Highly cold-resistant rubber dam

A technology of cold-resistant rubber and chloroprene rubber is applied in the field of rubber dams, which can solve the problems of poor cold resistance and can not meet the requirements of low temperature resistance of rubber dams, and can meet the requirements of low temperature resistance and physical and mechanical properties, and has good cold resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

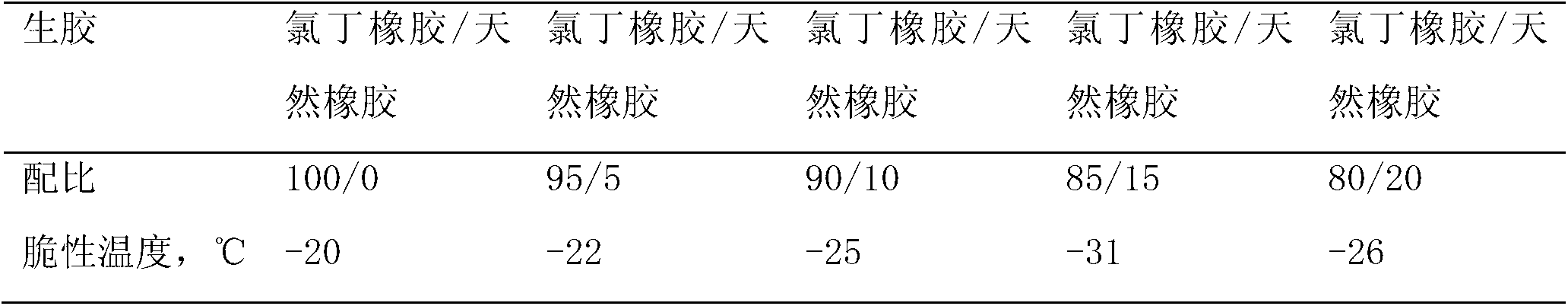

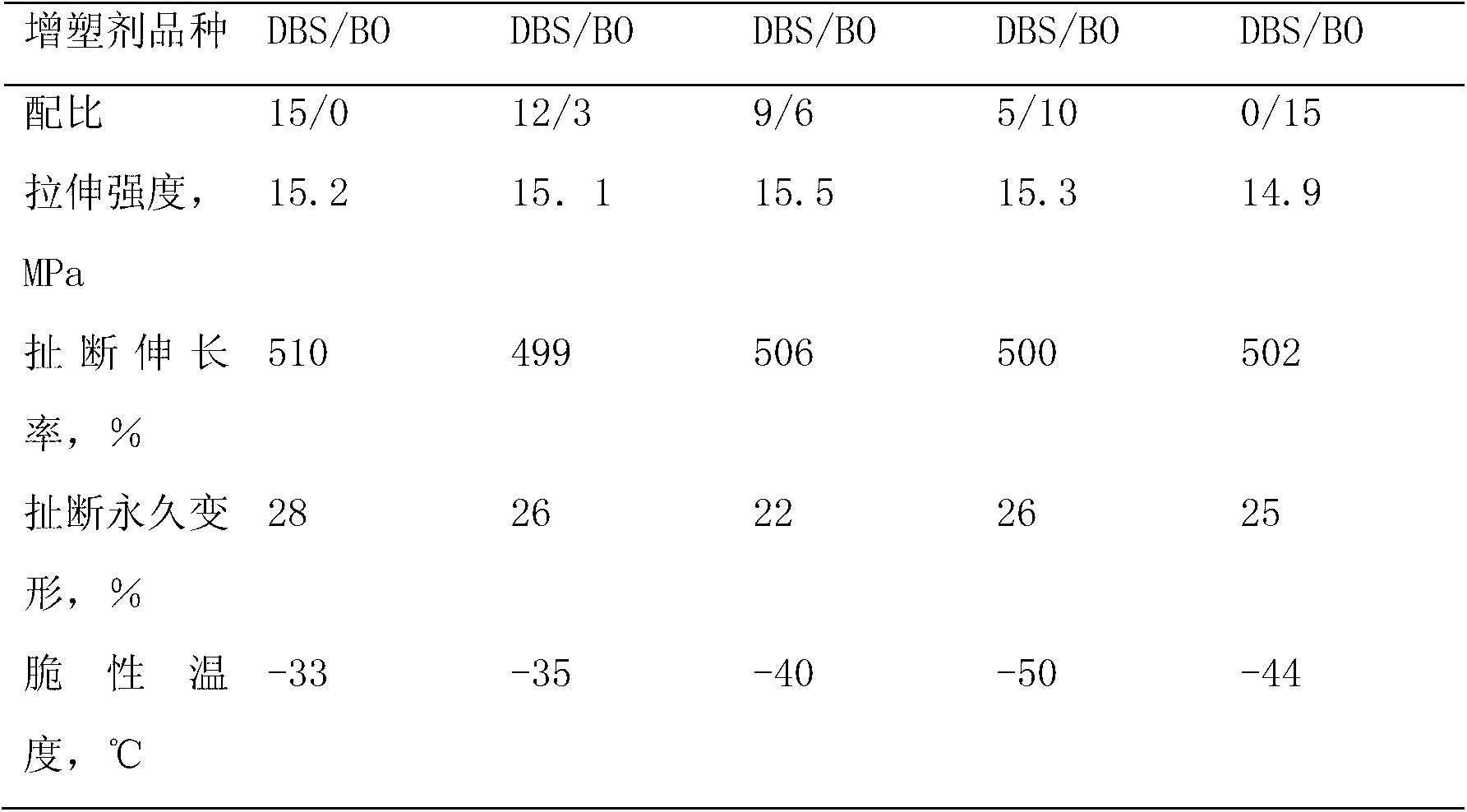

[0011] Under normal circumstances, we choose rubber varieties with low glass transition temperature and low crystallinity tendency, such as natural rubber, butadiene rubber, etc.; or introduce other unit molecules on the rubber macromolecule to destroy its regularity. In the present invention, the applicant selects chloroprene rubber, especially DCR-114 type chloroprene rubber, because it introduces 2 and 3 unit chlorine atoms on the chloroprene, which destroys the regularity of the polychloroprene molecular chain, It reduces its crystallization tendency, so it shows excellent anti-crystallization performance; and this product has good weather resistance and aging resistance, and is an excellent material for making high cold-resistant rubber dams. In order to comprehensively consider the cold resistance and physical and mechanical properties of the rubber dam, the applicant also uses neoprene and natural rubber in a certain proportion. The purpose of the combination is to destr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brittle temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com