Non-flame spread CPE rubber sheath material and preparation method thereof

A sheath material and rubber technology, applied in rubber insulators, plastic/resin/wax insulators, organic insulators, etc., can solve the problems of insufficient high temperature resistance, flammability and delay in case of open fire, etc., to achieve good flame retardant effect, Excellent high temperature resistance and improved safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

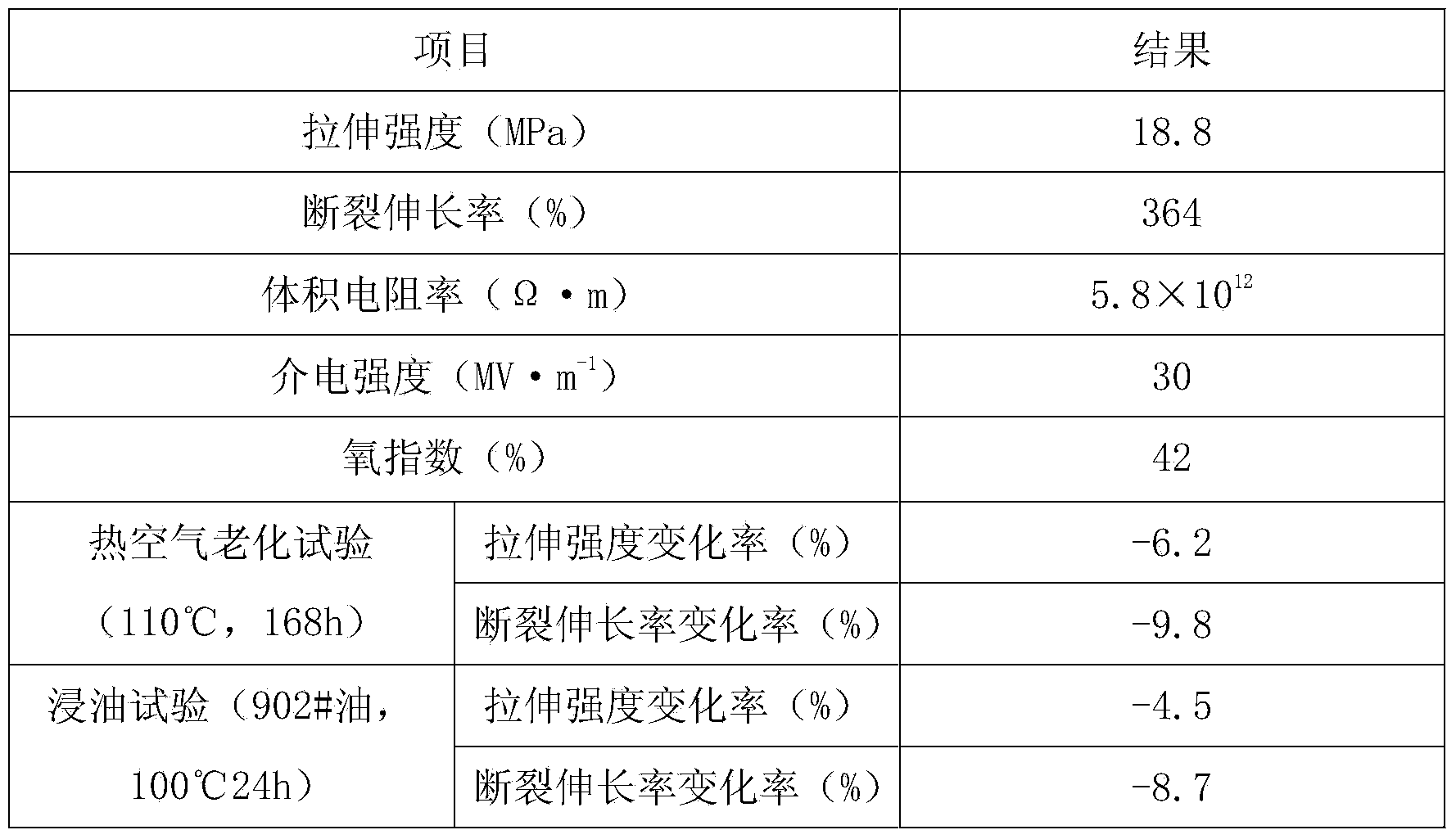

Examples

Embodiment Construction

[0012] A non-flammable CPE rubber sheath material, made of the following raw materials (kg): chlorinated polyethylene 70, polytetrafluoroethylene 18, dimethyl silicone rubber 12, chlorinated paraffin 15, precipitated white carbon black 35. Gas-mixed carbon black 20, calcium silicate 8, nano wollastonite 12, octyl epoxy stearate 5, dioctyl maleate 10, dicumyl peroxide 3, diallyl phthalate Ester 5, ammonium polyphosphate 15, coated red phosphorus 8, calcium hydroxide 4, zinc stearate 1.5, antioxidant 40200.8, antioxidant DLTP0.6, composite filler 4;

[0013] The preparation method of the described composite filler is as follows: a. get the raw materials of the following weight (kg): attapulgite 8, sepiolite 8, potassium feldspar 4, two (dioctyloxypyrophosphate) ethylene titanic acid Ester 1.5, titanium dioxide 4, nano-silica 5, nano-alumina 3, paraffin oil 6, polyisobutylene 4, ferrocene 2, zinc methacrylate 1, p-tert-octylphenol formaldehyde resin 8; b. Roast clay, sepiolite a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com