Cold resistant rubber

A technology of cold-resistant rubber and main rubber, which is applied in the field of rubber and can solve problems such as brittleness, hardening, and decreased elongation at break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

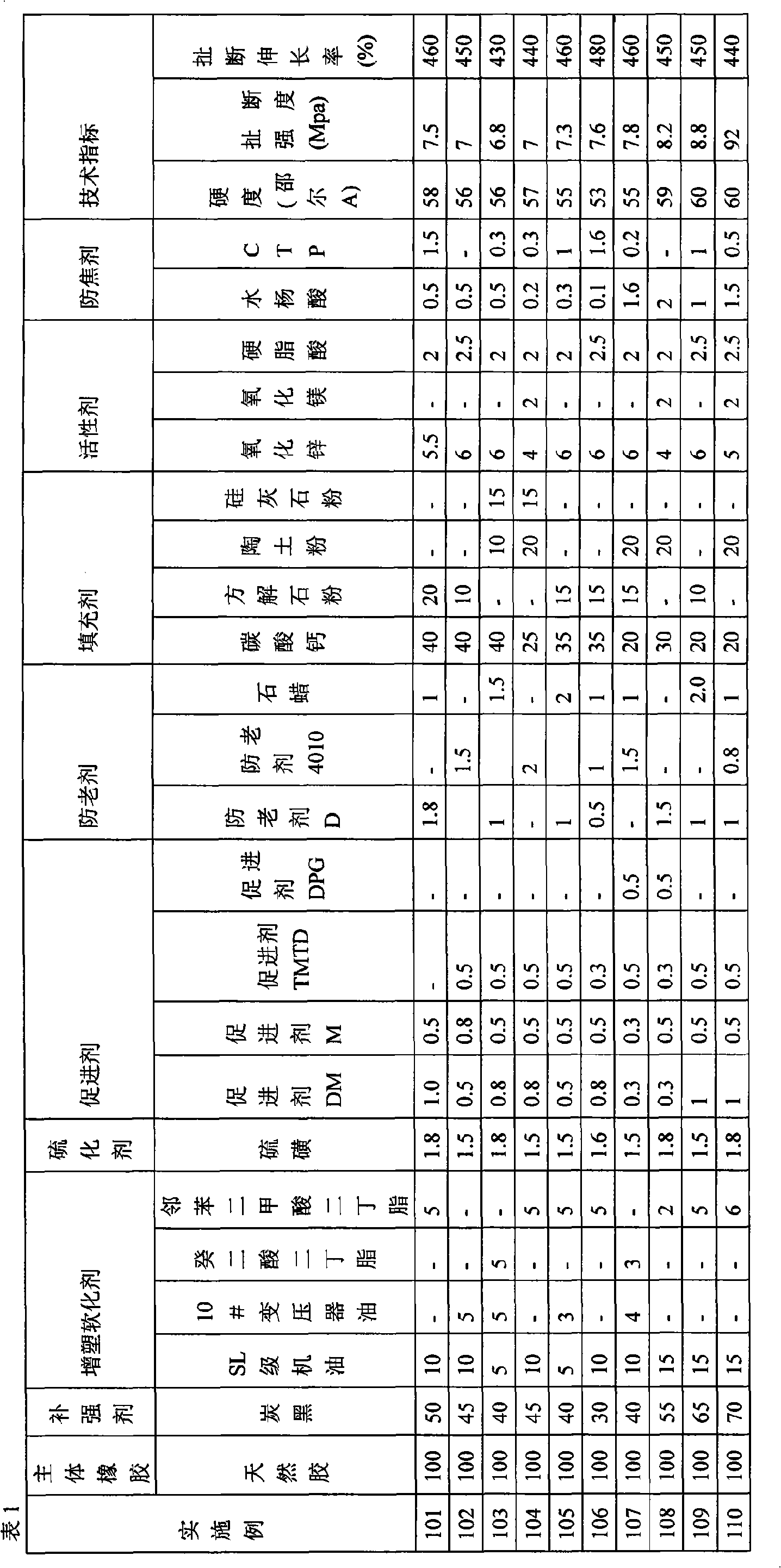

Embodiment 101-110

[0018] When 100kg of natural rubber is used as the main material to prepare the cold-resistant rubber sheet of the present invention, the material is firstly pretreated, and then the natural rubber is subjected to low-temperature thin-pass segmental mastication in an open mill, and the roller temperature is controlled between 40-60°C. During the first stage of mastication, it needs to be parked for 4-8 hours, then the second stage of plastication is carried out, and then it is parked for 8-24 hours for use. When mixing, first add reinforcing agent, filler, plasticizer softener, accelerator, active agent, anti-aging agent of different weights in Table 1, and finally add vulcanizing agent. A while to spare. When rolling out the sheet, the parked mixed rubber is first heat-smelted, thinned several times, and then the thickness is adjusted on the calender according to the product requirements, and the sheet is evenly released, so that it is preformed and vulcanized by pressure and...

