Cold-resistant low-compression permanent deformation rubber composition and preparation method thereof

A rubber composition and permanent deformation technology, applied in the field of rubber, can solve the problems of poor compression permanent performance of inorganic non-metallic fillers, no attention to low temperature performance, only focus on heat resistance, etc., to achieve good low temperature performance, excellent compression permanent deformation, The effect of small compression set

Active Publication Date: 2018-09-18

METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

View PDF8 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Inorganic non-metallic fillers have poor compression permanent properties compared to pure carbon black compositions

The raw rubber used in this invention is EPDM 3092E, the ethylene content of this grade of raw rubber is greater than 60%, and the low temperature performance is not good; its products only focus on heat resistance, not low temperature performance

[0005] Chinese patent CN201010570618.3 discloses a

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

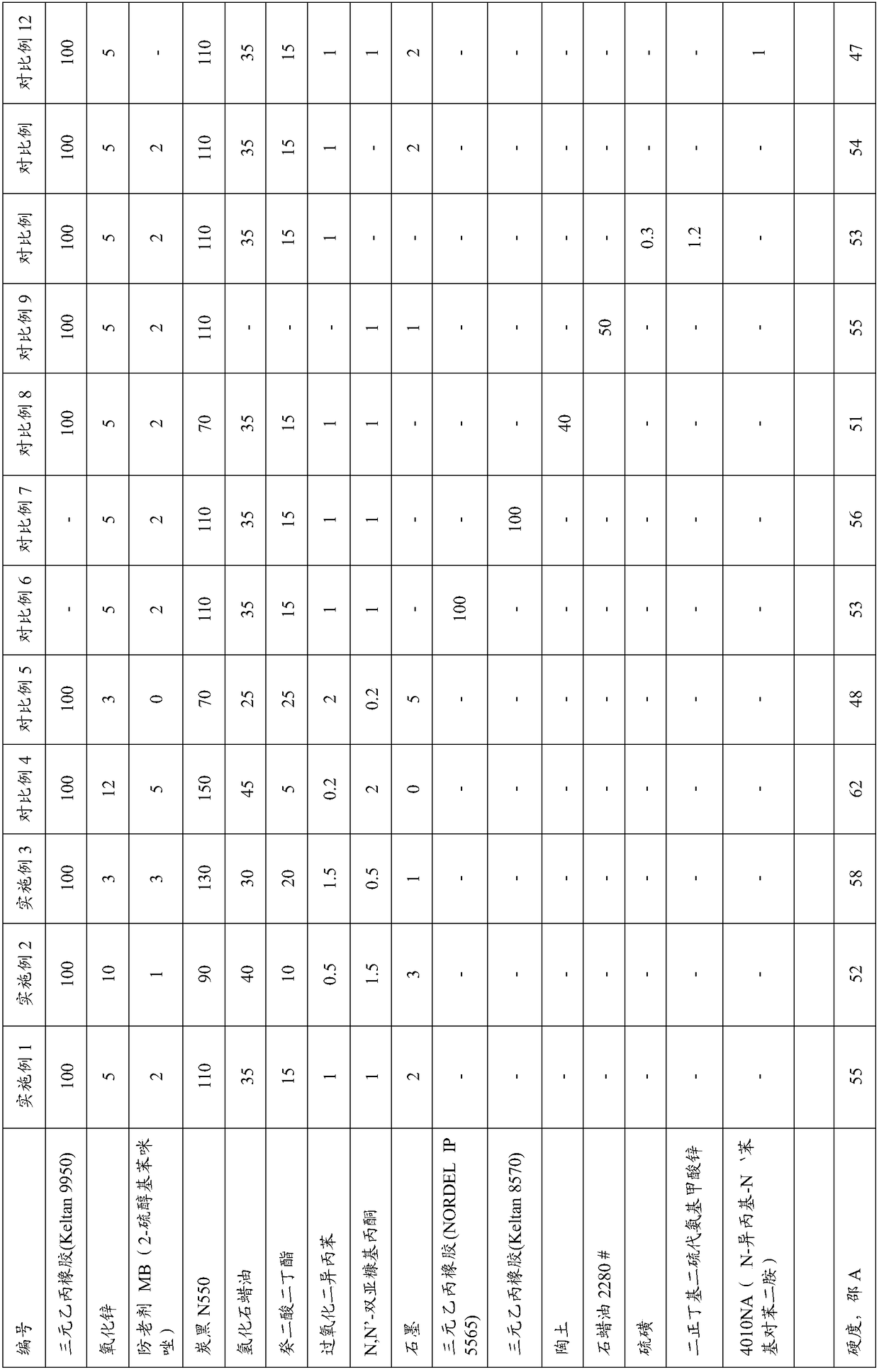

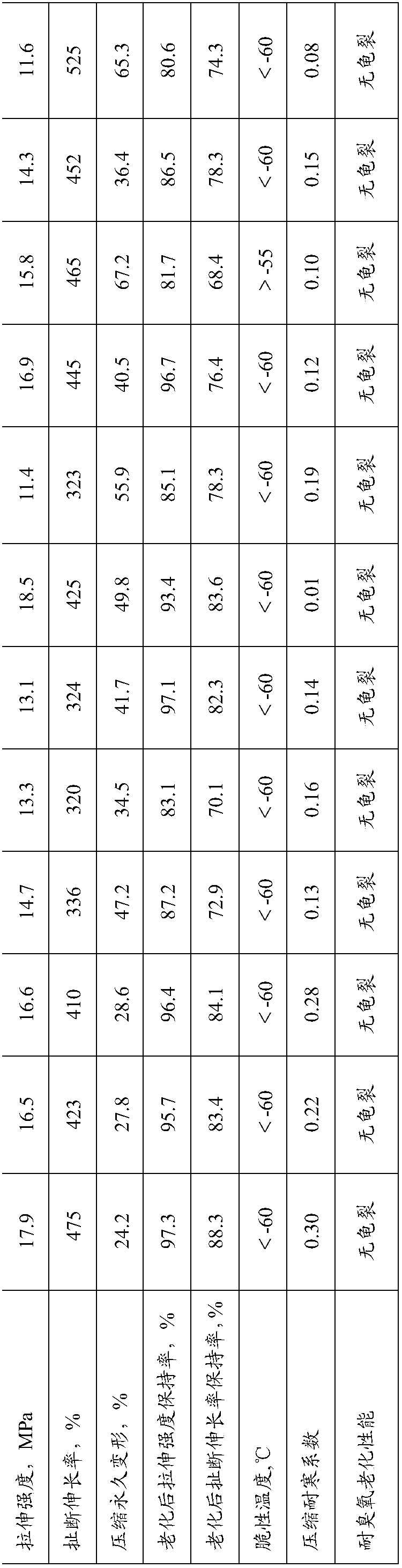

The invention provides a cold-resistant low-compression permanent deformation rubber composition, which comprises the following raw materials by weight: 100 parts of ethylene propylene diene monomer,3-10 parts of zinc oxide, 90-130 parts of carbon black, 30-40 parts of hydrogenated paraffin oil, 10-20 parts of dibutyl sebacate, 0.5-1.5 parts of dicumyl peroxide, 0.5-1.5 parts of N,N'-bisfurfurylideneacetone, 1-3 parts of an anti-aging agent MB, and 1-3 parts of graphite. According to the present invention, the rubber composition for the rubber