Polyvinyl chloride cable material

A polyvinyl chloride cable and high-density polyethylene technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of reducing the mechanical properties and processing properties of materials, poor compatibility, etc., and achieve good flame retardancy and weather resistance , the effect of a reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

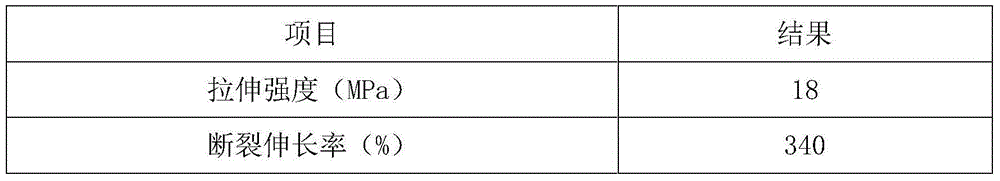

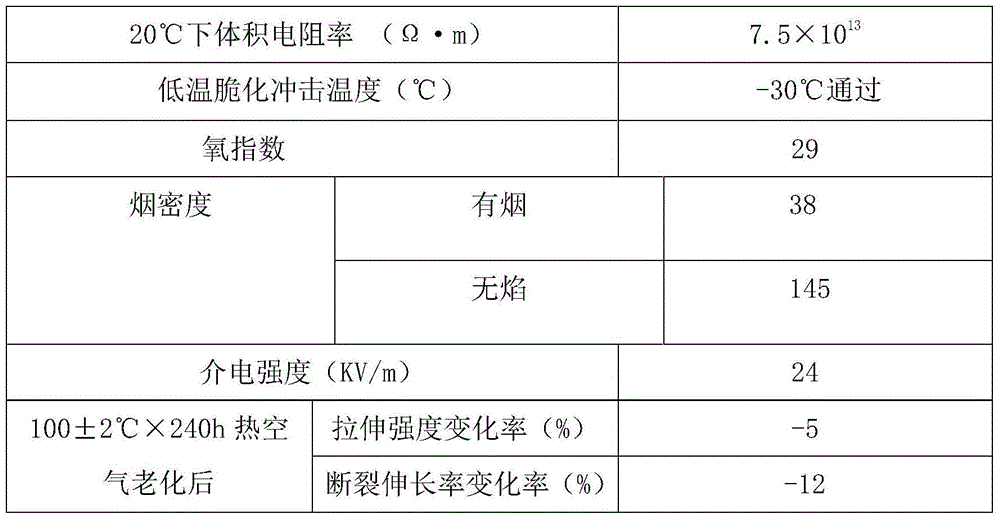

Examples

Embodiment Construction

[0017] A polyvinyl chloride cable material prepared from the following weight (kg) component raw materials:

[0018] Ethylene-vinyl acetate copolymer EVA 55, high-density polyethylene HDPE 14, epoxy acrylate 11, ABS resin 6, compatibilizer 7, 3-aminopropyltrimethoxysilane 1, aluminate coupling agent DL -411 2. Dolomite 5, sepiolite 4, beryllium oxide 1, zinc oxide 2, dibutyl phthalate 7, tributyl citrate 8, dioctyl maleate 4, oleic acid amide 0.2, Heavy calcium 11, barium stearate 1, oxidized polyethylene wax 0.2, zinc borate 13, molybdenum trioxide 5, iron oxide 1, modified filler 13,

[0019] Among them, the modified filler is prepared by the following method:

[0020] a. Take the following raw materials by weight: kaolin 184, medical stone 31, nano carbon 2, ascorbic acid 1, coix seed oil 2, aluminum nitride powder 1, zinc gluconate 3, jade powder 2, polyisobutylene 2, aluminate Coupling agent DL-411 2, stearic acid 2, antioxidant 10101;

[0021] b. Calcining kaolin and medical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com