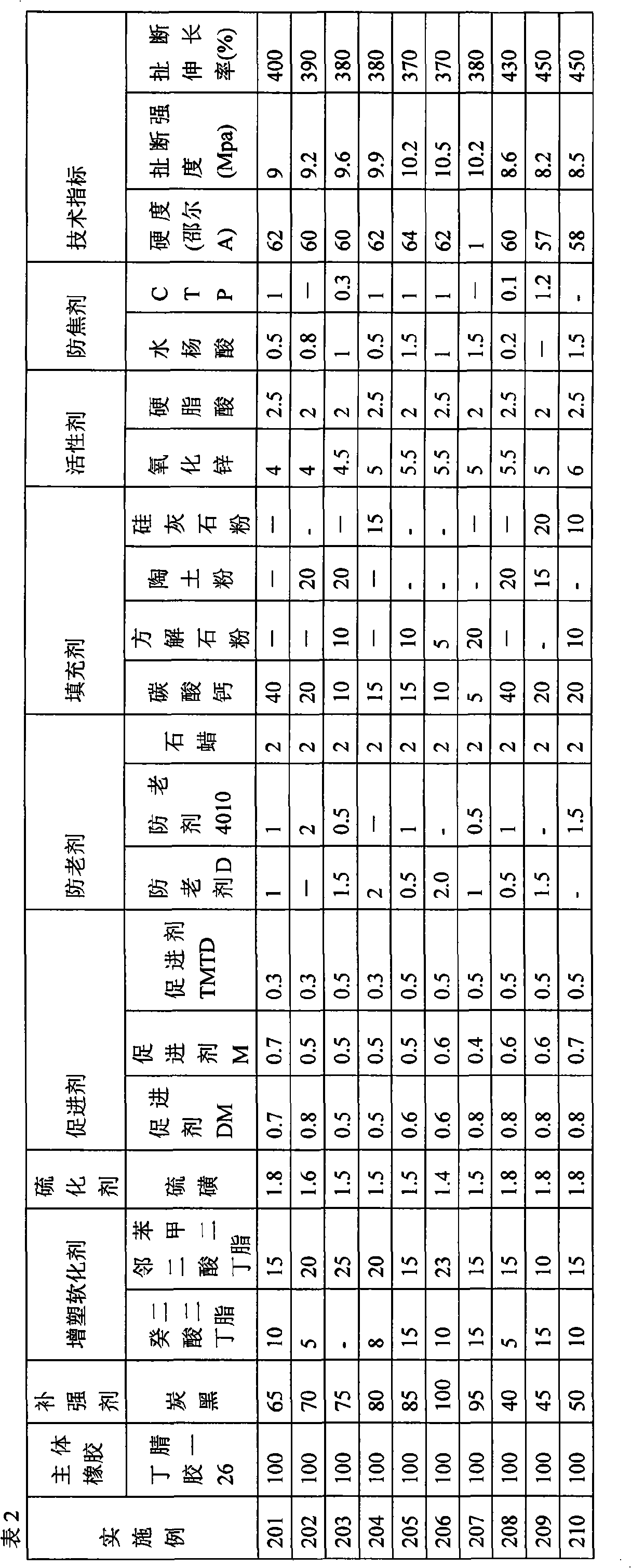

Embodiment 201-210

[0020] Referring to Table 2, when using 100kg nitrile rubber as the main material to prepare the cold-resistant rubber sheet of the present invention, at first the selected material is pretreated. Then the nitrile rubber is subjected to three-stage thin-pass mastication with a small roller distance and a low roller temperature (40-50°C). The mastication time of each stage is about 20 minutes, and it is fully parked and cooled in the middle. The performance of the mixing process of nitrile rubber is poor, the mixing time is long, and the heat generation is large, which is easy to cause scorch. The specific operation method and the order of adding materials (compounding agents with different weights in Table 2) are generally as follows. The roll temperature is kept at 40-45°C, and the roll distance is preferably 3-4mm. Add anti-aging agent, filler, etc. after the rubber material starts to soften, it is best to add reinforcing agent and liquid plasticizing softener alternately in...

