Thermoplastic fire retardant plastic

A technology of flame-retardant plastics and thermoplastics, applied in the field of thermoplastics, can solve the problems of flame-retardant plastics that cannot meet the requirements and hazards, and achieve good flame-retardant effects, less smoke, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

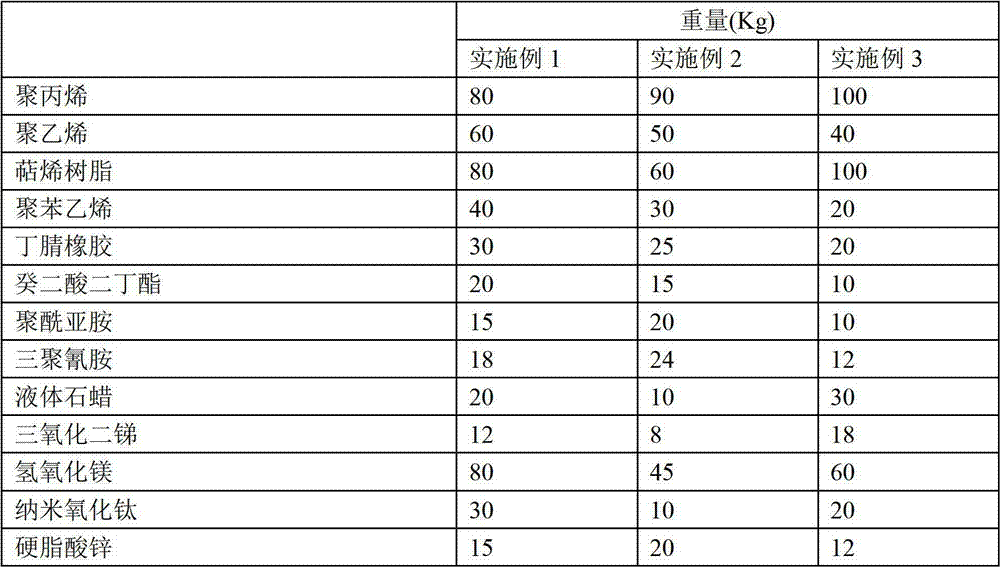

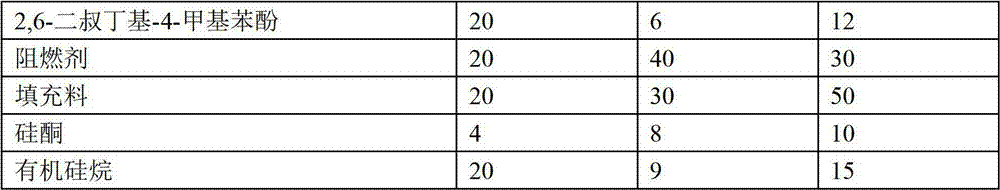

Examples

Embodiment 1

[0024] S1 Put the raw materials of each component into the kneader in proportion and mix them evenly;

[0025] S2 Add the mixture obtained in S1 into a twin-screw extruder, control the temperature of the extruder and die at 180°C, and cool the extrudate to ambient temperature;

[0026] S3 sends the cooled extrudate to the granulator to obtain the finished thermoplastic flame-retardant plastic granules.

Embodiment 2

[0028] The difference from Example 1 is that the temperature in step S2 is 220°C.

Embodiment 3

[0030] The difference from Example 1 is that the temperature in step S2 is 200°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com