Chloroprene rubber composition

A chloroprene rubber and composition technology, applied in the rubber field, can solve the problems of poor cold resistance of chloroprene rubber, low temperature cold resistance, affecting the service life of rubber products, etc., and achieve the effect of improving safety and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

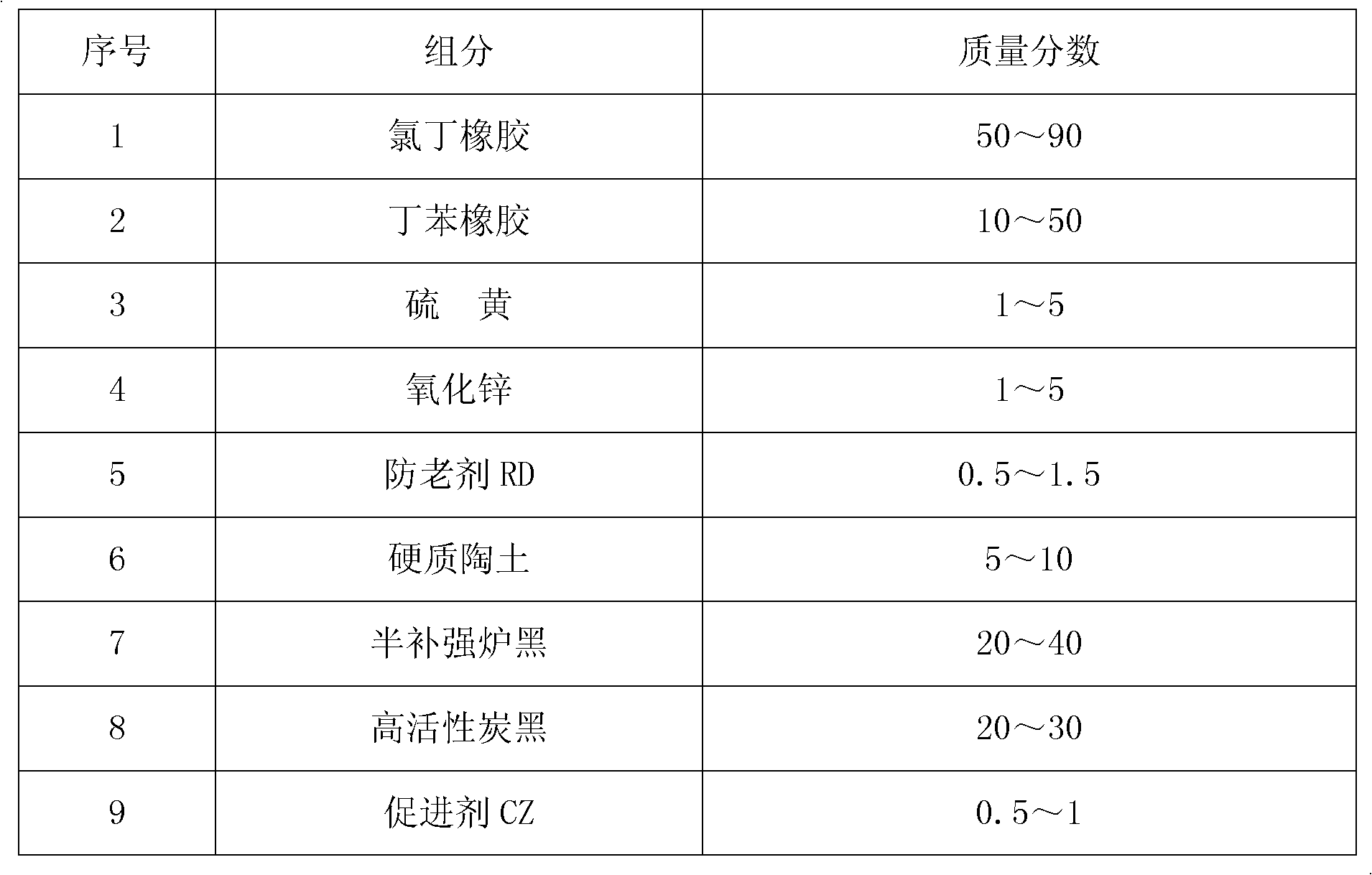

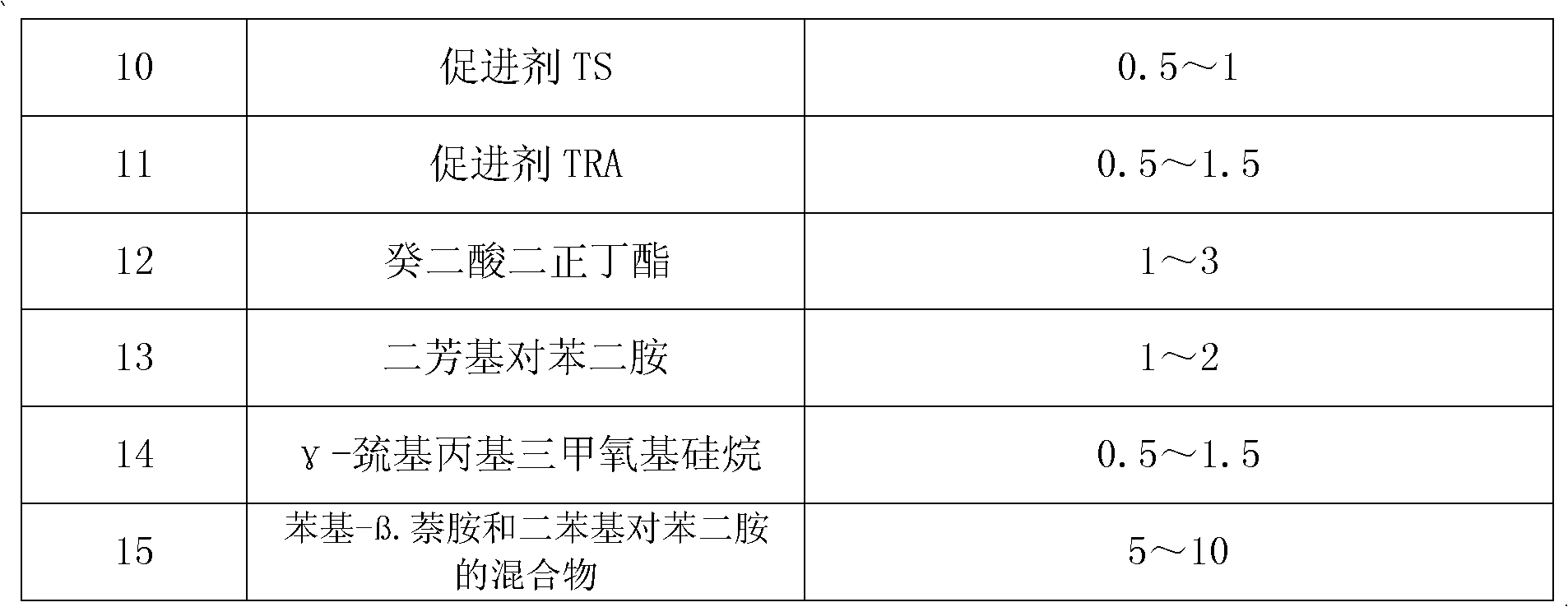

[0016] In parts by mass

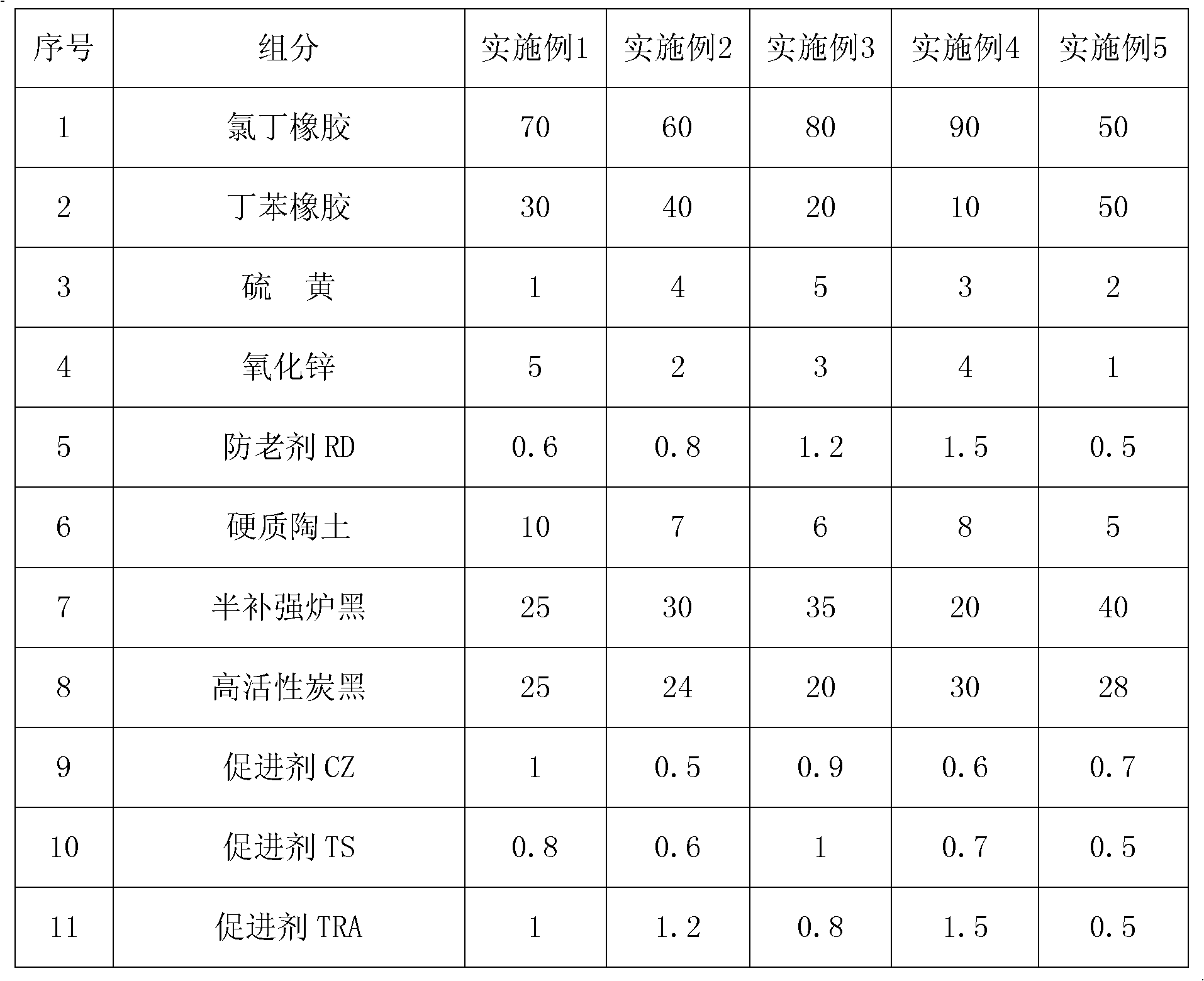

[0017]

[0018]

[0019] Carry out the usual mixing and processing according to the raw materials and dosage in the listed formula:

[0020] 1. Rubber and raw material weighing

[0021] 2. One stage of internal refining-one stage of refining-the next film

[0022] 3. The second stage of internal refining - the second stage of refining - the next film

[0023] 4. Vulcanized film

[0024] 5. Cut the style according to the standard

[0025] 6. Carry out experimental testing

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com