Low melting-point alloy powder spheroidizing and nano microcrystallizing process

The technology of alloy powder and process method is applied in the field of low melting point lead-free solder alloy powder spheroidization, microcrystalline and nanotechnology, which can solve the problem of not finding literature and the like, and achieve the effects of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

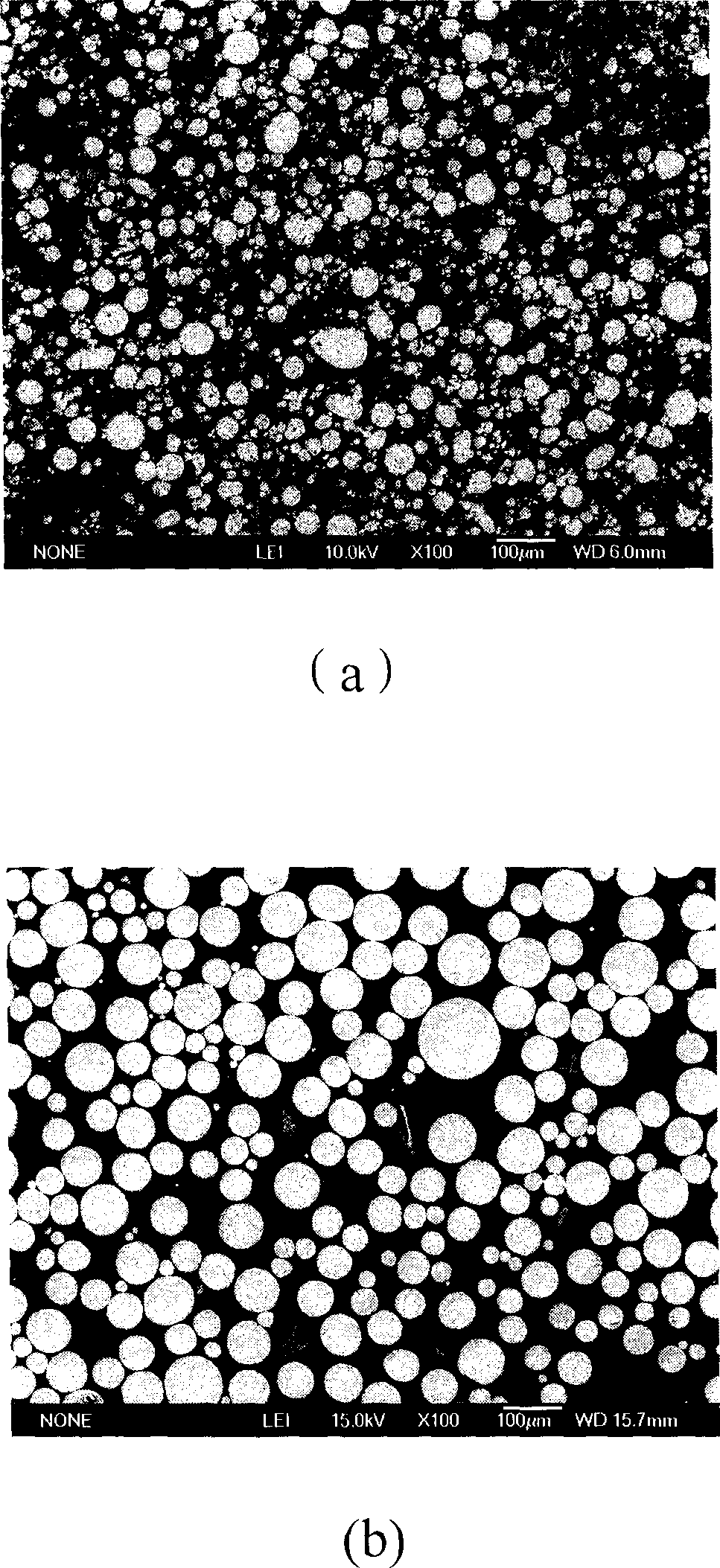

[0016] (1) at first 2g composition is that a kind of lead-free solder alloy of Sn-57wt%Bi is placed in the organic solvent mixed solution of 20ml by the low melting point alloy powder of irregular shape that high-pressure gas atomizing agent makes; The organic solvent mixes The liquid is prepared by the spheroidizing agent dibutyl decane dibutyrate and the dispersing agent polyethylene glycol octyl phenyl ether in a weight ratio of 1:1, and then it is dispersed evenly by an ultrasonic oscillator;