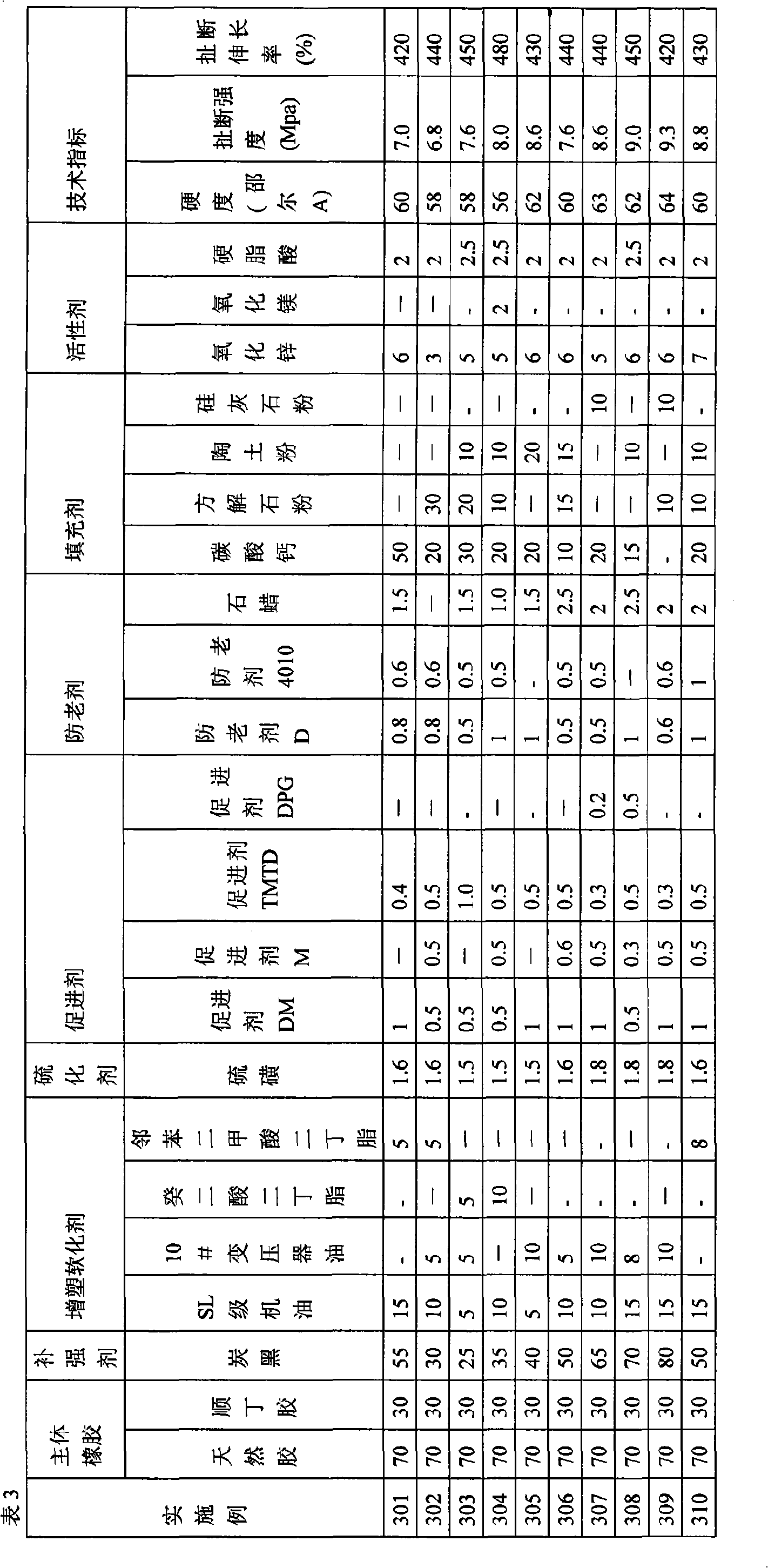

Embodiment 301-310

[0023] See Table 3. When using different weights of natural rubber and butadiene rubber together as the main material to prepare the cold-resistant rubber sheet, the selected materials are firstly pretreated, and then the natural rubber and butadiene rubber are masticated respectively. The method described in implementation case 1 carries out one section of plasticizing and stands for use. Butadiene rubber has a low molecular weight and lacks mastication effect, but proper mastication can make the rubber texture uniform and improve the physical and mechanical properties of the vulcanized rubber. Therefore, after the butadiene rubber is masticated at low temperature for a short time, the natural rubber that has been masticated for a period of time can be added for mixing and thinning. After the blended and masticated natural rubber and butadiene rubber are parked (about 10 hours), add different weights of compounding agents in Table 3 and mix them. The order of addition is gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com