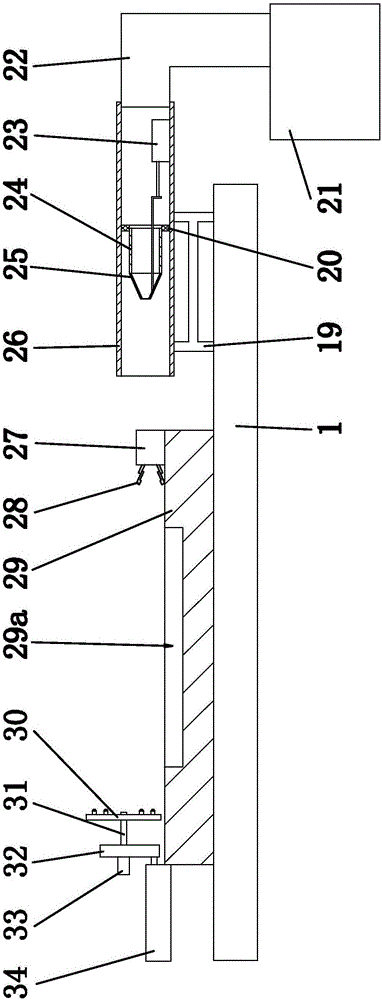

[0044] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0045] The production method of the improved pillowcase comprises the following steps:

[0046] a. Select raw materials according to weight ratio: 40-60 parts of water-based PU resin, 5-6 parts of emulsion, 0.5-2 parts of defoamer, 3-6 parts of antibacterial agent, 0.6-1 part of antioxidant, thickener 0.5-1.6 parts, 2-4 parts of magnesium oxide, 2-4 parts of zinc oxide and 12-26 parts of water; in this embodiment, weigh 50 parts of water-based PU resin, 5 parts of emulsion, 1 part of defoamer, 4 parts of anti-oxidant, 0.8 part of antioxidant, 1 part of thickener, 3 parts of magnesium oxide, 3 parts of zinc oxide and 20 parts of water;

[0047] b. The raw materials are mixed together by a mixer, the stirring temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com