[0017] (2) Place the organic solution mixture with the Sn-57wt% Bi alloy powder in a resistance furnace for heating, so that the temperature of the solution mixture reaches 260° C.;

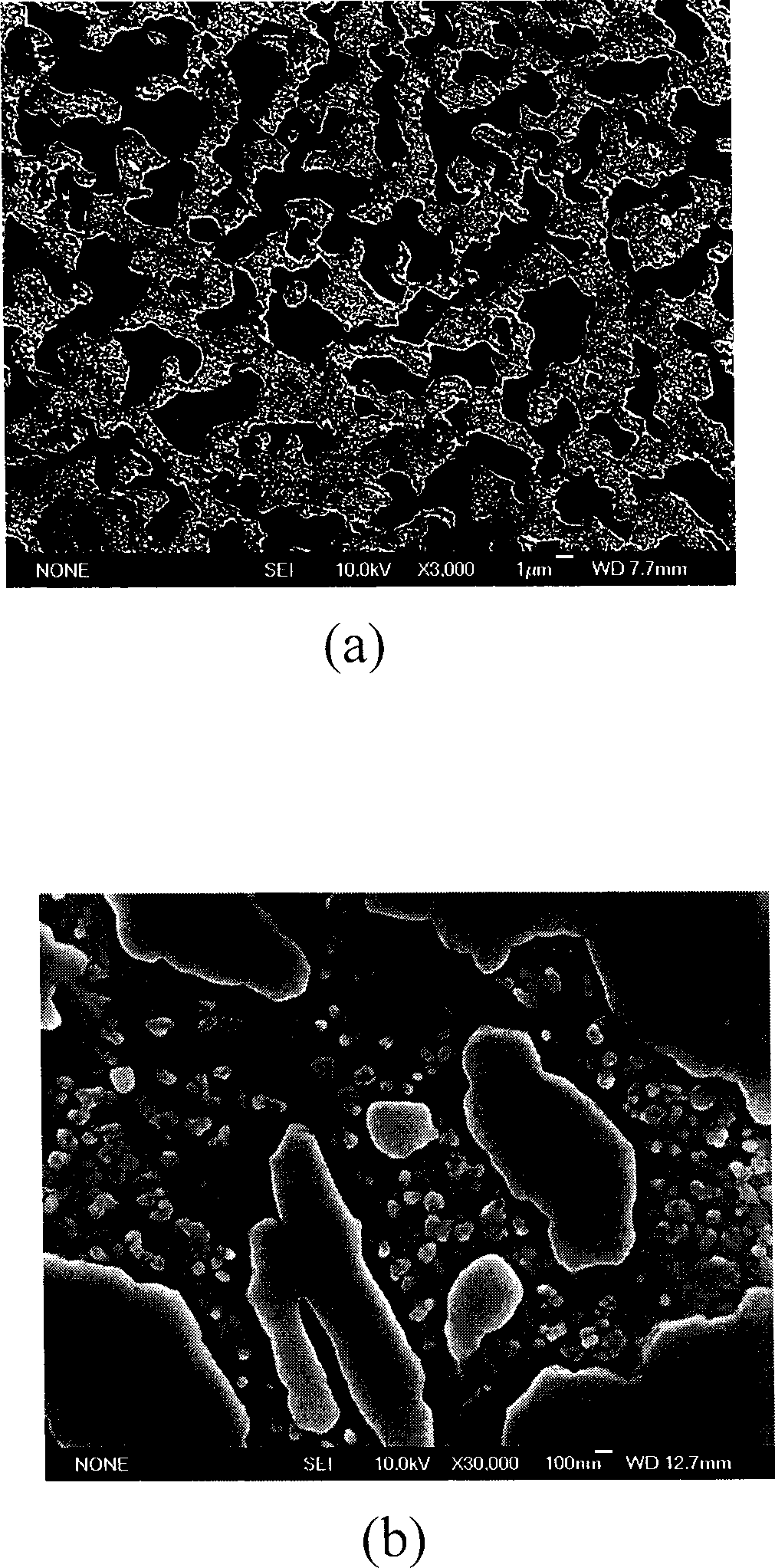

[0018] (3) Keep the above solution at the above temperature for 3 minutes at a constant temperature to ensure that the powder is completely melted, then make it automatically cool down to 150°C, and then quickly liquid quench it in an aqueous solution at room temperature, wait for a while, filter, wash,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com