Oil-resistant level PVC (Poly Vinyl Chloride) sheath material for power wire and preparation method thereof

A technology for power cords and sheathing materials, applied in circuits, electrical components, insulated cables, etc., can solve the problems of oil corrosion, power cord cracking, poor oil resistance, etc., and achieve good elasticity, long service life, and excellent corrosion characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

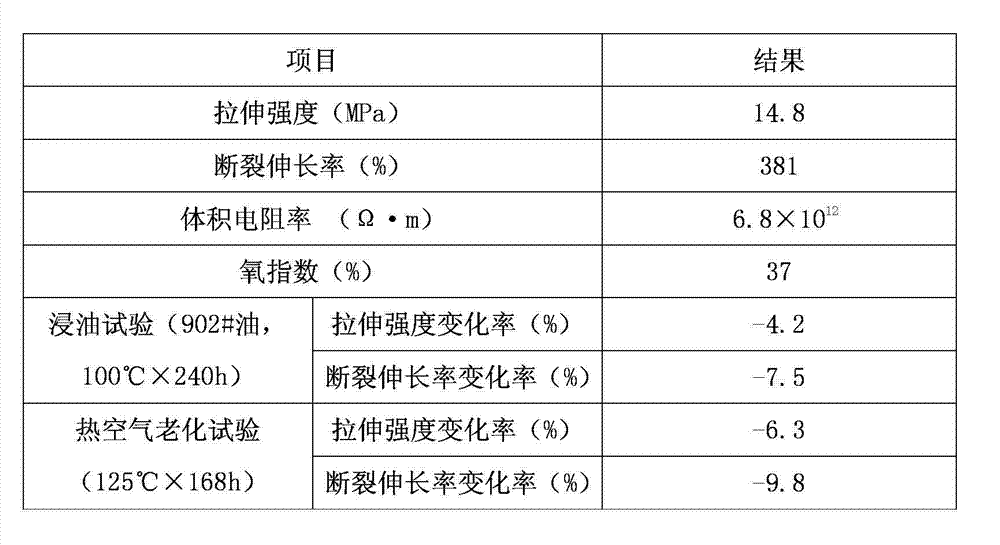

[0013] An oil-resistant PVC sheath material for power cords, prepared from the following weight (kg): polyvinyl chloride resin (WS-1300) 70, nitrile rubber (N220SH) 30, carbon black N660 25, Malay Dioctyl acid 10, light magnesium oxide 4, zinc oxide 3, dibenzothiazole disulfide 2, bispentylidene thiuram tetrasulfide 1.5, 1,4-bis-tert-butylperoxycumene 0.5 , triallyl isocyanurate 2, insoluble sulfur 0.8, coumarone resin 6, stearic acid 2, palm wax 2, 2-mercaptobenzothiazole 1.5, mercaptan methyl tin 1, nano Wollastonite 12, organic bentonite 8, composite filler 4;

[0014] The preparation method of the composite filler is as follows: a. Take the following raw materials by weight (kg): pyrophyllite 10, diopside 8, opalite 6, N-2-(aminoethyl)-3-aminopropyltrimethoxy Silane 1.5, calcium lignosulfonate 2, sodium silicate 4, tourmaline slag 6, nano-diamond 4, germanium stone powder 3, sodium stearate 1.5; b, calcining pyrophyllite, diopside and opalite at 550°C 6h, cooling, crushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com