vibration reducing pas or sealing pad is preparedby using the ethylene propylene diene monomer as the matrix material, using the carbon black as the reinforcing agent, using the hydrogenated paraffin oil and the dibutyl sebacate as the plasticizer,and using the dicumyl peroxide and the N,N'-bisfurfurylideneacetone as the vulcanizing agent, and has advantages of excellent cold resistance, excellent aging resistance and excellent low-compressionpermanent deformation.

Description

technical field [0001] The invention belongs to the field of rubber, and in particular relates to a rubber composition with excellent cold resistance, aging resistance and low compression set and a preparation method thereof. Background technique [0002] The Qinghai-Tibet Plateau has low temperature all year round and strong ultraviolet radiation. Due to the rich geothermal resources and the high content of sulfur dioxide in the air, EPDM rubber has become the best rubber type for various rubber damping pads on the Qinghai-Tibet Plateau railway line. EPDM rubber is copolymerized from three monomers of ethylene, propylene and non-conjugated diene. EPDM rubber has excellent resilience, ozone resistance, high and low temperature resistance, weather resistance, aging resistance and chemical resistance. [0003] Chinese patent CN107189236A discloses a heat-aging-resistant, low-pressure variable sulfur-vulcanized EPDM composition, preparation method, use and application products...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/16C08L91/06C08K13/02C08K3/04C08K5/11C08K5/14C08K3/22C08K5/1535

CPCC08K2003/2296C08L23/16C08L2201/08C08L91/06C08K13/02C08K3/04C08K5/11C08K5/14C08K3/22C08K5/1535

Inventor 贺春江王玮赵云行张国文毛昆朋

Owner METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com